Professional Documents

Culture Documents

Sheet Metal Cutter Plan - Metalworking Plans - Craftsmanspace

Uploaded by

ar02nbs100%(1)100% found this document useful (1 vote)

321 views17 pagesMaximal thickness of the steel sheets that you can cut with this tool is 2mm. Do not forget to chamfer the edges on items 1, 2, 3, 7 and 8. This way you will avoid injuries that can happen on very sharp edges.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMaximal thickness of the steel sheets that you can cut with this tool is 2mm. Do not forget to chamfer the edges on items 1, 2, 3, 7 and 8. This way you will avoid injuries that can happen on very sharp edges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

321 views17 pagesSheet Metal Cutter Plan - Metalworking Plans - Craftsmanspace

Uploaded by

ar02nbsMaximal thickness of the steel sheets that you can cut with this tool is 2mm. Do not forget to chamfer the edges on items 1, 2, 3, 7 and 8. This way you will avoid injuries that can happen on very sharp edges.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 17

Project: Sheet metal cutter Page 1 of 17

Sheet metal cutter

Maximal thickness of the steel sheets that you can cut with this tool is 2mm.

Lower knife (item 1) and Upper knife (item 2) have to be tempered in order to harden them

and besides that, these two items have to be made out of the quality steel with high hardness.

Do not forget to chamfer the edges on items 1, 2, 3, 7 and 8. This way you will avoid injuries

that can happen on very sharp edges. It should become a rule when you work with metal items that

are being made by cutting, milling or turning.

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 2 of 17

Parts List

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 3 of 17

2D Documentation

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 4 of 17

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 5 of 17

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 6 of 17

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 7 of 17

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 8 of 17

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 9 of 17

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 10 of 17

Standard Parts

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 11 of 17

Assemblage Instruction

1. Fasten the Support (item 3) to the edge of your workbench, or some other appropriate place.

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 12 of 17

2. Fasten the Lower knife (item 1) to the Support (item 3) with bolt binding.

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 13 of 17

3. Weld the Hexagon Head Bolts (item 9, M10 x 100mm) to the Lower Knife (item 1).

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 14 of 17

4. Fasten the Delimiter (item 8) to the previously made construction with bold binding.

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 15 of 17

5. Fasten the Upper Knife (item 2) to the previously made construction.

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 16 of 17

6. Fasten the Handle (item 7) to the previously made construction.

Project from www.craftsmanspace.com

Project: Sheet metal cutter Page 17 of 17

The procedure of cutting the sheet begins by placing delimiter on the required distance from the Lower

knife. After that, the steel sheet is being placed on the left between the knives, until it reach delimiter. By

pulling down the Handle, you will cut the sheet with the exact width as it is between delimiter and lower

knife.

If you want to cut metal sheet with bigger width than the maximal distance between delimiter and Lower

knife, youll have to remove a delimiter, mark the line on the sheet by hand and slowly cut the sheet by

that line.

Project from www.craftsmanspace.com

You might also like

- Serenity RPG Firefly Role Playing Game PDFDocument225 pagesSerenity RPG Firefly Role Playing Game PDFNathaniel Broyles67% (3)

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopFrom EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedNo ratings yet

- Steel Challenge Rules 2013Document36 pagesSteel Challenge Rules 2013jasonsivertsenNo ratings yet

- How To Formulate Parkerizing SolutionDocument3 pagesHow To Formulate Parkerizing SolutionOtter1zNo ratings yet

- Casted Lathe PDFDocument27 pagesCasted Lathe PDFFIREREALM66100% (2)

- Multiple Barrel FirearmsDocument6 pagesMultiple Barrel FirearmsYorgos KordoniasNo ratings yet

- 3 in 1 MachineDocument5 pages3 in 1 Machinemarandan85100% (1)

- Tap & Drill Chart W - Decimal Inch & MetricDocument10 pagesTap & Drill Chart W - Decimal Inch & MetricGanesh NatarajanNo ratings yet

- Chapter 3 - Bending Forming ShapingDocument11 pagesChapter 3 - Bending Forming ShapingFrigeri FrigeriNo ratings yet

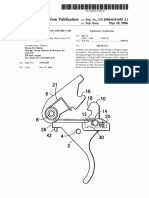

- Us 20060101695Document11 pagesUs 20060101695galak12001100% (1)

- Chimera ManualDocument12 pagesChimera ManualticocrazyNo ratings yet

- Sheet Metal Bench Shear PDFDocument14 pagesSheet Metal Bench Shear PDFmarianrkw100% (1)

- Revolver ChamferingDocument6 pagesRevolver ChamferingZardoz1090100% (1)

- Lathe Milling Attach PlansDocument7 pagesLathe Milling Attach Plansdodgydonkey100% (1)

- 3D Printed CETME/HK Bending Jig and MandrelDocument13 pages3D Printed CETME/HK Bending Jig and Mandrelrand0100% (1)

- Toolpost Attachment For A High Speed Rotary ToolDocument32 pagesToolpost Attachment For A High Speed Rotary Toolkokisko100% (1)

- M1911-A1 ReduxDocument62 pagesM1911-A1 Reduxtfour2000No ratings yet

- V3 ECM Tutorial v1.0Document40 pagesV3 ECM Tutorial v1.0lmkkilo3No ratings yet

- Handi Instr TwobDocument13 pagesHandi Instr TwobnotjustsomeoneNo ratings yet

- Easy Jig Information - 80% ArmsDocument2 pagesEasy Jig Information - 80% Arms9fakeemailNo ratings yet

- HMT Mandrel Bending 101Document80 pagesHMT Mandrel Bending 101zaiofracassadoNo ratings yet

- AKT020 Rivet Jaws InstructionsDocument12 pagesAKT020 Rivet Jaws InstructionsDale WadeNo ratings yet

- Screw ThreadsDocument7 pagesScrew ThreadsVille4everNo ratings yet

- Weedeater Trolling MotorDocument16 pagesWeedeater Trolling MotorJames McEwenNo ratings yet

- Tube Rolling MachineDocument4 pagesTube Rolling MachinePushpa Mohan RajNo ratings yet

- Panbrake PDFDocument39 pagesPanbrake PDFluisimtzNo ratings yet

- FM Testbank-Ch18Document9 pagesFM Testbank-Ch18David LarryNo ratings yet

- Tap-Drill Chart Recommend Tap Drill To Use For 75% Depth of ThreadDocument1 pageTap-Drill Chart Recommend Tap Drill To Use For 75% Depth of ThreadPliskinAJNo ratings yet

- Pneumatic Air Graver From BoltDocument69 pagesPneumatic Air Graver From BoltRuger B.No ratings yet

- Threading Operations of Lathe SystemDocument37 pagesThreading Operations of Lathe SystemResshille Ann T. SalleyNo ratings yet

- Eccentric Turning Attachment On Three Jaw LatheDocument50 pagesEccentric Turning Attachment On Three Jaw LatheSushant MahajanNo ratings yet

- 3 PhaseDocument9 pages3 PhaseArnulfo LavaresNo ratings yet

- Bar ClampDocument19 pagesBar Clampapi-200253170No ratings yet

- GG2 Operator's ManualDocument30 pagesGG2 Operator's ManualWerner Patric WengNo ratings yet

- DIY Knife Sharpening Jig Guided Knife SharpenerDocument15 pagesDIY Knife Sharpening Jig Guided Knife SharpenerAlejandro MaffoniNo ratings yet

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.From EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Rating: 5 out of 5 stars5/5 (1)

- Grinding Lathe Tools On A Belt Sander - Part 3 - MachinistBlogDocument11 pagesGrinding Lathe Tools On A Belt Sander - Part 3 - MachinistBlogredneckrepairsNo ratings yet

- Invoice ApprovalDocument54 pagesInvoice ApprovalHamada Asmr AladhamNo ratings yet

- Learning Module - Joints, Taps and SplicesDocument9 pagesLearning Module - Joints, Taps and SplicesCarlo Cartagenas100% (1)

- High Standard-MagazinesDocument3 pagesHigh Standard-MagazinesBob WilliamsNo ratings yet

- Preblending of Raw Materia1Document26 pagesPreblending of Raw Materia1Mohammed Abdo100% (1)

- NCP - DMDocument4 pagesNCP - DMMonica Garcia88% (8)

- ISO 10816 - Severidad en Vibracion PDFDocument2 pagesISO 10816 - Severidad en Vibracion PDFJuan Carlos Bonifacio BricenoNo ratings yet

- China's Military UAV Industry - 14 June 2013Document21 pagesChina's Military UAV Industry - 14 June 2013Deep Kanakia100% (1)

- Machining FundamentalsDocument32 pagesMachining FundamentalsCh TalhaNo ratings yet

- Making The Keats Angle Plate From CastingsDocument15 pagesMaking The Keats Angle Plate From CastingsJohn SmithNo ratings yet

- Corbin World Directory of Custom Bullet Makers 2001Document94 pagesCorbin World Directory of Custom Bullet Makers 2001aikidomoysesNo ratings yet

- Filing, Drilling, Forming M1 U6Document29 pagesFiling, Drilling, Forming M1 U6Sergey ShkapovNo ratings yet

- Airgun Internal BallisticsDocument6 pagesAirgun Internal BallisticsTimothy PNo ratings yet

- ACESORIOScatalog PDFDocument80 pagesACESORIOScatalog PDFlmelmelmeNo ratings yet

- The Jewell Trigger ManualDocument7 pagesThe Jewell Trigger ManualFrederik LavoieNo ratings yet

- Negrini Hard Gun Cases CatalogDocument10 pagesNegrini Hard Gun Cases CatalognegrinicasesNo ratings yet

- Experiment p1 Metal Cutting ProcessDocument13 pagesExperiment p1 Metal Cutting Processvipin_shrivastava25No ratings yet

- Ballistics of Air Gun PDFDocument3 pagesBallistics of Air Gun PDFWalter MendezNo ratings yet

- Cly Mer Catalogue Vol 11Document36 pagesCly Mer Catalogue Vol 11ravenofthenightNo ratings yet

- GB 50a-2Document1 pageGB 50a-2Kevin Blaner100% (1)

- Floating Reamer InstructionsDocument1 pageFloating Reamer InstructionsAndrew DeutschmanNo ratings yet

- ChicopeerfDocument15 pagesChicopeerfRomG78No ratings yet

- Beginning Scale: Part 20 - Gun DetailingDocument2 pagesBeginning Scale: Part 20 - Gun DetailingjorgeNo ratings yet

- Dbs22 enDocument14 pagesDbs22 enmilivoj11No ratings yet

- 12 GaDocument1 page12 GaWesley MaiaNo ratings yet

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Roller BearingDocument182 pagesRoller BearingbbkghrtyNo ratings yet

- Heating ElementsDocument2 pagesHeating ElementsKamal MishraNo ratings yet

- GEC 300MW Data Sheet PDFDocument51 pagesGEC 300MW Data Sheet PDFar02nbsNo ratings yet

- 4 - Vanessa-Mathebula-WS PDFDocument26 pages4 - Vanessa-Mathebula-WS PDFar02nbsNo ratings yet

- BBAG MPR and STR LISTSDocument25 pagesBBAG MPR and STR LISTShimanshu ranjanNo ratings yet

- Verilog GATE AND DATA FLOWDocument64 pagesVerilog GATE AND DATA FLOWPRIYA MISHRANo ratings yet

- Ibragimova Lesson 4Document3 pagesIbragimova Lesson 4Dilnaz IbragimovaNo ratings yet

- Pds Hempel's Maestro Water Borne Primer 28830 En-GbDocument2 pagesPds Hempel's Maestro Water Borne Primer 28830 En-GbKalaiyazhagan ElangeeranNo ratings yet

- Under Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisDocument13 pagesUnder Suitable Conditions, Butane, C: © OCR 2022. You May Photocopy ThisMahmud RahmanNo ratings yet

- Annex A - Scope of WorkDocument4 pagesAnnex A - Scope of Workمهيب سعيد الشميريNo ratings yet

- Historical Perspective of OBDocument67 pagesHistorical Perspective of OBabdiweli mohamedNo ratings yet

- 5 24077 Rev2 PDFDocument3 pages5 24077 Rev2 PDFJavier GarcíaNo ratings yet

- Most Probable Number (MPN) Test: Principle, Procedure, ResultsDocument4 pagesMost Probable Number (MPN) Test: Principle, Procedure, ResultsHammad KingNo ratings yet

- Visual Inspection ReportDocument45 pagesVisual Inspection ReportKhoirul AnamNo ratings yet

- Multibody Dynamics Modeling and System Identification For A Quarter-Car Test Rig With McPherson Strut Suspension PDFDocument122 pagesMultibody Dynamics Modeling and System Identification For A Quarter-Car Test Rig With McPherson Strut Suspension PDFnecromareNo ratings yet

- Net Pert: Cable QualifierDocument4 pagesNet Pert: Cable QualifierAndrés Felipe Fandiño MNo ratings yet

- Small Data, Big Decisions: Model Selection in The Small-Data RegimeDocument10 pagesSmall Data, Big Decisions: Model Selection in The Small-Data Regimejuan carlos monasterio saezNo ratings yet

- Technology 6 B Matrixed Approach ToDocument12 pagesTechnology 6 B Matrixed Approach ToNevin SunnyNo ratings yet

- University of Southern Philippines Foundation. College of Engineering and ArchitectureDocument7 pagesUniversity of Southern Philippines Foundation. College of Engineering and ArchitectureJason OwiaNo ratings yet

- Chapter 10 OutlineDocument3 pagesChapter 10 OutlineFerrari75% (4)

- Landcorp FLCC Brochure 2013 v3Document6 pagesLandcorp FLCC Brochure 2013 v3Shadi GarmaNo ratings yet

- Pepperberg Notes On The Learning ApproachDocument3 pagesPepperberg Notes On The Learning ApproachCristina GherardiNo ratings yet

- L5T-112 Manual - 2007 - Issue 1.1 PDFDocument16 pagesL5T-112 Manual - 2007 - Issue 1.1 PDFfluidaimaginacionNo ratings yet

- Model 900 Automated Viscometer: Drilling Fluids EquipmentDocument2 pagesModel 900 Automated Viscometer: Drilling Fluids EquipmentJazminNo ratings yet

- Ericsson For Sale From Powerstorm 4SA03071242Document8 pagesEricsson For Sale From Powerstorm 4SA03071242wd3esaNo ratings yet

- Introduction of ProtozoaDocument31 pagesIntroduction of ProtozoaEINSTEIN2D100% (2)

- Lecture 1 Electrolyte ImbalanceDocument15 pagesLecture 1 Electrolyte ImbalanceSajib Chandra RoyNo ratings yet