Professional Documents

Culture Documents

Exam Specifications PE Che Apr 2011

Exam Specifications PE Che Apr 2011

Uploaded by

dr.c.is.dr.c0 ratings0% found this document useful (0 votes)

8 views3 pagesExam Specifications PE Che Apr 2011

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentExam Specifications PE Che Apr 2011

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesExam Specifications PE Che Apr 2011

Exam Specifications PE Che Apr 2011

Uploaded by

dr.c.is.dr.cExam Specifications PE Che Apr 2011

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

1

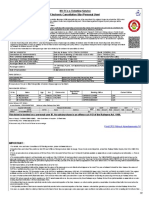

NCEES Principles and Practice of Engineering Examination

CHEMICAL Exam Specifications

Effective Beginning with the April 2011 Examinations

The exam is an 8-hour open-book exam. It contains 40 multiple-choice questions in the 4-hour

morning session, and 40 multiple-choice questions in the 4-hour afternoon session. Examinee

works all questions.

The exam uses both the International System of units (SI) and the US Customary System (USCS).

The exam is developed with questions that will require a variety of approaches and methodologies,

including design, analysis, and application.

The knowledge areas specified as examples of kinds of knowledge are not exclusive or exhaustive

categories.

Approximate

Percentage of

Examination

I. Mass/Energy Balances and Thermodynamics 23%

A. Mass Balances 10%

1. Material balances with no reaction (e.g., phase behavior,

mass, volume, density, composition, purge, bypass)

2. Material balances with reaction (e.g., multiple reactions,

incomplete reactions, excess reactant, purge, bypass, recycle,

combustion)

B. Energy Balances and Thermodynamics 13%

1. Energy balances on non-reactive systems (e.g., sensible heat,

latent heat, heat of solution)

2. Energy balances on reactive systems (e.g., heat of reaction

and combinations with sensible heat; latent heat; heat of

solution)

3. Power cycles (e.g., refrigeration, engines, turbines, heat

recovery)

II. Heat Transfer

16%

A. Mechanisms 9%

1. Heat transfer without phase change (e.g., thermal

conductivity, heat capacity, conduction, convection,

free/forced heat transfer coefficients/correlations, radiation,

combinations thereof)

2. Heat transfer with phase change (e.g., vaporization and

evaporation, condensation, sublimation, crystallization,

latent heat)

B. Applications 7%

1. Heat exchange equipment design (e.g., overall heat transfer

coefficient, fouling factors, LMTD, F-factor, equipment

selection, insulation)

2. Heat exchange equipment analysis [e.g., pressure drop,

fouling effects, performance evaluation (NTU), changes in

parameters]

2

III. Kinetics 11%

A. Reaction Parameters 6%

1. Rate equation (e.g., rate constant, activation energy, order of

reaction, mechanisms, catalysis)

2. Chemical equilibria (e.g., temperature and pressure

dependence, composition)

B. Reactors 5%

1. Conversion in single reactors [e.g., batch reactor, continuous

stirred tank reactor (CSTR), plug flow reactor (PFR)]

2. Conversion in complex reactors (e.g., reactors in series: CSTR

and/or PFR, multiphase reactors, fluidized beds, packed

beds, recycle, bioreactors)

3. Yield and selectivity

IV. Fluids 16%

A. Mechanical-Energy Balance 12%

1. Flow behavior (e.g., viscosity; velocity; Reynolds number;

friction factor; pressure drop in pipes, valves, and fittings;

expansion/ contraction; porous media; particle dynamics;

fluidization; sonic velocity; laminar/turbulent; two-phase

flow)

2. Flow applications (e.g., potential and kinetic energy, friction,

flow networks, mixing, pumps, NPSH, turbines,

compressors, drivers, solids handling)

B. Flow and Pressure Measurement Techniques 4%

1. Flow measurement application (e.g., mass and volumetric

meters) and pressure measurement application (e.g.,

permanent pressure drop, differential pressure devices)

V. Mass Transfer 14%

A. Phase Equilibria 5%

1. Ideal systems (e.g., Henry's Law, Raoult's Law, Dalton's Law,

ideal gas law, vapor pressure)

2. Non-ideal systems (e.g., activity coefficients, fugacity

coefficients, azeotropes, immiscible/partially miscible

phases, equations of state)

3. Phase equilibrium applications (e.g., bubble point, dew point,

flash, critical states)

B. Continuous Vapor-Liquid Contactors 8%

1. Material and energy balances for trayed units and packed

units (e.g., absorption, stripping, distillation)

2. Design parameters for trayed units (e.g., minimum flow rates

and reflux, minimum and theoretical stages, feed location,

tray selection, capacity/efficiency, flooding, dumping, tray

hydraulics)

3. Design parameters for non-trayed units (e.g., minimum flow

rates and reflux, minimum stages, theoretical stages/NTU,

feed location, packing selection, capacity/efficiency, flooding,

pressure drop, mass transfer coefficients/height of transfer

units)

3

C. Miscellaneous Mass Transfer Processes 1%

1. Continuous, batch, and semicontinuous (e.g., drying,

membranes, extraction, crystallization, filtration, leaching,

humidification, diffusion, adsorption, absorption, stripping,

distillation)

VI. Plant Design and Operation 20%

A. Economic Considerations 1%

1. Cost estimation and project evaluation (e.g., capital costs,

depreciation, operating costs, risk evaluation, optimization,

return on investment)

B. Design 10%

1. Process design (e.g., process flow sheets, P&ID,

specifications, procedures, modeling/simulation, scale-up,

process or product development, boundary conditions)

2. Process equipment design (e.g., equipment selection,

optimization, design temperature, design pressure)

3. Siting considerations (e.g., security, ingress, egress, plant

layout, utilities, natural disasters, human factors)

4. Instrumentation and process control (e.g., sensors, controller

actions, feedback/feed-forward actions)

5. Materials of construction (e.g., material properties and

selection, corrosion considerations)

C. Operation 4%

1. Process and equipment reliability (e.g., testing, preventive

maintenance, startup/shutdown procedures, robustness)

2. Process improvement and troubleshooting (e.g.,

debottlenecking, experimental design and evaluation,

optimization)

D. Safety, Health, and Environment 5%

1. Protection systems [e.g., pressure/vacuum relief valves

(safety valves), flares, rupture disks, vents, vacuum breakers,

inerting, seal legs, discharge location, configuration, fire

protection]

2. Industrial hygiene (e.g., MSDS, exposure limits and control,

noise control, ventilation, personal protective equipment)

3. Hazard identification and management [e.g., flammability/

explosive limits, auto-ignition, reactor stability, process

hazard analysis, safety integrity level (SIL), management of

change]

4. Environmental considerations (e.g., emissions evaluation,

permitting, pollution prevention, mitigation, waste

determination)

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pull Out Test MethodologyDocument5 pagesPull Out Test MethodologyAnonymous pnYxtPhLNo ratings yet

- Usborne - My Very First ArtDocument48 pagesUsborne - My Very First ArtOki SeptianNo ratings yet

- Niton XL3 T LibraryDocument3 pagesNiton XL3 T LibraryB_Vieira100% (1)

- Jsce PDFDocument530 pagesJsce PDFKhin Sandi KoNo ratings yet

- BohemianRhapsodyFlexyPercTimbales ScoDocument1 pageBohemianRhapsodyFlexyPercTimbales ScomartinNo ratings yet

- Lesson Number/ Title/Focus Key Understanding (KU) and Key Questions (KQ) Activities/ Teaching StrategiesDocument5 pagesLesson Number/ Title/Focus Key Understanding (KU) and Key Questions (KQ) Activities/ Teaching StrategiesCeline Grace Monterero50% (2)

- Trademark Search ReportDocument13 pagesTrademark Search ReportSayali GangalNo ratings yet

- 05 PumpsDocument80 pages05 PumpsRoberto O'ConnorNo ratings yet

- Fee Management SystemDocument44 pagesFee Management SystemSangeetha G67% (3)

- AspenTech Announces Availability of AspenONE V8 FINAL - For at - Com 12-10-2012Document3 pagesAspenTech Announces Availability of AspenONE V8 FINAL - For at - Com 12-10-2012imoomexNo ratings yet

- Diagnostic Reports PE Exam Diagnostic Report and Interpretation1Document2 pagesDiagnostic Reports PE Exam Diagnostic Report and Interpretation1imoomexNo ratings yet

- AspenTech AspenONE 8.0 InstallDocument6 pagesAspenTech AspenONE 8.0 InstallimoomexNo ratings yet

- Discoverability ScoreDocument8 pagesDiscoverability ScoreimoomexNo ratings yet

- Plume RiseDocument32 pagesPlume RiseimoomexNo ratings yet

- Key Words:: Module 04: Targeting Lecture 14: No. of Units TargetDocument8 pagesKey Words:: Module 04: Targeting Lecture 14: No. of Units TargetimoomexNo ratings yet

- Metal Oxide Varistors MOVs NTEDocument3 pagesMetal Oxide Varistors MOVs NTEElectronicos CaldasNo ratings yet

- WWW Studocu Com in N 29646569 Sid 01682568219Document1 pageWWW Studocu Com in N 29646569 Sid 01682568219Nivetha SelvamuruganNo ratings yet

- Tir Kannan 3Document19 pagesTir Kannan 3Bala_9990No ratings yet

- Maschler Reflection1Document3 pagesMaschler Reflection1Anne C MNo ratings yet

- A Study On Consumer Behaviour On Retail Food ChainsDocument15 pagesA Study On Consumer Behaviour On Retail Food ChainsHardeep SharmaNo ratings yet

- Management On Temporary Storage MaterialsDocument39 pagesManagement On Temporary Storage MaterialsTN QwertyNo ratings yet

- Condo QuestionnaireDocument5 pagesCondo QuestionnaireMansoorNo ratings yet

- Business Presentation Raw Script by AndromedaDocument2 pagesBusiness Presentation Raw Script by AndromedaHumanCremation DeathmetalNo ratings yet

- Carneychris Businessplan Busn499Document6 pagesCarneychris Businessplan Busn499api-238588764No ratings yet

- A&P by John UpdikeDocument4 pagesA&P by John Updikenazish aliNo ratings yet

- ADAPT DeflectionsDocument27 pagesADAPT DeflectionsCarsonBakerNo ratings yet

- 30 Things To Do Before Turning 30Document8 pages30 Things To Do Before Turning 30Bruce WayneNo ratings yet

- Literature Review On Sugar Industry in IndiaDocument6 pagesLiterature Review On Sugar Industry in Indiazrpcnkrif100% (1)

- Irctcs E-Ticketing Service Electronic Cancellation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Cancellation Slip (Personal User)Sundar ManiNo ratings yet

- CKLA G4U8 Treasure Island TGDocument354 pagesCKLA G4U8 Treasure Island TGMadisonNo ratings yet

- CompTIA IT Fundamentals Certification Exam ObjectivesDocument13 pagesCompTIA IT Fundamentals Certification Exam ObjectivesSameerUsmaniNo ratings yet

- Activity 2.1: I. Write The Pronoun That Can Take The Place of Each NounDocument2 pagesActivity 2.1: I. Write The Pronoun That Can Take The Place of Each NounMark Alvin Jay CarpioNo ratings yet

- E Book MelangeDocument88 pagesE Book MelangeConfidence FoundationNo ratings yet

- Cobra ODE Installation Manual (English) v1.4Document49 pagesCobra ODE Installation Manual (English) v1.4criticalllNo ratings yet

- University of Dar Es Salaam: Business SchoolDocument60 pagesUniversity of Dar Es Salaam: Business SchoolMaster KihimbwaNo ratings yet

- (IJCST-V12I2P2) :K Pushpalatha, DR R KalaiarasiDocument12 pages(IJCST-V12I2P2) :K Pushpalatha, DR R Kalaiarasieditor1ijcstNo ratings yet

- Reported SpeechDocument12 pagesReported Speechgaggokhome kimNo ratings yet