Professional Documents

Culture Documents

Qualification

Qualification

Uploaded by

Saúl Santiago Sánchez0 ratings0% found this document useful (0 votes)

38 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views5 pagesQualification

Qualification

Uploaded by

Saúl Santiago SánchezCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

USP 36 General Information / 1058 Analytical Instrument Qualification 1

1058 ANALYTICAL INSTRUMENT

QUALIFICATION

INTRODUCTION

A large variety of laboratory equipment, instruments, and

computerized analytical systems, ranging from simple nitro-

gen evaporators to complex multiple-function technologies

(see Instrument Categories), are used in the pharmaceutical

industry to acquire data to help ensure that products are

suitable for their intended use. An analysts objective is to

consistently obtain reliable and valid data suitable for the

intended purpose. Depending on the applications, users val-

idate their procedures, calibrate their instruments, and per-

form additional instrument checks, such as system suitability

Figure 1. Components of data quality. tests and analysis of in-process quality control check samples

to help ensure that the acquired data are reliable. With the

increasing sophistication and automation of analytical instru-

ments, an increasing demand has been placed on users to

qualify their instruments. Analytical Instrument Qualification

Unlike method validation and system suitability activities,

analytical instrument qualification (AIQ) currently has no AIQ is the collection of documented evidence that an in-

specific guidance or procedures. Competing opinions exist strument performs suitably for its intended purpose. Use of

regarding instrument qualification and validation procedures a qualified instrument in analyses contributes to confidence

and the roles and responsibilities of those who perform in the validity of generated data.

them. Consequently, various approaches have been used for

instrument qualification, approaches that require varying

Analytical Method Validation

amounts of resources and generate widely differing amounts

of documentation. This chapter provides a scientific ap-

Analytical method validation is the collection of docu-

proach to AIQ and considers AIQ as one of the major com-

mented evidence that an analytical procedure is suitable for

ponents required for generating reliable and consistent data.

its intended use. Use of a validated procedure with qualified

Note that the amount of rigor applied to the qualification

analytical instruments provides confidence that the proce-

process will depend on the complexity and intended use of

dure will generate test data of acceptable quality. Additional

the instrumentation. This approach emphasizes AIQs place

guidance on validation of compendial procedures may be

in the overall process of obtaining reliable data from analyti-

found in the general information chapter Validation of Com-

cal instruments.

pendial Procedures 1225.

Validation versus Qualification

System Suitability Tests

In this chapter, the term validation is used for manufac-

System suitability tests verify that the system will perform

turing processes, analytical procedures, and software proce-

in accordance with the criteria set forth in the procedure.

dures and the term qualification is used for instruments.

These tests are performed along with the sample analyses to

Thus, the phrase analytical instrument qualification (AIQ)

ensure that the systems performance is acceptable at the

is used for the process of ensuring that an instrument is

time of the test. USP general chapter Chromatography 621

suitable for its intended application.

presents a more detailed discussion of system suitability tests

as related to chromatographic systems.

COMPONENTS OF DATA QUALITY

Quality Control Check Samples

There are four critical components involved in the genera-

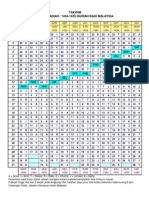

tion of reliable and consistent data (quality data). Figure 1 Many analysts carry out their tests on instruments stan-

shows these components as layered activities within a qual- dardized using reference materials and/or calibration stan-

ity triangle. Each layer adds to the overall quality. Analytical dards. Some analyses also require the inclusion of quality

instrument qualification forms the base for generating qual- control check samples to provide an in-process or ongoing

ity data. The other components essential for generating assurance of the tests suitable performance. In this manner,

quality data are analytical method validation, system suita- AIQ and analytical method validation contribute to the qual-

bility tests, and quality control check samples. These quality ity of analysis before analysts conduct the tests. System suita-

components are described below. bility tests and quality control checks help ensure the quality

of analytical results immediately before or during sample

analysis.

ANALYTICAL INSTRUMENT QUALIFICATION

PROCESS

The following sections address in detail the AIQ process.

The other three components of building quality into analyti-

cal dataanalytical method validation, system suitability

2 1058 Analytical Instrument Qualification / General Information USP 36

Table 1. Timing, Applicability, and Activities for Each Phase of Analytical Instrument Qualification*

Operational Performance

Design Qualification Installation Qualification Qualification Qualification

Timing and Applicability

Prior to purchase of a new At installation of each instrument After installation or Periodically at specified intervals

model of instrument (new, old, or existing major repair of for each instrument

unqualified) each instrument

Activities

Assurance of manufacturers Description Fixed parameters Preventive maintenance and

DQ repairs

Assurance of adequate support Instrument delivery Establish practices to address

availability from manufacturer operation, calibration,

maintenance, and change control

Utilities/facility Environment Instruments fitness for use in

laboratory Assembly and installation

Network and data storage Secure data

storage, backup,

and archive

Installation verification Instrument function Performance checks

tests

* Activities under each phase are usually performed as given in the table. However, in some cases, it may be more appropriate to perform or

combine a given activity with another phase. Such activities spanning more than one qualification phase are shown as connected by double

arrows. If an activity listed under a given phase is performed under another phase, it is not necessary to repeat the activity under the phase where

the activity is listed. Performing the activity is far more important than the phase under which the activity is performed.

tests, and quality control check samplesare not within the the selected environment, and that this environment is suit-

scope of this chapter. able for the instrument. IQ applies to an instrument that is

new or was pre-owned, or to any instrument that exists on

site but has not been previously qualified. Relevant parts of

Qualification Phases

IQ would also apply to a qualified instrument that has been

transported to another location or is being reinstalled for

Instrument qualification is not a single continuous pro-

other reasons, such as prolonged storage. The activities and

cess, but instead results from several discrete activities. For

documentation typically associated with IQ are as follows.

convenience, these activities can be grouped into four

DescriptionProvide a description of the instrument or

phases: design qualification (DQ), installation qualification

the collection of instrument components, including its man-

(IQ), operational qualification (OQ), and performance quali-

ufacturer, model, serial number, software version, and loca-

fication (PQ).

tion. Use drawings and flow charts where appropriate.

Some AIQ activities cover more than one qualification

Instrument DeliveryEnsure that the instrument, phase, and analysts potentially could perform them during

software, manuals, supplies, and any other instrument ac- more than one of the phases (see Table 1). However, in

cessories arrive as specified in the purchase order and that many instances there is need for specific order to the AIQ

they are undamaged. For a pre-owned or existing instru- activities; for example, installation qualification must occur

ment, manuals and documentation should be obtained. first in order to initiate other qualification activities. The AIQ

activities will be defined and documented. Utilities/Facility/EnvironmentVerify that the installa-

tion site satisfactorily meets manufacturer-specified environ-

mental requirements.

DESIGN QUALIFICATION

Assembly and InstallationAssemble and install the in-

strument, and perform any preliminary diagnostics and test-

Design qualification (DQ) is the documented collection of

ing. Assembly and installation may be done by the manu-

activities that define the functional and operational specifica-

facturer, vendor, specialized engineers, or qualified in-house

tions of the instrument and criteria for selection of the ven-

personnel. Manufacturer-established installation tests and

dor, based on the intended purpose of the instrument. De-

guides provide a valuable baseline reference for determining

sign qualification (DQ) may be performed not only by the

instrument acceptance. Any abnormal event observed dur-

instrument developer or manufacturer but also may be per-

ing assembly and installation merits documenting. Installa-

formed by the user. The manufacturer is generally responsi-

tion packages purchased from the manufacturer or the ven-

ble for robust design and maintaining information describ-

dor may, however, need to be supplemented with user-

ing how the analytical instrument is manufactured (design

specific criteria.

specifications, functional requirements, etc.) and tested

Network and Data StorageSome analytical systems

before shipment to users. Nonetheless, the user should en-

require users to provide network connections and data stor-

sure that commercial off-the-shelf (COTS) instruments are

age capabilities at the installation site. When required, con-

suitable for their intended application and that the manufac-

nect the instrument to the network, and check its function-

turer has adopted a quality system that provides for reliable

ality.

equipment. Users should also determine the manufacturers

capability for support installation, services, and training. This Installation VerificationPerform the initial diagnostics

determination might be aided by the users previous interac- and testing of the instrument after installation.

tion with the manufacturer.

OPERATIONAL QUALIFICATION

INSTALLATION QUALIFICATION

After a successful IQ, the instrument is ready for OQ test-

Installation qualification (IQ) is the documented collection ing. Operational qualification (OQ) is the documented col-

of activities necessary to establish that an instrument is de- lection of activities necessary to demonstrate that an instru-

livered as designed and specified, and is properly installed in ment will function according to its operational specification

USP 36 General Information / 1058 Analytical Instrument Qualification 3

in the selected environment. Testing activities in the OQ ment is used. It may also be scheduled for regular intervals.

phase may consist of these test parameters. Experience with the instrument can influence this decision.

It may be useful to repeat the same PQ tests each time the

Fixed ParametersThese tests measure the instruments

instrument is used so that a history of the instruments per-

nonchanging parameters such as length, height, weight,

formance can be compiled. Alternatively, the instrument

voltage inputs, acceptable pressures, and loads. If the manu-

may be incorporated into an integrated support system to

facturer-supplied specifications for these parameters satisfy

assure that it remains continually qualified. Some system

the user, the test requirements may be waived. However, if

suitability tests or quality control checks that are performed

the user wants to confirm the parameters, testing can be

concurrently with the test samples also imply that the in-

performed at the users site. Fixed parameters do not

strument is performing suitably.

change over the life of the instrument, and therefore never

need redetermination. [NOTEThese tests could also be per- Preventive Maintenance and RepairsWhen an instru-

formed during the IQ phase (see Table 1); if so, fixed pa- ment fails to meet PQ test specifications, it requires mainte-

rameters need not be redetermined as part of OQ testing.] nance or repair. A periodic preventive maintenance may also

be recommended for many instruments. The relevant PQ

Secure Data Storage, Backup, and ArchivingWhen

test(s) should be repeated after the needed maintenance or

applicable, test secure data handling such as storage,

repair to ensure that the instrument remains qualified.

backup, audit trails, and archiving at the users site accord-

ing to written procedures. Practices for Operation, Calibration, Maintenance, and

Change ControlEstablish practices to maintain and cali-

Instrument Function TestsInstrument functions re-

brate the instrument. Each maintenance and calibration ac-

quired by the user should be tested to verify that the instru-

tivity should be documented.

ment operates as intended by the manufacturer. Manufac-

turer-supplied information is useful in identifying

specifications for these parameters and in designing tests to

ROLES AND RESPONSIBILITIES

evaluate the identified parameters. Users, or their qualified

designees, should perform these tests to verify that the in-

strument meets manufacturer or user specifications in the

users environment. Users

The extent of OQ testing that an instrument undergoes

depends on its intended applications. Therefore, no specific Users are ultimately responsible for instrument operations

OQ tests for any instrument or application are offered in and data quality. The users group encompasses analysts,

this chapter. their supervisors, instrument specialists, and organization

Routine analytical tests do not constitute OQ testing. OQ management. Users should be adequately trained in the in-

tests are specifically designed to verify the instruments op- struments use, and their training records should be main-

eration according to specifications in the users environ- tained as required by the regulations.

ment, and repeating the testing at regular intervals may not Users should also be responsible for qualifying their instru-

be required. However, when the instrument undergoes ma- ments because their training and expertise in the use of

jor repairs or modifications, relevant OQ and/or PQ tests instruments make them the best-qualified group to design

should be repeated to verify whether the instrument contin- the instrument test(s) and specification(s) necessary for suc-

ues to operate satisfactorily. If an instrument is moved to cessful AIQ. Consultants, equipment manufacturer or ven-

another location, an assessment should be made of what, if dors, validation specialists, and quality assurance (QA) per-

any, OQ test should be repeated. sonnel can advise and assist as needed, but the final

OQ tests can be modular or holistic. Modular testing of responsibility for qualifying instruments lies with the users.

individual components of a system may facilitate interchang- The users must also maintain the instrument in a qualified

ing of such components without requalification. Holistic state by routinely performing PQ.

tests, which involve the entire system, are also acceptable.

Quality Unit

PERFORMANCE QUALIFICATION

The role of the Quality Unit in AIQ remains the same as

for any other regulated activity. Quality personnel are re- Performance qualification (PQ) is the documented collec-

sponsible for assuring that the AIQ process meets compli- tion of activities necessary to demonstrate that an instru-

ance requirements, that processes are being followed, and ment consistently performs according to the specifications

that the intended use of the equipment is supported by defined by the user, and is appropriate for the intended use.

valid and documented data. After IQ and OQ have been performed, the instruments

continued suitability for its intended use is demonstrated

through performance qualification. The PQ phase may in-

Manufacturers

clude the following parameters.

Performance ChecksSet up a test or series of tests to

Manufacturers and developers are responsible for DQ

verify the acceptable performance of the instrument for its

when designing the instrument. They are also responsible

intended use. PQ tests are usually based on the instruments

for validation of relevant processes used in manufacturing

typical on-site applications and may consist of analyzing

and assembly of the instrument. Manufacturers should test

known components or standards. The tests should be based

the assembled instruments before shipping them to users.

on good science and reflect the general intended use of the

Finally, it is desirable that manufacturers and vendors

instrument. Some system suitability tests or quality control

should notify all known users about hardware defects dis-

checks that are performed concurrently with the test sam-

covered after a products release; offer user training, service,

ples can be used to demonstrate that the instrument is per-

repair, and installation support; and invite user audits as

forming suitably. PQ tests may resemble those performed

necessary.

during OQ, but the specifications for their results may be

set differently if required. Nevertheless, user specifications

for PQ tests should demonstrate trouble-free instrument op- SOFTWARE VALIDATION

eration for the intended applications. As is the case with OQ

testing, PQ tests may be modular or holistic. Software used for analytical work can be classified into

Testing frequency depends on the ruggedness of the in- three categories: firmware; instrument control, data acquisi-

strument and the criticality of the tests performed. Testing tion, and processing software; and stand-alone software. Al-

may be unscheduledfor example, each time the instru- though software validation is not the primary focus of this

4 1058 Analytical Instrument Qualification / General Information USP 36

chapter, the following sections describe in which cases this addition as a result of the installed change. Where the

activity is under the scope of the analytical instrument change calls for additions, deletions, or revisions to the OQ

qualification. or PQ tests, follow the procedure outlined below.

Operational QualificationRevise OQ tests as necessi-

tated by the change. Perform the relevant tests affected by

Firmware

the change. This ensures the instruments effective operation

after the change is installed.

Computerized analytical instruments contain integrated

Performance QualificationRevise PQ tests as necessi- chips with low-level software (firmware). Such instruments

tated by the change. Perform the PQ testing after installa- will not function without properly operating firmware, and

tion of the change if similar testing is not already performed users generally cannot alter firmware design or function.

during OQ. In the future, perform the revised PQ testing. Firmware is therefore considered a component of the instru-

For changes to firmware and to software for instrument ment itself. Indeed, the qualification of hardware is not pos-

control, data acquisition, and processing, change control is sible without operating it via its firmware. Thus, when the

performed through DQ/IQ/OQ/PQ of the affected instru- hardware (that is, the analytical instrument) is qualified at

ment. Change control for stand-alone software requires the users site, the integrated firmware is also essentially

user-site testing of changed functionality. qualified. No separate on-site qualification of the firmware is

needed. Whenever possible, the firmware version should be

recorded as part of the IQ activities. Any changes made to

AIQ DOCUMENTATION

firmware versions should be tracked through change control

of the instrument (see Change Control, below).

Documents obtained during instrument qualification

should be retained in an accessible manner. Where multiple

Instrument Control, Data Acquisition, and instruments of one kind exist, documents common to all

instruments and documents specific to an instrument may Processing Software

be stored separately. During change control, additional doc-

uments may supplement those obtained during the qualifi- Software for instrument control, data acquisition, and pro-

cation process, and both sets of documents should be re- cessing for many of todays computerized instruments is

tained and maintained in a suitable manner that allows for loaded on a computer connected to the instrument. Opera-

appropriate protection and access. tion of the instrument is then controlled via the software,

leaving fewer operating controls on the instrument. Also,

the software is needed for data acquisition and postacquisi-

INSTRUMENT CATEGORIES

tion calculations. Thus, both hardware and software, their

functions inextricably intertwined, are critical to providing

Modern laboratories typically include a suite of instru-

analytical results.

ments and equipment varying from simple nitrogen evapo-

The manufacturer should perform DQ, validate this

rators to complex automated instruments. Therefore, apply-

software, and provide users with a summary of validation.

ing a single set of principles to qualifying such dissimilar

At the user site, holistic qualification, which involves the en-

instruments would be scientifically inappropriate. Users are

tire instrument and software system, is more efficient than

most capable of establishing the level of qualification

modular validation of the software alone. Thus, the user

needed for an instrument. On the basis of the level needed,

qualifies the instrument control, data acquisition, and pro-

it is convenient to categorize instruments into three groups:

cessing software by qualifying the instrument according to

A, B, and C, as defined below. Examples of instruments in

the AIQ process.

each group are provided. Note that the list of instruments

provided here is for illustration only and is not meant to be

Stand-Alone Software exhaustive. It does not provide the exact category for an

instrument at a user site. That category should be deter-

An authoritative guide for validating stand-alone software, mined by users for their specific instruments or applications.

such as LIMS, is available.

1

The validation process is adminis- The exact grouping of an instrument must be determined

tered by the software developer, who also specifies the de- by users for their specific requirements. Depending on indi-

velopment model appropriate for the software. Validation vidual user requirements, the same instrument may appro-

takes place in a series of activities planned and executed priately fall into one group for one user and another group

through various stages of the development cycle. for another user. Therefore, a careful selection of groups by

users is highly encouraged.

CHANGE CONTROL

Group A

Changes to instruments, including software, become inev-

Group A includes standard equipment with no measure- itable as manufacturers add new features and correct known

ment capability or usual requirement for calibration, where defects. However, implementing all such changes may not

the manufacturers specification of basic functionality is ac- always benefit users. Users should therefore adopt changes

cepted as user requirements. Conformance of Group A they deem useful or necessary and should also assess the

equipment with user requirements may be verified and doc- effects of changes to determine what, if any, requalification

umented through visual observation of its operation. Exam- is required. The change control process enables them to do

ples of equipment in this group are nitrogen evaporators, this.

magnetic stirrers, vortex mixers, and centrifuges. Change control may follow the DQ/IQ/OQ/PQ classifica-

tion process. For DQ, evaluate the changed parameters, and

determine whether need for the change warrants imple-

Group B

menting it. If implementation of the change is needed, in-

stall the changes to the system during IQ. Evaluate which of

Group B includes standard equipment and instruments

the existing OQ and PQ tests need revision, deletion, or

providing measured values as well as equipment controlling

1

General Principles of Software Validation: Final Guidance for Industry and FDA physical parameters (such as temperature, pressure, or flow)

Staff, U.S. Department of Health and Human Services, Food and Drug Admin-

that need calibration, where the user requirements are typi-

istration, Rockville, MD, January 11, 2002. http://www.fda.gov/Medi-

cally the same as the manufacturers specification of func-

calDevices/DeviceRegulationandGuidance/GuidanceDocuments/ucm085281.

tionality and operational limits. Conformance of Group B htm (accessed December 2012.

instruments or equipment to user requirements is deter-

USP 36 General Information / 1058 Analytical Instrument Qualification 5

mined according to the standard operating procedures for atomic absorption spectrometers

the instrument or equipment, and documented during IQ differential scanning calorimeters

and OQ. Examples of instruments in this group are bal- dissolution apparatus

ances, melting point apparatus, light microscopes, pH me- electron microscopes

ters, variable pipets, refractometers, thermometers, titrators, flame absorption spectrometers

and viscometers. Examples of equipment in this group are high-pressure liquid chromatographs

muffle furnaces, ovens, refrigerator-freezers, water baths, mass spectrometers

pumps, and dilutors. microplate readers

thermal gravimetric analyzers

X-ray fluorescence spectrometers

Group C

X-ray powder diffractometers

densitometers

Group C includes instruments and computerized analytical

diode-array detectors

systems, where user requirements for functionality, opera-

elemental analyzers

tional, and performance limits are specific for the analytical

gas chromatographs

application. Conformance of Group C instruments to user

IR spectrometers

requirements is determined by specific function tests and

near-IR spectrometers

performance tests. Installing these instruments can be a

Raman spectrometers

complicated undertaking and may require the assistance of

UV/Vis spectrometers

specialists. A full qualification process, as outlined in this

inductively coupled plasma-emission spectrometers

document, should apply to these instruments. Examples of

instruments in this group include the following:

You might also like

- Mapa Modbus Lufkin RPC V6.16Document104 pagesMapa Modbus Lufkin RPC V6.16juanjovm77No ratings yet

- 1NZ-FE Engine Description PDFDocument17 pages1NZ-FE Engine Description PDFjuanNo ratings yet

- Validation Vs QualificationDocument1 pageValidation Vs QualificationKiran ChokshiNo ratings yet

- CSV SopDocument1 pageCSV SopjeetNo ratings yet

- Presentation On Busbar Arrangement, 87B & 50BF ProtectionDocument55 pagesPresentation On Busbar Arrangement, 87B & 50BF Protectionabu sayedNo ratings yet

- Completed Jen and Larry's Mini Case Study Working Papers Fall 2014Document10 pagesCompleted Jen and Larry's Mini Case Study Working Papers Fall 2014ZachLoving100% (1)

- 1058 Analytical Instrument QualificationDocument8 pages1058 Analytical Instrument QualificationmagicianchemistNo ratings yet

- ISO/GMP/FDA Training Validation: Topic: Date: 2/23/2012 Facility: SS White India Trainer: Hollie JohnsonDocument17 pagesISO/GMP/FDA Training Validation: Topic: Date: 2/23/2012 Facility: SS White India Trainer: Hollie JohnsonMitulNo ratings yet

- FeasibilityDocument8 pagesFeasibilityOTNo ratings yet

- Missing Functional Level Access Control: OWASP Web App Top 10Document6 pagesMissing Functional Level Access Control: OWASP Web App Top 10erickNo ratings yet

- Instrument Risk AssessmentDocument5 pagesInstrument Risk AssessmentJinna SmaNo ratings yet

- Ahura TruScan ManualDocument116 pagesAhura TruScan ManualMarc HoffmanNo ratings yet

- General RequirementsDocument8 pagesGeneral RequirementsRaviTejaMeganathanNo ratings yet

- Lecture 9 - QAQC PDFDocument37 pagesLecture 9 - QAQC PDFTMTNo ratings yet

- Basic Aspects of Process Validation of Solid Oral Dosage FormsDocument15 pagesBasic Aspects of Process Validation of Solid Oral Dosage FormsAbeer TamimiNo ratings yet

- DataQUCM IP2014Document286 pagesDataQUCM IP2014Ayush_21No ratings yet

- WHOPIR LPR 04-06dec2019Document13 pagesWHOPIR LPR 04-06dec20196E.57Pawar RushiNo ratings yet

- Honey Analysis by HPLCDocument3 pagesHoney Analysis by HPLCOmar BinshehabNo ratings yet

- Data Integrity PDFDocument25 pagesData Integrity PDFencelleNo ratings yet

- Dell EMC Validates Your Virtualized Genetec Video Management System Before It Reaches Your HandsDocument11 pagesDell EMC Validates Your Virtualized Genetec Video Management System Before It Reaches Your HandsPrincipled TechnologiesNo ratings yet

- Issuance of DocumentsDocument2 pagesIssuance of DocumentsAshok KumarNo ratings yet

- Oos SopDocument10 pagesOos SopSolomonNo ratings yet

- GES 501 - Instrument Calibration Ver 4Document31 pagesGES 501 - Instrument Calibration Ver 4muhammad nomanNo ratings yet

- Mark PDFDocument42 pagesMark PDFdavincicode888No ratings yet

- Yaswanth V&VDocument3 pagesYaswanth V&VValidationNo ratings yet

- Data Validation, Processing, and Reporting Data ValidationDocument8 pagesData Validation, Processing, and Reporting Data ValidationNaga Ajay Kumar DintakurthiNo ratings yet

- Gravimetric Calibration Testing Pova Iso8655 White Paper en 1 DataDocument7 pagesGravimetric Calibration Testing Pova Iso8655 White Paper en 1 DataJhon David VillanuevaNo ratings yet

- Quality ControlDocument78 pagesQuality ControlAhmad Yusrizal FaizinNo ratings yet

- Abraham Lincoln: ContactDocument1 pageAbraham Lincoln: ContactMiguel Angel Condori RoqueNo ratings yet

- SaivDocument5 pagesSaivRohith korrapatiNo ratings yet

- RTP 10i Tablet Press IQ/OQ: We Don't Just Sell Machines - We Provide ServiceDocument34 pagesRTP 10i Tablet Press IQ/OQ: We Don't Just Sell Machines - We Provide ServiceAndreas StathatosNo ratings yet

- Omgoing Stability Testing - Innovations - in - Pharmaceutical - TechnologyDocument3 pagesOmgoing Stability Testing - Innovations - in - Pharmaceutical - TechnologyJuan RojasNo ratings yet

- SOP-000182637 Phase 1a Investigation ChecklistDocument2 pagesSOP-000182637 Phase 1a Investigation ChecklistSebastian LopezNo ratings yet

- Empower 2 21 CFR 11 Compliance WorksheetDocument14 pagesEmpower 2 21 CFR 11 Compliance Worksheetjeet100% (1)

- Changing Room: Estoque, Carmela Kate Q. Baria, Jemmalyn R January 21, 2017 January 21, 2017Document3 pagesChanging Room: Estoque, Carmela Kate Q. Baria, Jemmalyn R January 21, 2017 January 21, 2017jemma bariaNo ratings yet

- CG - Webinar - CSA - Guidelines From FDA - Final Post Webinar v4.7 PDFDocument13 pagesCG - Webinar - CSA - Guidelines From FDA - Final Post Webinar v4.7 PDFAbdessamad IsmailiNo ratings yet

- OOT NWDocument2 pagesOOT NWSagar ChavanNo ratings yet

- QMS InspectionDocument41 pagesQMS InspectionJulienne Dela CruzNo ratings yet

- Validation Protocol, HVAC I O PQDocument52 pagesValidation Protocol, HVAC I O PQSf BztprkNo ratings yet

- Variations TGADocument128 pagesVariations TGAJaime Andrés García BNo ratings yet

- Validation and Qualification of Pharmaceutical ProductsDocument25 pagesValidation and Qualification of Pharmaceutical ProductsUgas Husen100% (1)

- CGMP GuidelinesDocument23 pagesCGMP GuidelinesRyan 1112No ratings yet

- Simultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFDocument7 pagesSimultaneous Determination of Methylparaben + Propylparaben + Hidrocortisone Topical Cream PDFNájla KassabNo ratings yet

- Turkey Qualification ValidationDocument28 pagesTurkey Qualification ValidationBalesh NidhankarNo ratings yet

- QP-QA-03-Final InspectionDocument2 pagesQP-QA-03-Final InspectionDebkanta Das100% (1)

- 4 Egac SystemDocument55 pages4 Egac SystemWaleed El-azabNo ratings yet

- DMF Guidance For Submission V 1.0Document14 pagesDMF Guidance For Submission V 1.0Raj DesaiNo ratings yet

- GMP Failure InvestigationDocument3 pagesGMP Failure InvestigationYousifNo ratings yet

- Supplementary Training Modules On Good Manufacturing PracticeDocument31 pagesSupplementary Training Modules On Good Manufacturing Practicesagaram_sNo ratings yet

- Guideline On Stability Testing For Applications For Variations To A Marketing AuthorisationDocument8 pagesGuideline On Stability Testing For Applications For Variations To A Marketing Authorisation刘朝阳No ratings yet

- Verification of Compendia Methods - 7jun2013 - KMDocument52 pagesVerification of Compendia Methods - 7jun2013 - KMnsk79in@gmail.comNo ratings yet

- VAL - 170401 - BMAA VAL Activity 3 URS - Template PDFDocument10 pagesVAL - 170401 - BMAA VAL Activity 3 URS - Template PDFDineshNo ratings yet

- DataDocument4 pagesDatavg_vvgNo ratings yet

- Agilent Audit Trail Software 914942 PDFDocument85 pagesAgilent Audit Trail Software 914942 PDFMorcos LokaNo ratings yet

- Life Cycle ModelsDocument196 pagesLife Cycle ModelsSaliniNo ratings yet

- Validation of Mixer Double Cone BlenderDocument6 pagesValidation of Mixer Double Cone BlenderSyed RizviNo ratings yet

- Swapna Ramidi: SR Validation EngineerDocument3 pagesSwapna Ramidi: SR Validation EngineerVijay LS SolutionsNo ratings yet

- Validation Master PlanDocument3 pagesValidation Master PlangauravphdNo ratings yet

- VAL - 170401 - BMAA VAL Activity 3 URS - TemplateDocument10 pagesVAL - 170401 - BMAA VAL Activity 3 URS - TemplateEcolor SRL100% (1)

- Events Presentations Raci 121126Document22 pagesEvents Presentations Raci 121126mokhtari asmaNo ratings yet

- Professional SummaryDocument3 pagesProfessional SummaryVijay LS SolutionsNo ratings yet

- Empower 3 FR3: System Administrator's GuideDocument80 pagesEmpower 3 FR3: System Administrator's GuideJailer AlvearNo ratings yet

- Reg A USP 1058 Analytical Instrument QualificationDocument8 pagesReg A USP 1058 Analytical Instrument QualificationRomen MoirangthemNo ratings yet

- Ee3 Idiots 2009 Hindi DVDRip XviD E-SuB XRGDocument160 pagesEe3 Idiots 2009 Hindi DVDRip XviD E-SuB XRGSyipah ImahNo ratings yet

- Acriminal - minds.S01E04.DVDRip - Xvid TOPAZDocument44 pagesAcriminal - minds.S01E04.DVDRip - Xvid TOPAZSyipah ImahNo ratings yet

- Announcement To All Students On Examination SlipDocument2 pagesAnnouncement To All Students On Examination SlipSyipah ImahNo ratings yet

- Stress and SatisfactionDocument7 pagesStress and SatisfactionSyipah ImahNo ratings yet

- 11 ReflectionDocument8 pages11 ReflectionSyipah ImahNo ratings yet

- Takwim 2013Document1 pageTakwim 2013Syipah ImahNo ratings yet

- Satria Neo EastmalaysiaDocument2 pagesSatria Neo EastmalaysiaSyipah ImahNo ratings yet

- Poverty and InequalityDocument8 pagesPoverty and InequalityKristineMaeMagoTejadaNo ratings yet

- Facilitate Learning SessionDocument8 pagesFacilitate Learning SessionJoviner Yabres LactamNo ratings yet

- CONTI Industrial Valves CatalogDocument72 pagesCONTI Industrial Valves CatalogAlvaro Manuel Abian FernandezNo ratings yet

- Nitroeyhane 121Document19 pagesNitroeyhane 121dogandodog100% (1)

- Family LawDocument10 pagesFamily LawPRIYANSHI BAINWALANo ratings yet

- Multinational Companies - Marxist TheoryDocument2 pagesMultinational Companies - Marxist TheoryGiorgos AnastopoulosNo ratings yet

- Heinz ContractDocument3 pagesHeinz ContractDaniel CookNo ratings yet

- SITHKOP009 Assessment Task 1 V10.0Document24 pagesSITHKOP009 Assessment Task 1 V10.0Anchisa SarnkhoksungNo ratings yet

- Evaluation of Sensors: For Mine Fire Detection Using An Atmospheric Monitoring SystemDocument9 pagesEvaluation of Sensors: For Mine Fire Detection Using An Atmospheric Monitoring SystemMario GaitanNo ratings yet

- Mr5 ManualDocument16 pagesMr5 ManualShakazooka Shakawah Kcir SamejjNo ratings yet

- Dam Safety and Monitoring InstrumentationDocument4 pagesDam Safety and Monitoring Instrumentationina_criNo ratings yet

- Arta - Application Note: No 1: The Arta MeasuringboxDocument10 pagesArta - Application Note: No 1: The Arta MeasuringboxAlessandro BiliottiNo ratings yet

- Terminal:Port of ABCXYZ Baseline Criteria Compliance Assessment ScorecardDocument3 pagesTerminal:Port of ABCXYZ Baseline Criteria Compliance Assessment ScorecardsandralimisaNo ratings yet

- The Internet of Things 2005Document212 pagesThe Internet of Things 2005mvs87No ratings yet

- Zabit Acer - Ottoman ModernizationDocument7 pagesZabit Acer - Ottoman ModernizationSenad HasanagićNo ratings yet

- RovenskiDocument2 pagesRovenskiLeo KutsNo ratings yet

- Japanese Mayo: Leave Comments BelowDocument12 pagesJapanese Mayo: Leave Comments BelowLancemachang EugenioNo ratings yet

- Newmark BnonlinearDocument2 pagesNewmark BnonlinearDivy JainNo ratings yet

- Multiple-Choice-Questions FinalDocument3 pagesMultiple-Choice-Questions FinalFreann Sharisse Austria100% (1)

- Lab ManualDocument95 pagesLab ManualKalpit KauraseNo ratings yet

- Syntheses, Structures, and Magnetic Behavior of New Azide Linked Compounds With One-And Two-Dimensional StructuresDocument9 pagesSyntheses, Structures, and Magnetic Behavior of New Azide Linked Compounds With One-And Two-Dimensional StructuresSubhradeep MistryNo ratings yet

- Farmers Testimonial For SubtitleDocument5 pagesFarmers Testimonial For Subtitlemark dela ramaNo ratings yet

- COM2014 PAPERID-8565Thwaites ProtectedDocument44 pagesCOM2014 PAPERID-8565Thwaites ProtectedmineralmadnessNo ratings yet

- Bi-Directional Replication: With Conflict Detection and Resolution (CDR) Using Oracle Goldengate 12CDocument25 pagesBi-Directional Replication: With Conflict Detection and Resolution (CDR) Using Oracle Goldengate 12CNainika KedarisettiNo ratings yet

- d-Copia300MF 400MF 500MFaien548702Document290 pagesd-Copia300MF 400MF 500MFaien548702rokebyschoolNo ratings yet

- Proposal Teknis Project. GITC Duri Pulo - Fire PumpDocument25 pagesProposal Teknis Project. GITC Duri Pulo - Fire PumpSyncroFlo IndonesiaNo ratings yet