Professional Documents

Culture Documents

Disclosure To Promote The Right To Information

Disclosure To Promote The Right To Information

Uploaded by

ADIPESHOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Disclosure To Promote The Right To Information

Disclosure To Promote The Right To Information

Uploaded by

ADIPESHCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 13687 (1993): Internal combustion engines - Radiators -

Heat dissipation performance - Method of test [TED 2:

Automotive Primemovers]

IS 13687 : 1993

Indian Standard

I NTERNAL COMBUSTI ON ENGI NES -

RADI ATORS - HEAT DI SSI PATI ON

PERFORMANCE - METHOD OF TEST

UDC 62143 : 629113

0 BI S 1993

BUREAU OF INDIAN STANDARDS y

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARC

NEW DELHI 110002

December 1993 Price Group 4

( Reaffirmed 2003 )

Automotive Primemovers Sectional Committee. TED 2

FOREWORD

This Indian Standard was adopted by the Bureau of Indian Standards, after the draft finalized by

the Automotive Primemovers Sectional Committee had been approved by the Transport Engineering

Division Council.

This Indian Standard specifies the method of test for assessing the heat transfer efficiency of

radiators used in road vehicles. The efficiency of cooling arrangement of an internal combustion

engine when fitted with a radiator may be judged mainly by its heat transfer performance. The

principle adopted for assessment makes use of a wind tunnel arrangement with provisions for

measuring the pressure and temperatures of air, coolant and flow rate in front and rear of the

radiator. Typical performance curves and recording of test results are given in Annex B and

Annex C. This standard is an important adjunct to IS 761 I : 1993 Internal combustion engines -

Radiators - Specification (first revision ) and IS 13686 : 1993 Internal combustion engines -

Radiators - Methods of test.

In the preparation of this Indian Standard considerable assistance has been derived from:

JIS D 1614-1970 Heat dissipation test code of radiators for automobiles issued by the Japanese

Jndustrial Standards Committee.

In reporting the results of a test or analysis made in accordance with this standard, if the final

value, observed or calculated, is to be rounded off, it shall be done in accordance with 1s 2 : 1960

Rules for rounding off numerical values ( revised ).

P

I ndian Standard

IS 13687 : 1993

INTERNAL COMBUSTION ENGINES-

RADIATORS- HEAT DISSIPATION

PERFORMANCE- METHOD OF TEST

1 SCOPE

This Indian Standard specifiesthe method of test for

assessing heat dissipation performance of automotive

radiators.

2 REFERENCES

The followingIndian Standards are necessary adjuncts

to this standard:

ZS No. Title

7611 : 1993 Internal combustion engines -

Radiators - Specification (first

revision)

13686 : 1993 Internal combustion engines -

Radiators - Methods of test

3 TERMINOI,OGY

3.0 For the purpose of this standard, the following

definitions shall apply.

3.1 Converted Heat Dissipation Rate

The heat dissipation rate of the cooling water (hereinafter

referred to as waterside), which is converted to the

state where inlet temperature difference between water

and air is 60C, and is expressed by the unit of

kilocalorie per hour (kcal/h).

3.2 Heat Dissipation Rate on Waterside

The heat dissipation rate under test conditions, expressed

as the quantity of heat which water loses under, and is

expressed by the unit of kilocalories per hour (kcal/h).

3.3 Heat Reception Rate on Airside

The heat rate which the cooling air (hereinafter, referred

to as air receives under test conditions and is expressed

by the unit of kilocalories per hour (kcal/h).

3.4 Inlet Temperature Difference

The difference between the inlet temperatures ofwater

and air expressed by the unit of degree Celsius (C).

3.5 Water Flow Rate

The flow rate of water which passes through the

radiator expressed in litres per minute (l/mm).

3.6 Air Velocity at Frontal Area

The flow rate of air passing through the radiator

divided by the frontal area and is expressed in metre

per second (m/s).

3.7 Pressure Loss of Waterside

The difference of static pressure between the water

side inlet and outlet of the radiator which is measured

at the test state and is expressed by the unit of mercury

column height of millimetre (mm Hg).

3.8 Pressure Loss of Airside

The difference of static pressure between the airside

inlet and outlet of the radiator, measured at the test

state and is expressed by height of water column in

millimetre (mm Aq).

3.9 Upstream End

Area before the radiator which permits entry of air into

the radiator.

3.10 Downstre+n End

Area after the radiator which permits exit of air away

from the radiator.

4 TEST REQUIREMENTS

4.1 The radiator shall comply with IS 7611 : 1993.

4.2 The test room conditions shall be steady and at

normal ambient temperature and humidity. The air

flow shall be steady without large fluctuations.

4.3 Unless otherwise specified the water used for test

purposes shall be clear without suspended impurities

and the radiator inlet water temperature maintained at

85 + 5OC at the dissipation state. The temperature shall-

be recorded at steady state conditions and a variation

of 2 2OC in the water inlet temperature is permissible

between successive readings.

4.4 The measuring equipment shall be calibrated before

start of test.

4.5 The test room shall be maintained ,at steady

atmospheric condition.

5 TESTING AND MEASURING- ARRANGE-

MENTS

,

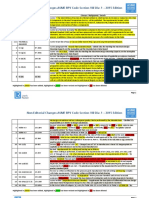

5.1 The test apparatus is broadly divided into waterside

IS 13687 : 1993

circuits and airside (wind tumlel) circuits. The typical

testing arrangement is shown in Fig. 1.

5.2 Waterside Circuit

5.2.1 The waterside circuit shall be equipped with

separators in order to prevent mixing of air and vapour

in the waterside circuit of the radiator. The hot water

tank shall be so designed as to prevent air and vapour

locking.

5.2.2 The water pump may be connected, to either

side of the inlet pipe or the outlet pipe of the radiator.

Care shall be taken to avoid any cavitation.

5.2.3 The rate of heat generation by hot water tank

shall be enough to maintain heat dissipation rate and

shall be adjustable in all ranges of heat dissipation.

5.3 Airside (Wind Tunnel) Circuit

5.3.1 Wind Tunnel

The air flow passing through radiator shall. be

adjustable. The arrangement shall include fan, throttle

devices such as orifice, shutter, cone. The comiecting

tube between the main body of the wind tunnel and

the radiator shall be interchangeable to take care of

variations in size and shape of radiator:The shape of

the connecting tube shall be such that the front of the

radiator receives a uniform parallel flow,of air. All

joints shall be totally airtight.

5.3.2 An alternate suction type arrangement with

wind tunnel is also permissible when mutually agreed

between the manufacturer and the purchaser. The

details of such arrangement are given in Annex A.

5.4 Measuring Equipments

5.4.1 Water Flowmeter

The water flowmeter used shall have an accuracy

of + 2% of maximum scale.

5.4.2 Air Flowmeter

The air flowmeter used shall be based on Pitot tube or

Orifice or Nozzle. The minimum scale for liquid

column shall be 1 mm on 30 inclined type manometer

or that having a vertical column.

5.4.3 Pressure Gauges

For waterside the liquid mercury column gauge shall

have a minimum one mm accuracy. For the airside to

measure pressure loss, the liquid column gauge shall

have at least 1 mm accuracy. For measuring atmospheric

pressure, a Fortins barometer is recommended.

5.4.4 Thermometers

For measuring the temperatures the thermometers

used shall have at least t O.lC accuracy for waterside

and lC accuracy airside. For room temperature and

humidity, a wet and dry bulb thermometer shall be

used.

6 TESTS

6.1 The airside circuit is completed by connecting the

radiator and wind tmmelwith the connecting tube. The

waterside circuit of the test apparatus is connected to

the inlet and outlet pipes of the radiator. When the

radiator (see Fig. 1) reaches stable conditions with

specified rate of air and water flow, the heat tratifer

and pressure loss tests shall be conducted.

6.2 The following are measured:

a) Atmospheric pressure and humidity

b) Inlet and outlet water temperatures

c) Inlet and outlet air temperatures

d) Rate of air and water flow

e) Wind velocity

f) Pressure loss -Water and air sides.

6.3 Flow measurements shall be made after stable

conditions are reached. When Pitot tube is used for air

flow, only the control air velocity may be measured

and the ratio of mean to centre velocity shall be used

for computing the rate of airflow. The airflow is to be

measured in the air inlet side.

6.4 Pressure Loss Measurements

The pressure loss measurement of waterside

is to be made at the position as near as

possible to the end of inlet and outlet pipe of

radiator.

The pressure loss measurement of airside is to

be near the radiator at the upstream and down-

steam end both locations being equidistant

from centre line of radiator core.

6.5 Temperature of water shall be measured as

accurately as possible, near the inlet and outlet pipe of

radiator. The measurement of air temperatures is to be

made at the upstream and downstream end of the

radiator. Inlet air temperature may be measured at the

centre of core. In the case of outlet air temperature,

measurements be made at least at four places covering

entire core face and the mean temperature shall be

calculated. The point of location of thermometer shall

be such that it does not receive radiant heat from the

radiator.

7 CAILXJ LATIONS

7.1 From the results obtained, the heat dissipated on

the waterside shall be calculated and this value shall be

judged by heat received on airside simultaneously.

The air velocity on the upstream side shall also be

calculated.

7.2 Heat Dissipation on Waterside shall be calculated

by the following formula:

Qw~ = GVV x Cw [T, - T,]

where

QMJ = ;te &heat dissipated on the waterside,

ca

2

OUNTER 80

CONNECTNIG .T

. THERMOMETER FOR

INLET AIR TEMPER

THERMOMETER FOR THE

LET WATER TEMPERATURE

COLUMN GAUGE

WATER) FOR THE AIR

PRESSURE LOSS

STREAM END

w

METER FOR THE

AIR TEMPERATURE

0 COLUMN GAUGE(MERCURY)

THE WATER SIDE PRESSURE LOSS -

WATER TEMPERATURE

HOT WATER TAN

VOLT METER. / WATER FLOW METER\ \LIQUID COLUMN GAUGE(WATER) .

WATER FLOW ADJbSTING

FOR THE AIR FLOW METER

FIG. 1 TYPICAL TESITNG ARHANGEMENT

G

s

IS 13687 : 1993

Gw =

T, =

Tz =

weight of water circulated through the ra-

diator per hour (kg/h)

VWX vx lo- x60

volume of water flow per minute in litres

weight of water per unit volume (kg/nt3)

specific heat of water, assumed as 1.0

(kcal/kgOC)

inlet water temperature, OC

outlet w at er temperature, OC

NOTE 1 -The value of weight of water corresponding I O the

temperature of water recorded closes1 IO the flowmeter shall be

used (sac Fig. 2).

loo-

- 960

-

go-=-

80 ; 970

-

70: -

y- 980

60- __

so- _

1% 1

40- J

( k$- n3)

5

990

FIG. 2 TEMPERATIJ RE AND WEIGHT PER UNIT VOLLIME

OF WAXR

NOTE 2 -For validity of test results. heat received on airsidc

shall be within -C lO% OC heat dissipated on waterside.

7.2.1 Hcwt Received on Airside

Qo =

where

Qcr =

Ctr =

Go x Ctr (T, - T,)

heat received ou the airside, (kcal/h)

specific heat ofair, kcal/kgoC(assuuted as

024 kcal/kgV)

T, =

T, =

Gn =

Ga =

where

Vrr =

A =

nieaii outlet air temperature, OC

iiilet air temperature, OC

weight of air passing through per hour,

(kg/h)

Vn xA

rate of air, (nt/h)

(To be determiued by Orifice/Pitot Tube

methods)

weight of air per unit voluu~ (kg/n?)

7.3 Method of Calculation for Rate of Air, Va

7.3.1 Pitot Tube Method

where

s =

v,, =

Vtr = 3 600 x S x Vnl

cross-sectional area of wind tunnel at the

measuring position, (&)

nmn air velocity in the wind tunnel at the

nicasuriug positioii (m/s)

.I

2gpd

also V,,, = \ 1 -

V

A

where

&Y =

pd =

=

A =

acceleratioudue to gravity, m/s(9.8 m/s*)

dynamic pressure in Pitot Tube

(Arithmetic mean of pressure II,, II,, . . . . .

L)

l/m (/II + II, . . . . . . . . llm>

weight of air per unit volun~e (kghd)

7.3.2 U,sing the OriJicc

Vr1=3600xtrxBxmx

where

c1 =

B =

m =

px =

K =

fz =

tlow coefficient

correction coefficient by expansion of air

arca of opcniug of Orifice (n$)

pressure difference inuuediately in front

altd behind the Orifice (nun Act)

weight of air per unit volume inme-

diately in front of Orifice (kg/m)

accelerationduc togravity, nt/s(9.8 m/s?)

7.4 Air Velocity of Frontside Area (!htf)

Vrr

vc11 =

Fx3600

where

Vwf = frontside area air velocity, (m/s)

Vf7 = rate of air (Same connotation as in 7.3.1

and 7.3.2)

F = frout side area, (II?)

7.5 Weight of Air per IJnit Volume (A) shall be

Calculated from the Equation

1.293xH

A

= (1 + 0.003 67 x r(l) 760

H = atmospheric pressure, nm of mercury

(Room condition)

(mm l-tfg )

IS 13687 : 1993

where

tn = atmospheric temperature, OC (obtainable

from Fig. 3).

7.6 The dissipated heat shall be corrected by multiplying

the rate of heat dissipated on the waterside (Qw) with

the ratio of60 divided by difference in inlet temperatures

of water (T,) and air (T,) respectively. T,, 7, and Q,,.

have sanle connotation as in 7.2.

8 TEST RESULTS

8.1 The heat dissipation performance curves shall be

plotted as in Amex B.

8.2 The results shall be recorded in accordance with

Annex C.

t

0

( Wm3)

FIG. 3 MONOGRAPH OF A

ANNEX A

(Clause 5.3.2)

SIICTION TYPE WIND TUNNEI, AI<HANGEMENI

A-l TEST APPARATUS

A-1.1 The test apparatus comprises 21 typical

suctiorl

tYPe

wind tumrl arrangement with

coiiiiecting tube and arrangenic tit for nicasureiiieiit for

velocity and pressure. The arraogement is show11 in

Fig. 4 aud 5.

EXPANDING TUBE

A-l.2 Connecting Tube

When the connecting tube transits from iI circular

shape to a circular shape, from a rectangular shape to

a circular shape or from a circular shape to a

rectaiigul;ir shape, the rules dcscribcd below Shi l l I be

observed :

3orrlax.

REDUCING TUBE

FIG. 4 CONNECTXVC; TLruzs

5

IS 13687 :

a)

b)

where

L

D

AREA RATIO

- TRANSITION FROM RECTANGLE TO CIRCLE

--- -

TRANSITION FROM CIRCLE TO RECTANGLE

FIG. 5 LENGTH OF CONNJ ZCIING TUBE

The angle between the connecting tube and

the axial line in the case of the transition

from a circular shape to a circular shape shall

be not more than 14O for the expanding tube,

and not more than 300 for the reducing tube

c)

(see Fig. 4).

In the case of the transition from a rectangular

shape to a circular shape (see Fig. S), the rule

described in thefollowing equation (discharge

side) applies:

In the case of the transition from a circular

shape to a rectangular shape (see Fig. 5), the

rule described in the following equation

(suction side) applies:

For reducing tube (m s 1) : L/D r 1.8

For expanding tube (m r 1) : L/D r 4

For reducing tube (m r 1) : L/D r 1.8

For expanding tube (m s 1) : iiD L 4

L J

m=

= length of connecting tube

a

=

= inside diameter of measuring duct

b =

9t.D

area ratio = -

4ab

length of long side of rectangle

length of short side of rectangle

6

IS 13687 : 1993

ANNEX B

(Foreword, and Clause 8.1)

HEAT DISSIPATION PERFORMANCE OF RADIATOR

S1 No.

Batch No.

Name of manufacturer

Type

Grade

Manufacturer part number

Date of test

Room temperature

Humidity

Atmospheric pressure

Test apparatus

Tested by

oC

percent

mm Hg

HEAT DISSIPATION QUANTITY 1 1

0 5 10 15 20 25

AIR VELOCITY OF THE FRONTAL AREA vaf (m/s)

0 100 200

WATER FLOW VOLUME Vw(l/minI

AN EXAMPLE OF HEAT DISSIPATION PERFORMANCE CURVE

NOTE-The heat dissipation rate in this table is to be corrected for the inlet temperature difference achieved for a difference of 6OT

between inlet water temperature and upstream air temperature.

7

/

I

I

,

,

,

I

I

-

I

I

I

I

=

I

=

t

-

t

-

I

I

=

I

=

I

I

I

Standard Mark

The use of the Standard Mark is governed by the provisions of the Bureau of Indim

Standards Act. 1986 and the Rules and Regulations made thereunder. The Standard Mark on

products covered by an Indian Standard conveys the assurance that they have been produced

to comply with the requirements of that standard under a well defined system of inspection,

testing and quality control which is devised and supervised by BIS and operated by the

producer. Standard marked products are also continuously checked by BIS for conformity

to that standard as a further safeguard. Details of conditions under which a licence for the

use of the Standard Mark may be granted to manufacturers or producers may be obtained

from the Bureau of Indian Standards.

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of I ndian Standards Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications.

No part of these publications may be reproduced in

any form without the prior permission in writing of BIS.

This does not preclude the free use, in the

course of implementing the standard, of necessary details,

such as symbols and sizes, type or grade

designations. Enquiries relating to copyright be addressed to the Director ( Publications ), BIS.

Review of Indian Standards

,

Amendments are issued to standards as the need arises on the basis of comments. Standards are also

reviewed periodically; a standard along with amendments is reaffirmed when such review indicates that no

changes are needed; if the review indicates that changes are needed, it is taken up for revision. Users of

Indian Standards should ascertain that they are in possession of the latest amendments or edition by

referring to the latest issue of BIS Handbook and Standards Monthly Additions. Comments on this

Indian Standard may be sent to BIS giving the following reference:

Dot : No. TED 2 (5213 )

Amendments Issued Since Publication

Amend No. Date of Issue Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones : 331 01 31, 331 13 75 Telegrams : Manaksanstha

( Common to all Offices )

Regional Offices:

Cantral : Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern : l/14 C. 1. T. Scheme VII M, V. I. P. Road. Maniktolr

CALCUTTA 700054

Telephone

331 01 31

(

331 13 75

37 84 99, 37 85 61

37 86 26, 37 86 62

Northern : SC0 445-446, Sector 35-C, CHANDIGARH 160036 53 38 43, 53 16 40

53 23 84

Southern : C. I. T. Campus, IV Cross Road, MADRAS 600113 c 235 02 16, 235 04 42

235 15 19, 235 23 15

Western : Manakalaya, E9 MIDC, Marol, Andheri ( East ) 632 92 95, 632 78 58

BOMBAY 400093

{

632 78 91, 632 78 92

Branches : AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATORE.

FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPLJR. KANPUR.

LUCKNOW. PATNA. THlRUVANANfHAPURAM.

Printed at Printrade, New Delhi, India

You might also like

- Performance and Efficiency Test of A Refrigeration Plant Test ProcedurDocument4 pagesPerformance and Efficiency Test of A Refrigeration Plant Test ProcedurEJ TolentinoNo ratings yet

- Air PreheaterDocument11 pagesAir PreheaterSuresh Ramakrishnan100% (1)

- Test Code For Cooling Tower SlidesDocument12 pagesTest Code For Cooling Tower SlidesFouzan AbdullahNo ratings yet

- Appendix D: Amcp 706-361Document31 pagesAppendix D: Amcp 706-361JuanCarlosLopezNo ratings yet

- Capacity of BlowerDocument7 pagesCapacity of Blowersushant_jhawerNo ratings yet

- Standard Test Method For API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Document9 pagesStandard Test Method For API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)hasseemNo ratings yet

- D1160Document18 pagesD1160guadalupegomezperezNo ratings yet

- Performance Evaluation of A Air Conditioner According To Different Test Standards PDFDocument9 pagesPerformance Evaluation of A Air Conditioner According To Different Test Standards PDFIAEME PublicationNo ratings yet

- D 7345Document15 pagesD 7345Asep TheaNo ratings yet

- Simplified Numerical Model For A Flat Continuous Triangle Fins Air Cooled Heat Exchanger Using A Step by Step TechniqueDocument23 pagesSimplified Numerical Model For A Flat Continuous Triangle Fins Air Cooled Heat Exchanger Using A Step by Step TechniquemunkkkkNo ratings yet

- Eurovent 6/11 Thermal Test Method For Ducted Fan Coil UnitsDocument14 pagesEurovent 6/11 Thermal Test Method For Ducted Fan Coil Unitsjames_chan2178No ratings yet

- ASTM D287 API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Document3 pagesASTM D287 API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Jaime Mamani PirapiNo ratings yet

- HVAC T and C StandardsDocument67 pagesHVAC T and C StandardsArun kumarNo ratings yet

- Test Methods For Air Curtain Units: Amca Standard 220-91Document17 pagesTest Methods For Air Curtain Units: Amca Standard 220-91Jay SuguitanNo ratings yet

- Ac 2013 FinDocument15 pagesAc 2013 FinRay WangNo ratings yet

- 8.8 Boiler Efficiency TestDocument17 pages8.8 Boiler Efficiency TestRINJUNo ratings yet

- 08 Chapter 3Document22 pages08 Chapter 3BALAJI CHOUHANNo ratings yet

- Paes 126Document13 pagesPaes 126shuvatheduva123123123No ratings yet

- Article CFB Anslysis On Coal State Test of 300MW CFB BoilerDocument8 pagesArticle CFB Anslysis On Coal State Test of 300MW CFB Boilernguyenhuutan91No ratings yet

- DLT 1027-2006 工业冷却塔测试规程-enDocument30 pagesDLT 1027-2006 工业冷却塔测试规程-en郭允超No ratings yet

- Design of Air Conditioning System in AutomobileDocument5 pagesDesign of Air Conditioning System in AutomobilemhdmkNo ratings yet

- HVACDocument17 pagesHVACashwini_kumar1984No ratings yet

- GS 30RB 27PDDocument9 pagesGS 30RB 27PDKike PadillaNo ratings yet

- MP 0 2400 74 Sept 10Document21 pagesMP 0 2400 74 Sept 10Abhishek MishraNo ratings yet

- Probe Nozzles: The Probe Nozzles Are Constructed of Type 316Document41 pagesProbe Nozzles: The Probe Nozzles Are Constructed of Type 316nana supriatnaNo ratings yet

- Probe Nozzles: The Probe Nozzles Are Constructed of Type 316Document41 pagesProbe Nozzles: The Probe Nozzles Are Constructed of Type 316Đàm QuânNo ratings yet

- Service Manual Ariston T2Document52 pagesService Manual Ariston T2cris_43100% (1)

- System Practices For Halocarbon Refrigerants: Refrigerant Flow RatesDocument30 pagesSystem Practices For Halocarbon Refrigerants: Refrigerant Flow RatesChristine Joy Allas RapanotNo ratings yet

- R - AC Lecture 38Document22 pagesR - AC Lecture 38Narulita B. PutriNo ratings yet

- ASTM D6549 - Determination of Cooling Characteristics of QuenchantsDocument7 pagesASTM D6549 - Determination of Cooling Characteristics of QuenchantsjesusladoNo ratings yet

- Bee - Code Development Project: Draft Code ON Fluid Piping SystemsDocument49 pagesBee - Code Development Project: Draft Code ON Fluid Piping SystemsNaveen ShettyNo ratings yet

- EA Guidelines On The Calibration of Temperature Block CalibratorsDocument14 pagesEA Guidelines On The Calibration of Temperature Block CalibratorsSriniramu SriniramuNo ratings yet

- Mech3005 Lab1112 Fancoil PDFDocument5 pagesMech3005 Lab1112 Fancoil PDFbilal almelegy100% (1)

- 0708 R RE 001 Design BasisDocument11 pages0708 R RE 001 Design BasisHimawan Sigit NugrohoNo ratings yet

- Spec. HVAC DesignDocument7 pagesSpec. HVAC Designmihai_serban13No ratings yet

- Astm d2029 Dew PTDocument6 pagesAstm d2029 Dew PTvlcmstne04No ratings yet

- D2882Document6 pagesD2882rimi7alNo ratings yet

- AHRI Standard 450-2007 - Perform Ace Rating of Water-Cooled Refrigerant Condenser, Remote TypeDocument11 pagesAHRI Standard 450-2007 - Perform Ace Rating of Water-Cooled Refrigerant Condenser, Remote TypeFernando OliveiraNo ratings yet

- The Specific Objectives of This Chapter Are To:: 38.2 - General Rules For Duct DesignDocument6 pagesThe Specific Objectives of This Chapter Are To:: 38.2 - General Rules For Duct DesignSalehAfadlehNo ratings yet

- Tech Specs For Nitrogen GeneratorDocument5 pagesTech Specs For Nitrogen Generatorn.hartonoNo ratings yet

- Comp Air Design GuideDocument23 pagesComp Air Design GuideSaurabh Singh100% (1)

- Chapter 4 - Gas Piping Installations PDFDocument14 pagesChapter 4 - Gas Piping Installations PDFGeorge_Wabag_2014No ratings yet

- Disawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Document8 pagesDisawas Experimental Investigation On The Performance of The Refrigeration Cycle Using A Two Phase Ejector As An Expansion Device 2004Mohamed HassanainNo ratings yet

- E PR 330Document28 pagesE PR 330np_bogdanNo ratings yet

- Thermodynamics Lap 11 FinalDocument8 pagesThermodynamics Lap 11 Finalaquib14125No ratings yet

- Air Dryer Manual - 2Document20 pagesAir Dryer Manual - 2Khasan MuntahaNo ratings yet

- Gas Meter SelectionDocument7 pagesGas Meter SelectiongiromadNo ratings yet

- Astm d445Document8 pagesAstm d445Anonymous 6meMTlNo ratings yet

- Use of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformDocument22 pagesUse of The (Nline Gas Chromatograph For Gas Sales From An Offshor PlatformAlcimar MonteiroNo ratings yet

- Water Cooled Chiller - SOPDocument13 pagesWater Cooled Chiller - SOParunceedee100% (4)

- Cooling TowersDocument9 pagesCooling TowersTapan KumarNo ratings yet

- Gas Reticulation Project Group 8Document13 pagesGas Reticulation Project Group 8Mohd Hafiz50% (2)

- Application of Measuring Gas Flow in The DowncomerDocument4 pagesApplication of Measuring Gas Flow in The DowncomerAhmad NilNo ratings yet

- Astm D1160.2012Document19 pagesAstm D1160.2012Leny PortoNo ratings yet

- 1.1test MethodologyDocument14 pages1.1test MethodologyjvfcvNo ratings yet

- 2.3operator Manual of SDLF-80Document27 pages2.3operator Manual of SDLF-80pachara sarntiyakulNo ratings yet

- Advanced Temperature Measurement and Control, Second EditionFrom EverandAdvanced Temperature Measurement and Control, Second EditionNo ratings yet

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Paishancha Vyavhar (In Marathi) PDFDocument102 pagesPaishancha Vyavhar (In Marathi) PDFADIPESHNo ratings yet

- Introduction To Theory of Machines: June 2015Document9 pagesIntroduction To Theory of Machines: June 2015ADIPESHNo ratings yet

- Catalog Ankor TeploenergoDocument24 pagesCatalog Ankor TeploenergoADIPESHNo ratings yet

- Diffusion: Atoms Moving and Changing PlacesDocument24 pagesDiffusion: Atoms Moving and Changing PlacesADIPESHNo ratings yet

- Heat ExchangerDocument17 pagesHeat ExchangerADIPESHNo ratings yet

- ASM Subject Guide - AluminumDocument43 pagesASM Subject Guide - AluminumADIPESHNo ratings yet

- Pipe & Weld Digital X-Ray Inspection Systems: VJ TechnologiesDocument4 pagesPipe & Weld Digital X-Ray Inspection Systems: VJ TechnologiesADIPESHNo ratings yet

- Alpema StandardsDocument84 pagesAlpema StandardsADIPESHNo ratings yet

- Alpema StandardsDocument84 pagesAlpema StandardsADIPESHNo ratings yet

- Influence On The Performance of Cryogenic Counter-Flow Heat Exchangers Due To Longitudinal Conduction, Heat In-Leak and Property VariationsDocument16 pagesInfluence On The Performance of Cryogenic Counter-Flow Heat Exchangers Due To Longitudinal Conduction, Heat In-Leak and Property VariationsADIPESHNo ratings yet

- Newsletter 12 Refrigerant Line Sizing - Part II Suction and Discharge LinesDocument4 pagesNewsletter 12 Refrigerant Line Sizing - Part II Suction and Discharge LinesADIPESHNo ratings yet

- Riveted, Bolted & Welded ConnectionsDocument61 pagesRiveted, Bolted & Welded ConnectionsADIPESHNo ratings yet

- Cold Rolled Sheets HINDALCODocument3 pagesCold Rolled Sheets HINDALCOADIPESHNo ratings yet

- Module 2Document111 pagesModule 2ADIPESHNo ratings yet

- Basic Unit ConvertionDocument30 pagesBasic Unit ConvertionADIPESHNo ratings yet

- Trane ENL Fans in Air-Handling SystemsDocument68 pagesTrane ENL Fans in Air-Handling SystemsADIPESHNo ratings yet

- Whitehopleman Com Coating Rings BallsDocument11 pagesWhitehopleman Com Coating Rings BallsMomar Talla DiawNo ratings yet

- Plumbing: Wholesale CatalogDocument92 pagesPlumbing: Wholesale CatalogTan Kang YaoNo ratings yet

- Pfeifer Preisliste PlenDocument340 pagesPfeifer Preisliste PlenMichał WarbudNo ratings yet

- Tunnel Formwork Technology ManualDocument162 pagesTunnel Formwork Technology ManualPatrick LegaspiNo ratings yet

- Beton Prategang: Members Analysis Under FlexureDocument47 pagesBeton Prategang: Members Analysis Under Flexurezacoeb_a1669No ratings yet

- Whirlpool Acre Pair Part List - 8167608Document7 pagesWhirlpool Acre Pair Part List - 8167608thatbaddogNo ratings yet

- Weldability of 17-4 PH Stainless Steel in Centrifugal Compressor Impeller ApplicationsDocument7 pagesWeldability of 17-4 PH Stainless Steel in Centrifugal Compressor Impeller ApplicationsMurad AlamNo ratings yet

- Greek Code For Seismic Resistant Structures (EAK 2000)Document109 pagesGreek Code For Seismic Resistant Structures (EAK 2000)eltopo2No ratings yet

- COP 101 Version 12 Document (Text) June 2012Document45 pagesCOP 101 Version 12 Document (Text) June 2012DFNo ratings yet

- Asme CCase 2038-4Document2 pagesAsme CCase 2038-4ADAMJSRAONo ratings yet

- Etching and Lithography in MicrofabricationDocument8 pagesEtching and Lithography in MicrofabricationWhizzWrNo ratings yet

- Manual de Servicio Del Aire Acondicionado LGDocument39 pagesManual de Servicio Del Aire Acondicionado LGcarlosavictoriaNo ratings yet

- Roll-Up DoorDocument4 pagesRoll-Up DoorMario M. NavallascaNo ratings yet

- Ion Implantation in Silicon TechnologyDocument3 pagesIon Implantation in Silicon Technologyparu_693No ratings yet

- Analysis of Stress Distribution Around Pin Loaded Holes in Orthotropic PlatesDocument6 pagesAnalysis of Stress Distribution Around Pin Loaded Holes in Orthotropic Plateskhudhayer1970No ratings yet

- Shanta Business District - E-BrochureDocument22 pagesShanta Business District - E-Brochuretuhin.ahmedNo ratings yet

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 pagesNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnNo ratings yet

- CDW2602 Drawing Ii Study GuideDocument89 pagesCDW2602 Drawing Ii Study GuideMasithembe Tera DumezweniNo ratings yet

- 9 ThhisDocument18 pages9 ThhiskpiafoaNo ratings yet

- 21A00188 PlansDocument19 pages21A00188 PlansPDD DDCLANDNo ratings yet

- Floating Head Heat Exchanger MaintenanceDocument15 pagesFloating Head Heat Exchanger MaintenanceASWIN.MTNo ratings yet

- Potential For Earthen MaterialsDocument15 pagesPotential For Earthen MaterialstimothyNo ratings yet

- RCC14 Crack WidthDocument4 pagesRCC14 Crack Widthmoussafour100% (1)

- NA Topic 4 Bridge Design Seminar Colombo March 2016Document171 pagesNA Topic 4 Bridge Design Seminar Colombo March 2016Cesar CabreraNo ratings yet

- Non-Editorial Changes ASME BPV Code Section VIII Div. 1 - 2015 EditionDocument41 pagesNon-Editorial Changes ASME BPV Code Section VIII Div. 1 - 2015 EditionRamakrishnan AmbiSubbiahNo ratings yet

- Multi Pressure SystemsDocument14 pagesMulti Pressure SystemsDeepakNo ratings yet

- Magnetic MaterialsDocument18 pagesMagnetic MaterialsAmitKumarNo ratings yet

- Performansi Mesin Pendingin Tipe Chiller Untuk Cold Storage Dan IndoorDocument8 pagesPerformansi Mesin Pendingin Tipe Chiller Untuk Cold Storage Dan IndoorMamad ParidNo ratings yet

- Lecture 2 - PychrometryDocument90 pagesLecture 2 - PychrometryTajul Aiman Tajul AnuarNo ratings yet

- DR - Fixit Roofseal UltraDocument3 pagesDR - Fixit Roofseal Ultrareshmitapalla100% (1)