Professional Documents

Culture Documents

EuroDish - Stirling

EuroDish - Stirling

Uploaded by

Puzi Ultraapandi0 ratings0% found this document useful (0 votes)

14 views9 pagespengaplikasian stirling engine

Original Title

EuroDish – Stirling

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpengaplikasian stirling engine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views9 pagesEuroDish - Stirling

EuroDish - Stirling

Uploaded by

Puzi Ultraapandipengaplikasian stirling engine

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 9

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

Stuttgart; June, 2001

EuroDish Stirling

System Description

A new decentralised Solar

Power Technology

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

Stuttgart; June, 2001

Content:

1. The Dish - Stirling System

2. The Concentrator

3. The Tracking System

4. The Stirling Engine

5. Function of the Stirling Engine

6. The Receiver

7. Technical Data

The Project was co-financed by:

European Community under Contract No. Jor3-CT98-0242

Page - 3

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

General description of

EuroDish Stirling System

Stuttgart; June, 2001

1. The Dish-Stirling System

Dish-Stirling Systems transfer concentrated

solar radiation with high efficiencies into electrical

energy. Essentially the system consists of the fol-

lowing components:

Parabolic solar concentrator

Tracking system

Solar heat exchanger (Receiver)

Stirling engine with generator

The parabolic concentrator reflects the incoming

solar radiation onto a cavity receiver which is

located at the concentrators focal point. The solar

radiation is absorbed by the heat exchanger

(receiver) and thus heats the working gas (helium)

of the Stirling engine to temperatures of about

650

o

C. This heat is converted into mechanical

energy by the Stirling engine. An electrical

generator, directly connected to the crankshaft of

the engine, converts the mechanical energy into

electricity (AC). To constantly keep the reflected

radiation at the focal point during the day, a sun-

tracking system rotates the solar concentrator

continuously about two axes to follow the daily path

of the sun.

The electrical output of the system is proportional

to the size of the reflector, its optical losses and the

efficiencies of the Stirling engine and the generator.

Dish-Stirling Systems are small power generation sets which generate electricity by using di-

rect solar radiation. The capacity of a single unit is typically between 5 and 25 (50) kW

el

. This

size and the modularity of the single units qualifies the Dish-Stirling system for very flexible

applications. They are ideal for stand-alone or other decentralised applications. In clusters

with a capacity of up to 10 MW, Dish-Stirling systems are even expected to meet moderate-

scale grid-connected demands.

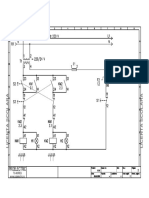

Concentrator shell

Elevation bearing

Concentrator ring truss

Switch case

Stirling engine package

Stirling support structure

Turntable

Azimuth drive arc

Reinforced concrete ring foundation

Azimuth drive

Elevation drive arc

Page - 4

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

General description of

EuroDish Stirling System

Stuttgart; June, 2001

2. The Concentrator

3. The Tracking System

Generally speaking the con-

centrator delivers the fuel for

the Stirling engine. It reflects

and concentrates the direct solar

radiation in the so-called focal

point. For the operation of the

Stirling engine, temperatures as

high as possible are desired.

Therefore a large point-focus

concentrator with an axial

symmetrical shape is used for

this system.

The concentrator consists out of

12 single segments made out of

glass fibre resin. When

mounted the segments form a

nearly perfect parabolic shell.

The rim of the shell is stiffened

by a ring truss to which later on

the bearings and the Stirling

support structure are attached.

Thin glass mirrors, 0.8 mm

thick, are glued onto the front

side of the segments in order to

obtain a durable high reflectiv-

ity of around 94%.

Since the concentrator

always needs to be per-

fectly oriented towards the

sun, it is mounted on a

two-axial tracking sys-

tem. Therefore a simple

movable steel construction

standing on six wheels has

been developed. Both the

horizontal and the vertical

orientation of the concen-

trator is done by a small

servomotor.

The orientation towards the

sun is either determined by

a sun tracking sensor, or by

a special computer program

which predicts the position

of the sun.

Page - 5

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

General description of

EuroDish Stirling System

Stuttgart; June, 2001

4. The Stirling - Engine

The Stirling cycle is the most efficient

thermodynamic cycle to transform heat into

mechanical or electrical energy. As far back as in

1826 the Stirling engine was invented by the

Scottish Rev. Robert Stirling. In the 19

th

century

thousands of engines of this type had already been

in use. The Stirling engine has some extraordinary

properties:

Compared to an Otto or Diesel engine, which

runs on internal combustion, the Stirling en-

gine depends only on external heat supply,

with no preference on how the heat is gener-

ated. Thus the Stirling engine is the ideal can-

didate to convert solar heat into mechanical

energy.

In the Stirling engine a constant amount of

working gas (helium or hydrogen) is constantly

heated and cooled. Due to expansion when

heated and contraction when cooled, the work-

ing gas sets two pistons in motion, which both

are connected to a crankshaft, and thus delivers

energy.

Since the efficiency of the Stirling engine in-

creases with increasing upper process tempera-

ture, this engine is the ideal combination to pro-

duce energy with a solar collector.

As there is no internal combustion, this engine

produces almost no noise.

The potential life-cycle of a Stirling engine is

extraordinarily high since there is no internal

pollution of pistons and bearings due to combus-

tion of fuels.

Due to the flexibility of the heat source, a Stir-

ling engine can also be operated with a hybrid

receiver. This means that with an additionally

installed burner, the required heat can also be

generated with fossil fuels (Bio-gas etc.).Thus

the system is also available during cloudy peri-

ods and during night-time.

As a hybrid operated system, especially when using

Bio-gas as additional energy source, the Dish-

Stirling system fulfils all the requirements which

can be demanded from a future oriented, environ-

mentally friendly energy system.

Schlaich Bergermann und Partner (SBP) together with SOLO developed the V160/V161 Stirling engine

seen in the pictures. This is currently the most reliable and most advanced Stirling engine available (Pic-

ture with solar-only receiver).

Page - 6

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

General description of

EuroDish Stirling System

Stuttgart; June, 2001

5. Function of the Stirling Engine

In the most simple version, a Stirling engine consists of a sealed

system with two cylinders (expansion and compression cylinder)

filled with a working gas (helium). The pistons of these cylinders

are connected to one crankshaft. If now the working gas in the

expansion cylinder (working cylinder) is heated (by the sun) it

will expand due to the increasing temperature; pushes the piston

down (1-2) and thus induces power. Part of this power is now

used to push the hot working gas from the expansion cylinder into

the compression cylinder (2-3): On its way the working gas

passes through a regenerator where a major part of its heat is

stored and also through a water cooled gas cooler, where it will be

cooled further down. (2-3).Once completely in the compression

cylinder, this piston will return due to the inertia of the crankshaft,

and the working gas is compressed at low temperature (3-4). By

reabsorbing the heat stored in the regenerator the gas is pushed

back into the working cylinder. (4-1).

Overall the expansion of the hot gas in the working cylinder de-

livers more energy than is needed for the compression of the cold

gas in the compression cylinder. This surplus of energy can be

used to operate an electric generator which is directly hooked to

the crankshaft of the engine.

1

4

P

r

e

s

s

u

r

e

Volume

3

2

T

e

m

p

e

r

a

t

u

r

e

3 4

1 2

T

H

T

K

Entropie

Compression

Cylinder

Solar Radiation

Expansion

Cylinder

Cooler

Regenerator

4-1 Displacement of the Gas into the Expansion

Cylinder and recharing of the stored heat

in the Regenerator

4

2

Compression

Cylinder

Solar Radiation

Expansion

Cylinder

Cooler

Regenerator

2-3 Displacement of the Working gas into the

Compression Cylinder and

heat storage in the Regenerator

Compression

Cylinder

Solar Radiation

Expansion

Cylinder

Helium

Cooler

Regenerator

3-4 Compression of the cold Working Gas;

T = const.

3

1

Solar Radiation

Expansion

Cylinder

Compression

Cylinder

Helium

Cooler

Regenerator

1-2 Heating and expansion of the Working Gas;

T = const.

Page - 7

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

General description of

EuroDish Stirling System

Stuttgart; June, 2001

6. The Receiver: Link between Collector and Engine

The receiver is the link between the concentrator

and the Stirling engine. It has essentially two tasks:

1. To absorb as much of the solar radiation re-

flected onto it from the concentrator as possible.

2. To pass on this absorbed energy to the Stirling

engine in form of heat with the least possible

losses.

In general there are two types of receivers. One type

is a solar-only receiver which can only be operated

during sunshine. The other type is a hybrid receiver

which is additionally equipped with a gas burner

and can be operated the whole day.

As solar-only receiver, a

tube receiver was developed

which is directly connected

to the cylinder heads of the

Stirling engine. The re-

ceiver consists of very thin

tubes, approx. 3mm in di-

ameter, which resist very

high temperatures. They

form an almost closed area

which is the absorber sur-

face. The concentrated solar

radiation heats the working

gas to approx. 650

o

C.

Solar Receiver for the SBP/SOLO V-160/161 Stirling engine

Hybrid Receiver (DLR)

In addition to the solar ab-

sorbing surface, the hybrid

receiver is equipped with a

gas burner. Thus the Stirling

engine can be operated during

times when the sun is covered

with clouds or even in dark-

ness. The hybrid Dish-Stirling

system thus has the advantage

of being available 24 hours a

day. Therefore this system

can be the ideal substitute for

Diesel engines which are

currently used to high num-

bers.

Page - 8

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

General description of

EuroDish Stirling System

Stuttgart; June, 2001

7. Technical Data

Concentrator

Diameter 8.5 m

Projected area 56.7 m

Focal Length 4.5 m

Average concentration factor 2500

Reflectivity 94 %

Tracking and Control Partners

Suspension azimuth Schlaich Bergermann und Partner; D

Stow position face down SOLO Kleinmotoren GmbH; D

max. allowable wind velocity during operation 65 km/h Klein+Stekl GmbH; D

Survival wind velocity in stow position 160 km/h MERO-Raumstruktur GmbH&Co; D

Drive servo motor DLR eV; D

Drive velocity 60 /min. Inabensa SA; ES

Control system PC, micro controller CIEMAT; ES

Data transfer InterBus-S

Remote control telephone / WWW

Stirling engine

Type single acting, 90 V-engine

Swept volume 160 cm

Gross power output 9 kW

Net power output 8.4 kW

Grid connection 400 V, 50 Hz, 3 phase

Receiver gas temperature 650 C

Working gas helium

Gas pressure 20-150 bar

Power control pressure control

Page - 9

Schlaich Bergermann

und Partner GbR

Structural Consulting Engineers

General description of

EuroDish Stirling System

Stuttgart; June, 2001

Contact for Inquiries and Project Proposals:

Partner in the co-operation

Contact person Address

Schlaich Bergermann

und Partner GbR

Dipl. Phys. W. Schiel Hohenzollernstrae

D 70178 Stuttgart/Germany

Tel.: +49 711 / 6 48 71-0

Fax: +49 711 / 6 48 71-66

http: www.sbp.de

e-mail: w.schiel@sbp.de

MERO-Raumstruktur GmbH&Co Mr. Rb Max-Mengeringhausenstrae 5

D-97084 Wrzburg/Germany

Tel: +49 931 6670-0

Fax: +49 931 6670-535

e-mail: Guenter.rueb@mero.de

You might also like

- Audi A3-A4 Hidden Secret Service MenuDocument4 pagesAudi A3-A4 Hidden Secret Service MenuKakasi HatakeNo ratings yet

- Competency 4Document2 pagesCompetency 4Jae RiondangaNo ratings yet

- Chapter-1: Nuclear Power PlantDocument14 pagesChapter-1: Nuclear Power PlantMohammad AmmarNo ratings yet

- E1 Characteristic Curve of The Fuel CellDocument4 pagesE1 Characteristic Curve of The Fuel Celllianghong.koh5914100% (1)

- Fyp ThesisDocument54 pagesFyp ThesisLindsay WestNo ratings yet

- Photovoltaic Thermal Hybrid Solar CollectorDocument4 pagesPhotovoltaic Thermal Hybrid Solar CollectorFrederic WustNo ratings yet

- A Two-Stage Stirling CryocoolerDocument7 pagesA Two-Stage Stirling CryocoolerrkoGearNo ratings yet

- Factory Io Assembler Structurat OB1Document3 pagesFactory Io Assembler Structurat OB1fcompart100% (1)

- Lab-Report-Dishwashing FinallDocument3 pagesLab-Report-Dishwashing FinallKyle BanceNo ratings yet

- Flaktwoods Final DrawingDocument180 pagesFlaktwoods Final DrawingBui Duy ThanhNo ratings yet

- Power Generation With Solar Dish Stirling EngineDocument6 pagesPower Generation With Solar Dish Stirling EngineFaysal Abdul FattahNo ratings yet

- Introduction in Stirling EngineDocument4 pagesIntroduction in Stirling EngineTzvetelina PetrovaNo ratings yet

- Electricity Generation Using Solar Powered Stirling Engine: Blessy Joy, Priya John, Anjuman Habeeb, Jeffy Marin JoseDocument5 pagesElectricity Generation Using Solar Powered Stirling Engine: Blessy Joy, Priya John, Anjuman Habeeb, Jeffy Marin JoseIntan Vara DibaNo ratings yet

- Solar Power Tower123Document16 pagesSolar Power Tower123Quaks143No ratings yet

- Stirling CycleDocument23 pagesStirling CycleRishi KulkarniNo ratings yet

- Mini Solar Water HeaterDocument23 pagesMini Solar Water HeaterROCKY DUBEYNo ratings yet

- A Review On Working of Compressor Less RefrigeratorDocument4 pagesA Review On Working of Compressor Less RefrigeratorSelvaraji MuthuNo ratings yet

- Solar Thermal Power PlantDocument32 pagesSolar Thermal Power Plantvigneshgemini100% (1)

- Energy Conversion DevicesDocument20 pagesEnergy Conversion Devicessanjay sajeevNo ratings yet

- Final Year Project SynopsisDocument3 pagesFinal Year Project SynopsisEngr Majid Ali BaigNo ratings yet

- A Detailed Thermal Model of A Parabolic Trough Collector Receiver PDFDocument9 pagesA Detailed Thermal Model of A Parabolic Trough Collector Receiver PDFAnikilatorBoy100% (1)

- Solar Thermal Energy Part 1Document19 pagesSolar Thermal Energy Part 1Tushar SanwareyNo ratings yet

- Heat Balance Test On Computerised Single Cylinder Diesel Engine Fitted With Eddy Current DynamometerDocument4 pagesHeat Balance Test On Computerised Single Cylinder Diesel Engine Fitted With Eddy Current DynamometerNagaraj MuniyandiNo ratings yet

- Principles of Direct Thermoelectric Conversion - Heat Input EquationDocument15 pagesPrinciples of Direct Thermoelectric Conversion - Heat Input EquationhportezNo ratings yet

- Recent Concepts in Thermoelectric Power Generation: (1,2) - Two Factors WereDocument10 pagesRecent Concepts in Thermoelectric Power Generation: (1,2) - Two Factors WereRajakumar DNo ratings yet

- Solar Powered Stirling Engine Driven Water PumpDocument6 pagesSolar Powered Stirling Engine Driven Water PumpInternational Journal of Research in Engineering and TechnologyNo ratings yet

- 1361450193chapter 05 Parabolic TroughDocument106 pages1361450193chapter 05 Parabolic Troughpthakur234No ratings yet

- Fuel CellsDocument6 pagesFuel CellsJayan PillaiNo ratings yet

- Classification of Heat EnginesDocument20 pagesClassification of Heat EnginesParva ShrivastavaNo ratings yet

- Photovoltaic Thermal PV-T Systems A ReviewDocument6 pagesPhotovoltaic Thermal PV-T Systems A ReviewIJOCAASNo ratings yet

- ARESDocument64 pagesARESHarshal SonarNo ratings yet

- Seminar ReviewDocument13 pagesSeminar ReviewRutuja JadhavNo ratings yet

- Solar RefrigeratorDocument12 pagesSolar RefrigeratorSheeraz AliNo ratings yet

- Synchronous MachineDocument32 pagesSynchronous MachineVishal MaheshwariNo ratings yet

- Biomass Supported Solar Thermal Hybrid Power Plant FinalDocument17 pagesBiomass Supported Solar Thermal Hybrid Power Plant Finaltejasammidi100% (1)

- Introduction To Super CapacitorsDocument28 pagesIntroduction To Super CapacitorsLokesh EshwaraiahNo ratings yet

- Seminar PPT On Solar Updraft TowerDocument23 pagesSeminar PPT On Solar Updraft TowerM Sajid Chry100% (7)

- Modelling and Simulation of Hybrid Micro Grid Employing DG, PV, Wind and Fuel CellDocument7 pagesModelling and Simulation of Hybrid Micro Grid Employing DG, PV, Wind and Fuel Cellرافع العرفيNo ratings yet

- Biomass Supported Solar Thermal Hybrid Power PlantDocument3 pagesBiomass Supported Solar Thermal Hybrid Power PlantRaghav MestaNo ratings yet

- Lead Acid Battery DesulphatorDocument2 pagesLead Acid Battery Desulphatoricarus_fallenNo ratings yet

- Electricity From Magnetism CH 18.3 8thDocument23 pagesElectricity From Magnetism CH 18.3 8ththegedusNo ratings yet

- Parabolic Dish ConcentratorDocument1 pageParabolic Dish ConcentratorArjunSinghNo ratings yet

- Introduction To Non Conventional Energy SystemsDocument234 pagesIntroduction To Non Conventional Energy SystemsCarib100% (1)

- Parabolic Trough Solar CollectorDocument42 pagesParabolic Trough Solar CollectorMahrukh ZAIDI100% (2)

- Introduction To Solar RefrigeratorDocument2 pagesIntroduction To Solar RefrigeratorChetna KohliNo ratings yet

- Flujo de Aire PDFDocument10 pagesFlujo de Aire PDFJoffre Lautaro Benavides Seminario100% (1)

- Thermal Energy Storage SystemsDocument69 pagesThermal Energy Storage SystemsPundarika G Ganga NaikNo ratings yet

- Energies: Experimental and Numerical Analyses of A Flat Plate Photovoltaic/Thermal Solar CollectorDocument21 pagesEnergies: Experimental and Numerical Analyses of A Flat Plate Photovoltaic/Thermal Solar CollectorAmmar Bany AtaNo ratings yet

- Simulink Dfig Lab - 061114Document8 pagesSimulink Dfig Lab - 061114Fer AguvegNo ratings yet

- Laser Ignition SystemDocument6 pagesLaser Ignition SystemAkshay KakaniNo ratings yet

- Research PaperDocument5 pagesResearch Paper2692rimmiNo ratings yet

- Information About The Electric Iron Invention: How An Electric Iron WorksDocument6 pagesInformation About The Electric Iron Invention: How An Electric Iron WorksSwagat Pradhan100% (1)

- PV 1Document98 pagesPV 1Noman Ahmed KhanNo ratings yet

- Solar Tracking ReportDocument31 pagesSolar Tracking ReportHailemariam WeldegebralNo ratings yet

- PV-Wind Hybrid SystemsDocument24 pagesPV-Wind Hybrid SystemssahitNo ratings yet

- Analysis of A Hybrid Solar Collector Photovoltaic Thermal PVTDocument9 pagesAnalysis of A Hybrid Solar Collector Photovoltaic Thermal PVTslaxunixNo ratings yet

- A Comprehensive Project Report ON "Feasibility Study of Solar Cell "Document18 pagesA Comprehensive Project Report ON "Feasibility Study of Solar Cell "Chaitanya VaidyaNo ratings yet

- MHDDocument33 pagesMHDkashyapNo ratings yet

- Solar ControllerDocument5 pagesSolar ControllerdjbujyNo ratings yet

- 6 Seminar Report - 07Document25 pages6 Seminar Report - 07vikasNo ratings yet

- Magneto Hydro Dynamic (MHD) Power GenerationDocument12 pagesMagneto Hydro Dynamic (MHD) Power Generationmdayyub100% (1)

- Solar Battery ChargerDocument23 pagesSolar Battery ChargerAshok ChaurasiaNo ratings yet

- Research and Development in Non-Mechanical Electrical Power Sources: Proceedings of the 6th International Symposium Held at Brighton, September 1968From EverandResearch and Development in Non-Mechanical Electrical Power Sources: Proceedings of the 6th International Symposium Held at Brighton, September 1968No ratings yet

- Muting Light Curtain DOC V21 enDocument59 pagesMuting Light Curtain DOC V21 enfcompartNo ratings yet

- Formule Masina AsincronaDocument1 pageFormule Masina AsincronafcompartNo ratings yet

- 01 TSRA IntroducereDocument12 pages01 TSRA IntroducerefcompartNo ratings yet

- Project2-S7 - 300 Ec GR II / PLC - 1 (CPU 319-3 PN/DP) / Program BlocksDocument1 pageProject2-S7 - 300 Ec GR II / PLC - 1 (CPU 319-3 PN/DP) / Program BlocksfcompartNo ratings yet

- MICROMO DC Motor Calculations White Paper Refresh 2018Document14 pagesMICROMO DC Motor Calculations White Paper Refresh 2018fcompartNo ratings yet

- Factory Io Assembler Structurat FB1Document4 pagesFactory Io Assembler Structurat FB1fcompartNo ratings yet

- Power Supply SIEMENSDocument4 pagesPower Supply SIEMENSjose2525No ratings yet

- Proelectric: Tg-Mures W W W.C Adelec Tric.r oDocument1 pageProelectric: Tg-Mures W W W.C Adelec Tric.r ofcompartNo ratings yet

- 02 B Schema de ComandaDocument1 page02 B Schema de ComandafcompartNo ratings yet

- Organizare Activitate ExpertDocument5 pagesOrganizare Activitate ExpertfcompartNo ratings yet

- Proelectric: Tg-Mures W W W.C Adelec Tric.r oDocument1 pageProelectric: Tg-Mures W W W.C Adelec Tric.r ofcompartNo ratings yet

- Mech Gate 2014 Session 4Document22 pagesMech Gate 2014 Session 4Rahul SoniNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Document2 pagesSolenoid Valves 2/2 210: Pilot Operated Hung Diaphragm 3/8 To 1 1/2Samuel ZabalaNo ratings yet

- Catia Prismatic Machining BookDocument196 pagesCatia Prismatic Machining BookGrittyBurns100% (2)

- Archistics: Aalekh Gupta Daksh PooniaDocument9 pagesArchistics: Aalekh Gupta Daksh PooniaDaksh PooniaNo ratings yet

- Kenmore Bottom Freezer 795713Document33 pagesKenmore Bottom Freezer 795713cybersaloonNo ratings yet

- Seaplus Catalog 200905vol1Document12 pagesSeaplus Catalog 200905vol1Marvvv100% (1)

- TAKTL ResearchDocument15 pagesTAKTL Researchdilian bikovNo ratings yet

- Development of Soybean Protein-Based Bioplastic Infused With Fertilizing Properties From Casein of Cow's MilkDocument32 pagesDevelopment of Soybean Protein-Based Bioplastic Infused With Fertilizing Properties From Casein of Cow's Milkjimbo09No ratings yet

- VCS 5036-5 Restricted Substance Management-IMDSDocument13 pagesVCS 5036-5 Restricted Substance Management-IMDSMemo Gonzalez AlemanNo ratings yet

- ReynoArch Exterior Louvers ShadeCardDocument2 pagesReynoArch Exterior Louvers ShadeCardIsha Eye HospitalNo ratings yet

- Jonathan R. Molina: Position Desired: Welder Personal InformationDocument2 pagesJonathan R. Molina: Position Desired: Welder Personal InformationHarry DemeterioNo ratings yet

- Temperature Indicator Controller (Digital) : (Product Code 1.1 To 1.16)Document5 pagesTemperature Indicator Controller (Digital) : (Product Code 1.1 To 1.16)YoganandhKNo ratings yet

- EarthingDocument5 pagesEarthingDerick VellaNo ratings yet

- 2015 KABAR CatalogDocument19 pages2015 KABAR CatalogCarolDiasNo ratings yet

- 6141 Ecomax Bi Rev (1409)Document2 pages6141 Ecomax Bi Rev (1409)Trịnh Minh KhoaNo ratings yet

- Wagi Valve Asia Pacific SDN - BHD.: Delivery RecordsDocument7 pagesWagi Valve Asia Pacific SDN - BHD.: Delivery Recordsunnamed90No ratings yet

- Bien Dong RobbenDocument4 pagesBien Dong Robbenhoavotinh2011No ratings yet

- Warehouse CodeDocument522 pagesWarehouse CodeMD Minhazur RahmanNo ratings yet

- SummerDocument0 pagesSummermyyyyyrNo ratings yet

- Homogeneous CatalysisDocument7 pagesHomogeneous Catalysisrafael lopezNo ratings yet

- XL For Footing DesignDocument47 pagesXL For Footing DesignAyazAkramNo ratings yet

- Review of Energy Management at NoodsbergDocument3 pagesReview of Energy Management at Noodsbergbonginkosi mathunjwaNo ratings yet

- Gas Turbine ManufactureDocument51 pagesGas Turbine Manufacturejuntosidekoik4No ratings yet

- Lesson 4. Boiler MountingsDocument4 pagesLesson 4. Boiler MountingsalexdenychenkoNo ratings yet

- Cyclic Deformation Behavior of AISI 347 in The VHCF Regime at Ambient Temperature and 300 °C - Daniel2022 PDFDocument10 pagesCyclic Deformation Behavior of AISI 347 in The VHCF Regime at Ambient Temperature and 300 °C - Daniel2022 PDFMac NeryNo ratings yet

- Primark Apparel Test Manual V17 June 2021Document107 pagesPrimark Apparel Test Manual V17 June 2021Ahmed AksarNo ratings yet