Professional Documents

Culture Documents

CPP Tank DSGN Calc Rev C

CPP Tank DSGN Calc Rev C

Uploaded by

Mohammed EljammalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CPP Tank DSGN Calc Rev C

CPP Tank DSGN Calc Rev C

Uploaded by

Mohammed EljammalCopyright:

Available Formats

TABLE OF CONTENT PAGE

1 2-3

2 4-6

3 7-9

4 10-13

5 14-15

6 16-17

7 18-19

8 20

9 21

10 22

11 23

12 24-27

13 28-30

14 31-34

15 35-36

16 37

17 38

18 39

19 40

20 41

21 42

Note : Lifting Lug Design calc is done on separate document

(Please refer to LIFTING LUG DESIGN CALC : Doc No. CPP-CIS-MCPD-201)

T-950 ROOF WALL CALC

WEIGHT SUMMARY

CPP-STIFFENER SECTIONAL PROPERTIES

NOZZLE THICKNESS CALC - T-950

WIND LOADING - T-950

LOAD AT BASE & TRANSPORTATION LOAD CALC - T-950

BASE PLATE DESIGN CALCULATION - T-950

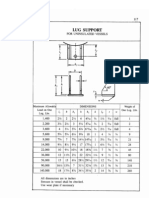

LEG DESIGN CALCULATION- T-950

LOAD AT BASE & TRANSPORTATION LOAD CALC - T-910/T-920/T-940

BASE PLATE DESIGN CALCULATION - T-910/T-920/T-940

LEG DESIGN CALCULATION- T-910/T-920/T-940

T-950 SIDE WALL CALC

T-950 BTM WALL CALC

DESIGN DATA

CPP-T-910/T-920/T-940SIDE WALL CALC

CPP-T-910/T-920/T-940 BTM WALL CALC

CPP-T-910/T-920/T-940 ROOF WALL CALC

NOZZLE THICKNESS CALC - T-910

WIND LOADING - T-910/T-920/T-940

NOZZLE THICKNESS CALC - T-920

NOZZLE THICKNESS CALC - T-940

CPP-Tank Design Calc

Page 1 of 42

DESIGN DATA

ITEM NO. : T-910 ( CORROSION INHIBITOR TANK )

DISCHARGE PRESSURE : WATER FULL (+0.7/-0.03) psig

DESIGN TEMPERATURE :

131

o

F

OPERATING PRESSURE : ATMOSPHERIC

OPERATING TEMPERATURE : AMBIENT

WORKING VOLUME :

4.1 m

3

MATERIAL : STAINLESS STEEL 316L

TRIM NO. : B6

DESIGN CODE ROARK'S FORMULA STRESS AND STRAIN & ASME SECT VII DIV 1

NOZZLE SIZE RATING SERVICE

MW 600 MANWAY

N1 50 150#SWRF FILLING CONNECTION

N2 50 150#SWRF VENT CONNECTION

N3 50 150#SWRF FEED TO PUMP

N4 50 150#SWRF DRAIN

N5 50 150#SWRF OVERFLOW

K1A 50 150#SWRF LEVEL GAUGE HIGH

K1B 50 150#SWRF LEVEL GAUGE LOW

ITEM NO. : T-920 ( POUR POINT DEPRESENT STORAGE TANK )

DISCHARGE PRESSURE : WATER FULL (+0.7/-0.03) psig

DESIGN TEMPERATURE :

131

o

F

OPERATING PRESSURE : ATMOSPHERIC

OPERATING TEMPERATURE : AMBIENT

WORKING VOLUME :

4.0 m

3

MATERIAL : STAINLESS STEEL 316L

TRIM NO. : B6

DESIGN CODE ROARK'S FORMULA STRESS AND STRAIN & ASME SECT VII DIV 1

NOZZLE SIZE RATING SERVICE

MW 600 MANWAY

N1 50 150#SWRF FILLING CONNECTION

N2 50 150#SWRF VENT CONNECTION

N3 50 150#SWRF FEED TO PUMP

N4 50 150#SWRF DRAIN

N5 50 150#SWRF OVERFLOW

K1A 50 150#SWRF LEVEL GAUGE HIGH

K1B 50 150#SWRF LEVEL GAUGE LOW

K2 51 150#SWRF PRESSURE GAUGE

K3 52 150#SWRF PVRV/FLAME ARRESTOR

CPP-Tank Design Calc

Page 2 of 42

DESIGN DATA

ITEM NO. : T-940 ( DEMULSIFIER STORAGE TANK )

DISCHARGE PRESSURE : WATER FULL (+0.7/-0.03) psig

DESIGN TEMPERATURE :

131

o

F

OPERATING PRESSURE : ATMOSPHERIC

OPERATING TEMPERATURE : AMBIENT

WORKING VOLUME :

4.0 m

3

MATERIAL : STAINLESS STEEL 316L

TRIM NO. : B6

DESIGN CODE ROARK'S FORMULA STRESS AND STRAIN & ASME SECT VII DIV 1

NOZZLE SIZE RATING SERVICE

MW 600 MANWAY

N1 50 150#SWRF FILLING CONNECTION

N2 50 150#SWRF VENT CONNECTION

N3 50 150#SWRF FEED TO PUMP

N4 50 150#SWRF DRAIN

N5 50 150#SWRF OVERFLOW

N6 50 150#SWRF SPARE

N7 50 150#SWRF SPARE

K1A 50 150#SWRF LEVEL GAUGE HIGH

K1B 50 150#SWRF LEVEL GAUGE LOW

ITEM NO. : T-950 ( WATER FLOCCULANT TANK )

DISCHARGE PRESSURE : WATER FULL (+0.7/-0.03) psig

DESIGN TEMPERATURE :

131

o

F

OPERATING PRESSURE : ATMOSPHERIC

OPERATING TEMPERATURE : AMBIENT

WORKING VOLUME :

2.5 m

3

MATERIAL : STAINLESS STEEL 316L

TRIM NO. : B6

DESIGN CODE ROARK'S FORMULA STRESS AND STRAIN & ASME SECT VII DIV 1

NOZZLE SIZE RATING SERVICE

MW 600 MANWAY

N1 50 150#SWRF FILLING CONNECTION

N2 50 150#SWRF VENT CONNECTION

N3 50 150#SWRF FEED TO PUMP

N4 50 150#SWRF DRAIN

N5 50 150#SWRF OVERFLOW

K1A 50 150#SWRF LEVEL GAUGE HIGH

K1B 50 150#SWRF LEVEL GAUGE LOW

CPP-Tank Design Calc

Page 3 of 42

SIDE WALL DESIGN CALCULATION

TANK NO. : T-910 / T-920 / T-940

Tank Height, H = 98.4 in 2500 mm

Tank Width, W = 59.06 in 1500 mm

Tank Length, L = 59.06 in 1500 mm

Design Pressure = Full Water (+0.7/-0.03) psig

Design Temp. = 131 F

Material = A 240 316L

As per Table 11.4 Case No.1a Chapter 10 of Roark's

Rectangular plate, all edges simply supported, with uniform loads over entire plate.

g = 9.81

m/s

2

liq = 1000

kg/m

3

a = 24.61 in = 625 mm

b = 19.69 in = 500 mm

a/b = 1.2500

b = 0.3954 Loading q = liq

gH

a = 0.0655 = 24525

N/m

2

g 0.4608 = 3.5561 psi

E = 2.9E+07 psi = 3.5561 psi

t = 0.2362 in 6.0 mm

c.a = 0.0000 in 0 mm

t (corr) = 0.2362 in 6.0 mm

At Center,

Maximum Deflection, = -(aqb

4

)/Et

3

t/2 = 0.118 in

= -0.09

= 0.09 in Max Deflection < t/2 : O.K

Maximum Bending stress, s =(bqb

2

)/ t

2

= 9,765 psi <

allowable

16,700 psi. : OK

Max Bending stress < allowable : O.K

Material A 240 316L

Yield Stress, sy = 25000 psi

Stress Ratio, s/ sy = 0.391

At center of long side,

Maximum reaction force per unit length normal to the plate surface,

R = gqb

= 32.25 lb/in

= 3644.27 N/mm

S

a

S

S

S

b

CPP-Tank Design Calc

Page 4 of 42

SIDE WALL HORIZONTAL STIFFENER CALCULATION

TANK NO. : T-910 / T-920 / T-940

Maximum bending moment occurs at the point where dM/dx = 0 and shear force is zero,

that is, at the middle of the beam.

L = 500 mm = 19.69 in

35.00 lb/in = 250 mm = 9.8 in

Load q = 3.5561 psi

unit load W = q x psi

= 35.00 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x = L/2 = 9.84 in

Maximum moment, M

max

= WL

2

/8

= 1695 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.068

in

3

Use FB 65 x 6

I/y = 0.258 in

3

> (I/y)

required

O.K

Therefore, s = 6576 psi <

allowable

16700 psi O.K

Deflection

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x =L/2= 9.84 in

max

=

(5WL

4

)

384EI

= 0.007 < L/360 = 0.0547 in

The stiffener size used is adequate.

Wb

Wa

X

W

CPP-Tank Design Calc

Page 5 of 42

SIDE WALL VERTICAL STIFFENER CALCULATION

TANK NO. : T-910 / T-920 / T-940

L = 625 mm = 24.61 in

= 312.5 mm = 12.3 in

43.75 lb/in

Load q = 3.5561 psi

unit load W = q x psi

= 43.75 lb/in

24.61 in

Bending Moment

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.548L = 13.48 in

Maximum moment, M

max

=

0.0215WL

2

= 570 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.023

in

3

1. Checking Section Modulus (Z) of stiffener :

Stiffener size = FB 65 x 6

Section Modulus of stiffener is OK

Z = I/y

Z

stiffener

= 0.258

in

3

> 0.023

in

3

Z

required

2. Checking stiffener Bending stress (s ) :

s = M/Z Max bending stress of stiffener is OK

s

stiffener

= M

max

/ Z

stiffener

Therefore, s

stiffener

= 2209 psi < 16700 psi

allowable

Deflection

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.525L = 12.92 in

d

max

=

= 0.0286 in < L/360) 0.0684 in

Therefore the size used is adequate.

0.001309 x WL

4

EI

Wb

Wa

X

W

CPP-Tank Design Calc

Page 6 of 42

BOTTOM WALL DESIGN CALCULATION

TANK NO. : T-910 / T-920 / T-940

Tank Height, H = 98.4 in 2500 mm

Tank Width, W = 59.06 in 1500 mm

Tank Length, L = 59.06 in 1500 mm

Design Pressure = Full Water (+0.7/-0.03) psig

Design Temp. = 131 F

Material = A 240 316L

As per Table 11.4 Case No.1a Chapter 10 of Roark's

Rectangular plate, all edges simply supported, with uniform loads over entire plate.

g = 9.81

m/s

2

liq = 1000

kg/m

3

a = 19.69 in = 500 mm

b = 19.69 in = 500 mm

a/b = 1.0000

b = 0.2874 Loading q = liq

gH

a = 0.0444 = 24525

N/m

2

g 0.4200 = 3.5561 psi

E = 2.9E+07 psi = 3.5561 psi

t = 0.2362 in 6.0 mm

c.a = 0.0000 in 0 mm

t (corr) = 0.2362 in 6.0 mm

At Center,

Maximum Deflection, = -(aqb

4

)/Et

3

t/2 = 0.118 in

= -0.06

= 0.06 in Max Deflection < t/2 : O.K

Maximum Bending stress, s =(bqb

2

)/ t

2

= 7,097 psi <

allowable

16,700 psi : OK

Max Bending stress < allowable : O.K

Material A 240 316L

Yield Stress, sy = 25000 psi

Stress Ratio, s/ sy = 0.284

At center of long side,

Maximum reaction force per unit length normal to the plate surface,

R = gqb

= 29.40 lb/in

= 3321.96 N/mm

S

a

S

S

S

b

CPP-Tank Design Calc

Page 7 of 42

BOTTOM WALL HORIZONTAL STIFFENER CALCULATION (1)

TANK NO. : T-910 / T-920 / T-940

Maximum bending moment occurs at the point where dM/dx = 0 and shear force is zero,

that is, at the middle of the beam.

L = 500 mm = 19.69 in

35.00 lb/in = 250 mm = 9.8 in

Load q = 3.5561 psi

unit load W = q x psi

= 35.00 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x = L/2 = 9.84 in

Maximum moment, M

max

= WL

2

/8

= 1695 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.068

in

3

Use FB 65 x 6

I/y = 0.258 in

3

> (I/y)

required

O.K

Therefore, s = 6576 psi <

allowable

16700 psi O.K

Deflection

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x =L/2= 9.84 in

max

=

(5WL

4

)

384EI

= 0.007 < L/360 = 0.0547 in

The stiffener size used is adequate.

Wb

Wa

X

W

CPP-Tank Design Calc

Page 8 of 42

BOTTOM WALL VERTICAL STIFFENER CALCULATION

TANK NO. : T-950

L = 500 mm = 19.69 in

= 250 mm = 9.8 in

35.00 lb/in

Load q = 3.5561 psi

unit load W = q x psi

= 35.00 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.548L = 10.79 in

Maximum moment, M

max

=

0.0215WL

2

= 292 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.012

in

3

1. Checking Section Modulus (Z) of stiffener :

Stiffener size = FB 65 x 6

Section Modulus of stiffener is OK

Z = I/y

Z

stiffener

= 0.258

in

3

> 0.012

in

3

Z

required

2. Checking stiffener Bending stress (s ) :

s = M/Z Max bending stress of stiffener is OK

s

stiffener

= M

max

/ Z

stiffener

Therefore, s

stiffener

= 1131 psi < 16700 psi

allowable

Deflection

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.525L = 10.33 in

d

max

=

= 0.006 in < L/360) 0.0547 in

Therefore the size used is adequate.

0.001309 x WL

4

EI

Wb

Wa

X

W

CPP-Tank Design Calc

Page 9 of 42

ROOF WALL DESIGN CALCULATION

TANK NO. : T-910 / T-920 / T-940

Tank Height, H 98.4 in 2500 mm Roof weight = 233.69 lb

Tank Width, W 59.06 in 1500 mm Misc. weight = 11.02 lb

Tank Length, L 59.06 in 1500 mm Live load,LL = 0.00 psi

Dead load,TDL = 0.20 psi

Design Pressure = Full Water (+0.7/-0.03) psig Conc. load, CL = 0.00 psi

Design Temp. = 131 F

Material = A 240 316L

As per Table 11.4 Case No.1a Chapter 10 of Roark's

Rectangular plate, all edges simply supported, with uniform loads over entire plate.

g = 9.81

m/s

2

liq = 1000

kg/m

3

a = 19.69 in 500 mm

b = 19.69 in 500 mm

a/b = 1.0000

b = 0.2874 Loading q = Live load +DeadLoad +Conc.Load

a = 0.0444 = 0.200 psi

g = 0.4200

E =2.90E+07 psi =

t = 0.2362 in 6.0 mm

c.a = 0.0000 in 0 mm

t (corr) = 0.2362 in 6.0 mm

At Center,

Maximum Deflection, = -(aqb

4

)/Et

3

t/2 = 0.118 in

= 0.00

= 0.00 in Max Deflection < t/2 : O.K

Maximum Bending stress, s = (bqb

2

)/ t

2

= 400 psi <

allowable

16,700 psi : OK

Max Bending stress < allowable : O.K

Material A 240 316L

Yield Stress, sy = 25000 psi

Stress Ratio, s/ sy = 0.016

At center of long side,

Maximum reaction force per unit length normal to the plate surface,

R = gqb

= 1.66 lb/in

= 187.27 N/mm

S

a

S

S

S b

CPP-Tank Design Calc

Page 10 of 42

ROOF WALL WEIGHT CALCULATION

Weight Per pcs Qty Total

450NB Blind = 100 1 100 kg

450NB Pipe = 12 1 12 kg

450NB Slip On = 59 1 59 kg

50NB WNRF = 1.02 1 1.02 kg

50NB Pipe = 15 1 15 kg

Piping & Accs = 5 1 5 kg

Stiffener (FB65 X 6) = 19 1 19 kg

Roof plate = 106 1 106 kg

Misc weight = 5 1 5 kg

Total Weight 317.02 kg

698.91 lb

Total Loading (pressure) acting on the roof plate is calculated as shown below

Dead Load = 317.02 kg

F = m x g = 3109.97 N

Area = a x b = 2.25

m

2

P = F/A = 1382.21 Pa

= 0.200 psi

Concentrated Load = 0.00 kg

F = m x g = 0.00 N

Area = a x b = 2.25

m

2

P = F/A = 0.00 Pa

= 0.00 psi

Live Load, LL = 0.00

kg/m

2

= 0.00 psi

extra load 0.00

ROOF STIFFENER LOCATION

CPP-Tank Design Calc

Page 11 of 42

ROOF WALL HORIZONTAL STIFFENER CALCULATION

TANK NO. : T-910 / T-920 / T-940

Maximum bending moment occurs at the point where dM/dx = 0 and shear force is zero,

that is, at the middle of the beam.

L = 500 mm = 19.69 in

1.97 lb/in = 250 mm = 9.8 in

Load q = 0.200 psi

unit load W = q x psi

= 1.97 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x = L/2 = 9.84 in

Maximum moment, M

max

= WL

2

/8

= 96 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.004

in

3

Use FB 65 x 6

I/y = 0.258 in

3

> (I/y)

required

O.K

Therefore, s = 371 psi <

allowable

16700 psi O.K

Deflection

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x =L/2= 9.84 in

max

=

(5WL

4

)

384EI

= 0.000 < L/360 = 0.0547 in

The stiffener size used is adequate.

Wb

Wa

X

W

CPP-Tank Design Calc

Page 12 of 42

ROOF WALL VERTICAL STIFFENER CALCULATION

TANK NO. : T-910 / T-920 / T-940

L = 500 mm = 19.69 in

= 250 mm = 9.8 in

1.97 lb/in

Load q = 0.2005 psi

unit load W = q x psi

= 1.97 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.548L = 10.79 in

Maximum moment, M

max

=

0.0215WL

2

= 16 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.001

in

3

1. Checking Section Modulus (Z) of stiffener :

Stiffener size = FB 65 x 6

Section Modulus of stiffener is OK

Z = I/y

Z

stiffener

= 0.258

in

3

> 0.001

in

3

Z

required

2. Checking stiffener Bending stress (s ) :

s = M/Z Max bending stress of stiffener is OK

s

stiffener

= M

max

/ Z

stiffener

Therefore, s

stiffener

= 64 psi < 16700 psi

allowable

Deflection

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.525L = 10.33 in

d

max

=

= 0.0003 in < L/360) 0.0547 in

The stiffener size used is adequate.

0.001309 x WL

4

EI

Wb

Wa

X

W

CPP-Tank Design Calc

Page 13 of 42

NOZZLE THICKNESS CALCULATION

TANK NO. : T-910

NOZZLE NO : N1 / N2 / N3 / N4 / N5 / K1A / K1B

DESIGN CONDITIONS WELDS

Neck:

P 0.0245 MPa tc1 =0.7*t 4.20 mm

DT 55

o

C tc2 =0.7*tn 2.80 mm

CAe / CAi 0 / 0 mm tc3 xxx

tc =Min[tc1,tc2,tc3] 2.80 mm

Pad:

Fr1 =0.5*te xxx mm

Fr2 =0.5*t xxx mm

SHELL PROPERTIES Fr3 = xxx mm

Fr =Min[Fr1,Fr2,Fr3] mm

Summary:

Material: A 240 316L External Leg 6 mm

S @(55

o

C) 115.15 MPa Internal Leg 0 mm

Wall Thickness, ts 6 mm Pad Leg 0 mm

tr = 3 mm

t =ts - CA 6 mm LIMIT OF REINFORCEMENT .UG - 40

NOZZLE SIZE: 50NB SCH 40S R1 =d 52.3 mm

R2 =Rn +tn +t 36.15 mm

trn = PRn .UG - 32 R =Max [R1,R2] 52.3 mm

2SE - 0.2P h1 =2.5*T1 15.00 mm

h2 =2.5*Tb1 +Tr1 10.00 mm

Material: A 312 TP316L h =Min [h1,h2] 10.00 mm

S @(55

o

C) 115.15 MPa Internal Projection 5.00 mm

OD 60.3 External Projection 150.00 mm

Wall Thickness, tb 4 mm

ID 52.3 mm MATERIAL STRENGTH RATIOS

Neck Slope 0

o

F =Figure UG-37 1.0 fr1 =Sn/Sv 1.0000

d =ID +(2*CA) +Tol. 52.3 mm fr2 =Sn/Sv 1.0000

Rn =d/2 26.15 mm fr4 =Sp/Sv 0.00

E 1.0 fr3 =Min[fr1,fr2,fr4] 0.0000

trn 0.00278 mm

tn =tb - CA 4 mm AREA AVAILABLE .UG - 37

PAD A

11

=d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1) 156.90 mm

2

A

12

=2(t+tn)(E1t-Ftr)-2tn(E1t-Ftr)(1-fr1) 60.00 mm

2

Material: A

1

= Max [A

11

, A

12

] 156.90 mm

2

S @(55

o

C) 0 MPa

OD 0 mm A

21

=5(tn - trn)fr2.t 119.92 mm

2

Thickness =te 0 mm A

22

=5(tn - trn)fr2.tn 79.94 mm

2

Weld 0 mm A

2

= Min [A

21

, A

22

] 79.94 mm

2

A

3

= (Int.proj - CAi)(tn - CAi).fr2 20.00 mm

2

FLANGE

A

41

=

(Ext.Leg - CAe)

2

.fr3 0.00 mm

2

Material: A 182 F316L A

42

=

(Int.Leg - CAi)

2

.fr2 0.00 mm

2

Type: 150 #SW A

43

=

(Pad.Leg - CAe)

2

.fr4 0.00 mm

2

Rating at 55

o

C 1.943 MPa A

4

= Sum[A

41

,A

42

,A

43

] 0.00 mm

2

AREA REQUIRED UG - 37 A

5

= (Pad OD - Noz OD).te.fr4 0.00 mm

2

A =d.tr.F +2.tn.tr.F(1-fr1) 156.9 mm

2

TOTAL AREA AVAILABLE = 256.84 mm

2

OK

CPP-Tank Design Calc

Page 14 of 42

NOZZLE THICKNESS CALCULATION

TANK NO. : T-910

NOZZLE NO : MW

DESIGN CONDITIONS WELDS

Neck:

P 0.0245 MPa tc1 =0.7*t 4.20 mm

DT 55

o

C tc2 =0.7*tn 4.20 mm

CAe / CAi 0 / 0 mm tc3 xxx

tc =Min[tc1,tc2,tc3] 4.20 mm

Pad:

Fr1 =0.5*te xxx mm

Fr2 =0.5*t xxx mm

SHELL PROPERTIES Fr3 = xxx mm

Fr =Min[Fr1,Fr2,Fr3] mm

Summary:

Material: A 240 316L External Leg 6 mm

S @(55

o

C) 115.15 MPa Internal Leg 0 mm

Wall Thickness, ts 6 mm Pad Leg 0 mm

tr = 3 mm

t =ts - CA 6 mm LIMIT OF REINFORCEMENT .UG - 40

NOZZLE SIZE: 600NB R1 =d 597.6 mm

R2 =Rn +tn +t 310.8 mm

trn = PRn .UG - 32 R =Max [R1,R2] 597.6 mm

2SE - 0.2P h1 =2.5*T1 15.00 mm

h2 =2.5*Tb1 +Tr1 15.00 mm

Material: A 240 316L h =Min [h1,h2] 15.00 mm

S @(55

o

C) 115.15 MPa Internal Projection 5.00 mm

OD 609.6 External Projection 150.00 mm

Wall Thickness, tb 6 mm

ID 597.6 mm MATERIAL STRENGTH RATIOS

Neck Slope 0

o

F =Figure UG-37 1.0 fr1 =Sn/Sv 1.0000

d =ID +(2*CA) +Tol. 597.6 mm fr2 =Sn/Sv 1.0000

Rn =d/2 298.8 mm fr4 =Sp/Sv 0.00

E 1.0 fr3 =Min[fr1,fr2,fr4] 0.0000

trn 0.03181 mm

tn =tb - CA 6 mm AREA AVAILABLE .UG - 37

PAD A

11

=d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1) 1792.80 mm

2

A

12

=2(t+tn)(E1t-Ftr)-2tn(E1t-Ftr)(1-fr1) 72.00 mm

2

Material: A

1

= Max [A

11

, A

12

] 1792.80 mm

2

S @(55

o

C) 0 MPa

OD 0 mm A

21

=5(tn - trn)fr2.t 179.05 mm

2

Thickness =te 0 mm A

22

=5(tn - trn)fr2.tn 179.05 mm

2

Weld 0 mm A

2

= Min [A

21

, A

22

] 179.05 mm

2

A

3

= (Int.proj - CAi)(tn - CAi).fr2 30.00 mm

2

FLANGE

A

41

=

(Ext.Leg - CAe)

2

.fr3 0.00 mm

2

Material: A 182 F316L A

42

=

(Int.Leg - CAi)

2

.fr2 0.00 mm

2

Type: 150 # A

43

=

(Pad.Leg - CAe)

2

.fr4 0.00 mm

2

Rating at 55

o

C 1.943 MPa A

4

= Sum[A

41

,A

42

,A

43

] 0.00 mm

2

AREA REQUIRED UG - 37 A

5

= (Pad OD - Noz OD).te.fr4 0.00 mm

2

A =d.tr.F +2.tn.tr.F(1-fr1) 1792.8 mm

2

TOTAL AREA AVAILABLE = 2001.85 mm

2

OK

CPP-Tank Design Calc

Page 15 of 42

NOZZLE THICKNESS CALCULATION

TANK NO. : T-920

NOZZLE NO : N1 / N2 / N3 / N4 / N5 / K1A / K1B / K2 / K3

DESIGN CONDITIONS WELDS

Neck:

P 0.0245 MPa tc1 =0.7*t 4.20 mm

DT 55

o

C tc2 =0.7*tn 2.80 mm

CAe / CAi 0 / 0 mm tc3 xxx

tc =Min[tc1,tc2,tc3] 2.80 mm

Pad:

Fr1 =0.5*te xxx mm

Fr2 =0.5*t xxx mm

SHELL PROPERTIES Fr3 = xxx mm

Fr =Min[Fr1,Fr2,Fr3] mm

Summary:

Material: A 240 316L External Leg 6 mm

S @(55

o

C) 115.15 MPa Internal Leg 0 mm

Wall Thickness, ts 6 mm Pad Leg 0 mm

tr = 3 mm

t =ts - CA 6 mm LIMIT OF REINFORCEMENT .UG - 40

NOZZLE SIZE: 50NB SCH 40S R1 =d 52.3 mm

R2 =Rn +tn +t 36.15 mm

trn = PRn .UG - 32 R =Max [R1,R2] 52.3 mm

2SE - 0.2P h1 =2.5*T1 15.00 mm

h2 =2.5*Tb1 +Tr1 10.00 mm

Material: A 312 TP316L h =Min [h1,h2] 10.00 mm

S @(55

o

C) 115.15 MPa Internal Projection 5.00 mm

OD 60.3 External Projection 150.00 mm

Wall Thickness, tb 4 mm

ID 52.3 mm MATERIAL STRENGTH RATIOS

Neck Slope 0

o

F =Figure UG-37 1.0 fr1 =Sn/Sv 1.0000

d =ID +(2*CA) +Tol. 52.3 mm fr2 =Sn/Sv 1.0000

Rn =d/2 26.15 mm fr4 =Sp/Sv 0.00

E 1.0 fr3 =Min[fr1,fr2,fr4] 0.0000

trn 0.00278 mm

tn =tb - CA 4 mm AREA AVAILABLE .UG - 37

PAD A

11

=d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1) 156.90 mm

2

A

12

=2(t+tn)(E1t-Ftr)-2tn(E1t-Ftr)(1-fr1) 60.00 mm

2

Material: A

1

= Max [A

11

, A

12

] 156.90 mm

2

S @(55

o

C) 0 MPa

OD 0 mm A

21

=5(tn - trn)fr2.t 119.92 mm

2

Thickness =te 0 mm A

22

=5(tn - trn)fr2.tn 79.94 mm

2

Weld 0 mm A

2

= Min [A

21

, A

22

] 79.94 mm

2

A

3

= (Int.proj - CAi)(tn - CAi).fr2 20.00 mm

2

FLANGE

A

41

=

(Ext.Leg - CAe)

2

.fr3 0.00 mm

2

Material: A 182 F316L A

42

=

(Int.Leg - CAi)

2

.fr2 0.00 mm

2

Type: 150 #SW A

43

=

(Pad.Leg - CAe)

2

.fr4 0.00 mm

2

Rating at 55

o

C 1.943 MPa A

4

= Sum[A

41

,A

42

,A

43

] 0.00 mm

2

AREA REQUIRED UG - 37 A

5

= (Pad OD - Noz OD).te.fr4 0.00 mm

2

A =d.tr.F +2.tn.tr.F(1-fr1) 156.9 mm

2

TOTAL AREA AVAILABLE = 256.84 mm

2

OK

CPP-Tank Design Calc

Page 16 of 42

NOZZLE THICKNESS CALCULATION

TANK NO. : T-920

NOZZLE NO : MW

DESIGN CONDITIONS WELDS

Neck:

P 0.0245 MPa tc1 =0.7*t 4.20 mm

DT 55

o

C tc2 =0.7*tn 4.20 mm

CAe / CAi 0 / 0 mm tc3 xxx

tc =Min[tc1,tc2,tc3] 4.20 mm

Pad:

Fr1 =0.5*te xxx mm

Fr2 =0.5*t xxx mm

SHELL PROPERTIES Fr3 = xxx mm

Fr =Min[Fr1,Fr2,Fr3] mm

Summary:

Material: A 240 316L External Leg 6 mm

S @(55

o

C) 115.15 MPa Internal Leg 0 mm

Wall Thickness, ts 6 mm Pad Leg 0 mm

tr = 3 mm

t =ts - CA 6 mm LIMIT OF REINFORCEMENT .UG - 40

NOZZLE SIZE: 600NB R1 =d 597.6 mm

R2 =Rn +tn +t 310.8 mm

trn = PRn .UG - 32 R =Max [R1,R2] 597.6 mm

2SE - 0.2P h1 =2.5*T1 15.00 mm

h2 =2.5*Tb1 +Tr1 15.00 mm

Material: A 240 316L h =Min [h1,h2] 15.00 mm

S @(55

o

C) 115.15 MPa Internal Projection 5.00 mm

OD 609.6 External Projection 150.00 mm

Wall Thickness, tb 6 mm

ID 597.6 mm MATERIAL STRENGTH RATIOS

Neck Slope 0

o

F =Figure UG-37 1.0 fr1 =Sn/Sv 1.0000

d =ID +(2*CA) +Tol. 597.6 mm fr2 =Sn/Sv 1.0000

Rn =d/2 298.8 mm fr4 =Sp/Sv 0.00

E 1.0 fr3 =Min[fr1,fr2,fr4] 0.0000

trn 0.03181 mm

tn =tb - CA 6 mm AREA AVAILABLE .UG - 37

PAD A

11

=d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1) 1792.80 mm

2

A

12

=2(t+tn)(E1t-Ftr)-2tn(E1t-Ftr)(1-fr1) 72.00 mm

2

Material: A

1

= Max [A

11

, A

12

] 1792.80 mm

2

S @(55

o

C) 0 MPa

OD 0 mm A

21

=5(tn - trn)fr2.t 179.05 mm

2

Thickness =te 0 mm A

22

=5(tn - trn)fr2.tn 179.05 mm

2

Weld 0 mm A

2

= Min [A

21

, A

22

] 179.05 mm

2

A

3

= (Int.proj - CAi)(tn - CAi).fr2 30.00 mm

2

FLANGE

A

41

=

(Ext.Leg - CAe)

2

.fr3 0.00 mm

2

Material: A 182 F316L A

42

=

(Int.Leg - CAi)

2

.fr2 0.00 mm

2

Type: 150 # A

43

=

(Pad.Leg - CAe)

2

.fr4 0.00 mm

2

Rating at 55

o

C 1.943 MPa A

4

= Sum[A

41

,A

42

,A

43

] 0.00 mm

2

AREA REQUIRED UG - 37 A

5

= (Pad OD - Noz OD).te.fr4 0.00 mm

2

A =d.tr.F +2.tn.tr.F(1-fr1) 1792.8 mm

2

TOTAL AREA AVAILABLE = 2001.85 mm

2

OK

CPP-Tank Design Calc

Page 17 of 42

NOZZLE THICKNESS CALCULATION

TANK NO. : T-940

NOZZLE NO : N1 / N2 / N3 / N4 / N5 / N6 / N7 / K1A / K1B

DESIGN CONDITIONS WELDS

Neck:

P 0.0245 MPa tc1 =0.7*t 4.20 mm

DT 55

o

C tc2 =0.7*tn 2.80 mm

CAe / CAi 0 / 0 mm tc3 xxx

tc =Min[tc1,tc2,tc3] 2.80 mm

Pad:

Fr1 =0.5*te xxx mm

Fr2 =0.5*t xxx mm

SHELL PROPERTIES Fr3 = xxx mm

Fr =Min[Fr1,Fr2,Fr3] mm

Summary:

Material: A 240 316L External Leg 6 mm

S @(55

o

C) 115.15 MPa Internal Leg 0 mm

Wall Thickness, ts 6 mm Pad Leg 0 mm

tr = 3 mm

t =ts - CA 6 mm LIMIT OF REINFORCEMENT .UG - 40

NOZZLE SIZE: 50NB SCH 40S R1 =d 52.3 mm

R2 =Rn +tn +t 36.15 mm

trn = PRn .UG - 32 R =Max [R1,R2] 52.3 mm

2SE - 0.2P h1 =2.5*T1 15.00 mm

h2 =2.5*Tb1 +Tr1 10.00 mm

Material: A 312 TP316L h =Min [h1,h2] 10.00 mm

S @(55

o

C) 115.15 MPa Internal Projection 5.00 mm

OD 60.3 External Projection 150.00 mm

Wall Thickness, tb 4 mm

ID 52.3 mm MATERIAL STRENGTH RATIOS

Neck Slope 0

o

F =Figure UG-37 1.0 fr1 =Sn/Sv 1.0000

d =ID +(2*CA) +Tol. 52.3 mm fr2 =Sn/Sv 1.0000

Rn =d/2 26.15 mm fr4 =Sp/Sv 0.00

E 1.0 fr3 =Min[fr1,fr2,fr4] 0.0000

trn 0.00278 mm

tn =tb - CA 4 mm AREA AVAILABLE .UG - 37

PAD A

11

=d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1) 156.90 mm

2

A

12

=2(t+tn)(E1t-Ftr)-2tn(E1t-Ftr)(1-fr1) 60.00 mm

2

Material: A

1

= Max [A

11

, A

12

] 156.90 mm

2

S @(55

o

C) 0 MPa

OD 0 mm A

21

=5(tn - trn)fr2.t 119.92 mm

2

Thickness =te 0 mm A

22

=5(tn - trn)fr2.tn 79.94 mm

2

Weld 0 mm A

2

= Min [A

21

, A

22

] 79.94 mm

2

A

3

= (Int.proj - CAi)(tn - CAi).fr2 20.00 mm

2

FLANGE

A

41

=

(Ext.Leg - CAe)

2

.fr3 0.00 mm

2

Material: A 182 F316L A

42

=

(Int.Leg - CAi)

2

.fr2 0.00 mm

2

Type: 150 #SW A

43

=

(Pad.Leg - CAe)

2

.fr4 0.00 mm

2

Rating at 55

o

C 1.943 MPa A

4

= Sum[A

41

,A

42

,A

43

] 0.00 mm

2

AREA REQUIRED UG - 37 A

5

= (Pad OD - Noz OD).te.fr4 0.00 mm

2

A =d.tr.F +2.tn.tr.F(1-fr1) 156.9 mm

2

TOTAL AREA AVAILABLE = 256.84 mm

2

OK

CPP-Tank Design Calc

Page 18 of 42

NOZZLE THICKNESS CALCULATION

TANK NO. : T-940

NOZZLE NO : MW

DESIGN CONDITIONS WELDS

Neck:

P 0.0245 MPa tc1 =0.7*t 4.20 mm

DT 55

o

C tc2 =0.7*tn 4.20 mm

CAe / CAi 0 / 0 mm tc3 xxx

tc =Min[tc1,tc2,tc3] 4.20 mm

Pad:

Fr1 =0.5*te xxx mm

Fr2 =0.5*t xxx mm

SHELL PROPERTIES Fr3 = xxx mm

Fr =Min[Fr1,Fr2,Fr3] mm

Summary:

Material: A 240 316L External Leg 6 mm

S @(55

o

C) 115.15 MPa Internal Leg 0 mm

Wall Thickness, ts 6 mm Pad Leg 0 mm

tr = 3 mm

t =ts - CA 6 mm LIMIT OF REINFORCEMENT .UG - 40

NOZZLE SIZE: 600NB R1 =d 597.6 mm

R2 =Rn +tn +t 310.8 mm

trn = PRn .UG - 32 R =Max [R1,R2] 597.6 mm

2SE - 0.2P h1 =2.5*T1 15.00 mm

h2 =2.5*Tb1 +Tr1 15.00 mm

Material: A 240 316L h =Min [h1,h2] 15.00 mm

S @(55

o

C) 115.15 MPa Internal Projection 5.00 mm

OD 609.6 External Projection 150.00 mm

Wall Thickness, tb 6 mm

ID 597.6 mm MATERIAL STRENGTH RATIOS

Neck Slope 0

o

F =Figure UG-37 1.0 fr1 =Sn/Sv 1.0000

d =ID +(2*CA) +Tol. 597.6 mm fr2 =Sn/Sv 1.0000

Rn =d/2 298.8 mm fr4 =Sp/Sv 0.00

E 1.0 fr3 =Min[fr1,fr2,fr4] 0.0000

trn 0.03181 mm

tn =tb - CA 6 mm AREA AVAILABLE .UG - 37

PAD A

11

=d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1) 1792.80 mm

2

A

12

=2(t+tn)(E1t-Ftr)-2tn(E1t-Ftr)(1-fr1) 72.00 mm

2

Material: A

1

= Max [A

11

, A

12

] 1792.80 mm

2

S @(55

o

C) 0 MPa

OD 0 mm A

21

=5(tn - trn)fr2.t 179.05 mm

2

Thickness =te 0 mm A

22

=5(tn - trn)fr2.tn 179.05 mm

2

Weld 0 mm A

2

= Min [A

21

, A

22

] 179.05 mm

2

A

3

= (Int.proj - CAi)(tn - CAi).fr2 30.00 mm

2

FLANGE

A

41

=

(Ext.Leg - CAe)

2

.fr3 0.00 mm

2

Material: A 182 F316L A

42

=

(Int.Leg - CAi)

2

.fr2 0.00 mm

2

Type: 150 # A

43

=

(Pad.Leg - CAe)

2

.fr4 0.00 mm

2

Rating at 55

o

C 1.943 MPa A

4

= Sum[A

41

,A

42

,A

43

] 0.00 mm

2

AREA REQUIRED UG - 37 A

5

= (Pad OD - Noz OD).te.fr4 0.00 mm

2

A =d.tr.F +2.tn.tr.F(1-fr1) 1792.8 mm

2

TOTAL AREA AVAILABLE = 2001.85 mm

2

OK

CPP-Tank Design Calc

Page 19 of 42

WIND LOADING - BS 6399 - PART 2 -1997

ITEM : CPP (T-910 / T-920 / T-940 )

PROJ ECT NO.PM329 EAST PIATU DEVELOPMENT PROJECT

Terrain Category = 1

Region = D

Basic Wind Speed Vb = 50.00 m/s

Shielding Factor Ms = 1

Topographic Factor Sa = 1

Direction Factor Sd = 1

Probability Factor Sp = 1

Seasonal Factor Ss = 1

Terrain and Building Factor Sb = 1

Design Wind Speed Vz = 50.00 m/s ( Vb x Sa x Sd x Sp x Ss )

Effective (Design) Wind speed Ve = 50.00 m/s ( Vz x Sb )

Dynamic Pressure qz = 1.5325 kPa ( 0.613 x Ve

2

x 10

-3

)

Drag Coefficient Cd = 1

H = 3,500 mm

Width = 2,800 mm

Az = 9,800,000 mm

2

3

5

0

0

H / Width = 1.25

Kar = 1

Cd' = 1 ( Cd x Kar )

Wind Force Fw = 15018.5 N ( Cd' x qz x Az ) / 10

3

Height to COG h = 1750.000 mm ( H / 2 )

Overturning Moment Mw = 26282375 Nmm ( Fw x h )

2800

CPP-Tank Design Calc

Page 20 of 42

LOAD AT BASE & TRANSPORTATION LOAD CALCULATION

ITEM : CPP (T-910 / T-920 / T-940 )

PROJ ECT NO. PM329 EAST PIATU DEVELOPMENT PROJECT

WEIGHTS

Empty We = 1999 kg ------> 19606 N

EXTERNAL LOADS

Wind Force Fw = 15,019 N

Earthquake Force Feq = 0 N

F

D

= 2971 N [( 0.5 x We )

2

+( 1.4 x We )

2

]

0.5

Wind Moment Mw = 26,282,375 Nmm

Earthquake Moment Meq = 0 Nmm

Transportation Moment Mc = 5,199,302 Nmm ( F

D

x COG

) COG

= 1750 mm

(H/2)

Maximum Shear Force F = 15,019 N

Maximum O/T Moment M = 26,282,375 Nmm

HOLD DOWN BOLTS

Bolt Material... = A 193 GR B7

Bolt Yield Stress. Sy = 207 MPa

Bolt UTS.... Su = 507 MPa

Allowable Tensile...... Ft = 124.2 MPa

Allowable Shear... Fs = 69 MPa

Bolt Size... = M16

Bolt Number..... N = 2

Tensile Area.... A

T = 146 mm

2

Shear Area..A

S = 225 mm

2

Bolt PCD.. PCD = 1980.64 mm

SHEAR STRESS IN BOLT

Shear / Bolt, fs = F

N x As

33.37 MPa OK

69 MPa

since fs <Fs the shear stress is OK

Transportation Force

fs =

Fs =

CPP-Tank Design Calc

Page 21 of 42

LEG BASEPLATE DESIGN

ITEM : CPP (T-910 / T-920 / T-940 )

PROJ ECT NO. PM329 EAST PIATU DEVELOPMENT PROJECT

Refer Dennis R Moss Procedure 3-10

tb =

Q = Maximum Load / Support = 4901 N

F = Baseplate Width = 170 mm

A = Baseplate Length = 170 mm

Fb = Allowable Bending Stress = 163.68 MPa ( 0.66 Fy )

tb = 4.7 mm

Use Tb = 10 mm OK

BASE PLATE WELD CHECKING

Maximum stress due to Q & F =max(Q, F)/Aw = 3.68 N/mm

2

< 86.9 N/mm

2

OK

Weld leg size, g = 6.0 mm

Length of weld, l =2*( 2*F +2*A ) = 1360 mm

Area of weld, Aw =0.5*g*l = 4080 mm

2

J oint efficiency for fillet weld, E = 0.6 -

Welding stress for steel, fw = 144.8 N/mm

2

Allowable stress for weld, fw =E*fw = 86.9 N/mm

2

Maximum vertical force, Q = 4901.4 N

Maximum horizontal force, F = 15018.5 N

3 x Q x F

4 x A x Fb

CPP-Tank Design Calc

Page 22 of 42

LEG DESIGN CALCULATION

ITEM : CPP (T-910 / T-920 / T-940 )

PROJ ECT NO. PM329 EAST PIATU DEVELOPMENT PROJECT

LEG DATA

Material.....= A 36

Yield Stress, Sy...= 248.2

N/mm

2

Allowable Axial Stress, fall....= 148.9

N/mm

2

( 0.6 x Sy )

Allowable Bending Stress, fball.......= 165.5 N/mm

2

( 2/3 x Sy )

LEG GEOMETRY :- I-BEAM 152 x 152 x 23 kg/m

A = 2920 mm

2

Ixx = 12500000

mm

4

d = 76.2 mm

e = 76.2 mm

L = 152.4 mm

r = 9 mm

AXIAL STRESS

Axial Stress, fa = F / A = 1.68 N/mm

2

BENDING STRESS

Bending Stress, fb = P x L x e = 13.95 N/mm

2

Ixx

COMBINED STRESS

Combined Stress, f =(fa/fall +fb/fball) = 0.10

Since Combined Stress is < 1.00 The Leg Design is OK!

e

d

X X

CPP-Tank Design Calc

Page 23 of 42

SIDE WALL (1) DESIGN CALCULATION (@ Length = 1500mm )

TANK NO. : T-950

Tank Height, H = 98.4 in 2500 mm

Tank Width, W = 59.06 in 1500 mm

Tank Length, L = 59.06 in 1500 mm

Design Pressure = Full Water (+0.7/-0.03) psig

Design Temp. = 131 F

Material = A 240 316L

As per Table 11.4 Case No.1a Chapter 10 of Roark's

Rectangular plate, all edges simply supported, with uniform loads over entire plate.

g = 9.81

m/s

2

liq = 1000

kg/m

3

a = 24.61 in = 625 mm

b = 19.69 in = 500 mm

a/b = 1.2500

b = 0.3954 Loading q = liq

gH

a = 0.0655 = 24525

N/m

2

g = 0.4608 = 3.5561 psi

E = 2.9E+07 psi = 3.5561 psi

t = 0.2362 in 6.0 mm

c.a = 0.0000 in 0 mm

t (corr) = 0.2362 in 6.0 mm

At Center,

Maximum Deflection, = -(aqb

4

)/Et

3

t/2 = 0.118 in

= -0.09

= 0.09 in Max Deflection < t/2 : O.K

Maximum Bending stress, s =(bqb

2

)/ t

2

= 9,765 psi <

allowable

16,700 psi. : OK

Max Bending stress < allowable : O.K

Material A 240 316L

Yield Stress, sy = 25000 psi

Stress Ratio, s/ sy = 0.391

At center of long side,

Maximum reaction force per unit length normal to the plate surface,

R = gqb

= 32.25 lb/in

= 3644.27 N/mm

S

a

S

S

S

b

CPP-Tank Design Calc

Page 24 of 42

SIDE WALL (2) DESIGN CALCULATION (@ Length = 1000mm )

TANK NO. : T-950

Tank Height, H = 98.4 in 2500 mm

Tank Width, W = 59.06 in 1500 mm

Tank Length, L = 59.06 in 1500 mm

Design Pressure = Full Water (+0.7/-0.03) psig

Design Temp. = 131 F

Material = A 240 316L

As per Table 11.4 Case No.1a Chapter 10 of Roark's

Rectangular plate, all edges simply supported, with uniform loads over entire plate.

g = 9.81

m/s

2

liq = 1000

kg/m

3

a = 24.61 in = 625 mm

b = 19.69 in = 500 mm

a/b = 1.2500

b = 0.3954 Loading q = liq

gH

a = 0.0655 = 24525

N/m

2

g 0.4608 = 3.5561 psi

E = 2.9E+07 psi = 3.5561 psi

t = 0.2362 in 6.0 mm

c.a = 0.0000 in 0 mm

t (corr) = 0.2362 in 6.0 mm

At Center,

Maximum Deflection, = -(aqb

4

)/Et

3

t/2 = 0.118 in

= -0.09

= 0.09 in Max Deflection < t/2 : O.K

Maximum Bending stress, s =(bqb

2

)/ t

2

= 9,765 psi <

allowable

16,700 psi : OK

Max Bending stress < allowable : O.K

Material A 240 316L

Yield Stress, sy = 25000 psi

Stress Ratio, s/ sy = 0.391

At center of long side,

Maximum reaction force per unit length normal to the plate surface,

R = gqb

= 32.25 lb/in

= 3644.27 N/mm

S

a

S

S

S

b

CPP-Tank Design Calc

Page 25 of 42

SIDE WALL HORIZONTAL STIFFENER CALCULATION

TANK NO. : T-950

Maximum bending moment occurs at the point where dM/dx = 0 and shear force is zero,

that is, at the middle of the beam.

L = 500 mm = 19.69 in

35.00 lb/in = 250 mm = 9.8 in

Load q = 3.5561 psi

unit load W = q x psi

= 35.00 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x = L/2 = 9.84 in

Maximum moment, M

max

= WL

2

/8

= 1695 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.068

in

3

Use FB 65 x 6

I/y = 0.258 in

3

> (I/y)

required

O.K

Therefore, s = 6576 psi <

allowable

16700 psi O.K

Deflection

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x =L/2= 9.84 in

max

=

(5WL

4

)

384EI

= 0.007 < L/360 = 0.0547 in

The stiffener size used is adequate.

Wb

Wa

X

W

CPP-Tank Design Calc

Page 26 of 42

SIDE WALL VERTICAL STIFFENER CALCULATION

TANK NO. : T-950

L = 625 mm = 24.61 in

= 312.5 mm = 12.3 in

43.75 lb/in

Load q = 3.5561 psi

unit load W = q x psi

= 43.75 lb/in

24.61 in

Bending Moment

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.548L = 13.48 in

Maximum moment, M

max

=

0.0215WL

2

= 570 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.023

in

3

1. Checking Section Modulus (Z) of stiffener :

Stiffener size = FB 65 x 6

Section Modulus of stiffener is OK

Z = I/y

Z

stiffener

= 0.258

in

3

> 0.023

in

3

Z

required

2. Checking stiffener Bending stress (s ) :

s = M/Z Max bending stress of stiffener is OK

s

stiffener

= M

max

/ Z

stiffener

Therefore, s

stiffener

= 2209 psi < 16700 psi

allowable

Deflection

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.525L = 12.92 in

d

max

=

= 0.029 in < L/360) 0.068 in

Therefore the size used is adequate.

0.001309 x WL

4

EI

Wb

Wa

X

W

CPP-Tank Design Calc

Page 27 of 42

BOTTOM WALL DESIGN CALCULATION

TANK NO. : T-950

Tank Height, H = 98.4 in 2500 mm

Tank Width, W = 59.06 in 1500 mm

Tank Length, L = 39.37 in 1000 mm

Design Pressure = Full Water (+0.7/-0.03) psig

Design Temp. = 131 F

Material = A 240 316L

As per Table 11.4 Case No.1a Chapter 10 of Roark's

Rectangular plate, all edges simply supported, with uniform loads over entire plate.

g = 9.81

m/s

2

liq = 1000

kg/m

3

a = 19.69 in = 500 mm

b = 19.69 in = 500 mm

a/b = 1.0000

b = 0.2874 Loading q = liq

gH

a = 0.0444 = 24525

N/m

2

g 0.4200 = 3.5561 psi

E = 2.9E+07 psi = 3.5561 psi

t = 0.2362 in 6.0 mm

c.a = 0.0000 in 0 mm

t (corr) = 0.2362 in 6.0 mm

At Center,

Maximum Deflection, = -(aqb

4

)/Et

3

t/2 = 0.118 in

= -0.06

= 0.06 in Max Deflection < t/2 : O.K

Maximum Bending stress, s =(bqb

2

)/ t

2

= 7,097 psi <

allowable

16,700 psi : OK

Max Bending stress < allowable : O.K

Material A 240 316L

Yield Stress, sy = 25000 psi

Stress Ratio, s/ sy = 0.284

At center of long side,

Maximum reaction force per unit length normal to the plate surface,

R = gqb

= 29.40 lb/in

= 3321.96 N/mm

S

a

S

S

S

b

CPP-Tank Design Calc

Page 28 of 42

BOTTOM WALL HORIZONTAL STIFFENER CALCULATION (1)

TANK NO. : T-950

Maximum bending moment occurs at the point where dM/dx = 0 and shear force is zero,

that is, at the middle of the beam.

L = 500 mm = 19.69 in

35.00 lb/in = 250 mm = 9.8 in

Load q = 3.5561 psi

unit load W = q x psi

= 35.00 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x = L/2 = 9.84 in

Maximum moment, M

max

= WL

2

/8

= 1695 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.068

in

3

Use FB 65 x 6

I/y = 0.258 in

3

> (I/y)

required

O.K

Therefore, s = 6576 psi <

allowable

16700 psi O.K

Deflection

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x =L/2= 9.84 in

max

=

(5WL

4

)

384EI

= 0.007 < L/360 = 0.0547 in

The stiffener size used is adequate.

Wb

Wa

X

W

CPP-Tank Design Calc

Page 29 of 42

BOTTOM WALL VERTICAL STIFFENER CALCULATION

TANK NO. : T-950

L = 500 mm = 19.69 in

= 250 mm = 9.8 in

35.00 lb/in

Load q = 3.5561 psi

unit load W = q x psi

= 35.00 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.548L = 10.79 in

Maximum moment, M

max

=

0.0215WL

2

= 292 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.012

in

3

1. Checking Section Modulus (Z) of stiffener :

Stiffener size = FB 65 x 6

Section Modulus of stiffener is OK

Z = I/y

Z

stiffener

= 0.258

in

3

> 0.012

in

3

Z

required

2. Checking stiffener Bending stress (s ) :

s = M/Z Max bending stress of stiffener is OK

s

stiffener

= M

max

/ Z

stiffener

Therefore, s

stiffener

= 1131 psi < 16700 psi

allowable

Deflection

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.525L = 10.33 in

d

max

=

= 0.006 in < L/360) 0.0547 in

Therefore the size used is adequate.

0.001309 x WL

4

EI

Wb

Wa

X

W

CPP-Tank Design Calc

Page 30 of 42

ROOF WALL DESIGN CALCULATION

TANK NO. : T-950

Tank Height, H 98.4 in 2500 mm Roof weight = 156.53 lb

Tank Width, W 59.06 in 1500 mm Misc. weight = 11.02 lb

Tank Length, L 39.37 in 1000 mm Live load,LL = 0.00 psi

Dead load,TDL = 0.26 psi

Design Pressure = Full Water (+0.7/-0.03) psig Conc. load, CL = 0.00 psi

Design Temp. = 131 F

Material = A 240 316L

As per Table 11.4 Case No.1a Chapter 10 of Roark's

Rectangular plate, all edges simply supported, with uniform loads over entire plate.

g = 9.81

m/s

2

liq = 1000

kg/m

3

a = 39.37 in 1000 mm

b = 19.69 in 500 mm

a/b = 2.0000

b = 0.6102 Loading q = Live load +DeadLoad +Conc.Load

a = 0.1110 = 0.259 psi

g = 0.5030

E =2.90E+07 psi =

t = 0.2362 in 6.0 mm

c.a = 0.0000 in 0 mm

t (corr) = 0.2362 in 6.0 mm

At Center,

Maximum Deflection, = -(aqb

4

)/Et

3

t/2 = 0.118 in

= -0.01

= 0.01 in Max Deflection < t/2 : O.K

Maximum Bending stress, s = (bqb

2

)/ t

2

= 1,097 psi <

allowable

16,700 psi : OK

Max Bending stress < allowable : O.K

Material A 240 316L

Yield Stress, sy = 25000 psi

Stress Ratio, s/ sy = 0.044

At center of long side,

Maximum reaction force per unit length normal to the plate surface,

R = gqb

= 2.56 lb/in

= 289.73 N/mm

S

a

S

S

S b

CPP-Tank Design Calc

Page 31 of 42

ROOF WALL WEIGHT CALCULATION

Weight Per pcs Qty Total

450NB Blind = 100 1 100 kg

450NB Pipe = 12 1 12 kg

450NB Slip On = 59 1 59 kg

50NB WNRF = 1.02 1 1.02 kg

50NB Pipe = 15 1 15 kg

Piping & Accs = 5 1 5 kg

Stiffener (FB65 X 6) = 10 1 10 kg

Roof plate = 71 1 71 kg

Misc weight = 5 1 5 kg

Total Weight 273.02 kg

601.91 lb

Total Loading (pressure) acting on the roof plate is calculated as shown below

Dead Load = 273.02 kg

F = m x g = 2678.33 N

Area = a x b = 1.50

m

2

P = F/A = 1785.55 Pa

= 0.259 psi

Concentrated Load = 0.00 kg

F = m x g = 0.00 N

Area = a x b = 1.50

m

2

P = F/A = 0.00 Pa

= 0.00 psi

Live Load, LL = 0.00

kg/m

2

= 0.00 psi

extra load 0.00

ROOF STIFFENER LOCATION

CPP-Tank Design Calc

Page 32 of 42

ROOF WALL HORIZONTAL STIFFENER CALCULATION

TANK NO. : T-950

Maximum bending moment occurs at the point where dM/dx = 0 and shear force is zero,

that is, at the middle of the beam.

L = 1000 mm = 39.37 in

5.10 lb/in = 500 mm = 19.7 in

Load q = 0.259 psi

unit load W = q x psi

= 5.10 lb/in

39.37 in

Bending Moment

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x = L/2 = 19.69 in

Maximum moment, M

max

= WL

2

/8

= 988 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.040

in

3

Use FB 65 x 6

I/y = 0.258 in

3

> (I/y)

required

O.K

Therefore, s = 3831 psi <

allowable

16700 psi O.K

Deflection

As per Table 8.1 Case 2e of Roark's (Uniform load on entire span)

At x =L/2= 19.69 in

max

=

(5WL

4

)

384EI

= 0.017 < L/360 = 0.1094 in

The stiffener size used is adequate.

Wb

Wa

X

W

CPP-Tank Design Calc

Page 33 of 42

ROOF WALL VERTICAL STIFFENER CALCULATION

TANK NO. : T-950

L = 500 mm = 19.69 in

= 250 mm = 9.8 in

2.55 lb/in

Load q = 0.2590 psi

unit load W = q x psi

= 2.55 lb/in

19.69 in

Bending Moment

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.548L = 10.79 in

Maximum moment, M

max

=

0.0215WL

2

= 21 lb-in

M/I = s/y

(I/y)

required

= M/s

= 0.001

in

3

1. Checking Section Modulus (Z) of stiffener :

Stiffener size = FB 65 x 6

Section Modulus of stiffener is OK

Z = I/y

Z

stiffener

= 0.258

in

3

> 0.001

in

3

Z

required

2. Checking stiffener Bending stress (s ) :

s = M/Z Max bending stress of stiffener is OK

s

stiffener

= M

max

/ Z

stiffener

Therefore, s

stiffener

= 82 psi < 16700 psi

allowable

Deflection

As per Table 8.1 Case 2d of Roark's (Uniformly increasing load)

At x = 0.525L = 10.33 in

d

max

=

= 0.0004 in < L/360) 0.0547 in

The stiffener size used is adequate.

0.001309 x WL

4

EI

Wb

Wa

X

W

CPP-Tank Design Calc

Page 34 of 42

NOZZLE THICKNESS CALCULATION

TANK NO. : T-985

NOZZLE NO : N1 / N2 / N3 / N4 / N5 / K1A / K1B

DESIGN CONDITIONS WELDS

Neck:

P 0.0245 MPa tc1 =0.7*t 4.20 mm

DT 55

o

C tc2 =0.7*tn 3.88 mm

CAe / CAi 0 / 0 mm tc3 xxx

tc =Min[tc1,tc2,tc3] 3.88 mm

Pad:

Fr1 =0.5*te xxx mm

Fr2 =0.5*t xxx mm

SHELL PROPERTIES Fr3 = xxx mm

Fr =Min[Fr1,Fr2,Fr3] mm

Summary:

Material: A 240 316L External Leg 6 mm

S @(55

o

C) 115.15 MPa Internal Leg 0 mm

Wall Thickness, ts 6 mm Pad Leg 0 mm

tr = 3 mm

t =ts - CA 6 mm LIMIT OF REINFORCEMENT .UG - 40

NOZZLE SIZE: 50NB SCH 40S R1 =d 49.22 mm

R2 =Rn +tn +t 36.15 mm

trn = PRn .UG - 32 R =Max [R1,R2] 49.22 mm

2SE - 0.2P h1 =2.5*T1 15.00 mm

h2 =2.5*Tb1 +Tr1 13.85 mm

Material: A 312 TP316L h =Min [h1,h2] 13.85 mm

S @(55

o

C) 115.15 MPa Internal Projection 5.00 mm

OD 60.3 External Projection 150.00 mm

Wall Thickness, tb 5.54 mm

ID 49.22 mm MATERIAL STRENGTH RATIOS

Neck Slope 0

o

F =Figure UG-37 1.0 fr1 =Sn/Sv 1.0000

d =ID +(2*CA) +Tol. 49.22 mm fr2 =Sn/Sv 1.0000

Rn =d/2 24.61 mm fr4 =Sp/Sv 0.00

E 1.0 fr3 =Min[fr1,fr2,fr4] 0.0000

trn 0.00262 mm

tn =tb - CA 5.54 mm AREA AVAILABLE .UG - 37

PAD A

11

=d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1) 147.66 mm

2

A

12

=2(t+tn)(E1t-Ftr)-2tn(E1t-Ftr)(1-fr1) 69.24 mm

2

Material: A

1

= Max [A

11

, A

12

] 147.66 mm

2

S @(55

o

C) 0 MPa

OD 0 mm A

21

=5(tn - trn)fr2.t 166.12 mm

2

Thickness =te 0 mm A

22

=5(tn - trn)fr2.tn 153.39 mm

2

Weld 0 mm A

2

= Min [A

21

, A

22

] 153.39 mm

2

A

3

= (Int.proj - CAi)(tn - CAi).fr2 27.70 mm

2

FLANGE

A

41

=

(Ext.Leg - CAe)

2

.fr3 0.00 mm

2

Material: A 182 F316L A

42

=

(Int.Leg - CAi)

2

.fr2 0.00 mm

2

Type: 150 #SW A

43

=

(Pad.Leg - CAe)

2

.fr4 0.00 mm

2

Rating at 55

o

C 1.943 MPa A

4

= Sum[A

41

,A

42

,A

43

] 0.00 mm

2

AREA REQUIRED UG - 37 A

5

= (Pad OD - Noz OD).te.fr4 0.00 mm

2

A =d.tr.F +2.tn.tr.F(1-fr1) 147.66 mm

2

TOTAL AREA AVAILABLE = 328.75 mm

2

OK

CPP-Tank Design Calc

Page 35 of 42

NOZZLE THICKNESS CALCULATION

TANK NO. : T-985

NOZZLE NO : MW

DESIGN CONDITIONS WELDS

Neck:

P 0.0245 MPa tc1 =0.7*t 4.20 mm

DT 55

o

C tc2 =0.7*tn 4.20 mm

CAe / CAi 0 / 0 mm tc3 xxx

tc =Min[tc1,tc2,tc3] 4.20 mm

Pad:

Fr1 =0.5*te xxx mm

Fr2 =0.5*t xxx mm

SHELL PROPERTIES Fr3 = xxx mm

Fr =Min[Fr1,Fr2,Fr3] mm

Summary:

Material: A 240 316L External Leg 6 mm

S @(55

o

C) 115.15 MPa Internal Leg 0 mm

Wall Thickness, ts 6 mm Pad Leg 0 mm

tr = 3 mm

t =ts - CA 6 mm LIMIT OF REINFORCEMENT .UG - 40

NOZZLE SIZE: 600NB R1 =d 597.6 mm

R2 =Rn +tn +t 310.8 mm

trn = PRn .UG - 32 R =Max [R1,R2] 597.6 mm

2SE - 0.2P h1 =2.5*T1 15.00 mm

h2 =2.5*Tb1 +Tr1 15.00 mm

Material: A 240 316L h =Min [h1,h2] 15.00 mm

S @(55

o

C) 115.15 MPa Internal Projection 5.00 mm

OD 609.6 External Projection 150.00 mm

Wall Thickness, tb 6 mm

ID 597.6 mm MATERIAL STRENGTH RATIOS

Neck Slope 0

o

F =Figure UG-37 1.0 fr1 =Sn/Sv 1.0000

d =ID +(2*CA) +Tol. 597.6 mm fr2 =Sn/Sv 1.0000

Rn =d/2 298.8 mm fr4 =Sp/Sv 0.00

E 1.0 fr3 =Min[fr1,fr2,fr4] 0.0000

trn 0.03181 mm

tn =tb - CA 6 mm AREA AVAILABLE .UG - 37

PAD A

11

=d(E1t - Ftr) - 2tn(E1t - Ftr)(1 - fr1) 1792.80 mm

2

A

12

=2(t+tn)(E1t-Ftr)-2tn(E1t-Ftr)(1-fr1) 72.00 mm

2

Material: A

1

= Max [A

11

, A

12

] 1792.80 mm

2

S @(55

o

C) 0 MPa

OD 0 mm A

21

=5(tn - trn)fr2.t 179.05 mm

2

Thickness =te 0 mm A

22

=5(tn - trn)fr2.tn 179.05 mm

2

Weld 0 mm A

2

= Min [A

21

, A

22

] 179.05 mm

2

A

3

= (Int.proj - CAi)(tn - CAi).fr2 30.00 mm

2

FLANGE

A

41

=

(Ext.Leg - CAe)

2

.fr3 0.00 mm

2

Material: A 182 F316L A

42

=

(Int.Leg - CAi)

2

.fr2 0.00 mm

2

Type: 150 # A

43

=

(Pad.Leg - CAe)

2

.fr4 0.00 mm

2

Rating at 55

o

C 1.943 MPa A

4

= Sum[A

41

,A

42

,A

43

] 0.00 mm

2

AREA REQUIRED UG - 37 A

5

= (Pad OD - Noz OD).te.fr4 0.00 mm

2

A =d.tr.F +2.tn.tr.F(1-fr1) 1792.8 mm

2

TOTAL AREA AVAILABLE = 2001.85 mm

2

OK

CPP-Tank Design Calc

Page 36 of 42

WIND LOADING - BS 6399 - PART 2 -1997

ITEM : CPP (T-950 )

PROJ ECT NO.PM329 EAST PIATU DEVELOPMENT PROJECT

Terrain Category = 1

Region = D

Basic Wind Speed Vb = 50.00 m/s

Shielding Factor Ms = 1

Topographic Factor Sa = 1

Direction Factor Sd = 1

Probability Factor Sp = 1

Seasonal Factor Ss = 1

Terrain and Building Factor Sb = 1

Design Wind Speed Vz = 50.00 m/s ( Vb x Sa x Sd x Sp x Ss )

Effective (Design) Wind speed Ve = 50.00 m/s ( Vz x Sb )

Dynamic Pressure qz = 1.5325 kPa ( 0.613 x Ve

2

x 10

-3

)

Drag Coefficient Cd = 1

H = 3,500 mm

Width = 2,800 mm

Az = 9,800,000 mm

2

3

5

0

0

H / Width = 1.25

Kar = 1

Cd' = 1 ( Cd x Kar )

Wind Force Fw = 15018.5 N ( Cd' x qz x Az ) / 10

3

Height to COG h = 1750.000 mm ( H / 2 )

Overturning Moment Mw = 26282375 Nmm ( Fw x h )

2800

CPP-Tank Design Calc

Page 37 of 42

LOAD AT BASE & TRANSPORTATION LOAD CALCULATION

ITEM : CPP (T-950 )

PROJ ECT NO. PM329 EAST PIATU DEVELOPMENT PROJECT

WEIGHTS

Empty We = 1361 kg ------> 13353 N

EXTERNAL LOADS

Wind Force Fw = 15,019 N

Earthquake Force Feq = 0 N

F

D

= 2024 N [( 0.5 x We )

2

+( 1.4 x We )

2

]

0.5

Wind Moment Mw = 26,282,375 Nmm

Earthquake Moment Meq = 0 Nmm

Transportation Moment Mc = 3,541,163 Nmm ( F

D

x COG

) COG

= 1750 mm

(H/2)

Maximum Shear Force F = 15,019 N

Maximum O/T Moment M = 26,282,375 Nmm

HOLD DOWN BOLTS

Bolt Material... = A 193 GR B7

Bolt Yield Stress. Sy = 207 MPa

Bolt UTS.... Su = 507 MPa

Allowable Tensile...... Ft = 124.2 MPa

Allowable Shear... Fs = 69 MPa

Bolt Size... = M16

Bolt Number..... N = 2

Tensile Area.... A

T = 146 mm

2

Shear Area..A

S = 225 mm

2

Bolt PCD.. PCD = 1980.64 mm

SHEAR STRESS IN BOLT

Shear / Bolt, fs = F

N x As

33.37 MPa OK

69 MPa

since fs <Fs the shear stress is OK

Transportation Force

fs =

Fs =

CPP-Tank Design Calc

Page 38 of 42

LEG BASEPLATE DESIGN

ITEM : CPP (T-950 )

PROJ ECT NO. PM329 EAST PIATU DEVELOPMENT PROJECT

Refer Dennis R Moss Procedure 3-10

tb =

Q = Maximum Load / Support = 3338 N

F = Baseplate Width = 170 mm

A = Baseplate Length = 170 mm

Fb = Allowable Bending Stress = 163.68 MPa ( 0.66 Fy )

tb = 3.9 mm

Use Tb = 10 mm OK

BASE PLATE WELD CHECKING

Maximum stress due to Q & F =max(Q, F)/Aw = 3.68 N/mm

2

< 86.9 N/mm

2

OK

Weld leg size, g = 6.0 mm

Length of weld, l =2*( 2*F +2*A ) = 1360 mm

Area of weld, Aw =0.5*g*l = 4080 mm

2

J oint efficiency for fillet weld, E = 0.6 -

Welding stress for steel, fw = 144.8 N/mm

2

Allowable stress for weld, fw =E*fw = 86.9 N/mm

2

Maximum vertical force, Q = 3338.3 N

Maximum horizontal force, F = 15018.5 N

3 x Q x F

4 x A x Fb

CPP-Tank Design Calc

Page 39 of 42

LEG DESIGN CALCULATION

ITEM : CPP (T-950 )

PROJ ECT NO. PM329 EAST PIATU DEVELOPMENT PROJECT

LEG DATA

Material.....= A 36

Yield Stress, Sy...= 248.2

N/mm

2

Allowable Axial Stress, fall....= 148.9

N/mm

2

( 0.6 x Sy )

Allowable Bending Stress, fball.......= 165.5 N/mm

2

( 2/3 x Sy )

LEG GEOMETRY :- I-BEAM 152 x 152 x 23 kg/m

A = 2920 mm

2

Ixx = 12500000

mm

4

d = 76.2 mm

e = 76.2 mm

L = 152.4 mm

r = 9 mm

AXIAL STRESS

Axial Stress, fa = F / A = 1.14 N/mm

2

BENDING STRESS

Bending Stress, fb = P x L x e = 13.95 N/mm

2

Ixx

COMBINED STRESS

Combined Stress, f =(fa/fall +fb/fball) = 0.09

Since Combined Stress is < 1.00 The Leg Design is OK!

e

d

X X

CPP-Tank Design Calc

Page 40 of 42

WEIGHT SUMMARY

ITEM : CPP (T-910 / T-920 / T-940 / T-950)

PROJ ECT NO. PM329 EAST PIATU DEVELOPMENT PROJECT

ITEM QTY SET WEIGHT

T-910 / T-920 / T-940

SIDE PLATE 1.5 m x 2.5 m x 6 thk 4 3 2119.5 kg

BASE PLATE 1.5 m x 1.5 m x 6 thk 1 3 317.9 kg

ROOF PLATE 1.5 m x 1.5 m x 6 thk 1 3 317.9 kg

STIFFENER

SIDE WALL FB 65 x 6 x 17.5 m 4 3 2571.7 kg

ROOF PLATE FB 65 x 6 x 2.0 m 1 3 18.4 kg

BOTTOM PLATE FB 65 x 6 x 12.0 m 1 3 110.2 kg

NOZZLE / OPENINGS 1 3 315.0 kg

MISC (PIPING / OTHERS) 1 3 225.0 kg

T-950

SIDE PLATE (1) 1.5 m x 2.5 m x 6 thk 2 1 353.3 kg

SIDE PLATE (2) 1.0 m x 2.5 m x 6 thk 2 1 235.5 kg

BASE PLATE 1.5 m x 1.0 m x 6 thk 1 1 70.7 kg

ROOF PLATE 1.5 m x 1.0 m x 6 thk 1 1 70.7 kg

STIFFENER

SIDE WALL (1) FB 65 x 6 x 17.5 m 2 1 214.3 kg

SIDE WALL (2) FB 65 x 6 x 12.5 m 2 1 153.1 kg

ROOF PLATE FB 65 x 6 x 2.0 m 1 1 6.1 kg

BOTTOM PLATE FB 65 x 6 x 10.0 m 1 1 30.6 kg

NOZZLE / OPENINGS 1 1 105.0 kg

MISC (PIPING / OTHERS) 1 1 122.0 kg

CPP SKID SUPPORT

UC254x254x73 kg/m

2

30.8 m x 73 kg/m2 1 1 2250.5 kg

UC152x152x23 kg/m

2

6.6 m x 23 kg/m2 1 1 152.7 kg

TOTAL WEIGHT 9,760 kg

height width length

Tank Volume (T910/T920/T940) 2.5 m x 1.5 m x 1.5 mm = 5.6

m

3

Tank Volume (T950) 2.5 m x 1.0 m x 1.5 mm = 3.8

m

3

CPPT-910 / T-920 / T-940 - Water Weight [ Volume x Density(@1000 kg/m

3

)] 9,375 kg

SUMMARY

9,760 kg

19,135 kg

19,135 kg

WIRE ROPE DIAMETER USED = 24 ton Design safety Factor = 1.8

SWL OF SLING USED = 6.3 ton Design Weight of Load = 38,731 lb

17,568 kg

DESCRIPTION

EMPTY WEIGHT

OPERATING WEIGHT (Empty Weight +Water Weight)

FULL WATER WEIGHT

CPP-Tank Design Calc

Page 41 of 42

SECTIONAL STIFFENER PROPERTIES CALCULATION

TANK NO. : CPP (T-910/T-920/T-940/T-950)

Stiffener Size FB 65 x 6

Material, A 240 316L

Yield Stress,

y

25000 psi

Allowable Stress,

allowable

16700 psi

Where :

d1 = 65 mm

b1 = 6 mm

PART Area (a) y a x y h

h

2

a x h

2

bd

3

/12

I section

mm

2

mm

mm

3

mm

mm

2

mm

4

mm

4

mm

4

1 390 32.5 12675 0.00 0 0 137312.5 137312.5

TOTAL 390 32.5 12675 0.00 0 0 137312.5 137312.5

Calculating Sectional Properties of stiffener :

C = SAy = 12675

SA 390

C = 32.50 mm

Second Moment of Inertia of Stiffener

I = 137312.5

mm

4

= 0.3299

in

4

Section Modulus of Stiffener

Z = 4225

mm

3

= 0.2578

in

3

h

C

1

b1

y1

d1

Stiffener

CPP-Tank Design Calc

Page 42 of 42

You might also like

- Rectangular Tank Design ROARKS FORMULADocument40 pagesRectangular Tank Design ROARKS FORMULANavasOT100% (3)

- Padeye Design CheekDocument3 pagesPadeye Design CheekBolarinwa89% (9)

- Swing Bolt Closure Design - Pressure VesselDocument12 pagesSwing Bolt Closure Design - Pressure VesselRasatja Yongskulrote100% (2)

- Design Rectangular TankDocument4 pagesDesign Rectangular Tankrenji_danny75% (4)

- Lifting Lug and Support LugDocument5 pagesLifting Lug and Support Lugkhuong_uno100% (2)

- Mechanical Design Calculation of FRP Tank: Project No. - Rev. 02 Document No. 1-074-9/DKP/18 Page 1 of 20Document25 pagesMechanical Design Calculation of FRP Tank: Project No. - Rev. 02 Document No. 1-074-9/DKP/18 Page 1 of 20muchamad yasinNo ratings yet

- Pressure Vessel Lifting Lug CalculationDocument2 pagesPressure Vessel Lifting Lug Calculationtekstep767% (3)

- API 650 Water Storage TankDocument60 pagesAPI 650 Water Storage TankHgagselim Selim100% (2)

- Crossover Area Calc For Floating HeadDocument2 pagesCrossover Area Calc For Floating HeadRitesh VishambhariNo ratings yet

- Potable Water Tank CalculationDocument37 pagesPotable Water Tank Calculationcamycax0% (1)

- 2 - 1 Ellipsoidal Head Blank DiameterDocument1 page2 - 1 Ellipsoidal Head Blank Diameterdownloadmonster100% (2)

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amar100% (1)

- Rectangular Tank Design ExelDocument43 pagesRectangular Tank Design ExelNguyễn Quốc PhượngNo ratings yet

- PV Elite ResultDocument239 pagesPV Elite ResultChaitanya Sai TNo ratings yet

- Design of HCL FRP Storage TANKDocument21 pagesDesign of HCL FRP Storage TANKHaries Bugarin GarciaNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- D51Document6 pagesD51Brandon AllenNo ratings yet

- Rectangular Tank CalculationDocument28 pagesRectangular Tank CalculationMohammed EljammalNo ratings yet

- Design-Calculation Acid Wash TankDocument5 pagesDesign-Calculation Acid Wash TankWiz DomNo ratings yet

- Rectangular Tanks:: Rectangle Tank DesignDocument23 pagesRectangular Tanks:: Rectangle Tank Designshna jabarNo ratings yet

- Calculate The Wall Thickness of Methanol Storage TankDocument4 pagesCalculate The Wall Thickness of Methanol Storage TankhaidirNo ratings yet

- Rectangular Tank SizingDocument66 pagesRectangular Tank SizinglavascudoNo ratings yet

- E.4 Leg Support CalculationDocument2 pagesE.4 Leg Support Calculationnaim100% (1)

- PPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationDocument4 pagesPPE-STD-CAL-ME-006 Rectangular Tank Thickness CalculationNadya Askar100% (1)

- Design of Pressure Vessel by Group 4Document46 pagesDesign of Pressure Vessel by Group 4anteneh tesfayeNo ratings yet

- Leg CalculationDocument21 pagesLeg CalculationBahtiar Anak LaNangNo ratings yet

- Ladder Rung Calc.Document1 pageLadder Rung Calc.Azwan ShahNo ratings yet

- Saddle AnalysisDocument17 pagesSaddle AnalysiscutefrenzyNo ratings yet

- Design of Partition PlateDocument5 pagesDesign of Partition Platepippo2378793No ratings yet

- 3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankDocument4 pages3.4 Finite Element Analysis of Wind Induced Buckling of Steel TankNurul HudaNo ratings yet

- 50 Inch Manhole Neck CalculationDocument2 pages50 Inch Manhole Neck CalculationLawrence LawrenceNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal Sattu100% (1)

- Spreaer Beam&Lifting Line Beam p3Document2 pagesSpreaer Beam&Lifting Line Beam p3Sabrang LorNo ratings yet

- Design Report - Pipe Support - R2 PDFDocument10 pagesDesign Report - Pipe Support - R2 PDFAkhilesh KajarekarNo ratings yet

- Quotation: Note: This Quotation Is Sent by Email and No Signature Is RequiredDocument1 pageQuotation: Note: This Quotation Is Sent by Email and No Signature Is RequiredSyazwan KhairulNo ratings yet

- Tailing LugDocument3 pagesTailing LugSajad AbdulNo ratings yet

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinNo ratings yet

- Nozzle Design Under Internal PressureDocument1 pageNozzle Design Under Internal PressurenamasralNo ratings yet

- Support RingDocument13 pagesSupport RingvamsiNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- RectangularDocument6 pagesRectangularhgag selim100% (1)

- Cone Calculations - AD MerkblatterDocument15 pagesCone Calculations - AD MerkblatterSajal KulshresthaNo ratings yet

- Thickness Calculation of Pressure Vessel ShellDocument16 pagesThickness Calculation of Pressure Vessel ShellClaudia BonocoreNo ratings yet

- WRC, PV Elite, NozzlePro Sign ConventionsDocument13 pagesWRC, PV Elite, NozzlePro Sign ConventionsADHIRAJ KOLINo ratings yet

- Mean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & AnalysisDocument3 pagesMean Metal Temperature For Fixed Heat Exchanger - Intergraph CADWorx & Analysisisrar khanNo ratings yet

- PV Newsletter - Skirt Connections PDFDocument5 pagesPV Newsletter - Skirt Connections PDFDivyesh PatelNo ratings yet

- Cbse Sports Calendar 2014 2015Document23 pagesCbse Sports Calendar 2014 2015डा. सत्यदेव त्यागी आर्यNo ratings yet

- 500-KL Tank Calculation Report Rev. BDocument64 pages500-KL Tank Calculation Report Rev. Bmochammad reygyansyahNo ratings yet

- Rectangular Tank SizingDocument8 pagesRectangular Tank Sizingvofaith100% (16)

- High HDT Superior Vinyl Ester Resin - Crest731Document3 pagesHigh HDT Superior Vinyl Ester Resin - Crest731GautamNo ratings yet

- Leg CalculationDocument10 pagesLeg Calculationmashudi_fikriNo ratings yet

- 2 - 1 Ellipsoidal Head Blank DiameterDocument1 page2 - 1 Ellipsoidal Head Blank Diameterdombipin100% (1)

- Studding FlangeDocument6 pagesStudding FlangeDarshan PanchalNo ratings yet

- Vessel DatasheetDocument1 pageVessel Datasheetsdrtfg100% (1)

- PV Elite Webinar 001Document23 pagesPV Elite Webinar 001MEC_GuiNo ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- API 650 Storage Tank TCA PreparationDocument86 pagesAPI 650 Storage Tank TCA PreparationBimal DeyNo ratings yet

- U3 PDFDocument1 pageU3 PDFEric SamNo ratings yet

- Vaporizer Specification SR No. Description Unit Design ParametersDocument1 pageVaporizer Specification SR No. Description Unit Design ParametersVenkatesan ManikandanNo ratings yet

- Contoh SoalDocument13 pagesContoh Soalmarkus andikaNo ratings yet

- Societe Egyptienne D'Entreprises (SEDE) : Lot A - Unit Iii Water Transmission SchemeDocument189 pagesSociete Egyptienne D'Entreprises (SEDE) : Lot A - Unit Iii Water Transmission SchemeALINo ratings yet

- Tank Calculation Sheet: I. Design Parameters: TK-9291-01 Demulsifier Injection TankDocument1 pageTank Calculation Sheet: I. Design Parameters: TK-9291-01 Demulsifier Injection TanknamasralNo ratings yet

- Skid Structure Calculation Rev.a - MBD - APPROVEDDocument45 pagesSkid Structure Calculation Rev.a - MBD - APPROVEDnamasral100% (6)

- 10 Most Popular Excel TricksDocument27 pages10 Most Popular Excel Tricksjoamer66No ratings yet

- Detail B: Page 1 of 2Document5 pagesDetail B: Page 1 of 2namasralNo ratings yet

- Pipe Database WeeblyDocument8 pagesPipe Database WeeblynamasralNo ratings yet

- B (MM) L (MM) B + L Length (M) Qty No of Face Area: ChannelDocument8 pagesB (MM) L (MM) B + L Length (M) Qty No of Face Area: ChannelnamasralNo ratings yet

- 2013.10.03 - Pocket Welding Detail PDFDocument1 page2013.10.03 - Pocket Welding Detail PDFnamasralNo ratings yet

- Allowable Secondary Stress..Document7 pagesAllowable Secondary Stress..namasralNo ratings yet

- Butt Weld Branch OutletDocument2 pagesButt Weld Branch OutletnamasralNo ratings yet

- Typical P&ID Arrangement - Pig LAUNCHERDocument3 pagesTypical P&ID Arrangement - Pig LAUNCHERnamasralNo ratings yet

- Roof Calculation Book - UBC DESIGN PDFDocument70 pagesRoof Calculation Book - UBC DESIGN PDFStephanie CampbellNo ratings yet

- Legend: Marine Energy Sdn. Bhd. SapurakencanaDocument1 pageLegend: Marine Energy Sdn. Bhd. SapurakencananamasralNo ratings yet

- ASME Fatigue Life CurvesDocument3 pagesASME Fatigue Life CurvesnamasralNo ratings yet

- Nozzle Design Under Internal PressureDocument1 pageNozzle Design Under Internal PressurenamasralNo ratings yet

- Ral Colours For Coloursplash LockersDocument5 pagesRal Colours For Coloursplash Lockersnamasral100% (1)

- WRC 297 RWE NODE 6340 25febDocument4 pagesWRC 297 RWE NODE 6340 25febnamasralNo ratings yet

- COADE's Application of Welding Research Council Bulletins 107, 297 and 368Document3 pagesCOADE's Application of Welding Research Council Bulletins 107, 297 and 368shivabtowin3301100% (3)