Professional Documents

Culture Documents

Steel-Concrete Composite Coupling Beams - Behavior and Design

Steel-Concrete Composite Coupling Beams - Behavior and Design

Uploaded by

Tuấn Anh PhạmOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel-Concrete Composite Coupling Beams - Behavior and Design

Steel-Concrete Composite Coupling Beams - Behavior and Design

Uploaded by

Tuấn Anh PhạmCopyright:

Available Formats

Engineering Structures 23 (2001) 14801490

www.elsevier.com/locate/engstruct

Steel-concrete composite coupling beams behavior and design

Binginan Gong

a

, Bahram M. Shahrooz

b,*

a

S&B Infrastructure, Ltd., 3535 Sage Road, Houston, TX 77056-7011, USA

b

University of Cincinnati, Department of Civil and Environmental Engineering, 741 Baldwin Hall, PO Box 210071, Cincinnati,

OH 45221-00171, USA

Received 12 September 2000; received in revised form 16 January 2001; accepted 10 April 2001

Abstract

Structural steel/composite beams provide a viable alternative for coupling individual reinforced concrete wall piers. Well-estab-

lished guidelines for shear links in eccentrically braced steel frames form the basis of current design guidelines. However, these

provisions ignore the effects of nominally reinforced concrete encasement which typically surrounds the coupling beam, and are

based on overly conservative assumed deformation demands. A coordinated analytical and experimental research program at the

University of Cincinnati has focused on cyclic response of steel/composite coupling beams, their connections to reinforced concrete

walls, and overall behavior of composite coupled wall systems. Using the results from this study, guidelines for proper design and

detailing of steel/composite coupling beams and beam-wall connections have been developed. This paper summarizes the research

program, and highlights the basic concepts, important ndings, and recommendations. 2001 Elsevier Science Ltd. All rights

reserved.

Keywords: Composite construction; Coupling beams; Coupled walls; Cyclic testing; Mixed construction; Seismic design

1. Introduction

An efcient structural system can be achieved if the

openings in structural walls are arranged in a regular

pattern. In this manner, a number of individual wall piers

can be coupled together to produce a system with large

lateral stiffness and strength. The structural performance

at or near ultimate state can also be optimized by proper

detailing of the coupling beams (i.e., the beams that con-

nect the individual walls). Coupling beams should be

proportioned to avoid over coupling (i.e., a system that

acts as a single pierced wall) and light coupling (i.e.,

a system that performs as a number of isolated walls).

Extensive past research [18] has led to well established

seismic resistant design guidelines for reinforced con-

crete coupling beams. Current design provisions [9] typi-

cally result into diagonally reinforced deep beams in

order to satisfy the stiffness, strength, and energy dissi-

pation demands. The diagonal reinforcement consists of

* Corresponding author. Tel.: +1-513-556-3677; fax: +1-513-556-

2599.

E-mail address: bahram.shahrooz@uc.edu (B.M. Shahrooz).

0141-0296/01/$ - see front matter 2001 Elsevier Science Ltd. All rights reserved.

PII: S0141- 0296( 01) 00042- 6

relatively large diameter bars which have to be

adequately conned to avoid buckling at advanced limit

states. Anchorage of the reinforcing bars in wall piers

can pose difculties.

Structural steel or steelconcrete composite beams

provide a viable alternative, particularly for cases with

oor height restrictions. In contrast to conventionally

reinforced concrete members, steel/composite coupling

beams can be designed as a exural-yielding or shear-

yielding member. Therefore, a desirable mode of energy

dissipation is achieved depending on the particular case.

The main design issues are (a) proportioning and

detailing of steel/composite coupling beams, and (b)

beamwall connections. Depending on whether the wall

boundary element consists of structural steel columns or

reinforced concrete elements, the coupling beamwall

connection is different. In the former case, the connec-

tion is similar to steel beamcolumn connections. The

connection in the latter case, which is the focus of this

paper, is achieved by embedding the coupling beam

inside the wall piers and interfacing it with the wall

boundary element. The embedment length will clearly

have a major inuence on the performance of

steel/composite coupling beams.

1481 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

A number of recent studies at the University of Cin-

cinnati have been focused on examining seismic

response of such composite systems. An overview of the

research program is provided herein. Current design

guidelines [10] are evaluated, and a number of changes

are recommended.

2. Summary of current design guidelines

Steel coupling beams are designed according to the

provisions outlined in the 1997 NEHRP Recommended

Provisions for the Development of Seismic Regulations

for New Buildings [10]. These provisions are based on

seismic detailing of steel links in eccentrically braced

frames. The coupling beam rotation angle is arbitrarily

set equal to 0.09 rad. Note that for link beams this angle

is computed. The assumed coupling beam rotation is

rather conservative. For example, if the beam length is

less than 1.6 M

p

/V

p

(M

p

=plastic moment capacity;

V

p

=plastic shear capacity, i.e., 0.6 F

y

(d2t

f

)t

w

in which

F

y

=yield strength, d=beam depth, t

f

=ange thickness,

t

w

=web thickness), web stiffeners at (30 t

w

d/5) will

have to be provided. Considering that most coupling

beams are typically short, current design leads to closely

spaced web stiffeners. Steel coupling beams are often

encased inside nominally reinforced concrete elements,

e.g., in door lintels. However, due to lack of information

about the effects of concrete encasement, current design

guidelines are tacit about cases in which the coupling

beam is encased. Accordingly, most engineers ignore the

inuence of encasement apparently on the basis that (a)

the encasement is nominally reinforced and hence not

expected to signicantly contribute towards strength and

stiffness, and (b) the design will be more conservative

by not including the contribution of the encasing element

around the steel coupling beam. As a result, details for

preventing ange and web buckling are identical to those

used for unencased coupling beams, and the embedment

length is calculated to develop the design capacity of the

steel beam only.

No specic guidelines are provided for computing the

required embedment length, but references are made to

previous studies [1114] for further information. These

studies examined the applicability of two models pro-

posed by Marcakis and Mitchell [15] and Mattock and

Gaafar [16]. In Fig. 1, Mattock and Gaafars model is

illustrated. The applied shear (V

u

) is resisted by mobiliz-

ing an internal moment arm between bearing forces C

f

and C

b

. A parabolic distribution of bearing stresses is

assumed for C

b

, and C

f

is computed by using a uniform

stress equal to 0.85 f

c

where f

c

=concrete compressive

strength in MPa. The bearing stresses are assumed to be

distributed uniformly over the beam ange width. Fol-

lowing these assumptions and calibration against experi-

mental data for steel corbels subjected to monotonic

Fig. 1. Mattock and Gaafars model for computing embedment

length.

loading, this model calculates the required embedment

length (L

e

) according to Eq. (1) in which t

wall

=thickness

of wall pier, b

f

=beam ange width, and b

1

=ratio of the

average concrete compressive strength to the

maximum stress.

V

u

4.05f

c

t

wall

b

f

0.66

b

1

b

f

L

e

0.580.22b

1

0.88+

a

L

e

(1)

In this equation, the inection point is assumed to be

at the midspan; hence, the value of a is taken as one

half of the coupling beam span. The model proposed by

Marcakis and Mitchel generally results in a slightly

longer embedment length; however, the difference

between the two models is negligible [13,14]. Although

Marcakis and Mitchell [15] and Mattock and Gaafar [16]

originally developed their respective equations for

design of steel brackets attached to reinforced concrete

columns, previous studies at the University of Cincinnati

and elsewhere [1114] have shown that these models

result in acceptable performance for steel coupling

beams which are subjected to cyclic shear. Moreover,

the calculated embedment length from either model is

adequate to ensure a desirable mode of energy dissi-

pation for steel, unencased coupling beams by forming

the plastic hinges in the beam rather in the connection

region. Note that the value of V

u

in Eq. (1) should be

taken as the plastic shear capacity of the steel beam (i.e.,

V

p

=0.6 F

y

(d2t

f

)t

w

) to ensure adequate performance.

1482 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

Fig. 2. Plan view of selected prototype structure.

3. Response of steelconcrete composite coupling

beams

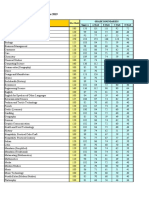

A recent study [17,18] has examined the effects of

concrete encasement. The test specimens were extracted

from a 20-story prototype building shown in Fig. 2. For

the chosen span length of the steel/composite coupling

beams, current design guidelines [10] require stiffener

plates to be placed at (30t

w

d/5) on one side of the web.

As part of the experimental phase of this study, which

was conducted in two phases, seven specimens were

tested. The main test variables, summarized in Table 1,

were (a) presence or lack of encasement, (b) the amount

of web stiffener in the steel beam, (c) presence or lack

of face bearing plates at the wallbeam interface, (d) the

level of shear force for which the beamwall connection

is designed, and (e) oor slab around the coupling beam.

The encasement was nominally reinforced with four 4.9

mm longitudinal bars and 4.9 mm transverse reinforce-

ment placed at one-half depth of the encasing element,

Table 1

Test specimens and test variables

Specimen I.D. Encasement Spacing of web stiffeners Force for connection design Face bearing plate Floor slab

Phase I

1 No L V

steel section

No No

2 Yes L V

steel section

No No

3 Yes 2L V

steel section

No No

4 Yes N/A

a

V

steel section

No No

Phase II

5 Yes N/A

a

V

composite section

No No

6 Yes N/A

a

V

composite section

Yes No

7 Yes N/A

a

V

composite section

Yes Yes

a

No web stiffeners were provided.

see Fig. 3. A low-strength concrete (f

c

=12 MPa) was

used for the encasement in order to accentuate nominal

connement around the steel coupling beam. In all the

specimens, auxiliary transfer bars had been attached

(through the use of mechanical half couplers) to the top

and bottom anges at two locations (Fig. 3) in an effort

to aid in the transfer of bearing forces to the surrounding

concrete [13,14]. Face bearing plates in specimens 6 and

7 consisted of a pair of 4.75 mm thick stiffeners welded

on both sides of the web. The face bearing plates were

located inside the wall boundary element transverse

reinforcement. Another pair of stiffeners were also added

at 125 mm from the face bearing plates under the auxili-

ary bars. The resulting concrete struts between these

plates (shown schematically in Fig. 3) are expected to

enhance the performance by reducing the contribution

of bearing stresses against the top and bottom anges.

The benets of face bearing plates have been demon-

strated in past studies on steel beam-reinforced concrete

column connections [19], and as part of testing of speci-

men No. 6. Additional details regarding the test speci-

mens and other aspects of the experimental program are

provided elsewhere [18]. The focus of this paper is on

specimens No. 1, 4, 5, and 7.

3.1. (a) Strength characteristics

The load-deection responses of the unencased speci-

men No. 1 and encased specimen No. 4 are plotted in

Fig. 4. The hysteresis loops are stable, and exhibit a sig-

nicant level of energy dissipation. Sudden drops during

the last cycles are primarily due to fracture of wall trans-

verse reinforcement passing through the steel beam web,

and fracture of the weld around the mechanical half

couplers which were used to attach the auxiliary bars to

the beam anges [18]. Both specimens could develop

and exceed the capacity computed based on the meas-

ured material properties [18]. For specimen No. 1, the

capacity is equal to the plastic shear capacity, i.e., 0.6

F

y

(d2t

f

)t

w

. The shear capacity of specimen No. 4 was

1483 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

Fig. 3. Specimen details.

computed by (a) superposition of the shear capacities of

the steel section and concrete beam, or (b) a ber cross

section analysis incorporating exure as well as shear.

The average value from these two analyses is plotted in

Fig. 4.

The nominally reinforced encasement around the steel

coupling beam is apparently adequate to prevent web

and ange buckling at advanced yielding. Note that

specimen No. 4 could develop 107 kN at a shear angle

of 0.057 rad. At this shear deformation, current NEHRP

provisions [10] require web stiffener plates at 1.5 times

the spacing used for specimen No. 2. Despite having no

stiffeners, specimen No. 4 could develop shears corre-

sponding to 1.10 V

p

. Hence, nominally reinforced

encasement around steel coupling beams is sufcient to

prevent web and ange buckling; and web stiffeners are

not needed.

3.2. (b) Energy dissipation characteristics

The dissipated energies are compared in Fig. 5. In an

effort to examine the performance of the specimens, the

dissipated energy was separated into two parts: (a) the

energy dissipated by plastic hinges in the beam

(Beam), and (b) the energy dissipated by inelastic

deformations in the connection region (Connection)

[18]. For specimen No. 1, the participation of beam

towards energy dissipation was more signicant than

that for specimen No. 4. Although the beam capacities

could be developed, the performance of the encased

specimen was not as desirable because inelastic action in

the connection region contributed more than the plastic

hinges in the beam. This behavior is attributed to the

provided embedment length.

3.3. (c) Revised embedment length

As indicated in Table 1, the required embedment

length for specimen No. 1 and No. 4 was, according

to current design guidelines and practice, computed to

develop the shear capacity of the steel coupling beam

only, i.e., 0.6 F

y

(d2t

f

)t

w

. The experimental data shown

in Fig. 4 suggest that nominally reinforced encasement

can increase the capacity by as much as 23%. Clearly,

if the provided embedment length is calculated to

develop a smaller shear, plastic hinges form in the con-

nection region before fully mobilizing the full capacity

of the composite beam. This performance is not desir-

able. A capacity design methodology, in which the

embedment length is computed to develop the capacity

of the composite beam and not the steel beam alone, is

proposed. This method requires that the contribution of

concrete encasement towards shear capacity is taken

into account.

In lieu of detailed techniques such as ber based mod-

els [18], a simple method based on combining the shear

capacity of the steel beam (V

steel

) and encasement (V

RC

)

appears to be a reasonable alternative, i.e., V

n

=V

steel

+V

RC

in which V

steel

=0.6 F

y

(d2t

f

)t

w

and V

RC

is computed

based on standard methods for reinforced concrete mem-

bers (e.g., [20:31899]), i.e., V

RC

=0.166f

c

bd+

A

v

f

y

d

s

where b=width of the encasement, d=effective depth of

the encasement, A

v

=total area of transverse reinforce-

1484 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

Fig. 4. Hysteresis responses of encased and unencased coupling

beams.

ment, and s=spacing of the transverse steel. In this sim-

plied approach, the constitutive models for concrete

and steel are idealized, and factors such as strain harden-

ing of the longitudinal and transverse steel are ignored;

the shear capacity of the reinforced concrete encasement

is based on the ACI method in which the concrete contri-

butions towards shear capacity from aggregate interlock,

dowel action of the longitudinal bars, and the uncracked

concrete are lumped together [21]; and the contribution

of the concrete beyond cracking is not included [22].

Therefore, this simple model needs to be calibrated so

that the computed capacity would be comparable to that

obtained from a more detailed analysis such as ber

modeling. A correction factor was determined by com-

paring the capacity computed from detailed ber section

analysis based on the modied compression eld theory

[22] and the capacity from the superposition method, i.e.,

V

n

=V

steel

+V

RC

. The parametric study included 24 cases

in which the concrete compressive and the steel yield

Fig. 5. Distribution of dissipated energy.

as well as the ultimate strength, dimensions of the steel

sections, and the overall encasement dimensions were

changed systematically. The ratio between the two com-

puted capacities ranges between 1.31 to 1.85 with an

average of 1.61 and a standard deviation of 0.075 [18].

Within the limitations of this parametric study, a cor-

rection factor of 1.6 is recommended and hence the

shear capacity of composite coupling beams is taken as

V

n

=1.6 (V

steel

+V

RC

). Additional studies covering a wider

range of parameters is necessary to further rene the rec-

ommended correction factor.

3.4. (d) Evaluation of revised embedment length

In an effort to evaluate the performance of coupling

beams for which the embedment length is calculated

based on the proposed capacity design method, strength

1485 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

and energy dissipation characteristics of specimens No.

4 and 5 are compared. Specimen No. 5 was generally

similar to those tested in the rst phase, except for a

longer embedment length that the revised procedure

would require, and the testing method which included

wall overturning moment in contrast to the rst four

specimens for which the wall overturning was not simu-

lated.

Normalized load-shear angle envelope curves of

specimens No. 4 and 5 are compared in Fig. 6. The verti-

cal axis is normalized with respect to the shear at the

onset of web yielding (V

y

). Shear angle at this stage (g

y

),

was used to normalize the measured shear angles. Prior

to yielding, the two specimens exhibit almost identical

load-deformation relationships. The response of speci-

men No. 5 shows a remarkable improvement in terms

of achieving higher ductilities and reduced strength

deterioration beyond the maximum load. For example,

at shear angle of 0.0885 radians, the load had dropped

only to 96% of the peak value. Specimen No. 5 also

developed a larger capacity in the positive direction

when the wall overturning moment produced compress-

ive stresses around the connection. Under negative bend-

ing, the two specimens developed rather similar loads,

although specimen No. 5 reached a slightly lower load

than specimen No. 4. This difference is attributed to the

presence or lack of wall overturning moment. The wall

overturning moment in specimen No. 5 resulted in ten-

sile stresses that reduced the level of bearing stress trans-

fer between the beam anges and the surrounding con-

crete in the connection region. Despite these stresses, the

load carrying capacity did not drop signicantly below

that for specimen No. 4 in which the connection region

was kept under a constant gravity compressive stress.

The longer embedment length in specimen No. 5, which

is the result of using the revised design methodology,

Fig. 6. Normalized load-deection curves.

Fig. 7. Distribution of dissipated energy for specimen No. 5.

delayed the connection failure until a higher capacity

could be developed, and hence the enhanced behavior.

A similar observation is made by evaluating the

energy dissipation characteristics of specimen No. 5

shown in Fig. 7 in which the total dissipated energy

(Total) is divided as discussed previously. The input

energy was predominately dissipated by inelastic defor-

mations in the coupling beam. Beyond shear angle of

0.05 rad., the participation of the connection was gradu-

ally increased although the plastic hinges in the beam

outside the connection continued to dissipate a reason-

able portion of the total energy. This trend is different

from that observed for specimen No. 4 (see Fig. 5). The

longer embedment length in specimen No. 5 evidently

enhanced the energy dissipation characteristics by reduc-

ing the contribution of the connection region.

Note that the contribution of oor slab is not included

in the proposed design method because (a) as seen in

Fig. 8 the contribution of slab is relatively negligible

because the additional tensile forces from the slab bars

Fig. 8. Moment-curvature response of composite coupling beam in

prototype structure.

1486 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

Fig. 9. Distribution of dissipated energy for specimen No. 7.

are relatively small in comparison to the tensile force in

the anges of a typical steel beam, and (b) the oor slab

wraps the connection region and reduces its participation

as illustrated in Fig. 9 [18]. The distribution of dissipated

energy clearly indicates that the slab and beam dissipated

the majority of the input energy, and the connection

essentially did not participate. Therefore, the contri-

bution of oor slab is neglected, and the embedment

length needs to be calculated to develop only 1.6

(V

steel

+V

RC

).

3.5. (e) Stiffness of composite coupling beams

The variation of peak-to-peak stiffness against shear

angle is plotted in Fig. 10. The initial stiffness of speci-

men No. 4 is 25% larger than that for specimen No. 1.

The initial stiffness for specimen No. 5 is less than the

stiffness of specimen No. 4 because this specimen was

accidentally loaded due to difculties in the computer-

based control of one of the actuators used for loading.

Specimen No. 5 had apparently experienced some minor

cracks before the testing program was started.

Fig. 10. Stiffness degradation of various composite coupling beam

specimens.

The oor slab clearly increases the initial stiffness of

specimen No. 7. However, at shear angle of about 0.005

rad., the signicance of slab is effectively lost. Beyond

this small level of deformation the stiffness of specimen

No. 7 drops to a level comparable to the initial stiffness

of the specimens without slab. When specimens were

loaded up to a shear angle of about 0.06 rad., all the

three specimens had reached about the same stiffness.

Therefore, although oor slabs increase the initial stiff-

ness of coupling beams, the contribution of the slab

deteriorates under small deformations and may be

ignored in seismic design and analysis.

4. Evaluation of impact of encasement on overall

structural response

The effects of the additional stiffness due to nominally

reinforced encasement around steel coupling beams,

which is ignored in current design guidelines, were

evaluated analytically by examining the overall response

of the prototype structure (Fig. 2). The larger stiffness

obviously results in smaller vibration periods. Such a

shift could inuence the dynamic behavior if the fre-

quencies coincide with the frequency band of the design

ground motion with high input energy content.

The demands in the walls and coupling beams are

affected by the changes in the coupling beam stiffness.

The concrete encasement increases the coupling beam

stiffness which in turn increases the level of coupling

action between the individual wall piers. For instance,

the wall axial load in the rst oor of the prototype struc-

ture increases by 40% when the inuence of encasement

is taken into account [17]. Such a large increase could

pose stability problems if the wall boundary elements

are designed for forces calculated based on ignoring the

encasement. In addition, the foundation system needs to

be designed for the increased demands in the walls. The

increase in wall shear force, which is about 10%, is not

perhaps as critical. The increases in beam design forces

are offset by the corresponding additional capacity due

to encasement. Therefore, design of walls and foun-

dation systems needs to incorporate the effects of

encasement around steel coupling beams. The numerical

values stated above are particular to the prototype struc-

ture, and are based on elastic analysis. For other struc-

tures with different geometries and stiffness character-

istics, the increase in the stiffness and hence the changes

in the design forces may be more or less. Moreover,

cracking of the encasement around the steel coupling

beam will reduce the stiffness of the composite coupling

beam, and hence the increased coupling action will be

less than that predicted from a simple elastic analysis.

Nevertheless, in view of the potential higher design

forces, the engineer should consider the increased stiff-

ness of composite coupling beams as one of the variables

in the design model.

1487 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

5. Evaluation of shear angle

Well established guidelines for shear links in eccentri-

cally-braced frames [23] form the basis of current guide-

lines [10] for design and detailing of steel/composite

coupling beams. The expected coupling beam rotation

angle plays an important role in the required beam

details such as the provision of stiffeners. Current design

guidelines [10] arbitrarily set the coupling beam shear

angle equal to 0.09 rad., and the beam is detailed accord-

ingly. Such a large angle results in closely spaced web

stiffeners. Note that the shear angle is computed for steel

link beams in eccentrically braced frames.

In order to examine whether this level of shear angle

(0.09 rad.) is reasonable and to understand the maximum

expected range of shear angle, the response of the proto-

type structure was evaluated. A pseudo three-dimen-

sional model of the prototype structure was constructed

(Fig. 11(a)). The torsional and vertical springs used in

the model are intended to simulate the outrigger action

of the transverse members. The walls were modeled by

an element (Fig. 11(b)) that incorporates axial, exural,

and shear deformations in the elastic and inelastic range

[24]. Both dynamic and static push-over analyses were

conduced [18]. For static analyses, the lateral loads were

Fig. 11. Analytical modeling of prototype structure.

assumed to be distributed uniformly or triangularly, and

three ground motion records (1940 El Centro NS, 1989

Loma Preita, and 1994 Northridge N60E) were used for

the dynamic analyses. Three different analyses were

conduced in which (a) the coupling beams were unen-

cased steel members, (b) the inuence of encasement

around the steel coupling beams was taken into account,

and (c) exibility at the foundation level was approxi-

mately taken into account by placing vertical and

rotational elastic springs under the column and wall

elements as shown in Fig. 11(c). The spring coefcients

were computed based on basic principles by assuming a

modulus of sub-grade of 54,260 kN/m

3

.

The maximum computed coupling beam shear angles

for various analyses are summarized in Table 2. The

level of shear angle for encased and unencased coupling

beams is considerably less than 0.09 rad. Only when the

foundation exibility was taken into account and lateral

loads were assumed to be distributed triangularly did the

coupling beam shear angle approach the value of 0.09

rad. stipulated in NHERP provisions [10]. However, at

this shear angle the roof lateral drift exceeds 10% of the

building height, which is well above acceptable levels,

and the base shear approaches 40% of the building

weight. For other cases with reasonable drifts, the com-

1488 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

Table 2

Maximum coupling beam shear angle (rad.)

a

Analysis Unencased xed base Encased xed base Encased exible base

Static push over: Rectangular lateral loads 0.0177 0.0198 0.0269

(1.2%) (1.3%) (2.0%)

Static push over: Triangular lateral loads 0.0328 0.0378 0.0884

(2.7%) (3.2%) (10.2%)

Dynamic:1940 El Centro NS 0.00391 0.00355 0.00388

Dynamic:1989 Loma Prieta 0.00709 0.0075 0.00673

Dynamic:1994 Northridge N60E 0.00208 0.0188 0.00209

a

The values in the parentheses are calculated roof drifts at maximum reported shear angle.

puted shear angles are signicantly less than 0.09 rad.

It is deemed that similar observations are made for other

well-proportioned buildings employing coupled walls.

Despite an effort to perform a reasonably complete

analysis of the prototype structure, major simplications

had to be made, e.g., (a) the three-dimensional behavior

of the structure is modeled rather crudely, (b) simulation

of the soil-structure action is very approximate, and (c)

the parameters in the wall and beam hysteretic models

were established based on subassembly tests with bound-

ary conditions different from those in an actual building.

The main reason behind the reported analytical study

was to explore the rationality of the assumed coupling

beam shear angle of 0.09 rad., in current design codes.

Additional detailed studies that overcome the stated limi-

tations of the current study are necessary.

Despite the simplicity of the analytical studies used

here, the current assumed shear angle of 0.09 rad.,

appears to be questionable and can lead to unnecessary

conservative detailing of steel coupling beams. Note that

the reported test results (Fig. 4) show that stiffeners can

be eliminated for steelconcrete composite coupling

beams; therefore, the focus of this discussion is on steel

coupling beams. More rational techniques for computing

the value of shear angle are needed.

The coupling beam shear angle is computed with ref-

erence to the collapse mechanism shown in Fig. 12

which corresponds to the expected behavior of coupled

wall systems, i.e., plastic hinges at the base of walls and

at the ends of coupling beams. The value of plastic

interstory drift angle (q

p

) is taken as C

d

q

e

(C

d

=deection

amplication factor dened by NEHRP [10]), where the

elastic interstory drift angle, q

e

, is computed under code

level lateral loads (e.g., [9,10]). Knowing the value of

q

p

, shear angle, g

p

, is calculated as g

P

=q

P

L

wall

L

in which

L

wall

is the distance between center lines of the wall piers

and L is the clear span of the coupling beam. Previous

experimental data suggest that the effective xed point

of steel or steelconcrete composite coupling beams is

about 1/3 of the embedment length from the face of the

wall [13,14,18]. Therefore, for consistency with experi-

mental observations it is recommended to take L

wall

as

Fig. 12. Analytical model for computing shear angle of coupling

beams.

L+0.6 L

e

in which L

e

is the embedment length of the

coupling beam inside each wall pier. Note that with the

exception of the assumed collapse mechanism and the

relationship between the shear angle and drift angle, the

proposed method is similar to that used for steel shear

links in eccentrically braced frames.

6. Summary and conclusions

Seismic behavior of steel and steelconcrete com-

posite coupling beams was evaluated through a coordi-

nated experimental and analytical research study. One of

the main objectives of the reported study was to scrutin-

ize current design guidelines, and to recommend modi-

cations if necessary. Based on the reported study, the

following conclusions are drawn. These conclusions are

clearly based on a relatively limited number of tests and

analytical studies. Additional test data from more com-

plete subassemblies and more detailed analytical studies

are recommended to supplement the results reported her-

ein.

1489 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

1. Nominal encasement around steel coupling beams

provides an effective means for preventing web buck-

ling. Hence, web stiffeners can be eliminated. Current

design codes need to be re-evaluated and relaxed for

the cases where the steel coupling beam is encased.

Available provisions appear to be overly conserva-

tive.

2. Although current design procedures result in a con-

servative design and detailing of encased steel coup-

ling beams, the increased strength and stiffness due

to the surrounding concrete encasement could have

detrimental effects on the overall performance if they

are not taken into account as part of the design.

3. Nominally reinforced encasement around steel coup-

ling beams is expected to increase the stiffness. The

additional stiffness increases the level of coupling

between walls, which in turn affects the distribution

of design forces. Most importantly, the wall axial load

at the base could substantially increase. The increased

stiffness of encased coupling beams has to be incor-

porated in design of coupled walls as well as foun-

dation systems.

4. Unless design calculations consider the contribution

of encasement towards shear capacity of composite

coupling beams, a signicant portion of the input

energy will be dissipated by inelastic deformations in

the connection region, which is not desirable. There-

fore, the embedment length has to be computed to

develop the expected shear capacity of the composite

section. In lieu of rened ber analyses, the shear

capacity may be taken as 1.6 times the sum of the

shear capacity of the steel beam and encasement. The

energy dissipation characteristics, ductility, and load-

carrying capacity of composite coupling beams are

substantially improved by using the proposed meth-

odology which leads into a longer embedment length.

5. The contribution of oor slab towards stiffness and

strength of composite coupling beams may be

ignored. The additional stiffness due to oor slab is

lost after rather small deformations. Contribution of

oor slab is less than that expected for reinforced con-

crete beams because the area of slab reinforcing bars

within the effective slab width is small in comparison

to the ange area of the coupling beam. The

additional strength may be ignored when the

embedment length is computed as the slab prevents

the formation of plastic hinges in the connection

region.

6. Relatively detailed inelastic static and dynamic analy-

ses suggest that the maximum expected coupling

beam shear angle in reasonably proportioned coupled

walls is probably less than the value assumed by cur-

rent design provisions. Until the availability of further

data, a simple procedure, similar to a well established

method for link beams in eccentrically braced frames,

is proposed to compute a more reliable estimate of

the expected coupling beam shear angle demands, and

hence the amount of stiffeners, if necessary, can be

established more rationally.

Acknowledgements

The research presented herein is based on an investi-

gation sponsored by the National Science Foundation

under grant no. BCS-9319838, with Dr. Shih Chi Liu as

the program director. Any opinions, ndings, and con-

clusions or recommendations expressed in this paper are

of those of the writers and do not necessarily reect the

views of the sponsors.

References

[1] Aktan AE, Bertero VV. The seismic resistant design of R/C

coupled structural walls. Report No. UCB/EERC-81/07, Univer-

sity of California, Berkeley: Earthquake Engineering Research

Center, 1981.

[2] Aristizabal-Ochoa JD. Dynamic response of coupled wall sys-

tems. ASCE J Struct Div 1982;108(8):184657.

[3] Aristizabal-Ochoa JD. Seismic behavior of slender coupled wall

systems. ASCE J Struct Div 1987;113(10):222134.

[4] Paulay T. The design of ductile reinforced concrete structural

walls for earthquake resistance. Earthquake Spectra

1986;2(4):783823.

[5] Paulay T. Coupling beams of reinforced concrete shear walls.

ASCE J Struct Div 1971;97(3):84362.

[6] Paulay T, Santhakumar AR. Ductile behavior of coupled shear

walls. ASCE J Struct Div 1976;102(1):93108.

[7] Shiu NK, Takayangi T, Corley WG. Seismic behavior of coupled

wall systems. ASCE J Struct Div 1984;110(5):105166.

[8] Shiu NK, Barney GB, Fiorato AE, Corley WG. Earthquake resist-

ant walls coupled wall test. Report to NSF submitted by Portland

Cement Association, Research and Development, Skokie, Illi-

nois, 1981.

[9] International Council of Building Ofcials (ICBO). Uniform

building code, vol. 2. Whitier, CA: Structural Engineering Design

Provisions, 1994.

[10] Building Seismic Safety Council (BSSC). NEHRP Rec-

ommended provisions for seismic regulations for new buildings

and other structures (FEMA 302) and Commentary (FEMA 303),

1997 edition. Washington, DC, 1998.

[11] Harries KA. Ductility and deformability of coupling beams in

reinforced concrete coupled walls. Proceedings of the Eighth

Canadian Conference on Earthquake Engineering, Vancouver,

June 1999, 1998:475481.

[12] Harries KA. Seismic design and retrot of coupled walls using

structural steel. PhD thesis, McGill University, 1995.

[13] Shahrooz BM, Remmetter MA, Qin F. Seismic response of com-

posite coupled walls. Composite Construction in Steel and Con-

crete II, ASCE, 1992:429441.

[14] Shahrooz BM, Remmetter MA, Qin F. Seismic design and per-

formance of composite coupled walls. ASCE J Struct Div

1993;119(11):3291309.

[15] Marcakis K, Mitchell D. Precast concrete connections with

embedded steel members. Prestressed Concrete Inst J

1980;25(4):88116.

1490 B. Gong, B.M. Shahrooz / Engineering Structures 23 (2001) 14801490

[16] Mattock AH, Gaafar GH. Strength of embedded steel sections as

brackets. ACI J 1982;79(2):8393.

[17] Gong B, Shahrooz BM, Gillum AJ. Cyclic response of composite

coupling beams. ACI Special Publication 174 Hybrid and

Composite Structures, Farmington Hills, MI, 1998:89112.

[18] Gong B, Shahrooz BM. Seismic behavior and design of com-

posite coupled wall systems. Report No. UC-CII 98/01, Cincin-

nati Infrastructure Institute, Cincinnati, OH, 1998.

[19] ASCE Task Committee on Design Criteria for Composite Struc-

tures in Steel and Concrete. Guidelines for design of joints

between steel beams and reinforced concrete columns. J Struct

Div, ASCE 1994;120(8):233057.

[20] American Concrete Institute (ACI) Committee 318. Building

code requirements for reinforced concrete and commentary (ACI

318-99/ACI 318R-99), Farmington Hills, MI, 1999.

[21] MacGregor JG. Reinforced concrete mechanics and design.

Englewood, NJ: Prentice Hall, 1992.

[22] Collins MP, Mitchell D. Prestressed concrete structures. Engle-

wood, NJ: Prentice Hall, 1991.

[23] American Institute of Steel Construction (AISC). Seismic pro-

visions for structural steel buildings, Chicago, IL, 1997.

[24] Kunnath SK, Reinhorn AM. IDARC-2D Version 3.1: Inelastic

damage analysis of reinforced concrete building structures. State

University of New York at Buffalo, 1994.

You might also like

- 2018 Sei Advocating For Performance Based Design ReportDocument20 pages2018 Sei Advocating For Performance Based Design ReportPraveen GavadNo ratings yet

- Industrial Training Report (Construction Sector)Document26 pagesIndustrial Training Report (Construction Sector)Hasan HM73% (22)

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 22Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 22Anonymous 0x2pwMCWgjNo ratings yet

- CRSI-PILECAP (Full Version)Document228 pagesCRSI-PILECAP (Full Version)xhq08No ratings yet

- High Strength Columns and Normal Strength Slabs (The Concrete Society UK)Document1 pageHigh Strength Columns and Normal Strength Slabs (The Concrete Society UK)thowchinNo ratings yet

- Design Example For Beams With Web OpeningsDocument9 pagesDesign Example For Beams With Web OpeningsMason Hahn100% (1)

- Post Tension Ing DesignDocument59 pagesPost Tension Ing DesignFrank StephensNo ratings yet

- Plastic Hinge Length of Reinforced Concrete ColumnsDocument11 pagesPlastic Hinge Length of Reinforced Concrete ColumnsSiavash BayeganNo ratings yet

- Watertight Roof Slabs Guidelines & General PrinciplesDocument29 pagesWatertight Roof Slabs Guidelines & General PrinciplesGoanengineerNo ratings yet

- ACI Strut and Tie Model Examples 1 PDFDocument64 pagesACI Strut and Tie Model Examples 1 PDFtagore 87No ratings yet

- Seismic Resistance of Type 2 Exterior Beam-ColumnDocument10 pagesSeismic Resistance of Type 2 Exterior Beam-ColumnMarimuthu Kaliyamoorthy100% (1)

- Software Engineering Text Book PDFDocument139 pagesSoftware Engineering Text Book PDFKotesh Dharavath100% (1)

- Tall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966From EverandTall Buildings: The Proceedings of a Symposium on Tall Buildings with Particular Reference to Shear Wall Structures, Held in the Department of Civil Engineering, University of Southampton, April 1966A. CoullRating: 5 out of 5 stars5/5 (1)

- Airey Taylor Consulting PT DesignDocument11 pagesAirey Taylor Consulting PT DesignLau Kim HwaNo ratings yet

- Concrete Columns PDFDocument9 pagesConcrete Columns PDFAnne Karollynne CastroNo ratings yet

- Tubular Structures PDFDocument101 pagesTubular Structures PDFAlex100% (1)

- Proposals For New One-Way Shear Equations For The 318 Building CodeDocument4 pagesProposals For New One-Way Shear Equations For The 318 Building CodepicottNo ratings yet

- Khaung - 2005 - Effects of Beam Bar Anchorage On Beam-Column Joint BehaviourDocument10 pagesKhaung - 2005 - Effects of Beam Bar Anchorage On Beam-Column Joint BehaviourMarimuthu KaliyamoorthyNo ratings yet

- An Improved Design Approach For Mat Foundation With Variable Thickness PDFDocument261 pagesAn Improved Design Approach For Mat Foundation With Variable Thickness PDFdxzaberNo ratings yet

- Seismic Design of Reinforced Concrete and Masonry BuildingDocument181 pagesSeismic Design of Reinforced Concrete and Masonry Buildingbladeyus1No ratings yet

- Guidelines For External Prestressing As Strengthening Technique For Concrete Structures PDFDocument10 pagesGuidelines For External Prestressing As Strengthening Technique For Concrete Structures PDFBobby ArlanNo ratings yet

- CCAAT55 Guide To Tilt-Up Design and ConstructionDocument54 pagesCCAAT55 Guide To Tilt-Up Design and ConstructionJose Jacobo Alvarez Saint-Hilaire100% (1)

- Basic ConceptsDocument22 pagesBasic ConceptsTan Yi LiangNo ratings yet

- Presentacion Star Seismic 2016Document68 pagesPresentacion Star Seismic 2016Rodrigo SilvaNo ratings yet

- Retrofitting of Reinforced Concrete Column by Steel JacketingDocument5 pagesRetrofitting of Reinforced Concrete Column by Steel JacketingAhsan RafiqNo ratings yet

- CompositeMegaColumns Full ReportDocument275 pagesCompositeMegaColumns Full ReportRonakShah100% (1)

- Sea OcDocument296 pagesSea OcJunaid Shah100% (1)

- Column Shortening-Compensation in Tall Buildings - PresentationsDocument28 pagesColumn Shortening-Compensation in Tall Buildings - Presentationsgulilero_yoNo ratings yet

- Seismic Design Guidlines For Special Hybrid Precast Concrete Shear Walls. KuramaDocument92 pagesSeismic Design Guidlines For Special Hybrid Precast Concrete Shear Walls. KuramaFawad Najam100% (2)

- Precast/ Prestressed Concrete BuildingsDocument0 pagesPrecast/ Prestressed Concrete BuildingsDinh Tuat Trieu100% (1)

- Ordinary Shear WallDocument1 pageOrdinary Shear WallArwen CerenoNo ratings yet

- CE697R DiaphragmsF12Document74 pagesCE697R DiaphragmsF12^passwordNo ratings yet

- Reinforced Concrete Design I: Dr. Nader OkashaDocument31 pagesReinforced Concrete Design I: Dr. Nader Okashavijaykumarz100% (1)

- Earthquake-Resistant Structures - Design Assessment and RehabilitationDocument536 pagesEarthquake-Resistant Structures - Design Assessment and RehabilitationMuhammad Arfan JadoonNo ratings yet

- Design of Reinforced Concrete Floor Systems: Professional Development SeriesDocument7 pagesDesign of Reinforced Concrete Floor Systems: Professional Development SeriesJCS100% (1)

- CoreBrace Brochure Dec 2011Document8 pagesCoreBrace Brochure Dec 2011lcoraoNo ratings yet

- Steel Deck Institute Design Manual For Composite Decks Form DeckDocument53 pagesSteel Deck Institute Design Manual For Composite Decks Form DeckAhmed LepdaNo ratings yet

- Construction Stage Analysis Reflecting Long-Term DeformationDocument18 pagesConstruction Stage Analysis Reflecting Long-Term DeformationAshish LoyaNo ratings yet

- FEMA P-58-2-SE Volume2 ImplementationDocument378 pagesFEMA P-58-2-SE Volume2 Implementation楊亞衡100% (1)

- ComFlor® ManualDocument132 pagesComFlor® ManualAhmedNo ratings yet

- Strut and Tie Models ACIDocument13 pagesStrut and Tie Models ACIRômulo Menck RomanichenNo ratings yet

- Seismic Masonry Guide 2nd Edition Oct 2018 R1 Split 4Document71 pagesSeismic Masonry Guide 2nd Edition Oct 2018 R1 Split 4Eduardo Martinez CaleroNo ratings yet

- Reduction of Differential Column Shortening in Tall BuildingsDocument4 pagesReduction of Differential Column Shortening in Tall BuildingsAyman BadrNo ratings yet

- MB PT Floors Dec17Document24 pagesMB PT Floors Dec17Alparslan GureNo ratings yet

- Dynamic Set For Shear Resistance UpgradeDocument2 pagesDynamic Set For Shear Resistance Upgradehessian123No ratings yet

- PTI 2009 PrestressedTanksDocument38 pagesPTI 2009 PrestressedTanksRodrigo LameirasNo ratings yet

- Minimizing Floor Vibration by Design and RetrofitDocument0 pagesMinimizing Floor Vibration by Design and RetrofitCrosman StefanNo ratings yet

- Evaluation of Modified Truss Model Approach For Beam in ShearDocument10 pagesEvaluation of Modified Truss Model Approach For Beam in ShearKinjal DaveNo ratings yet

- MB Structural Design Compendium May16Document52 pagesMB Structural Design Compendium May16aldert_path100% (2)

- Handout 5 13Document11 pagesHandout 5 13erikahuhuNo ratings yet

- Chapter 3 Direct Displacement Based DesignDocument68 pagesChapter 3 Direct Displacement Based DesignMuhammadNomanKNo ratings yet

- Compatibility Strut-and-Tie Modeling: Part I-Formulation: Aci Structural Journal Technical PaperDocument10 pagesCompatibility Strut-and-Tie Modeling: Part I-Formulation: Aci Structural Journal Technical PaperMunna SagiNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesFrom EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNo ratings yet

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- Steel-Concrete Composite Coupling Beams - Behavior and DesignDocument11 pagesSteel-Concrete Composite Coupling Beams - Behavior and DesignFrancisco Javier Torres AlvaradoNo ratings yet

- Computation: Numerical Modelling of Double-Steel Plate Composite Shear WallsDocument30 pagesComputation: Numerical Modelling of Double-Steel Plate Composite Shear WallsNasarKhanNo ratings yet

- Wcee2012 2737 PDFDocument10 pagesWcee2012 2737 PDFAkhil Nath P SNo ratings yet

- Paper#1155 Final RevisionDocument25 pagesPaper#1155 Final RevisioncyrusnasiraiNo ratings yet

- Mode III Fracture of An Arbitrary Oriented Crack in Two Dimensional Functionally Graded MaterialDocument6 pagesMode III Fracture of An Arbitrary Oriented Crack in Two Dimensional Functionally Graded MaterialcyrusnasiraiNo ratings yet

- Dynamic Analysis of DomeDocument6 pagesDynamic Analysis of Domecyrusnasirai100% (1)

- On The Stress Integration in Large Strain Elasto-Plasticity: Francisco J. Montáns, Klaus-Jürgen BatheDocument4 pagesOn The Stress Integration in Large Strain Elasto-Plasticity: Francisco J. Montáns, Klaus-Jürgen BathecyrusnasiraiNo ratings yet

- A Survey On Recent Developments in Second-Order Integration Methods For Plasticity ModelDocument6 pagesA Survey On Recent Developments in Second-Order Integration Methods For Plasticity ModelcyrusnasiraiNo ratings yet

- IJMTES030638Document7 pagesIJMTES030638Bobby LupangoNo ratings yet

- ME 130 Applied Engineering Analysis Class: Welcome ToDocument14 pagesME 130 Applied Engineering Analysis Class: Welcome ToNidaa Al AlousiNo ratings yet

- Neil Karlo Lozano Updated Resume 2022Document1 pageNeil Karlo Lozano Updated Resume 2022Sebastian XavierNo ratings yet

- Industrial Management: NHU - 601 Ajay ChaubeyDocument13 pagesIndustrial Management: NHU - 601 Ajay ChaubeyChaubey AjayNo ratings yet

- Classified Advertising: Gulf TimesDocument5 pagesClassified Advertising: Gulf TimessasikalaNo ratings yet

- Suspension Bridge Construction in Rural AreaDocument94 pagesSuspension Bridge Construction in Rural AreaPitiporn HasuankwanNo ratings yet

- Iec College of Art & FashionDocument10 pagesIec College of Art & FashionTyata SamratNo ratings yet

- Automation Technician Program (T950) : TuitionDocument2 pagesAutomation Technician Program (T950) : TuitionJuan EstebanNo ratings yet

- Grade Boundaries 2019Document5 pagesGrade Boundaries 2019HalapeñoNo ratings yet

- Course Information and Lesson Plan Design of Machine Elements-1 PDFDocument2 pagesCourse Information and Lesson Plan Design of Machine Elements-1 PDFAyushSaraswatNo ratings yet

- A Study of The Effectiveness of Case Study Approach in Software Engineering EducationDocument8 pagesA Study of The Effectiveness of Case Study Approach in Software Engineering EducationAkshay AggarwalNo ratings yet

- Structural Analysis II: A Course Material OnDocument3 pagesStructural Analysis II: A Course Material OnKarthik PalaniswamyNo ratings yet

- Basohli Cable Stayed Bridge - IndiaDocument7 pagesBasohli Cable Stayed Bridge - IndiajnshreyNo ratings yet

- My ResumeDocument2 pagesMy ResumeSathanandhNo ratings yet

- Bombardier CRJ 200-ElectricalDocument45 pagesBombardier CRJ 200-ElectricalRicardo Garcia100% (4)

- Assignment - 1 RC - IIDocument3 pagesAssignment - 1 RC - IIdawitdeginet096No ratings yet

- PfabDocument15 pagesPfabSudipto RoyNo ratings yet

- Abdul Qayyum: Mechanical Engineer (QA/QC)Document6 pagesAbdul Qayyum: Mechanical Engineer (QA/QC)Muhammad ZaidNo ratings yet

- RoofDocument55 pagesRoofRosele LabarreteNo ratings yet

- Rollsroyce Steering GearDocument11 pagesRollsroyce Steering GearRajib Kar100% (3)

- PM EceDocument4 pagesPM EceTolichoNo ratings yet

- Bachelor of Engineering (B.E)Document12 pagesBachelor of Engineering (B.E)Putta Shreyash ChandraNo ratings yet

- Application Form - Individual Consultant PDFDocument35 pagesApplication Form - Individual Consultant PDFTuhin BhuiyanNo ratings yet

- Stem Program Certification Rubric For Elementary SchoolDocument6 pagesStem Program Certification Rubric For Elementary Schoolapi-265500172No ratings yet

- RENR3814-09 Pump ControlDocument460 pagesRENR3814-09 Pump ControlDavid Mercado94% (17)

- 173 Armox 440t Uk Data SheetDocument2 pages173 Armox 440t Uk Data SheetErnestoNo ratings yet

- 77 1006 SafetyReliefValveDocument8 pages77 1006 SafetyReliefValverahul soniNo ratings yet

- ANSI-AWWA (American Water Works Association)Document1 pageANSI-AWWA (American Water Works Association)Vaniya GoelNo ratings yet