Professional Documents

Culture Documents

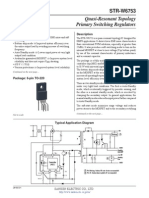

Quasi-Resonant Topology Primary Switching Regulators: STR-W6735

Quasi-Resonant Topology Primary Switching Regulators: STR-W6735

Uploaded by

perro sOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quasi-Resonant Topology Primary Switching Regulators: STR-W6735

Quasi-Resonant Topology Primary Switching Regulators: STR-W6735

Uploaded by

perro sCopyright:

Available Formats

SANKEN ELECTRIC CO., LTD.

http://www.sanken-ele.co.jp/en/

STR-W6735

Description

The STR-W6735 is a quasi-resonant topology IC designed for

SMPS applications. It shows lower EMI noise characteristics

than conventional PWM solutions, especially at greater than

2 MHz. It also provides a soft-switching mode to turn on the

internal MOSFET at close to zero voltage (V

DS

bottom point)

by use of the resonant characteristic of primary inductance

and a resonant capacitor.

The package is a fully molded TO-220, which contains the

controller chip (MIC) and MOSFET, enabling output power up

to 160 W with a 120 VAC input. The bottom-skip function skips

the first bottom of V

DS

and turns on the MOSFET at the second

bottom point, to minimize an increase of operating frequency

at light output load, improving system-level efficiency over

the entire load range.

There are two standby functions available to reduce the input

power under very light load conditions. The first is an auto-burst

mode operation, that is internally triggered by periodic sensing,

and the other is a manual standby mode, which is executed

by clamping the secondary output. In general applications,

the manual standby mode reduces the input power further

compared to the auto-burst mode.

The soft-start mode minimizes surge voltage and reduces

power stress to the MOSFET and to the secondary rectifying

Quasi-Resonant Topology

Primary Switching Regulators

Typical Application

Package: 6-pin TO-220

Continued on the next page

28103.30-5

Features and Benefits

Quasi-resonant topology IC Low EMI noise and soft

switching

Bottom-skip operation Improved system efficiency

over the entire output load by avoiding increase of

switching frequency

Standby burst mode operation => Lowers input power at

very light output load condition

Avalanche-guaranteed MOSFET Improves system-

level reliability and does not require V

DSS

derating

500 V / 0.57 , 160 W (120 VAC input)

Continued on the next page

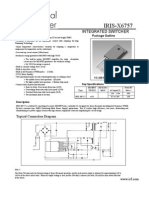

+B

GND

S1

P

D D

S/GND

VCC

S2

LowB

GND

For ErrAmp, Sanken SE series device recommended

For SI, Sanken linear regulator IC recommended

11

33 77

Controller

(MIC)

STR-W6735

66

OCP/BD

44

FB

ROCP

ErrAmp

SS/OLP

55

Standby

ON/OFF

Standby

Out

CX

RX

SI

A

B

B

A

2

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

Features and Benefits (continued)

Selection Guide

Part Number Package Packing

STR-W6735 TO-220 Bulk, 100 pieces

All performance characteristics given are typical values for circuit or

system baseline design only and are at the nominal operating voltage and

an ambient temperature of +25C, unless oth er wise stated.

Various protections Improved system-level reliability

Pulse-by-pulse drain overcurrent limiting

Overvoltage Protection (bias winding voltage sensing),

with latch

Overload Protection with latch

Maximum on-time limit

diodes during the start-up sequence. Various protections such as

overvoltage, overload, overcurrent, maximum on-time protections

and avalanche-energy-guaranteed MOSFET secure good system-

level reliability.

Applications include the following:

Set Top Box

LCD PC monitor, LCD TV

Printer, Scanner

SMPS power supplies

Description (continued)

Absolute Maximum Ratings at T

A

= 25C

Parameter Symbol Terminal Conditions Rating Unit

Drain Current

1

I

D

peak 1 - 3 Single pulse 20 A

Maximum Switching Current

2

I

Dmax

1 - 3 T

A

= 20C to 125C 20 A

Single Pulse Avalanche Energy

3

E

AS

1 - 3

Single pulse, V

DD

= 99 V, L = 20 mH,

I

Lpeak

= 5.8 A

380 mJ

Input Voltage for Controller (MIC) V

CC

4 - 3 35 V

SS/OLP Terminal Voltage V

SSOLP

5 - 3 0.5 to 6.0 V

FB Terminal Inflow Current I

FB

6 - 3 10 mA

FB Terminal Voltage V

FB

6 - 3 I

FB

within the limits of I

FB

0.5 to 9.0 V

OCP/BD Terminal Voltage V

OCPBD

7 - 3 1.5 to 5.0 V

MOSFET Power Dissipation

4

P

D1

1 - 3

With infinite heatsink 28.7 W

Without heatsink 1.3 W

Controller (MIC) Power Dissipation P

D2

4 - 3 V

CC

I

CC

0.8 W

Operating Internal Leadframe Temperature T

F

Refer to T

OP

20 to 115 C

Operating Ambient Temperature T

OP

20 to 115 C

Storage Temperature T

stg

40 to 125 C

Channel Temperature T

ch

150 C

1

Refer to figure 2

2

I

DMAX

is the drain current determined by the drive voltage of the IC and the threshold voltage, V

th

, of the MOSFET

3

Refer to figure 3

4

Refer to figure 5

3

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

Temperature, T

F

(C)

S

a

f

e

O

p

e

r

a

t

i

n

g

A

r

e

a

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

0

20

40

60

80

100

0 25 50 75 100 125 150

Drain-to-Source Voltage, V

DS

(V)

D

r

a

i

n

C

u

r

r

e

n

t

,

I

D

(

A

)

10.00

20.00

0.10

1.00

0.01

100.00

10 100 1000 1

1

m

s

0

.

1

m

s

C

u

rre

n

t lim

it

d

u

e

to

RD

S

(o

n

)

Refer to figure 1 for MOSFET SOA

temperature derating coefficient

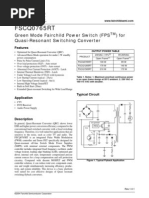

Figure 1 MOSFET Safe Operating Area

Derating Curve

Figure 2 MOSFET Safe Operating Area

Drain Current versus Voltage

at T

A

= 25C, Single Pulse

D

S/GND

OCP/BD

VCC

FB

Start

Stop

Burst

R

S

Q

Reg&

Iconst

OVP

DRIVE

Reg

Protection

latch

S

R Q

FB

OCP

BSD

BD

Bottom Selector

Counter SS/OLP

OLP

Delay

S

R

Q

OSC

MaxON

Soft Start

Burst

Control

Burst

Control

4

+

-

+

-

+

-

+

-

+

-

+

-

1

3

6

7

5

Terminal List Table

Number Name Description Functions

1 D Drain MOSFET drain

2 NC Clipped No connection

3 S/GND Source/ground terminal MOSFET source and ground

4 VCC Power supply terminal Input of power supply for control circuit

5 SS/OLP Soft Start/Overload Protection terminal Input to set delay for Overload protection and Soft Start operation

6 FB Feedback terminal

Input for Constant Voltage Control and Burst (intermittent) Mode

oscillation control signals

7 OCP/BD Overcurrent Protection/Bottom Detection Input for overcurrent detection and bottom detection signals

4

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

Channel Junction Temperature, T

J

(C)

E

A

S

T

e

m

p

e

r

a

t

u

r

e

D

e

r

a

t

i

n

g

C

o

e

f

f

i

c

i

e

n

t

(

%

)

0

20

40

60

80

100

25 50 75 100 125 150

Time, t (s)

T

r

a

n

s

i

e

n

t

T

h

e

r

m

a

l

R

e

s

i

s

t

a

n

c

e

,

R

J

C

(

C

/

W

)

0.001

0.010

0.100

1.000

10.000

100 10 10m 1m 100m 1

Ambient Temperature, T

A

(C)

P

o

w

e

r

D

i

s

s

i

p

a

t

i

o

n

,

P

D

1

(

W

)

0

5

10

15

20

25

30

0 20 40 60 80 100 120 140 160

P

D1

= 1.3 W at T

A

25C

Without heatsink

With infinite heatsink

P

D1

= 28.7 W at T

A

25C

Figure 3 MOSFET Avalanche Energy Derating Curve Figure 4 Transient Thermal Resistance

Figure 5 MOSFET Power Dissipation versus Temperature

5

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

ELECTRICAL CHARACTERISTICS

Characteristic Symbol Terminals Min. Typ. Max. Units

ELECTRICAL CHARACTERISTICS for Controller (MIC)

1

, valid at T

A

= 25C, V

CC

= 20 V, unless otherwise specified

Power Supply Start-up Operation

Operation Start Voltage V

CC(ON)

4 - 3 16.3 18.2 19.9 V

Operation Stop Voltage V

CC(OFF)

4 - 3 8.8 9.7 10.6 V

Circuit Current In Operation I

CC(ON)

4 - 3 6 mA

Circuit Current In Non-Operation I

CC(OFF)

4 - 3 100 A

Oscillation Frequency f

osc

1 - 3 19 22 25 kHz

Soft Start Operation Stop Voltage V

SSOLP(SS)

5 - 3 1.1 1.2 1.4 V

Soft Start Operation Charging Current I

SSOLP(SS)

5 - 3 710 550 390 A

Normal Operation

Bottom-Skip Operation Threshold Voltage 1 V

OCPBD(BS1)

7 - 3 0.720 0.665 0.605 V

Bottom-Skip Operation Threshold Voltage 2 V

OCPBD(BS2)

7 - 3 0.485 0.435 0.385 V

Overcurrent Detection Threshold Voltage V

OCPBD(LIM)

7 - 3 0.995 0.940 0.895 V

OCP/BDOCP/BD Terminal Outflow Current I

OCPBD

7 - 3 250 100 40 A

Quasi-Resonant Operation Threshold Voltage 1 V

OCPBD(TH1)

7 - 3 0.28 0.40 0.52 V

Quasi-Resonant Operation Threshold Voltage 2 V

OCPBD(TH2)

7 - 3 0.67 0.80 0.93 V

FB Terminal Threshold Voltage V

FB(OFF)

6 - 3 1.32 1.45 1.58 V

FB Terminal Inflow Current (Normal Operation) I

FB(ON)

6 - 3 600 1000 1400 A

Standby Operation

Standby Operation Start Voltage V

CC(S)

4 - 3 10.3 11.1 12.7 V

Standby Operation Start Voltage Interval V

CC(SK)

4 - 3 1.10 1.35 1.75 V

Standby Non-Operation Circuit Current I

CC(S)

4 - 3 20 56 A

FB Terminal Inflow Current, Standby Operation I

FB(S)

6 - 3 4 14 A

FB Terminal Threshold Voltage, Standby Operation V

FB(S)

6 - 3 0.55 1.10 1.50 V

Minimum On Time t

ON(MIN)

1 - 3 0.75 1.20 s

Maximum On Time t

ON(MAX)

1 - 3 27.5 32.5 39.0 s

Protection Operation

Overload Protection Operation Threshold Voltage V

SSOLP(OLP)

5 - 3 4.0 4.9 5.8 V

Overload Protection Operation Charging Current I

SSOLP(OLP)

5 - 3 16 11 6 A

Overvoltage Protection Operation Voltage V

CC(OVP)

4 - 3 25.5 27.7 29.9 V

Latch Circuit Holding Current

2

I

CC(H)

4 - 3 45 140 A

Latch Circuit Release Voltage

2

V

CC(La.OFF)

4 - 3 6.0 7.2 8.5 V

ELECTRICAL CHARACTERISTICS for MOSFET, valid at T

A

= 25C, unless otherwise specified

Drain-to-Source Breakdown Voltage V

DSS

1 - 3 500 V

Drain Leakage Current I

DSS

1 - 3 300 A

On Resistance R

DS(on)

1 - 3 0.57

Switching Time t

f

1 - 3 400 ns

Thermal Resistance R

CF

Channel to Internal

Frame

1.55 C/W

1

Current polarity with respect to the IC: positive current indicates current sink at the terminal named, negative current indicates source at the

terminal named.

2

Latch circuit refers to operation during Overload Protection or Overvoltage Protection.

6

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

ELECTRICAL CHARACTERISTICS Test Conditions*

Parameter Test Conditions

V

CC

(V)

Measure-

ment

Circuit

Operation Start Voltage VCC voltage at which oscillation starts. 020

1

Operation Stop Voltage VCC voltage at which oscillation stops. 208.8

Circuit Current In Operation Inflow current flowing into power supply terminal in oscillation. 20

Circuit Current In Non-operation Inflow current flowing into power supply terminal prior to oscillation. 15

Oscillation Frequency Oscillating frequency ( f

osc

= 1 / T ). 20

Soft Start Operation Stop Voltage

SS/OLP terminal voltage at which ISS/OLP reach 100 A by raising the SS/OLP terminal

voltage from 0 V gradually.

20 5

Soft Start Operation Charging

Current

SS/OLP terminal charging current (SS/OLP terminal voltage = 0 V).

Bottom-Skip Operation Threshold

Voltage 1

Input 1 s pulse width, as shown in waveform 1, to OCP/BD terminal twice after V

1-3

rises.

After that, offset the input waveform gradually from 0 V in the minus direction. Measurment

of the offset voltage V

OCPBD(BS1)

is taken when the V

1-3

start-to-fall point switches from two-

pulses-after to one-pulse-after. 20 3

Bottom-Skip Operation Threshold

Voltage 2

After measuring V

OCPBD(BS1)

, as shown in waveform 2, offset the input waveform gradually.

Measurment of the offset voltage V

OCPBD(BS2)

is taken when the V

1-3

start-to-fall point

switches from two-pulses-after to one-pulse-after.

Overcurrent Detection Threshold

Voltage

OCP/BD terminal voltage at which oscillation stops by lowering the OCP/BD terminal voltage

from 0 V gradually.

20 2

OCP/BDOCP/BD Terminal Outflow

Current

OCP/BD terminal outflow current (OCP/BD terminal voltage = 0.95 V).

Quasi-Resonant Operation

Threshold Voltage 1

OCP/BD terminal voltage at which oscillation starts with setting the OCP/BD terminal voltage

at 1 V, and then lowering the voltage gradually.

Quasi-Resonant Operation

Threshold Voltage 2

OCP/BD terminal voltage at which oscillation stops by raising the OCP/BD terminal voltage

from 0 V gradually.

FB Terminal Threshold Voltage

FB terminal voltage at which oscillation stops by raising the FB terminal voltage from 0 V

gradually.

20

4

FB Terminal Inflow Current (Normal

Operation)

FB terminal inflow current (FB terminal voltage = 1.6 V). 20

Standby Operation Start Voltage V

CC

voltage at which I

CC

reaches 1 mA (FB terminal voltage = 1.6 V). 015

Standby Operation Start Voltage

Interval

Specified by V

CC(SK)

= V

CC(S)

V

CC(OFF)

.

Standby Non-Operation Circuit

Current

Inflow current flowing into power supply terminals prior to oscillation (FB terminal voltage =

1.6 V).

10.2

FB Terminal Inflow Current, Standby

Operation

FB terminal inflow current (FB terminal voltage = 1.6 V). 10.2

FB Terminal Threshold Voltage

Standby Operation

FB terminal voltage at which oscillation starts by raising the FB terminal voltage from 0 V

gradually.

15

Minimum On Time Waveform between terminals 1 and 3 at low. 20 6

Maximum On Time Waveform between terminals 1 and 3 at low. 20 1

Overload Protection Operation

Threshold Voltage

SS/OLP terminal voltage at which oscillation stops. 20

5

Overload Protection Operation

Charging Current

SS/OLP terminal charging current (SS/OLP terminal voltage = 2.5 V).

Overvoltage Protection Operation

Voltage

V

CC

voltage at which oscillation stops. 030

1

Latch Circuit Holding Current Inflow current at V

CC(OFF)

0.3; after OVP operation.

V

CC(OFF)

0.3

Latch Circuit Release Voltage V

CC

voltage at which I

CC

reaches 20 A or lower by decreasing V

CC

after OVP operation. 306

*Oscillating operation is specified with a rectangular waveform between terminals 1 and 3.

7

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

AA

10V

1001

T

4.7k1

VCC

ICC

TON

VV

10

90

tf

D S/GND VCC SS/OLP FB OCP/BD

50

0.1,F

10V

1001

4.7k1

VCC

20V

D S/GND VCC SS/OLP FB OCP/BD

0.1,F

10V

1001

4.7k1

VCC

20V

D S/GND VCC SS/OLP FB OCP/BD

0.1,F

Measurement Circuit 1

Measurement Circuit 2

Measurement Circuit 3

8

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

Measurement Circuit 4

Measurement Circuit 6

Measurement Circuit 5

AA

10V

1001

4.7k1

VCC

VV

D S/GND VCC

SS/OLP FB OCP/BD

0.1,F

AA

VV

10V

1001

VCC

20V

D S/GND VCC SS/OLP FB OCP/BD

AA

VV

10V

1001

4.7k1

VCC

20V

D S/GND VCC SS/OLP FB OCP/BD

0.1,F

TONMIN)

9V OSC1

V1-3

5V

OSC1

200500nS

9

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

MOSFET

MOSFET measuring equipment

VDSS

IDSS

D S/GND VCC

SS/OLP FB OCP/BD

Avalanche

energy tester

IL

VDS

VCC

D S/GND VCC

SS/OLP FB OCP/BD

T1

VDSPeak

VDD

IL

0

30V

VCC

0

VDS

IDS

0.1,F

D S/GND VCC

SS/OLP FB OCP/BD

4.7k1

RDS(ON)=VDS(ON)/IDS

20V

VDS(ON)

Measurement Circuit 7

Measurement Circuit 9

Measurement Circuit 8

( )

DD DS

DS

AS

V Peak V

Peak V

I

L

Peak L E

=

2

2

1

Equation for calculation of

avalanche engery, E

AS

; to be

adjusted for I

L

Peak = 5.8 A

10

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

VDS

VOCP/BD

GND

VOCPBD(BS1)

VOCPBD(BS2)

GND

VDS

VOCP/BD

Waveform 2

Waveform 1

11

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

PACKAGE DIMENSIONS, TO-220

10.0 0.2

4.2 0.2

2.8 0.2

3

.

2

0

.

2

2.6 0.1

(

2

R

1

)

Terminal dimension at case surface

5.08 0.6

1.74

+0.2

0.1

1.34

+0.2

0.1

0.45

+0.2

0.1

1

6

.

9

0

.

3

1

0

.

4

0

.

5

5

.

0

0

.

5

7

.

9

0

.

2

4

0

.

2

2

.

8

M

A

X

(

5

.

4

)

Gate Burr

Branding

XXXXXXXX

XXXXXXXX

Gate burr: 0.3 mm (max.)

Terminal core material: Cu

Terminal treatment: Ni plating and solder dip

Heat sink material: Cu

Heat sink treatment: Ni plating

Leadform: 2003

Weight (approximate): 2.3 g

Dimensions in millimeters

Drawing for reference only

Branding codes (exact appearance at manufacturer discretion):

1st line, type: W6735

2nd line, lot: YMDD R

Where: Y is the last digit of the year of manufacture

M is the month (1 to 9, O, N, D)

DD is the 2-digit date

R is the manufacturer registration symbol

1 2 3 4 5 6 7

Terminal dimensions at case surface

6P1.27 0.15 = 7.62 0.15

Terminal dimension at lead tips

12

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

Because reliability can be affected adversely by improper

storage environments and handling methods, please observe

the following cautions.

Cautions for Storage

Ensure that storage conditions comply with the standard

temperature (5C to 35C) and the standard relative

humidity (around 40% to 75%); avoid storage locations

that experience extreme changes in temperature or

humidity.

Avoid locations where dust or harmful gases are present

and avoid direct sunlight.

Reinspect for rust on leads and solderability of the

products that have been stored for a long time.

Cautions for Testing and Handling

When tests are carried out during inspection testing and

other standard test periods, protect the products from

power surges from the testing device, shorts between

the product pins, and wrong connections. Ensure all test

parameters are within the ratings specified by Sanken for

the products.

Remarks About Using Silicone Grease with a Heatsink

When silicone grease is used in mounting the products on

a heatsink, it shall be applied evenly and thinly. If more

silicone grease than required is applied, it may produce

excess stress.

Volatile-type silicone greases may crack after long periods

of time, resulting in reduced heat radiation effect. Silicone

greases with low consistency (hard grease) may cause

cracks in the mold resin when screwing the products to a

heatsink.

Our recommended silicone greases for heat radiation

purposes, which will not cause any adverse effect on the

product life, are indicated below:

Type Suppliers

G746 Shin-Etsu Chemical Co., Ltd.

YG6260 Momentive Performance Materials Inc.

SC102 Dow Corning Toray Co., Ltd.

Cautions for Mounting to a Heatsink

When the flatness around the screw hole is insufficient, such

as when mounting the products to a heatsink that has an

extruded (burred) screw hole, the products can be damaged,

even with a lower than recommended screw torque. For

mounting the products, the mounting surface flatness should

be 0.05 mm or less.

Please select suitable screws for the product shape. Do not

use a flat-head machine screw because of the stress to the

products. Self-tapping screws are not recommended. When

using self-tapping screws, the screw may enter the hole

diagonally, not vertically, depending on the conditions of hole

before threading or the work situation. That may stress the

products and may cause failures.

Recommended screw torque: 0.588 to 0.785 Nm (6 to 8

kgfcm).

For tightening screws, if a tightening tool (such as a driver)

hits the products, the package may crack, and internal

stress fractures may occur, which shorten the lifetime of

the electrical elements and can cause catastrophic failure.

Tightening with an air driver makes a substantial impact.

In addition, a screw torque higher than the set torque can

be applied and the package may be damaged. Therefore, an

electric driver is recommended.

When the package is tightened at two or more places, first

pre-tighten with a lower torque at all places, then tighten

with the specified torque. When using a power driver, torque

control is mandatory.

Soldering

When soldering the products, please be sure to minimize

the working time, within the following limits:

2605C 101 s (Flow, 2 times)

38010C 3.50.5 s (Soldering iron, 1 time)

Soldering should be at a distance of at least 2.0 mm from

the body of the products.

Electrostatic Discharge

When handling the products, the operator must be

grounded. Grounded wrist straps worn should have at

least 1 M of resistance from the operator to ground to

prevent shock hazard, and it should be placed near the

operator.

Workbenches where the products are handled should be

grounded and be provided with conductive table and floor

mats.

When using measuring equipment such as a curve tracer,

the equipment should be grounded.

When soldering the products, the head of soldering irons

or the solder bath must be grounded in order to prevent

leak voltages generated by them from being applied to the

products.

The products should always be stored and transported in

Sanken shipping containers or conductive containers, or

be wrapped in aluminum foil.

13

SANKEN ELECTRIC CO., LTD.

28103.30-5

Quasi-Resonant Topology

Primary Switching Regulators

STR-W6735

The contents in this document are subject to changes, for improvement and other purposes, without notice. Make sure that this is the

latest revision of the document before use.

Application and operation examples described in this document are quoted for the sole purpose of reference for the use of the prod-

ucts herein and Sanken can assume no responsibility for any infringement of industrial property rights, intellectual property rights or

any other rights of Sanken or any third party which may result from its use.

Although Sanken undertakes to enhance the quality and reliability of its products, the occurrence of failure and defect of semicon-

ductor products at a certain rate is inevitable. Users of Sanken products are requested to take, at their own risk, preventative measures

including safety design of the equipment or systems against any possible injury, death, fires or damages to the society due to device

failure or malfunction.

Sanken products listed in this document are designed and intended for the use as components in general purpose electronic equip-

ment or apparatus (home appliances, office equipment, telecommunication equipment, measuring equipment, etc.).

When considering the use of Sanken products in the applications where higher reliability is required (transportation equipment and

its control systems, traffic signal control systems or equipment, fire/crime alarm systems, various safety devices, etc.), and whenever

long life expectancy is required even in general purpose electronic equipment or apparatus, please contact your nearest Sanken sales

representative to discuss, prior to the use of the products herein.

The use of Sanken products without the written consent of Sanken in the applications where extremely high reliability is required

(aerospace equipment, nuclear power control systems, life support systems, etc.) is strictly prohibited.

In the case that you use Sanken products or design your products by using Sanken products, the reliability largely depends on the

degree of derating to be made to the rated values. Derating may be interpreted as a case that an operation range is set by derating the

load from each rated value or surge voltage or noise is considered for derating in order to assure or improve the reliability. In general,

derating factors include electric stresses such as electric voltage, electric current, electric power etc., environmental stresses such

as ambient temperature, humidity etc. and thermal stress caused due to self-heating of semiconductor products. For these stresses,

instantaneous values, maximum values and minimum values must be taken into consideration.

In addition, it should be noted that since power devices or IC's including power devices have large self-heating value, the degree of

derating of junction temperature affects the reliability significantly.

When using the products specified herein by either (i) combining other products or materials therewith or (ii) physically, chemically

or otherwise processing or treating the products, please duly consider all possible risks that may result from all such uses in advance

and proceed therewith at your own responsibility.

Anti radioactive ray design is not considered for the products listed herein.

Sanken assumes no responsibility for any troubles, such as dropping products caused during transportation out of Sanken's distribu-

tion network.

The contents in this document must not be transcribed or copied without Sanken's written consent.

You might also like

- Nds3975 Dvb-s2 HD IrdDocument60 pagesNds3975 Dvb-s2 HD IrdAlee Herrera100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Esab-AristoMig 500-0459 293 990-Spare Parts-AZ295115Document16 pagesEsab-AristoMig 500-0459 293 990-Spare Parts-AZ295115JFernando MonteiroNo ratings yet

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6756Document8 pagesQuasi-Resonant Topology Primary Switching Regulators: STR-W6756perro sNo ratings yet

- STR W6753 DatasheetDocument8 pagesSTR W6753 DatasheetjgerabmNo ratings yet

- STR W6735 DatasheetDocument13 pagesSTR W6735 DatasheetloagerNo ratings yet

- STR W6735Document14 pagesSTR W6735proctepNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6759NDocument9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6759Nch3o10836266No ratings yet

- Datasheet STR 6757Document11 pagesDatasheet STR 6757Walter CarreroNo ratings yet

- Off-Line Quasi-Resonant Switching Regulators: STR-X6729Document9 pagesOff-Line Quasi-Resonant Switching Regulators: STR-X6729perro sNo ratings yet

- PWM Off-Line Switching Regulator Ics: Str-A6000H SeriesDocument13 pagesPWM Off-Line Switching Regulator Ics: Str-A6000H SeriesAnonymous Lfgk6vygNo ratings yet

- Allegro STR-W6765 PDFDocument15 pagesAllegro STR-W6765 PDFcomportNo ratings yet

- Transition-Mode PFC Controller: 1 FeaturesDocument17 pagesTransition-Mode PFC Controller: 1 Featuresadriancho66No ratings yet

- LTC 1625Document24 pagesLTC 1625Sakura KunNo ratings yet

- STRW6252Document15 pagesSTRW6252miltoncgNo ratings yet

- Datasheet PDFDocument15 pagesDatasheet PDFperro sNo ratings yet

- Document - SG3525A DDocument10 pagesDocument - SG3525A Donlinerahul823405No ratings yet

- IRIS-X6757: FeaturesDocument10 pagesIRIS-X6757: Featuresmiguel angel jaramilloNo ratings yet

- Tle6220gp DatasheetDocument18 pagesTle6220gp Datasheetmaelo99999No ratings yet

- SSC2001S Application NoteDocument18 pagesSSC2001S Application NoteGerardo Mendez CamarilloNo ratings yet

- DatasheetDocument12 pagesDatasheetDjalma MoreiraNo ratings yet

- 60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsDocument14 pages60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsIBSDIALLO0% (1)

- STR A6252 PDFDocument9 pagesSTR A6252 PDFFernando ChingaNo ratings yet

- SG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorDocument10 pagesSG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorJayesh SuryavanshiNo ratings yet

- L 6565Document17 pagesL 6565tatatabuchoNo ratings yet

- Data SheetDocument7 pagesData Sheetitamar_123No ratings yet

- DatasheetDocument13 pagesDatasheetebertecnicoNo ratings yet

- Microstepping DMOS Driver With Translator: Description Features and BenefitsDocument18 pagesMicrostepping DMOS Driver With Translator: Description Features and BenefitsSaid BoubkerNo ratings yet

- Data SheetDocument12 pagesData SheetMarcoAntonioCamanTraihuelNo ratings yet

- Tps 40057 PWPDocument33 pagesTps 40057 PWPcatsoithahuong84No ratings yet

- Motor Driver - Full-Bridge PWM - A3953-N5Document14 pagesMotor Driver - Full-Bridge PWM - A3953-N5Ludwig Schmidt100% (1)

- MP1542 r1.5Document11 pagesMP1542 r1.5Joshua KochNo ratings yet

- Linear LT3590Document16 pagesLinear LT3590CiobanuClaudiuNo ratings yet

- Uc3842b 3843BDocument10 pagesUc3842b 3843Bbob75No ratings yet

- P1027P65 (SMPS)Document30 pagesP1027P65 (SMPS)Jesus Silva67% (3)

- PS223Document11 pagesPS223seyyedali2006No ratings yet

- Fan 7530Document20 pagesFan 7530aldo_suviNo ratings yet

- Datasheet PDFDocument11 pagesDatasheet PDFIdelbrando RochaNo ratings yet

- 161 20551 0 FS7M0880Document16 pages161 20551 0 FS7M0880Edwin Vitovis TorresNo ratings yet

- STR W6000S Series Application NoteDocument20 pagesSTR W6000S Series Application NoteSutrisno OkNo ratings yet

- High Voltage Resonant Controller: DescriptionDocument17 pagesHigh Voltage Resonant Controller: DescriptionJesus SilvaNo ratings yet

- Ltc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching RegulatorsDocument28 pagesLtc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching Regulatorscatsoithahuong84No ratings yet

- High Efficiency Low-Side N-Channel Controller For Switching RegulatorsDocument33 pagesHigh Efficiency Low-Side N-Channel Controller For Switching Regulatorssoft4gsmNo ratings yet

- Infineon BTS6143D DS v01 00 enDocument18 pagesInfineon BTS6143D DS v01 00 enNacer MezghicheNo ratings yet

- LM350 DatasheetDocument12 pagesLM350 DatasheetOmarVelasquezC.No ratings yet

- NCP1337 PWM Current Mode Controller For Free Running Quasi Resonant OperationDocument14 pagesNCP1337 PWM Current Mode Controller For Free Running Quasi Resonant Operationcorrales_86No ratings yet

- 3685 FBDocument24 pages3685 FBPravin MevadaNo ratings yet

- Datasheet lm337Document8 pagesDatasheet lm337eduardo1011No ratings yet

- 5V-0.5A Very Low Drop Regulator With Reset: DescriptionDocument6 pages5V-0.5A Very Low Drop Regulator With Reset: DescriptionDan EsentherNo ratings yet

- Thb7128 InstructionsDocument9 pagesThb7128 InstructionsanhxcoNo ratings yet

- 5Q1265RT - CD1265RTDocument6 pages5Q1265RT - CD1265RTJulian Andres Rozo100% (1)

- BTS443Document14 pagesBTS443Negru P. PlantatieNo ratings yet

- RSP 3000 SpecDocument6 pagesRSP 3000 SpecGrigoriu CodrutaNo ratings yet

- R2A20121SP: Synchronous Phase Shift Full-Bridge Control ICDocument28 pagesR2A20121SP: Synchronous Phase Shift Full-Bridge Control ICdragon-red0816No ratings yet

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocument10 pagesNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Power Amplifier Applications Driver Stage Amplifier ApplicationsDocument3 pagesPower Amplifier Applications Driver Stage Amplifier Applicationsperro sNo ratings yet

- Old Company Name in Catalogs and Other DocumentsDocument13 pagesOld Company Name in Catalogs and Other Documentsperro sNo ratings yet

- Upc 4558 PDFDocument13 pagesUpc 4558 PDFperro sNo ratings yet

- CQ 0765RTDocument24 pagesCQ 0765RTsonivitel100% (2)

- STRG6653Document8 pagesSTRG6653perro sNo ratings yet

- Datasheet PDFDocument15 pagesDatasheet PDFperro sNo ratings yet

- ST 2SC1740: G S P Form A Is AvailableDocument2 pagesST 2SC1740: G S P Form A Is Availableperro sNo ratings yet

- Ta36n30p PDFDocument5 pagesTa36n30p PDFperro sNo ratings yet

- 2SC5200 PDFDocument8 pages2SC5200 PDFkimxoNo ratings yet

- A New Approach Ultra Low Voltage CMOS Logic Circuits AnalysisDocument5 pagesA New Approach Ultra Low Voltage CMOS Logic Circuits AnalysisijsretNo ratings yet

- PDF Pke4235piDocument20 pagesPDF Pke4235piRenato MeloNo ratings yet

- MR150 Product SpecDocument6 pagesMR150 Product SpecMohammed AbugharbiehNo ratings yet

- OSRAM SFH 309 DatasheetDocument16 pagesOSRAM SFH 309 DatasheetbarisNo ratings yet

- SIEMENS Cast Resin Bus TrunkDocument5 pagesSIEMENS Cast Resin Bus Trunktkdrt2166No ratings yet

- A Synthesizable Design of Amba-Axi Protocol For Soc IntegrationDocument8 pagesA Synthesizable Design of Amba-Axi Protocol For Soc IntegrationvjemmanNo ratings yet

- ABB Distribution Transformer Handbook (Step7)Document92 pagesABB Distribution Transformer Handbook (Step7)salmanejaz78675% (4)

- Data Sheet FOR High Mast Lighting System: Indian Oil Corporation LimitedDocument8 pagesData Sheet FOR High Mast Lighting System: Indian Oil Corporation Limitedbiswajit biswasNo ratings yet

- Replacement Parts Manual: Wall-Mounted Saso 2874 Certified Air ConditionerDocument10 pagesReplacement Parts Manual: Wall-Mounted Saso 2874 Certified Air ConditionerJhon SanabriaNo ratings yet

- 2013-2015 ALTIMA AND 2014-2016 ROGUE Enhanced Diagnostic Logic For CVT JudderDocument11 pages2013-2015 ALTIMA AND 2014-2016 ROGUE Enhanced Diagnostic Logic For CVT Juddermaxi sysNo ratings yet

- Data CommunicationsDocument271 pagesData CommunicationsCharles ReyesNo ratings yet

- Stm32f446ret6 PDFDocument202 pagesStm32f446ret6 PDFNguyen Trong NghiaNo ratings yet

- MJ 15003 (NPN)Document3 pagesMJ 15003 (NPN)Johanes StNo ratings yet

- TC BLD Owners Manual PDFDocument4 pagesTC BLD Owners Manual PDFPabNo ratings yet

- IoT Quiz-2Document9 pagesIoT Quiz-2vaishnav kNo ratings yet

- RF024 2101Document6 pagesRF024 2101Raul HurtadoNo ratings yet

- POSEICO ShortFormCatalogue20132014Document52 pagesPOSEICO ShortFormCatalogue20132014alvaror320No ratings yet

- Yaesu FT-100 SRF 7043 ReplacementDocument2 pagesYaesu FT-100 SRF 7043 ReplacementSebastian PettersNo ratings yet

- BatteryDocument0 pagesBatterymichaelliu123456No ratings yet

- Fuzzy Logic Based Farm Automation Using Arduino and Labview With X-Bee Based Control SystemDocument5 pagesFuzzy Logic Based Farm Automation Using Arduino and Labview With X-Bee Based Control SystemUnitomo BetterNo ratings yet

- Silicon Chip Magazine 2009-10 Oct PDFDocument108 pagesSilicon Chip Magazine 2009-10 Oct PDFLucilia Dos Santos100% (1)

- Convergence Region Questions and Answers - SanfoundryDocument11 pagesConvergence Region Questions and Answers - SanfoundrykshambelmekuyeNo ratings yet

- Circuit Board Layout Guidelines For Class-D AmplifiersDocument4 pagesCircuit Board Layout Guidelines For Class-D AmplifiersXavi AlonsoNo ratings yet

- FC 62 - Remote Control Memory - ABB SolutionsBankDocument6 pagesFC 62 - Remote Control Memory - ABB SolutionsBankmohdthasthakirNo ratings yet

- Current Harmonic Suppression For Dual Three-Phase PDFDocument11 pagesCurrent Harmonic Suppression For Dual Three-Phase PDFMoyasserengAlattarNo ratings yet

- Task 3 - Electromagnetic Waves in Guided Media Individual WorkDocument10 pagesTask 3 - Electromagnetic Waves in Guided Media Individual Workgabriel tejadaNo ratings yet

- IFCMI LF Instant Flow C Micro Mix Electric Tankless Low ActivationDocument4 pagesIFCMI LF Instant Flow C Micro Mix Electric Tankless Low ActivationswapnilupgadeNo ratings yet

- General Back Ground of Switchyard: Presenter: Sonam Tobgay Head, SmuDocument38 pagesGeneral Back Ground of Switchyard: Presenter: Sonam Tobgay Head, Smusherub wangdiNo ratings yet