Professional Documents

Culture Documents

Armstrong Steam Trap Testing Guide For Energy Conservation: Knowledge Not Shared Is Energy Wasted

Armstrong Steam Trap Testing Guide For Energy Conservation: Knowledge Not Shared Is Energy Wasted

Uploaded by

Tina Miller0 ratings0% found this document useful (0 votes)

5 views8 pages310

Original Title

310

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document310

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views8 pagesArmstrong Steam Trap Testing Guide For Energy Conservation: Knowledge Not Shared Is Energy Wasted

Armstrong Steam Trap Testing Guide For Energy Conservation: Knowledge Not Shared Is Energy Wasted

Uploaded by

Tina Miller310

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

Bulletin 310-D

Armstrong Steam Trap Testing

Guide for Energy Conservation

Knowledge Not Shared Is Energy Wasted

2

Steam Trap Testing Procedure

CAUTION: Valves in steam lines should be opened or

closed by authorized personnel only, following the correct

procedure for specific system conditions. Always isolate

steam trap from pressurized supply and return lines before

opening for inspection or repair. Isolate strainer from

pressurized system before opening to clean. Failure to

follow correct procedures can result in system damage and

possible bodily injury.

Ti ps On Listening

1. Some flow noises are best picked up with high

frequency electronic listening devices, but these

devices are not sensitive to mechanical sounds.

2. Low frequency meters, stethoscopes or even screw

drivers can be used to detect mechanical sounds, for

example: bucket dance, or the bubbling through the

bucket vent.

3. Before purchasing a listening device, check it out on

known conditions to see that it serves your purpose.

4. When checking traps on a manifold, be sure to check

them all. A good trap can telegraph a bad traps signal.

Check to see at which trap the signal is the loudest.

Thats probably the faulty trap.

I. Inverted Bucket

A. Is trap cold?

1. Yes, then:

a. Is steam shut off ? Yes, then turn on steam to

check trap. If still cold shut off steam. (Allow

sufficient time for purging of initial air.)

b. Is there a plugged strainer up stream of trap?

Yes, then clean strainer.

c. If no plugged strainer, open trap.

d. Is it over-pressured, orifice too large for applied

differential? Yes, then replace mechanism with

one for right pressure.

3

e. Is bucket vent plugged? Yes, clean it.

f. Is inlet or outlet plugged or mechanism

jammed with dirt? Yes, then clean it.

g. Is bucket unhooked? (worn mechanism) Yes,

then replace mechanism.

2. No, then listen to it.

a. Is it discharging intermittently? Yes, then it

is OK.

b. Is it relatively quiet, so you can hear the steady

bubbling through the bucket vent? Yes, then it

is OK, light load.

c. Does bubbling sound increase and decrease in

a kind of rolling sound? Yes, then it is

handling air. Check trap in an hour. If it is still

handling air, replace the standard bucket with a

thermic bucket. If air problem persists, replace

inverted bucket trap with a float and

thermostatic trap.

d. Is it discharging steadily with no bucket sound?

Yes, then it is too small. Replace trap with

larger one.

e. Is it discharging steadily with bucket dancing

up and down? Yes, then it has lost its prime.

Close a valve upstream or downstream of trap

for a few minutes and then re-open. If trap

does not catch its prime, mechanism is worn

(replace), or guide assembly is misaligned

(align. See instructions.) Internal check valve

on tube and coupling may be necessary to

cure chronic prime loss.

3. If trap is capsule construction, non-repairable,

remove it from the line in case of any malfunction,

and apply compressed air or a water stream to its

outlet and then its inlet. If this does not correct the

problem replace the trap.

4

II. Float & Thermostatic Trap

A. Is trap cold?

1. Yes, then:

a. Is steam shut off? Yes, then turn on steam to

check trap. If still cold shut off steam. (Allow

sufficient time for purging of initial air.)

b. Is there a plugged strainer up stream of trap?

Yes, then clean strainer.

c. If no plugged strainer, open trap.

d. Is it over-pressured, orifice too large for applied

differential? Yes, then replace mechanism with

one for right pressure.

e. Has thermostatic element failed shut? (Open

trap at room temperature, thermostatic valve

should be open.) Yes, then replace.

f. Is float collapsed? Yes, then replace.

g. Is float mechanism free to move open and

shut? No, then clean or ease binding parts of

mechanism or replace mechanism.

h. Is trap inlet or outlet plugged? Yes, then

clean it.

2. No, then listen to it.

A float and thermostatic trap modulates to the

load, so it discharges constantly. There is always

flow if there is a condensate load. If the trap is

passing live steam, this not only adds to flow

noise, but it also raises the pitch of the sound

because of the higher velocity.

If a valve upstream or downstream of the trap is

closed for a few minutes there will be a back-up of

condensate. When the valve is reopened, the float

valve should move to wide open until the back-up

condensate is clear. If the mechanism is OK,

there should now be a reduction in noise. If the

mechanism is faulty, live steam will be passed at

this time, which can be detected by a higher pitch

in the flow noise.

5

Is live steam discharge suspected? Yes, then shut

off steam, allow trap to cool and open trap.

a. Has thermostatic element failed open?

(Remove element from trap and place in

boiling water. It should close. Mounting the

discharge connection of the element on the

end of a tube permits blowing into the tube to

see if the valve is shut.)

b. Is foreign material in trap preventing free

operation of mechanism? Yes, then clean it.

c. Is mechanism binding open or is valve not

seating squarely on orifice? Yes, then ease

binding parts, align mechanism, or replace

mechanism.

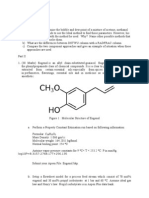

III. Disc Trap

A. Is trap cold?

1. Yes, then:

a. Is steam shut off? Yes, then turn on steam to

check trap. (Allow sufficient time for purging of

initial air.) If still cold, shut off steam.

b. Is there a plugged strainer up stream of trap?

Yes, then clean strainer.

c. If no plugged strainer, open trap.

d. Is disc free to be lifted from seats? No, then

clean it so it is free.

e. Is it plugged with dirt at inlet or outlet? Yes,

then clean it.

2. No, then: Listen to it:

a. Is it discharging intermittently, about six (6)

time/min.? Yes, then it is OK.

b. Is it discharging intermittently, about twelve

(12) times/minute or discharging steadily? Yes,

then it is worn and wasting excessive steam

and should be replaced OR it is too small and

should be replaced by larger trap. (New trap of

6

III. Disc Trap (Cont.)

proper size will intermit about six (6) times/

minute.) Or there is excessive back pressure.

B. If a disc trap is connected into a return line, dont

check visually by discharging it to atmosphere

through a test valve. This removes the back

pressure, which can cause problems if it exceeds

50% of the inlet pressure. The temperature of the

return line indicates its back pressure.

IV. Thermostatic Trap

A. Is trap cold?

1. Yes, then:

a. Is steam shut off? Yes, then turn on steam to

check trap. (Allow sufficient time for purging of

initial air.) If still cold, shut off steam.

b. I there a plugged strainer up stream of trap?

Yes, then clean the strainer.

c. If no plugged strainer, open trap.

d. Has thermostatic element failed shut? (Valve

should be open at room temperature.) Yes,

then replace it.

e. Is it plugged at inlet or outlet?

Yes, then clean it.

2. No, then listen to it.

a. Is it discharging intermittently? Yes, then it

is OK.

b. Is it discharging constantly? Yes, then spray

with water.

1.If it discharges more heavily briefly and shuts

off, it is OK.

2. If there is no change in sound

a. Close a valve upstream or downstream

for a few minutes. A short time after

reopening, is there a sudden rise in pitch

of the flow noise?

7

1. Yes, then trap has failed open. Shut off

steam and allow to cool. Open it and

clean it if dirt is preventing proper

functioning. If no dirt, remove element

from trap and place in boiling water. It

should close. Mounting the discharge

connection of the element on the end

of a tube permits blowing into the tube

to see if the valve is shut.

2. No, then trap is too small. Replace

with larger trap or add another of same

size in parallel.

3. If trap is capsule construction, non-

repairable, remove it from the line in

case of malfunction, and apply

compressed air or a water stream to

its outlet and then its inlet. If this does

not correct the problem replace the

trap. (Element must not experience

more than 40 psi pressure when cold.)

V. Sub-Cooling Trap

A. Is trap cold?

1. Yes, then:

a. Is steam shut off? Yes, then turn on steam to

check trap. (Allow sufficient time for purging of

initial air.) If still cold, shut off steam.

b. Is there a plugged strainer up stream of trap?

Yes, then clean strainer.

c. If no plugged strainer, open trap.

d. Is valve on seat at room temperature? Yes,

then replace element.

e. Is it plugged with dirt at inlet or outlet? Yes,

then clean it.

2. No then:

a. Observe trap discharge to atmosphere. (This is

the best way to check this trap.) Is there live

steam? Yes, then replace trap.

Traps on Superheated Steam

Do not use thermostatic or float and thermostatic traps,

which employ balanced pressure bellows, where

superheated steam will contact the element.

Inverted bucket traps can be used successfully on

superheated steam. When functioning properly they will be

at the saturation temperature of the pressure involved. If

one fails open it will be at the superheat temperature. An

inverted bucket trap on superheated steam is one of the

few combinations that can be checked successfully by

temperature.

Testing Schedule

For maximum trap life and steam economy, a regular

schedule should be set up for trap testing and preventative

maintenance. Trap size, operating pressure and importance

determine how frequently traps should be checked.

Drip Tracer Coil Process

0 - 100 1 1 2 3

101 - 250 2 2 2 3

251 - 450 2 2 3 4

450 and above 3 3 4 12

Suggested Yearl y Trap Testing Frequency

Operating

Pressure (psig)

Application

Armstrong Steam and Condensate Group

816 Maple Street, Three Rivers, Michigan 49093 - USA

Ph: (269) 273-1415 Fax: (269) 278-6555

www.armstronginternational.com

Bulletin No. 310-D 6/06 Printed in U.S.A.

2006 Armstrong International, Inc.

You might also like

- Systematic Methods of Water Quality Parameters Analysis: Analytical MethodsFrom EverandSystematic Methods of Water Quality Parameters Analysis: Analytical MethodsNo ratings yet

- Flat-Plate Solar Collectors For Water HeatingDocument271 pagesFlat-Plate Solar Collectors For Water HeatingelissiumNo ratings yet

- The Importance of Intensive Steam Trap ManagementDocument4 pagesThe Importance of Intensive Steam Trap ManagementRobert MontoyaNo ratings yet

- Pollution Control in Oil, Gas and Chemical PlantsDocument15 pagesPollution Control in Oil, Gas and Chemical PlantsPRAFULKUMAR PARMARNo ratings yet

- Vacuum Test Procedure PDFDocument2 pagesVacuum Test Procedure PDFDanilo de JurasNo ratings yet

- Tank CleaningDocument2 pagesTank CleaninghayatmdazharNo ratings yet

- Steven Greer TranscriptDocument44 pagesSteven Greer Transcriptpgeorg100% (1)

- 33kv Abb GisDocument21 pages33kv Abb GisViresh ShaunakNo ratings yet

- Heat Exchangers, Strainers and SeperatorsDocument12 pagesHeat Exchangers, Strainers and SeperatorsJaveed A. Khan100% (1)

- ISCC EU 205 GHG Emissions Calculation Methodology and GHG Audit 2.3Document28 pagesISCC EU 205 GHG Emissions Calculation Methodology and GHG Audit 2.3Murrali Raj JeyagapalNo ratings yet

- Water DisinfectionDocument24 pagesWater DisinfectionJaycen RussellNo ratings yet

- Deo Max N1Document2 pagesDeo Max N1Murrali Raj JeyagapalNo ratings yet

- 17.4 Boiler and Feed-Water TreatmentDocument28 pages17.4 Boiler and Feed-Water Treatmentnomeacuerdo1No ratings yet

- Where, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedDocument43 pagesWhere, The Temperature Ratio, Capacity Ratio, R A Value of 0.8 Is Generally Not AcceptedAditya DeokarNo ratings yet

- Corrosion Mechanisms of Mild Steel in Weak Acids - T. Tran - 2014 - PHD PDFDocument156 pagesCorrosion Mechanisms of Mild Steel in Weak Acids - T. Tran - 2014 - PHD PDFAsep Ridwan SetiawanNo ratings yet

- Pipeline DryingDocument2 pagesPipeline DryingAdan Farias de PinaNo ratings yet

- Handbook of Water TreatmentDocument501 pagesHandbook of Water Treatmenthenryzyg100% (2)

- Edo Wms Coe Cor Int XXX 014 178 206 Rev A DCVG WmsDocument16 pagesEdo Wms Coe Cor Int XXX 014 178 206 Rev A DCVG WmsErol DAĞNo ratings yet

- About Flame Arrestors and Detonation ArrestorsDocument8 pagesAbout Flame Arrestors and Detonation ArrestorsMurrali Raj JeyagapalNo ratings yet

- Descon Engineering - Abu Dhabi: Procedure For Chemical Cleaning of Heat Exchanger/ Fin Fan CoolerDocument4 pagesDescon Engineering - Abu Dhabi: Procedure For Chemical Cleaning of Heat Exchanger/ Fin Fan CoolerMohammad Fazal KhanNo ratings yet

- Case Studies in Pre Inspection: CleaningDocument4 pagesCase Studies in Pre Inspection: CleaningSamtron610No ratings yet

- Predict Storage Tank Heat Transfer Precisely Rev2Document16 pagesPredict Storage Tank Heat Transfer Precisely Rev2zefiloNo ratings yet

- Key To Successful Chemical Cleaning of BoilersDocument14 pagesKey To Successful Chemical Cleaning of BoilersNeeraj HegdeNo ratings yet

- Understanding and Eliminating Pressure Fluctuations in 2010 Process SafetyDocument6 pagesUnderstanding and Eliminating Pressure Fluctuations in 2010 Process SafetyandriNo ratings yet

- Metallurgical Failure AnalysisDocument4 pagesMetallurgical Failure AnalysisgirishnitwNo ratings yet

- Tanks, Terminals and Storage-Kim (Covestro Bechtel)Document12 pagesTanks, Terminals and Storage-Kim (Covestro Bechtel)cristianNo ratings yet

- Undestanding The PHEDocument6 pagesUndestanding The PHEMurrali Raj Jeyagapal100% (2)

- Chemicalcleaning For BoilerDocument16 pagesChemicalcleaning For Boilerak_thimiriNo ratings yet

- Tank Cleaning Robotic ServicesDocument2 pagesTank Cleaning Robotic ServicesgmitsutaNo ratings yet

- SOP Freeze DryingDocument4 pagesSOP Freeze Dryingazura_zfNo ratings yet

- Boiler Troubles: Prepared by S.I.Davis PresleyDocument26 pagesBoiler Troubles: Prepared by S.I.Davis PresleyAbinav Narayanan100% (1)

- 7 Steps To Boiler Chemical Cleaning and Treatment Selection in Thermal Power PlantDocument9 pages7 Steps To Boiler Chemical Cleaning and Treatment Selection in Thermal Power PlantAra SanirapNo ratings yet

- Hydrotest JHADocument29 pagesHydrotest JHABenjamin EmmanuelNo ratings yet

- Various Type of Steam TrapsDocument46 pagesVarious Type of Steam TrapsRamesh VenugopalNo ratings yet

- How Vci WorkDocument21 pagesHow Vci Work同道文档中心100% (1)

- Steam Trap Cross Reference GuideDocument5 pagesSteam Trap Cross Reference GuideTONNo ratings yet

- Solution Chapter 6Document26 pagesSolution Chapter 6Cara WhiteNo ratings yet

- HYDROMILLINGDocument24 pagesHYDROMILLINGJose Omar RodriguezNo ratings yet

- CESCO Technical ProposalDocument2 pagesCESCO Technical ProposalthmaraishriNo ratings yet

- Boiler Inspection PreparationDocument1 pageBoiler Inspection PreparationMirso100% (2)

- Boiler Safety Program Boiler ProgramDocument8 pagesBoiler Safety Program Boiler Programsalman akbarNo ratings yet

- Guideline Chlorine Gas Pipeline 10032019 RevisedDocument40 pagesGuideline Chlorine Gas Pipeline 10032019 RevisedDarshan PatelNo ratings yet

- Boiler Tube Failure PDFDocument8 pagesBoiler Tube Failure PDFmhd_bashiriNo ratings yet

- Spirax Sarco PDFDocument4 pagesSpirax Sarco PDFandresaroNo ratings yet

- Sea Water For HydrotestDocument2 pagesSea Water For HydrotestNakkolopNo ratings yet

- Liquid Liquid Separation TechnologyDocument16 pagesLiquid Liquid Separation TechnologyMurrali Raj JeyagapalNo ratings yet

- Fuel Injector Testing ReportDocument12 pagesFuel Injector Testing ReportZeke KazamiNo ratings yet

- Machine GuardingDocument81 pagesMachine GuardingCyril CruzNo ratings yet

- KOSUN Decanter Centrifuge Process in DrillingDocument2 pagesKOSUN Decanter Centrifuge Process in DrillingzmzmllllNo ratings yet

- StrippersDocument6 pagesStrippersDiliniNo ratings yet

- PiggingDocument5 pagesPiggingDendi AriyonoNo ratings yet

- Excess FLow ValveDocument9 pagesExcess FLow ValvechloeNo ratings yet

- Condenser Chemical CleaningDocument12 pagesCondenser Chemical CleaningBibhu Misra100% (1)

- Ultimate Unpiggable E-GuideDocument16 pagesUltimate Unpiggable E-Guidepatrick6364No ratings yet

- Metallurgical Condition AssessmentDocument2 pagesMetallurgical Condition AssessmentJohnNo ratings yet

- Condensate ReturnDocument24 pagesCondensate Returnwaheed2286No ratings yet

- Gas-Liquid AbsorptionDocument18 pagesGas-Liquid AbsorptionMahmoud HendawyNo ratings yet

- Procedure For Inspection and Sterilisation of Water Storage TanksDocument4 pagesProcedure For Inspection and Sterilisation of Water Storage TanksMuhammad Hussain BilalNo ratings yet

- Rotary Joint Reliability-2014Document24 pagesRotary Joint Reliability-2014Edgar Cordova HerreraNo ratings yet

- c2 PDFDocument78 pagesc2 PDFSyazaa SalimNo ratings yet

- The Oropesa. - (1943) P. 32Document10 pagesThe Oropesa. - (1943) P. 32itsroro1989No ratings yet

- Gas Chlorine StationsDocument46 pagesGas Chlorine StationsakramhomriNo ratings yet

- Applications of Different Types of Steam Traps - TLV - A Steam Specialist Company (United Arab Emirates) PDFDocument5 pagesApplications of Different Types of Steam Traps - TLV - A Steam Specialist Company (United Arab Emirates) PDFDũng LêNo ratings yet

- N2 Membrane Technical PDFDocument3 pagesN2 Membrane Technical PDFMargaret DaughertyNo ratings yet

- Typical Acid Cleaning Procedure For Compressor LinesDocument1 pageTypical Acid Cleaning Procedure For Compressor Linesrenjithv_4No ratings yet

- Restaurant in UAE (Page 3)Document4 pagesRestaurant in UAE (Page 3)jeevafoodstufftradingNo ratings yet

- Furnace Hot Spot Repair Report Reformer Malaysia Jan 2017 PDFDocument14 pagesFurnace Hot Spot Repair Report Reformer Malaysia Jan 2017 PDFRajabuddin AhmedNo ratings yet

- Disinfection Procedure For Water Distribution LinesDocument3 pagesDisinfection Procedure For Water Distribution Linesfa forb100% (1)

- Testing Procedures: Pressure Test Which Is Also Called The Modified Hydrostatic Test. Hydrostatic Testing Is Also A WayDocument5 pagesTesting Procedures: Pressure Test Which Is Also Called The Modified Hydrostatic Test. Hydrostatic Testing Is Also A Wayvaresh111No ratings yet

- Testing Steam Traps: IndexDocument3 pagesTesting Steam Traps: IndexArturo RockNo ratings yet

- Specific Gravity of Common Materials1Document1 pageSpecific Gravity of Common Materials1Murrali Raj JeyagapalNo ratings yet

- MSDS HexaneDocument9 pagesMSDS HexaneMurrali Raj JeyagapalNo ratings yet

- Wim BleachingDocument31 pagesWim BleachingSantiago TuestaNo ratings yet

- Basket Strainer - Inline: Plan ADocument2 pagesBasket Strainer - Inline: Plan AMurrali Raj JeyagapalNo ratings yet

- TemperatureRegulators PDFDocument8 pagesTemperatureRegulators PDFtecnidibujosNo ratings yet

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 pagesAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- Use and Maintenance Manual V360: Siata V360 Pag. 1 of 25Document25 pagesUse and Maintenance Manual V360: Siata V360 Pag. 1 of 25Murrali Raj JeyagapalNo ratings yet

- 70-Giaflex Heating Insulation SLDocument2 pages70-Giaflex Heating Insulation SLMurrali Raj JeyagapalNo ratings yet

- SBE Cement UltrasonicDocument24 pagesSBE Cement UltrasonicMurrali Raj JeyagapalNo ratings yet

- Mobrey: Boiler Water Level ControlsDocument12 pagesMobrey: Boiler Water Level ControlsMurrali Raj JeyagapalNo ratings yet

- Unisim Design Tutorial For Chee470: Queen'S University Department of Chemical EngineeringDocument75 pagesUnisim Design Tutorial For Chee470: Queen'S University Department of Chemical EngineeringMurrali Raj JeyagapalNo ratings yet

- Project Aspen VistaDocument4 pagesProject Aspen VistaMurrali Raj JeyagapalNo ratings yet

- DPX-15703A - Perkins 66 kVA (1103A-33T)Document7 pagesDPX-15703A - Perkins 66 kVA (1103A-33T)Edwin GallegosNo ratings yet

- Tutorial 3 Phy250Document4 pagesTutorial 3 Phy250Anonymous g3Jb4ZOsNo ratings yet

- Manual Burkert 1078-1 1078-2 PDFDocument35 pagesManual Burkert 1078-1 1078-2 PDFVũ PhongNo ratings yet

- Pink & Blue Energy DrinkDocument37 pagesPink & Blue Energy DrinkUsman KhawajaNo ratings yet

- 558-Report HapDocument2 pages558-Report HapAL-BARSHA AWBSNo ratings yet

- B.E AssignmentDocument2 pagesB.E AssignmentNayan AgrawalNo ratings yet

- Manuel en Englais de Moteur Pas A PasDocument82 pagesManuel en Englais de Moteur Pas A Pasminaud yann bileNo ratings yet

- Problem Set 4Document1 pageProblem Set 4Dniel Suarez RNo ratings yet

- NTPCDocument14 pagesNTPCAnkitaBansalNo ratings yet

- E44160 V10 REVIS00 Box 385162 B00 PUBLIC0Document374 pagesE44160 V10 REVIS00 Box 385162 B00 PUBLIC0SJVN CIVIL DESIGNNo ratings yet

- BiobriquetteDocument7 pagesBiobriquetteputri wahyuniNo ratings yet

- Water Supply Plumbing Systems in Buildings & Houses: D.Eloise Sanhitha R.No: 20021A0115Document13 pagesWater Supply Plumbing Systems in Buildings & Houses: D.Eloise Sanhitha R.No: 20021A0115115 Sanhitha DevadhiNo ratings yet

- Sample Position PaperDocument4 pagesSample Position PaperSage Rainelle LingatongNo ratings yet

- MAN - Electrical Noise ProcedureDocument25 pagesMAN - Electrical Noise ProcedureDimitrisNo ratings yet

- Optimal Design of A High-Speed PMSGDocument13 pagesOptimal Design of A High-Speed PMSGHuynh Thanh AnhNo ratings yet

- Biomass Gasifica+On The Piracicaba Biosyngas Project: September 17, 2012 Dr. Fernando LandgrafDocument34 pagesBiomass Gasifica+On The Piracicaba Biosyngas Project: September 17, 2012 Dr. Fernando LandgrafAna lisbeth Galindo NogueraNo ratings yet

- Disano 2013 158-169 Office PDFDocument12 pagesDisano 2013 158-169 Office PDFglisha84No ratings yet

- T BSP P S 1. What Is Inflation?Document18 pagesT BSP P S 1. What Is Inflation?gladys manaliliNo ratings yet

- C-Power ACB Catalogue 1.7Document35 pagesC-Power ACB Catalogue 1.7diwakarNo ratings yet

- Most Common Errors in Service Entrance and Load Side Installations Prior To Final DU InspectionDocument193 pagesMost Common Errors in Service Entrance and Load Side Installations Prior To Final DU InspectionJoel RemegioNo ratings yet

- RFP For Fast Start Ancillary Service Version 2Document32 pagesRFP For Fast Start Ancillary Service Version 2gabypayneNo ratings yet

- CE5215-Theory and Applications of Cement Composites - Lecture 6Document23 pagesCE5215-Theory and Applications of Cement Composites - Lecture 6Pranab Biswas100% (1)

- 2022 Spring CatalogDocument39 pages2022 Spring Catalogmjavad40001382No ratings yet

- SPP 12306020 & PK 22306020 (Parts)Document2 pagesSPP 12306020 & PK 22306020 (Parts)Budi SetiawanNo ratings yet

- WP-004 ICCP InspectionDocument5 pagesWP-004 ICCP InspectionYusuf Maulana SaitNo ratings yet