Professional Documents

Culture Documents

Metal Forming Processes-Mmft

Metal Forming Processes-Mmft

Uploaded by

Onkar KakadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Forming Processes-Mmft

Metal Forming Processes-Mmft

Uploaded by

Onkar KakadCopyright:

Available Formats

Metal Forming Processes

Metal Forming Processes

Dr.

Dr.

Pulak

Pulak

M.

M.

Pandey

Pandey

http://

http://

paniit.iitd.ac.in/~pmpandey

paniit.iitd.ac.in/~pmpandey

Introduction

Introduction

Practically all metals, which are not used in cast form are

Practically all metals, which are not used in cast form are

reduced to some standard shapes for subsequent processing.

reduced to some standard shapes for subsequent processing.

Manufacturing companies producing metals supply metals

Manufacturing companies producing metals supply metals

in form of ingots which are obtained by casting liquid metal

in form of ingots which are obtained by casting liquid metal

into a square cross section.

into a square cross section.

Slab (500 Slab (500- -1800 mm wide and 50 1800 mm wide and 50- -300 mm thick) 300 mm thick)

Billets (40 to 150 sq mm) Billets (40 to 150 sq mm)

Blooms (150 to 400 sq mm) Blooms (150 to 400 sq mm)

Sometimes continuous casting methods are also used to cast

Sometimes continuous casting methods are also used to cast

the liquid metal into slabs, billets or blooms.

the liquid metal into slabs, billets or blooms.

These shapes are further processed through hot rolling,

These shapes are further processed through hot rolling,

forging or extrusion, to produce materials in standard form

forging or extrusion, to produce materials in standard form

such as plates, sheets, rods, tubes and structural sections.

such as plates, sheets, rods, tubes and structural sections.

Sequence of operations for obtaining

Sequence of operations for obtaining

different shapes

different shapes

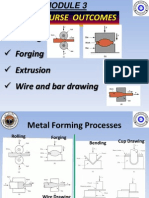

Primary Metal Forming Processes

Primary Metal Forming Processes

Rolling

Rolling

Forging

Forging

Extrusion

Extrusion

Tube and wire drawing

Tube and wire drawing

and Deep drawing

and Deep drawing

Although Punching and Blanking operations are

Although Punching and Blanking operations are

not metal forming processes however these will be

not metal forming processes however these will be

covered due to similarity with deep drawing

covered due to similarity with deep drawing

process.

process.

Rolling

Rolling

Change in grains structure in rolling

Change in grains structure in rolling

Salient points about rolling

Salient points about rolling

Rolling is the most extensively used metal forming

Rolling is the most extensively used metal forming

process and its share is roughly 90%

process and its share is roughly 90%

The material to be rolled is drawn by means of friction

The material to be rolled is drawn by means of friction

into the two revolving roll gap

into the two revolving roll gap

The compressive forces applied by the rolls reduce the

The compressive forces applied by the rolls reduce the

thickness of the material or changes its cross sectional

thickness of the material or changes its cross sectional

area

area

The geometry of the product depend on the contour of

The geometry of the product depend on the contour of

the roll gap

the roll gap

Roll materials are cast iron, cast steel and forged steel

Roll materials are cast iron, cast steel and forged steel

because of high strength and wear resistance

because of high strength and wear resistance

requirements

requirements

Hot rolls are generally rough so that they can bite the

Hot rolls are generally rough so that they can bite the

work, and cold rolls are ground and polished for good

work, and cold rolls are ground and polished for good

finish

finish

In rolling the crystals get elongated in the rolling direction.

In rolling the crystals get elongated in the rolling direction.

In cold

In cold

rolling crystal more or less retain the elongated shape but in h

rolling crystal more or less retain the elongated shape but in h

ot

ot

rolling they start reforming after coming out from the deformati

rolling they start reforming after coming out from the deformati

on

on

zone

zone

The peripheral velocity of rolls at entry exceeds that of the

The peripheral velocity of rolls at entry exceeds that of the

strip, which is dragged in if the interface friction is high

strip, which is dragged in if the interface friction is high

enough.

enough.

In the deformation zone the thickness of the strip gets reduced

In the deformation zone the thickness of the strip gets reduced

and it elongates. This increases the linear speed of the at the

and it elongates. This increases the linear speed of the at the

exit.

exit.

Thus there exist a neutral point where roll speed and strip

Thus there exist a neutral point where roll speed and strip

speeds are equal. At this point the direction of the friction

speeds are equal. At this point the direction of the friction

reverses.

reverses.

When the angle of contact

When the angle of contact

exceeds the friction angle

exceeds the friction angle

the

the

rolls cannot draw fresh strip

rolls cannot draw fresh strip

Roll torque, power etc. increase with increase in roll work

Roll torque, power etc. increase with increase in roll work

contact length or roll radius

contact length or roll radius

Pressure during rolling

Pressure during rolling

Typical pressure variation along

the contact length in flat rolling.

The peak pressure is located at

the neutral point. The area

beneath the curve, represents

roll force.

Friction in rolling: It depends on lubrication,

work material and also on the temperature. In

cold rolling the value of coefficient of friction

is around 0.1 and in warm working it is

around 0.2. In hot rolling it is around 0.4. In

hot rolling sticking friction condition is also

seen and then friction coefficient is observed

up to 0.7. In sticking the hot wok surface

adheres to roll and thus the central part of the

strip undergoes with a severe deformation.

Roll passes to get a 12 mm rod

Roll passes to get a 12 mm rod

from 100 x 100 mm billet

from 100 x 100 mm billet

Roll

Roll

configurations

configurations

in rolling mills

in rolling mills

Two

Two

-

-

high and three

high and three

-

-

high mills are generally

high mills are generally

used for initial and intermediate passes during

used for initial and intermediate passes during

hot rolling, while four

hot rolling, while four

-

-

high and cluster mills

high and cluster mills

are used for final passes.

are used for final passes.

Last two arrangements are preferred for cold

Last two arrangements are preferred for cold

rolling because roll in these configurations are

rolling because roll in these configurations are

supported by back

supported by back

-

-

up rolls which minimize

up rolls which minimize

the deflections and produce better tolerances.

the deflections and produce better tolerances.

Various Roll Configurations (a) Two Various Roll Configurations (a) Two- -high (b) Three high (b) Three- -high high

(c) Four (c) Four- -high (d) Cluster mill (e) Tandem mill high (d) Cluster mill (e) Tandem mill

back

Other deformation processes related to rolling

Other deformation processes related to rolling

Forging

Forging

Forging is perhaps oldest metal working process and was

Forging is perhaps oldest metal working process and was

known even during prehistoric days when metallic tools

known even during prehistoric days when metallic tools

were made by heating and hammering.

were made by heating and hammering.

Forging is basically involves plastic deformation of

Forging is basically involves plastic deformation of

material between two dies to achieve desired

material between two dies to achieve desired

configuration. Depending upon complexity of the part

configuration. Depending upon complexity of the part

forging is carried out as

forging is carried out as

open die forging and closed die

open die forging and closed die

forging.

forging.

In open die forging, the metal is compressed by repeated

In open die forging, the metal is compressed by repeated

blows by a mechanical hammer and shape is manipulated

blows by a mechanical hammer and shape is manipulated

manually.

manually.

In closed die forging, the desired configuration is

In closed die forging, the desired configuration is

obtained by squeezing the

obtained by squeezing the

workpiece

workpiece

between two shaped

between two shaped

and closed dies.

and closed dies.

On squeezing the die cavity gets completely filled and

On squeezing the die cavity gets completely filled and

excess material comes out around the periphery of the

excess material comes out around the periphery of the

die as

die as

flash

flash

which is later trimmed.

which is later trimmed.

Press forging and drop forging are two popular

Press forging and drop forging are two popular

methods in closed die forging.

methods in closed die forging.

In press forging the metal is squeezed slowly by a

In press forging the metal is squeezed slowly by a

hydraulic or mechanical press and component is

hydraulic or mechanical press and component is

produced in a single closing of die, hence the

produced in a single closing of die, hence the

dimensional accuracy is much better than drop

dimensional accuracy is much better than drop

forging.

forging.

Both open and closed die forging processes are carried

Both open and closed die forging processes are carried

out in hot as well as in cold state.

out in hot as well as in cold state.

In forging

In forging

favorable grain orientation

favorable grain orientation

of metal is

of metal is

obtained

obtained

Open and closed die forging

Open and closed die forging

back

Grain orientation in forging

Grain orientation in forging

Forging Machining

back

Barreling in

Barreling in

forging

forging

Flash less forging or

Flash less forging or

precision forging

precision forging

Self reading in forging

Self reading in forging

Fullering

Fullering

Edging

Edging

Cogging

Cogging

Upsetting

Upsetting

Heading

Heading

Swaging

Swaging

Radial forging etc.

Radial forging etc.

Go through any book on

Manufacturing processes

by Kalpakjian, Groover

or Degarmo

Extrusion

Extrusion

It is a relatively new process and its commercial

It is a relatively new process and its commercial

exploitation started early in the nineteenth century with the

exploitation started early in the nineteenth century with the

extrusion of lead pipes. Extrusion of steels became

extrusion of lead pipes. Extrusion of steels became

possible only after 1930 when extrusion chambers could

possible only after 1930 when extrusion chambers could

be designed to withstand high temperature and pressure.

be designed to withstand high temperature and pressure.

In extrusion, the material is compressed in a chamber and

In extrusion, the material is compressed in a chamber and

the deformed material is forced to flow through the die.

the deformed material is forced to flow through the die.

The die opening corresponds to the cross section of the

The die opening corresponds to the cross section of the

required product.

required product.

It is basically a hot working process, however, for softer

It is basically a hot working process, however, for softer

materials cold extrusion is also performed.

materials cold extrusion is also performed.

Direct and Indirect Extrusion

Direct and Indirect Extrusion

In direct extrusion metal flows in the In direct extrusion metal flows in the

same direction as that of the ram. same direction as that of the ram.

Because of the relative motion between Because of the relative motion between

the heated billet and the chamber walls, the heated billet and the chamber walls,

friction is severe and is reduced by using friction is severe and is reduced by using

molten glass as a lubricant in case of molten glass as a lubricant in case of

steels at higher temperatures. At lower steels at higher temperatures. At lower

temperatures, oils with graphite powder temperatures, oils with graphite powder

is used for lubrication. is used for lubrication.

In indirect extrusion process metal In indirect extrusion process metal

flows in the opposite direction of the flows in the opposite direction of the

ram. It is more efficient since it reduces ram. It is more efficient since it reduces

friction losses considerably. The process, friction losses considerably. The process,

however, is not used extensively because however, is not used extensively because

it restricts the length of the extruded it restricts the length of the extruded

component. component.

Impact Extrusion

Impact Extrusion

It is similar to indirect It is similar to indirect

extrusion. Here the punch extrusion. Here the punch

descends rapidly on to the descends rapidly on to the

blank which gets indirectly blank which gets indirectly

extruded on to the punch and extruded on to the punch and

to give a tubular section. The to give a tubular section. The

length of the tube formed is length of the tube formed is

controlled by the amount of controlled by the amount of

metal in the slug or by the metal in the slug or by the

blank thickness. Collapsible blank thickness. Collapsible

tubes for pastes are extruded tubes for pastes are extruded

by this method. by this method.

Hydrostatic Extrusion

Hydrostatic Extrusion

In this process the In this process the

friction between friction between

container wall and billet container wall and billet

is eliminated, however, is eliminated, however,

this process has got this process has got

limited applications in limited applications in

industry due to industry due to

specialized equipment & specialized equipment &

tooling and low tooling and low

production rate due to production rate due to

high set up time. high set up time.

Drawing

Drawing

Large quantities of wires, rods, Large quantities of wires, rods,

tubes and other sections are tubes and other sections are

produced by drawing process produced by drawing process

which is basically a cold which is basically a cold

working process. In this working process. In this

process the material is pulled process the material is pulled

through a die in order to through a die in order to

reduce it to the desired shape reduce it to the desired shape

and size. and size.

In a typical wire drawing In a typical wire drawing

operation, once end of the wire operation, once end of the wire

is reduced and passed through is reduced and passed through

the opening of the die, gripped the opening of the die, gripped

and pulled to reduce its and pulled to reduce its

diameter. diameter.

By successive drawing operation through dies of

By successive drawing operation through dies of

reducing diameter the wire can be reduced to a very

reducing diameter the wire can be reduced to a very

small diameter.

small diameter.

Annealing before each drawing operation permits

Annealing before each drawing operation permits

large area reduction.

large area reduction.

Tungsten Carbide dies are used to for drawing hard

Tungsten Carbide dies are used to for drawing hard

wires, and diamond dies is the choice for fine wires.

wires, and diamond dies is the choice for fine wires.

Tube drawing

Tube drawing

Tube drawing is also similar to wire drawing, except that a mand Tube drawing is also similar to wire drawing, except that a mandrel rel

of appropriate diameter is required to form the internal hole. of appropriate diameter is required to form the internal hole.

Here two arrangements are shown in figure (a) with a floating pl Here two arrangements are shown in figure (a) with a floating plug ug

and (b) with a moving mandrel and (b) with a moving mandrel

The process reduces the diameter and thickness of the tube. The process reduces the diameter and thickness of the tube.

Deep Drawing

Deep Drawing

This operation is

This operation is

extensively used to for

extensively used to for

making cylindrical

making cylindrical

shaped parts such as cups,

shaped parts such as cups,

shells, etc from sheet

shells, etc from sheet

metal.

metal.

As the blank is drawn into

As the blank is drawn into

the die cavity

the die cavity

compressive stress

compressive stress

is set

is set

up around the flange and

up around the flange and

it tends to

it tends to

wrinkle or

wrinkle or

buckle

buckle

the flange.

the flange.

Deformation of

Deformation of

workpiece

workpiece

during punch travel

during punch travel

Back

Defects in drawing

Defects in drawing

(a)Wrinkling in the flange or (b) in the wall (c) tearing, (a)Wrinkling in the flange or (b) in the wall (c) tearing,

(d) (d) earing earing, (e) surface scratches , (e) surface scratches

The effect of wrinkling and buckling can be seen from The effect of wrinkling and buckling can be seen from

the way a trapezoid on the outer surface of the blank is the way a trapezoid on the outer surface of the blank is

stretched in one direction and compressed in another stretched in one direction and compressed in another

direction to become a rectangle on the cup drawn. direction to become a rectangle on the cup drawn.

Wrinkling and buckling is avoided by applying a

Wrinkling and buckling is avoided by applying a

blank holder force through a blank holder.

blank holder force through a blank holder.

Blank holder force increases friction and hence the

Blank holder force increases friction and hence the

required punch load. Therefore, blank holder force

required punch load. Therefore, blank holder force

should be just enough to prevent wrinkling of the

should be just enough to prevent wrinkling of the

flange.

flange.

The edges of the punch and die are rounded for the

The edges of the punch and die are rounded for the

easy and smooth flow of metal.

easy and smooth flow of metal.

Sufficient clearance is also provided so that sheet

Sufficient clearance is also provided so that sheet

metal could be easily accommodated. In sufficient

metal could be easily accommodated. In sufficient

or large clearance may result into shearing and

or large clearance may result into shearing and

tearing of sheet.

tearing of sheet.

A drawn cup can be redrawn into a smaller cup

A drawn cup can be redrawn into a smaller cup

but it must be annealed to prevent failure.

but it must be annealed to prevent failure.

Punching and Blanking

Punching and Blanking

Punching and blanking Punching and blanking

operations are not metal operations are not metal

forming operations but are forming operations but are

discussed together with metal discussed together with metal

forming because of their forming because of their

similarity with deep drawing similarity with deep drawing

operation. operation.

Objective of punching and Objective of punching and

blanking is to remove blanking is to remove

material from the sheet metal material from the sheet metal

by causing rupture, the punch by causing rupture, the punch

and die corners are not and die corners are not

provided with the any radius. provided with the any radius.

Tool steel is the most Tool steel is the most

common material for tool and common material for tool and

die. Carbides are also used die. Carbides are also used

when high production is when high production is

needed. needed.

Comparison of metal forming processes

Comparison of metal forming processes

Self reading for your interest

Self reading for your interest

Defects in metal forming processes

Defects in metal forming processes

and their remedies. (use

and their remedies. (use

Kalpakjian

Kalpakjian

s

s

book)

book)

Defects in Rolling

Defects in Rolling

Defects in forging

Defects in forging

Defects in extrusion

Defects in extrusion

Surface cracking Surface cracking

piping piping

Internal cracking Internal cracking

You might also like

- Eyelet DrawingDocument49 pagesEyelet DrawingPra Vee33% (3)

- Soft Vs Hard ToolingDocument17 pagesSoft Vs Hard ToolingSurya Raghavendar100% (1)

- Progressive Die Design PDFDocument1 pageProgressive Die Design PDFSakthi VelNo ratings yet

- Pattern AllowancesDocument19 pagesPattern Allowancesimamuddeen100% (3)

- Mechanical Working of MetalsDocument76 pagesMechanical Working of MetalsPradip GuptaNo ratings yet

- Tool DesignDocument48 pagesTool DesignPAVIN ENGGNo ratings yet

- Injection MouldingDocument12 pagesInjection MouldingBalasubramaniam MuruganNo ratings yet

- Forging Design ConsiderationsDocument81 pagesForging Design ConsiderationssuneethaNo ratings yet

- Sheet Metal WorkingDocument26 pagesSheet Metal Workingvelavansu0% (1)

- Introduction To Flip ChipDocument58 pagesIntroduction To Flip ChipLakshman Yandapalli100% (1)

- My ForgingDocument20 pagesMy ForgingRam Janm SinghNo ratings yet

- Seminar Report HydroformingDocument11 pagesSeminar Report HydroformingAnuj Mandloi100% (2)

- ForgingDocument37 pagesForgingchris mushunjeNo ratings yet

- G2 DiscBrakeDocument33 pagesG2 DiscBrakesiddout2006No ratings yet

- ForgingDocument19 pagesForgingSarthakNo ratings yet

- Bulk Deformation Processes in Metal Forming: Part 1-RollingDocument53 pagesBulk Deformation Processes in Metal Forming: Part 1-RollingFirdaus Muhamad RifqiNo ratings yet

- Broach and Form ToolDocument20 pagesBroach and Form Toolsonu kumarNo ratings yet

- Metal FormingDocument49 pagesMetal FormingtejasNo ratings yet

- Tool Makers Microscope PPT - Siddhant SinghDocument15 pagesTool Makers Microscope PPT - Siddhant SinghSiddhant Singh100% (1)

- Chemical - Mechanical PolishingDocument7 pagesChemical - Mechanical PolishingMorcos Nashaat Daneil100% (1)

- Extrusión-Rolling and Forming ProcessDocument50 pagesExtrusión-Rolling and Forming Processquiron2010No ratings yet

- Rolling Lab PresentationDocument35 pagesRolling Lab PresentationNareshNo ratings yet

- Study of Wear Characteristics of Hardfaced Layers Made by E430 and E410 Electrodes Using SMAW ProcessDocument8 pagesStudy of Wear Characteristics of Hardfaced Layers Made by E430 and E410 Electrodes Using SMAW ProcessIJRASETPublicationsNo ratings yet

- Deep Drawing Literature ReviewDocument37 pagesDeep Drawing Literature ReviewS T100% (3)

- Metal FormingDocument40 pagesMetal Formingsreeeram100% (1)

- Extrusion and DrawingDocument19 pagesExtrusion and DrawingBatuhan YildizNo ratings yet

- Rapid Prototyping Full Seminar Report 989Document17 pagesRapid Prototyping Full Seminar Report 989Girish JawalageriNo ratings yet

- TB Grinding EnglishDocument20 pagesTB Grinding EnglishVk PrabakranNo ratings yet

- EIN 3390 Chap 17 Sheet-Forming Processes Part 1 Spring 2012Document50 pagesEIN 3390 Chap 17 Sheet-Forming Processes Part 1 Spring 2012sudharsans88No ratings yet

- Rapid Prototyping and Surface Modification TechniquesDocument46 pagesRapid Prototyping and Surface Modification TechniquesmanuNo ratings yet

- Compound Die Design: A Case Study: Sneha S. Pawar, R. S. DaluDocument4 pagesCompound Die Design: A Case Study: Sneha S. Pawar, R. S. DaluchupchapNo ratings yet

- Dies and Its TypesDocument2 pagesDies and Its TypesRajat AhujaNo ratings yet

- 2013 Theory All Inc Casting PDFDocument65 pages2013 Theory All Inc Casting PDFaamir_00No ratings yet

- Casting TheoryDocument22 pagesCasting TheoryJairam Atluri100% (1)

- Study of Forging Process Equipemnts-Practical-3Document12 pagesStudy of Forging Process Equipemnts-Practical-3prashantNo ratings yet

- Rapid Prototyping (RP) : Cad/Cam/CaeDocument45 pagesRapid Prototyping (RP) : Cad/Cam/CaePrashant AmbadekarNo ratings yet

- Electromagnetic FormingDocument15 pagesElectromagnetic FormingHimanshu Gupta50% (4)

- Casting: Shival Dubey Assistant Professor Mechanical EngineeringDocument31 pagesCasting: Shival Dubey Assistant Professor Mechanical EngineeringChirag TaterNo ratings yet

- Design of Components With Casting ConsiderationsDocument49 pagesDesign of Components With Casting ConsiderationsOrville SutariNo ratings yet

- Title: Objective: Electrode Discharge Machine Wirecut (EDM Wirecut)Document23 pagesTitle: Objective: Electrode Discharge Machine Wirecut (EDM Wirecut)Nur Shaheera Zainurin33% (3)

- Cold and Hot ForgingDocument6 pagesCold and Hot ForgingAnonymous vvO0nZWflrNo ratings yet

- Welding Processes and TechniqueDocument49 pagesWelding Processes and TechniqueRanendraNo ratings yet

- Design Considerations With Powder MetallurgyDocument15 pagesDesign Considerations With Powder MetallurgyTagaytayan MaritesNo ratings yet

- TALAT Lecture 3704: Deep DrawingDocument15 pagesTALAT Lecture 3704: Deep DrawingCORE MaterialsNo ratings yet

- Chips TypeDocument4 pagesChips TypeWajahat RasoolNo ratings yet

- Plastic Metal Forming of Metals and PowdersDocument20 pagesPlastic Metal Forming of Metals and Powdersيوسف عادل حسانينNo ratings yet

- Advanced Metal Cutting Technology (MAT-514 A) Patr 1Document25 pagesAdvanced Metal Cutting Technology (MAT-514 A) Patr 1Bizuayehu Tadesse100% (1)

- Processes Used To Form Metallic MaterialsDocument23 pagesProcesses Used To Form Metallic MaterialsHimanshu GuptaNo ratings yet

- Drilling Reaming & TappingDocument17 pagesDrilling Reaming & TappingLeo HsiehNo ratings yet

- Lecture Slide Metrology and Inspection - PPT PDFDocument30 pagesLecture Slide Metrology and Inspection - PPT PDFEdo EdgarNo ratings yet

- Milling and Turning OperationsDocument17 pagesMilling and Turning OperationsMuhammad ArifNo ratings yet

- Presses & Press Work 2Document27 pagesPresses & Press Work 2Sahil ShethNo ratings yet

- Lecture 05 (Metal Forming Processes)Document37 pagesLecture 05 (Metal Forming Processes)Mubashar ZahidNo ratings yet

- Cold FormingDocument7 pagesCold FormingglaxionNo ratings yet

- Rolling (Bulk Deformation Process)Document27 pagesRolling (Bulk Deformation Process)Kazal ArefinNo ratings yet

- Wire Drawing Shearing Processes FinalDocument19 pagesWire Drawing Shearing Processes FinalJairam AtluriNo ratings yet

- MT 2nd AssignmentDocument72 pagesMT 2nd AssignmentDixitNo ratings yet

- Bulk Deformatin Processes and EquipmentDocument46 pagesBulk Deformatin Processes and EquipmentarhlboyNo ratings yet

- Extrusion FundamentalsDocument5 pagesExtrusion FundamentalsJoNo ratings yet