Professional Documents

Culture Documents

Tech Report Unfinished

Uploaded by

api-247133505Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tech Report Unfinished

Uploaded by

api-247133505Copyright:

Available Formats

F.R.

T

EDD Project

Justin Bromeling and Logan Watkins

Work done at ACTC

May 13, 2014

B-day afternoon Spring EDD

Abstract:

Approximately 67% of fishermen break their fishing rods while transporting them in a

vehicle. The purpose of the truck bed cover design is so that it will transport fishing rods more

safely and efficiently while also using minimal space. When investigating it was found they have

things that would complete this task, but was really only for boats. Products such as the rod box,

the Rod Rack master, and the bungee strap for the ceilings of vehicles are such products, but all

these took up major space or the safety rating of the rods in that product were too low. In this

design both qualities were achieved. In the scope of the research and investigations, everything

was found and considered in the design of this project to invent this wondrous product. In the

research all findings were documented and pondered when investigating the best solution to the

problem that stand. Using wood, a bed cover was made in two separate frames then connecting

them with hinges in the middle. After, clips, tubes, and Velcro were mounted on the bottom to

hold the fishing rods. The top then got covered with metal sheeting and a couple coats of

undercoating (Rubberized Coating). Using these materials helped in the cost efficiency of the

product, but it also made the product much more durable putting this design decision on top.

I ntroduction:

In this project a product was to be either invented or innovated. This particular product

was on the lines of being both, but is mainly an innovation. The product created was a truck bed

cover that would also transport fishing rods safely and efficiently. In this report it will tell what

the product was, how it was made, material cost and list, a summary describing how the product

looks and what went into coming up with the actual design, and lastly it includes other product

documentation. When investigating it was concluded that design this product was feasibly smart

to build instead of just buying most of the parts. In the following pages it will be showed that

everything that could be done to complete our task of creating a truck bed cover that would carry

fishing rods was done, and while it also was made to meet certain criteria to have it transport

them safely and efficiently, so that the numbers that broke their fishing rods while carrying them

in a vehicle would slowly recede.

3

Material List and Cost:

Figure 1.3

Materials Cost

Velcro $10.79*1

Golf tubes $1.49*10

Clips (16 pack) $8.32*1

Wood Free

Screws Free

Undercoat (can) $4.50*4

Metal sheeting Free

Hinges Free

Total $52.01

Table of Contents:

1) List of Tables and Figures

2) Summary

3) Introduction

4) Procedures

5) Results and Discussion

6) Conclusion

7) References

8) Appendices

Summary:

An approximate of about 67% of all fishermen breaks their fishing rod while

transporting them in a vehicle. When investigating on sites on how many people have done this

it was concluded that this was a real problem that only a few have attempted to solve. Certain

attempts like the bungee rod holder which was truly unsafe, the rod box which took a lot of

space, or even the rod master that connects to the roof of a truck cap which also is unsafe for

the rods achieved only one of the two qualities that this product has. When designing the

fishing rod transporter a decision matrix was used to recommend materials that would be used

for the truck bed cover and also to recommend what type of fishing rod transporter would be

done. In concluding the build of this product it was found that the project turned out great and

that we successfully included both qualities in the design. The method used to investigate

whether this project was worth the approach of this project was feasible was by looking up

patents for the type of project that was done and also by looking up information via Google.

Once everything was in place and the project was in a state of being fully completed and

working then we were able to get the testing for the qualities was to be included (which were).

In conclusion everything ended in a big success.

2

Background:

According to the history of the rod transporter the first one was made from PVC piping and

would hold the rods in the back of the truck bed, but the rods would be exposed and still easily

broken. It would also take up a lot of space and was not the best design. When the rod box was

created to help keep fishing rods safe it did it successfully and the best, but this design was a big

space taker. Lastly, when the most new and approved Rod master fishing rod transporter was

built and put to use it was seen as the best, but still was a major space taker and the rods still

were just a bit unsafe. In conclusion of the history of these products it still has some issues with

the qualities it should have and then it also should worry about the fact that these are the most

important qualities a product should have.

Procedures:

1) Once the project was determine a design was then drafted.

2) When the design was made then materials were gathered.

3) Using wood two 8x3 frame were made then covered on top with two sheets of metal.

4) Once the frames were built then three braces were placed 2ft. apart in each.

5) Frames were then covered with a couple of coats of undercover coating (Rubberized

coating).

6) Rubberizing coat sits for about 2 hours.

7) Frames are flipped over then the golf tubes are place about 1ft. down from the top.

8) Clips were then place on the next brace down. Then Velcro is mounted all the way across

the frame to strap the rods into place.

9) Lastly, the two frames are then put together with hinges so that the bed cover will wing

upwards.

10) Test product and document results.

4

Results:

Test 1 Rod Placement Test Rod was placed in rod holders

and was successfully held.

Test 2 Hinge Test Hinges all worked in direction

it needed to go.

Test 3 Stress Test Tested how the materials

would hold up to shake and

move strenuously, which

successfully proved it

durablitiy.

Once all test were done and each proven to be successful then the product was finished

and all qualities that were meant to be in the product were. Each test done provided this proof

and also allowed us to see if the product could withstand certain things like weather.

5

References:

Dawn, W. (2007, May 27). The Rocket fishing rod is perfect for fishing with kids.

Retrieved from http://voices.yahoo.ocm/the-rocket-fishing-rod-perfect-fishing-with-

353093.html?

How people break their fishing rods. (2013, August 6). Retrieved from

http://www.kistlerrods.com/store/forum/why-do-some-people-break-more-rods/

Portarod History. (n.d.). Portarod History. Retrieved May 9, 2014, from

http://www.portarod.com/portARodStory.html

7

Conclusion:

In conclusion the product that was created is by far the best solution to this problem. It

solves several issues. An issue that is solved is the safety quality which most products

like this one did not solve. The second quality that the F.R.T has is efficiency, unlike

others this product does not use all the space that others do. In the future of the F.R.T

product it will have handles for easier lifting and placing. It will also be made of metal

instead of using wood to make these. Lastly, in the future thoughts of the product it will

have more weather resistance.

6

GANNT Chart:

Figure 1.2

Decision Matrices:

Figure 1.1

List of Figures and Tables:

Appendices: Decision Matrices- Figure 1.1

Appendices: GANNT Chart- Figure 1.2

Appendices: Material list and cost- Figure 1.3

Appendices: Pie chart- Figure 1.4

Appendices: Data- Figure 1.5

1

\

J ustification Chart and data:

Figure 1.4

Figure 1.5

Appendices:

8

You might also like

- Final ReportDocument5 pagesFinal Reportapi-289544082No ratings yet

- The Motorboat Book: Build & Launch 20 Jet Boats, Paddle-Wheelers, Electric Submarines & MoreFrom EverandThe Motorboat Book: Build & Launch 20 Jet Boats, Paddle-Wheelers, Electric Submarines & MoreRating: 1.5 out of 5 stars1.5/5 (2)

- P 639 PDFDocument23 pagesP 639 PDFMuhammad ibraheemNo ratings yet

- How to Build with Grid Beam: A Fast, Easy, and Affordable System for Constructing Almost AnythingFrom EverandHow to Build with Grid Beam: A Fast, Easy, and Affordable System for Constructing Almost AnythingRating: 4 out of 5 stars4/5 (2)

- ReverseengineeringDocument9 pagesReverseengineeringapi-282055042No ratings yet

- A Sluice Build PartIIIDocument84 pagesA Sluice Build PartIIIKristiana Anna100% (2)

- Advanced Building Envelope Components: Comparative ExperimentsFrom EverandAdvanced Building Envelope Components: Comparative ExperimentsNo ratings yet

- Design For Emerging Markets Final ReportDocument12 pagesDesign For Emerging Markets Final ReportDarren SlotnickNo ratings yet

- Innovative Building Materials Final Report PDFDocument38 pagesInnovative Building Materials Final Report PDFMark Anthony Liwag Nama100% (1)

- 2 2 1 A Productanalysis 2Document5 pages2 2 1 A Productanalysis 2api-308131962No ratings yet

- Sluice Build partIII 2 PDFDocument84 pagesSluice Build partIII 2 PDFjoseanselmoNo ratings yet

- Dilon Pavish Parasram - Cable Storage Made EasyDocument18 pagesDilon Pavish Parasram - Cable Storage Made Easyapi-370489125No ratings yet

- Inflatable Concrete Shelter Provides Quick Emergency HousingDocument5 pagesInflatable Concrete Shelter Provides Quick Emergency Housinghungndo100% (1)

- Let Me Tell You Something About Shipping Container HomesFrom EverandLet Me Tell You Something About Shipping Container HomesRating: 4 out of 5 stars4/5 (8)

- Inflatable Concrete Shelter Provides Quick Emergency HousingDocument4 pagesInflatable Concrete Shelter Provides Quick Emergency HousingNguyen Do Hung33% (3)

- Jackson Hersh Drake GarretDocument19 pagesJackson Hersh Drake Garretapi-614526867No ratings yet

- Report Rubber Band Car (Eng Design)Document6 pagesReport Rubber Band Car (Eng Design)Muhd AriffNo ratings yet

- ResultsDocument75 pagesResultsTATATAHERNo ratings yet

- Overland Vehicle Awning ProposalDocument3 pagesOverland Vehicle Awning Proposalapi-534922131No ratings yet

- Plastic Limit Analysis of Earthbag StructuresDocument50 pagesPlastic Limit Analysis of Earthbag StructuresMaggieNo ratings yet

- Brielle Lopresti - Science Fair Research Paper Rough DraftDocument5 pagesBrielle Lopresti - Science Fair Research Paper Rough Draftapi-535479847No ratings yet

- Engineering Design ReportDocument11 pagesEngineering Design ReportLaura GutierrezNo ratings yet

- Tender Submision ContractorDocument64 pagesTender Submision Contractorapi-353388154No ratings yet

- ProposalDocument11 pagesProposalapi-397091166No ratings yet

- Building A Wood Epoxy SharpieDocument12 pagesBuilding A Wood Epoxy SharpieAmy Rodriguez0% (2)

- Potfolio 1 1Document13 pagesPotfolio 1 1Racheal FNo ratings yet

- 1 9 A DesigninnovationDocument4 pages1 9 A Designinnovationapi-264767918No ratings yet

- Dams & Retaining Walls: ObjectivesDocument4 pagesDams & Retaining Walls: ObjectivesOsamaZaidNo ratings yet

- 002 Build A Better BumperDocument4 pages002 Build A Better BumperchangeflyNo ratings yet

- Homemade Hoverboard: Sti College Santa Rosa Complex, Balibago, Sta - Rosa, Laguna Physics 2Document4 pagesHomemade Hoverboard: Sti College Santa Rosa Complex, Balibago, Sta - Rosa, Laguna Physics 2marttramNo ratings yet

- Chapter IDocument15 pagesChapter IFernando LopezNo ratings yet

- A Comparative Study On Peel Adhesion Strength Between Duct Tape and Double-SidedDocument48 pagesA Comparative Study On Peel Adhesion Strength Between Duct Tape and Double-SidedAlan Je MusketerNo ratings yet

- Meraj XDocument184 pagesMeraj XMeraj aliNo ratings yet

- 3 3 1reportDocument12 pages3 3 1reportapi-302334715No ratings yet

- Project Icebreaker ProposalDocument10 pagesProject Icebreaker Proposalapi-375163452No ratings yet

- Stem TrebuchetDocument7 pagesStem Trebuchetapi-634196146No ratings yet

- C12 2.FAST2011.BagnellDocument6 pagesC12 2.FAST2011.BagnellPavel RemmyNo ratings yet

- Bridge ReportDocument53 pagesBridge ReportJean Kian86% (7)

- Stem 231 FinalpaperDocument10 pagesStem 231 Finalpaperapi-272481557No ratings yet

- Final PresentationDocument13 pagesFinal PresentationaustinodellNo ratings yet

- Geomembrane Research - PaperDocument18 pagesGeomembrane Research - PaperCaraUnggahNo ratings yet

- Capstone Project Final Design Report 2Document34 pagesCapstone Project Final Design Report 2api-386389836No ratings yet

- Mini-Project Final Technical Memo: Tiff Any Lontoc, Andrew PlaDocument16 pagesMini-Project Final Technical Memo: Tiff Any Lontoc, Andrew PlaAlyssaNo ratings yet

- Timber ManualDocument145 pagesTimber Manualspiderlance100% (1)

- Assignment 2 Skateboard Deck Design - Jared PrattDocument10 pagesAssignment 2 Skateboard Deck Design - Jared Prattapi-595082362No ratings yet

- A Review of Methods For The Manufacture of Residential Roofing MaterialsDocument28 pagesA Review of Methods For The Manufacture of Residential Roofing MaterialsAhmad YousefiNo ratings yet

- Proposal AntahsagiriDocument28 pagesProposal AntahsagiriVishal AgarwalNo ratings yet

- Project SummariesDocument13 pagesProject SummariesGriffin BeemillerNo ratings yet

- Boat Strength IBEXDocument46 pagesBoat Strength IBEXrakesh reghuNo ratings yet

- Final PresentationDocument9 pagesFinal PresentationaustinodellNo ratings yet

- Sel Case Study Mechanical CASCSMEN21Document21 pagesSel Case Study Mechanical CASCSMEN21BerkanErolNo ratings yet

- Exercises ProjectsWithCESEduPack MA UOC enDocument54 pagesExercises ProjectsWithCESEduPack MA UOC enLindi NewmanNo ratings yet

- Glass Bedding RiflesDocument34 pagesGlass Bedding RiflesclaidemoreNo ratings yet

- Similar SolutionsDocument1 pageSimilar Solutionsapi-247133505No ratings yet

- Decision Matrix 2Document1 pageDecision Matrix 2api-247133505No ratings yet

- Decision MatrixDocument1 pageDecision Matrixapi-247133505No ratings yet

- Gannt ChartDocument1 pageGannt Chartapi-247133505No ratings yet

- Justin Bromeling: Belton, SC 29627Document1 pageJustin Bromeling: Belton, SC 29627api-247133505No ratings yet

- Mini-Project PresentationDocument10 pagesMini-Project Presentationapi-247133505No ratings yet

- E1 2 Patent Searches - Activity TemplateDocument4 pagesE1 2 Patent Searches - Activity Templateapi-247133505No ratings yet

- IB Urban Environments Option G (Latest 2024)Document154 pagesIB Urban Environments Option G (Latest 2024)Pasta SempaNo ratings yet

- Design of Anchor Bolts Embedded in MasonryDocument6 pagesDesign of Anchor Bolts Embedded in MasonryAnonymous DJrec2No ratings yet

- Cem-FIL GRC Technical DataDocument91 pagesCem-FIL GRC Technical Datacbler100% (1)

- Template Research ProjectDocument13 pagesTemplate Research ProjectTuấn Anh Đoàn CôngNo ratings yet

- Event Management Study Material Free PDFDocument2 pagesEvent Management Study Material Free PDFKim0% (1)

- Unit 4:: Incident Commander and Command Staff FunctionsDocument16 pagesUnit 4:: Incident Commander and Command Staff FunctionsAntonio Intia IVNo ratings yet

- FR-F800 Instruction Manual PDFDocument614 pagesFR-F800 Instruction Manual PDFelivandrojuniorNo ratings yet

- CW3 - 4Document2 pagesCW3 - 4Rigel Zabate100% (1)

- Crestron Teams HardeningDocument20 pagesCrestron Teams HardeningmanishNo ratings yet

- C685C685M 14Document9 pagesC685C685M 14Alvin BaraNo ratings yet

- Triumph Spitfire MK4 - 1500Document108 pagesTriumph Spitfire MK4 - 1500Ricardo100% (1)

- NY Long Island Group - Jun 2008Document8 pagesNY Long Island Group - Jun 2008CAP History LibraryNo ratings yet

- Municipal Profile of Umingan, PangasinanDocument51 pagesMunicipal Profile of Umingan, PangasinanGina Lee Mingrajal Santos100% (1)

- Tata Consulting Engineers Design Guide For Auxiliary Steam HeaderDocument10 pagesTata Consulting Engineers Design Guide For Auxiliary Steam HeadervijayanmksNo ratings yet

- Vodacom Fibre - Application Form CPD - 23 August 2018Document8 pagesVodacom Fibre - Application Form CPD - 23 August 2018Mla Emmanuel ZondoNo ratings yet

- Port Er's Nat Iona L Dia Mon D Co Mpe Titiv Ea Dva Ntag Eof Natio NS'Document45 pagesPort Er's Nat Iona L Dia Mon D Co Mpe Titiv Ea Dva Ntag Eof Natio NS'Soha KhanNo ratings yet

- Blueprint of Banking SectorDocument33 pagesBlueprint of Banking SectormayankNo ratings yet

- MSCL PipeDocument9 pagesMSCL PipeAhmad Zakwan Asmad100% (1)

- Partial Full Volume of TankDocument8 pagesPartial Full Volume of TankBabita GuptaNo ratings yet

- PTL Ls Programme HandbookDocument34 pagesPTL Ls Programme Handbooksalak946290No ratings yet

- Newnew 151 ModelDocument1 pageNewnew 151 ModelCrestine Lily DongosaNo ratings yet

- Online Dating GuideDocument101 pagesOnline Dating Guidewoodyallen78No ratings yet

- Zodiac Working Boat MK6HDDocument4 pagesZodiac Working Boat MK6HDdan antonNo ratings yet

- Shrimp Aquaculture in Sarangani BayDocument5 pagesShrimp Aquaculture in Sarangani BayronanvillagonzaloNo ratings yet

- Tata Cellular V UOI: So Unreasonable That No Reasonable Person Acting Reasonably Could Have Made It)Document2 pagesTata Cellular V UOI: So Unreasonable That No Reasonable Person Acting Reasonably Could Have Made It)heretostudyNo ratings yet

- Consultants DirectoryDocument36 pagesConsultants DirectoryAnonymous yjLUF9gDTSNo ratings yet

- TABS 6SellSheetDocument4 pagesTABS 6SellSheetHernando MontenegroNo ratings yet

- London Borough Council Elections 2002Document257 pagesLondon Borough Council Elections 2002MisterMustardNo ratings yet

- DVD S2300Document106 pagesDVD S2300cristakeNo ratings yet

- Problem Solving 5Document4 pagesProblem Solving 5Raphael Pizarro ArceoNo ratings yet

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (10)

- House Rules: How to Decorate for Every Home, Style, and BudgetFrom EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Delicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreFrom EverandDelicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreRating: 4 out of 5 stars4/5 (11)

- Kawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreFrom EverandKawaii Crochet Garden: 40 super cute amigurumi patterns for plants and moreRating: 5 out of 5 stars5/5 (5)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- Big Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreFrom EverandBig Book of Pretty & Playful Appliqué: 150+ Designs, 4 Quilt Projects Cats & Dogs at Play, Gardens in Bloom, Feathered Friends & MoreRating: 4.5 out of 5 stars4.5/5 (3)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Edward's Menagerie: Dogs: 50 canine crochet patternsFrom EverandEdward's Menagerie: Dogs: 50 canine crochet patternsRating: 3 out of 5 stars3/5 (5)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesFrom EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesRating: 2 out of 5 stars2/5 (12)

- Siren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetFrom EverandSiren's Atlas US Terms Edition: An Ocean of Granny Squares to CrochetRating: 5 out of 5 stars5/5 (3)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- More than a Granny: 20 Versatile Crochet Square Patterns US VersionFrom EverandMore than a Granny: 20 Versatile Crochet Square Patterns US VersionRating: 1.5 out of 5 stars1.5/5 (2)

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

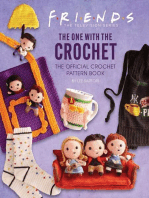

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesFrom EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNo ratings yet

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsFrom EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNo ratings yet

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)From EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)No ratings yet

- Design 555 Doilies Vintage Crochet Pattern eBookFrom EverandDesign 555 Doilies Vintage Crochet Pattern eBookRating: 2.5 out of 5 stars2.5/5 (2)

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetFrom EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetRating: 3.5 out of 5 stars3.5/5 (4)

- Two Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!From EverandTwo Simple Shapes = 26 Crocheted Cardigans, Tops & Sweaters: If you can crochet a square and rectangle, you can make these easy-to-wear designs!Rating: 3 out of 5 stars3/5 (2)