Professional Documents

Culture Documents

Friction Stir Welding

Uploaded by

robertalhaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Friction Stir Welding

Uploaded by

robertalhaCopyright:

Available Formats

1

STUDYING THE EFFECT OF SHOULDER GEOMETRY IN

FRICTION STIR WELDING OF AA1100 ALUMINIUM ALLOY

BASED ON THERMAL IMAGING

Sridhar I yer

2

STUDYING THE EFFECT OF SHOULDER GEOMETRY IN

FRICTION STIR WELDING OF AA1100 ALUMINIUM ALLOY

BASED ON THERMAL IMAGING

Thesis submitted to

I ndian Institute of Technology Kharagpur

For the award of the degree

of

Master of Technology

in

Manufacturing Science and Engineering

by

Sridhar Iyer

Roll No. 08ME3111

Under the guidance of

Prof. Surjya K. Pal

DEPARTMENT OF MECHANICAL ENGINEERING

INDIAN INSTITUTE OF TECHNOLOGY KHARAGPUR

April 2013

3

APPROVAL OF THE VIVA-VOCE BOARD

Certified that the thesis entitled Studying the effect of shoulder geometry in friction stir

welding of AA1100 aluminium alloy based on thermal imaging submitted by Sridhar Iyer

(08ME3111) to the Indian Institute of Technology, Kharagpur, for the award of the degree

Master of Technology in Manufacturing Science and Engineering has been accepted by the

external examiner and that the student has successfully defended the thesis in the viva-voce

examination held today.

(Supervisor)

(External Examiner)

Department of Mechanical Engineering

Indian Institute of Technology Kharagpur

4

CERTIFICATE

This is to certify that the thesis entitled Studying the effect of shoulder geometry in friction

stir welding of AA1100 aluminium alloy based on thermal imaging, submitted by Sridhar

Iyer (08ME3111) to Indian Institute of Technology, Kharagpur, is a record of bona fide research

work under my supervision and I consider it worthy of consideration for the award of the degree

of Master of Technology in Manufacturing Science and Engineering.

(Supervisor)

Date:

Department of Mechanical Engineering

Indian Institute of Technology Kharagpur

5

DECLARATION

I certify that

a. The work contained in the thesis is original and has been done by myself under

the general supervision of my supervisor(s).

b. The work has not been submitted to any other Institute for any degree or diploma.

c. I have followed the guidelines provided by the Institute in writing the thesis.

d. I have conformed to the norms and guidelines given in the Ethical Code of Conduct of the

Institute.

e. Whenever I have used materials (data, theoretical analysis, and text) from other sources, I

have given due credit to them by citing them in the text of the thesis and giving their details

in the references.

f. Whenever I have quoted written materials from other sources, I have put them under

quotation marks and given due credit to the sources by citing them and giving required

details in the references.

Signature of the Student

6

Abstract

Frictions stir welding is a relatively new solid state joining process. Over the past decade a lot of

research has been done on optimization of FSW parameters by analyzing the mechanical

properties. A few papers have analyzed the process using finite element methods, though the

process has a lot of lacunae as the onion ring formation and tool work-piece interaction havent

been fully incorporated in the model yet. In this study, a thermal imaging camera was used to

obtain temperature profiles while welding. The images obtained by the thermal imager were

processed in MATLAB to obtain the temperature isotherms. The welded joints were further

analyzed for tensile strength and micro-hardness. Moreover, a new tool with different shoulder

geometry was used and the results were compared to that of the conventional FSW tool.

7

Table of Contents

Abstract ......................................................................................................................................................... 6

Friction Stir Welding ..................................................................................................................................... 8

Process parameters .................................................................................................................................. 9

Micro-structural changes ........................................................................................................................ 10

Literature survey ......................................................................................................................................... 12

Weld Characteristics ............................................................................................................................... 12

Process Optimization .............................................................................................................................. 13

Temperature Measurement Techniques ................................................................................................ 13

Typical friction Stir Welding Defects ....................................................................................................... 15

Objective ..................................................................................................................................................... 17

Experimental Setup ..................................................................................................................................... 18

Machines/Instruments used during experiments .................................................................................. 18

Experimental Procedure ............................................................................................................................. 23

Experimental work .................................................................................................................................. 23

Micro-hardness ....................................................................................................................................... 25

Temperature Measurements .................................................................................................................. 25

Tensile Strength ...................................................................................................................................... 25

Results and discussion ................................................................................................................................ 26

Thermal Analysis ..................................................................................................................................... 26

Measurement of power .......................................................................................................................... 29

Tensile properties ................................................................................................................................... 32

Optical macrograph for weld cross section and tensile test specimen .................................................. 36

Micro-hardness ....................................................................................................................................... 38

Conclusion ................................................................................................................................................... 40

References .................................................................................................................................................. 41

8

Friction Stir Welding

Friction stir welding (FSW) is a solid state joining process. This means that the weld material

never changes to liquid state and the welding takes place below the welding temperature offering

excellent mechanical properties. FSW finds its application in the aircraft and automobile industry

for welding of aluminium plates. In FSW a rotating non consumable tool is transversely moved

along the welding line. The nib, i.e. the tool pin is slightly shorter than the depth of welding

required, with the shoulder in contact with the work piece. [1] Due to the rotating motion of the

tool, frictional heat is generated at the tool work piece interface. The weld obtained is the

combined result of this localized heat generated and the mechanical deformation due the plunged

tool tip. 95% of this heat generated flows to the work piece [2]. This causes softening of material

around the pin and the tool rotation leads to the flow of material from the front end to the back

end, thereby producing a weld in solid state with dynamic re-crystallization of the work material

At the start of joining, tool plunge, the tool undergoes only rotation motion till the shoulder

comes in contact with the work piece, this is called the dwelling period of the tool. After the

dwell phase longitudinal feed is provided and the tool moves along the weld direction as shown

in figure 2. The tool is then withdrawn after the welding is complete. [1]

Friction stir welding has several advantages over fusion welding method as there is no change of

state involved. Issues such as porosity, solidification and liquation cracking do not arise in the

case of FSW and the concentration of defects is low. It has been increasingly used to weld

difficult-to-weld aluminium alloys [6-9]

Figure 1 Schematic diagram FSW [3] Figure 2 Stages in FSW [4]

9

Some key benefits of FSW are [10]:

Low distortion of the work piece

Good dimension stability and repeatability

No loss of alloying elements

Improved safety due to the absence of toxic fumes or the spatter of molten material.

Easily automated on simple milling machines lower setup costs and less training.

Can operate in all positions (horizontal, vertical, etc.), as there is no weld pool.

No Filler material ; Cost reduction

Process parameters

For a successful weld, the temperature of the tool should be hot enough to enable extensive

plastic deformation of the work piece; else voids or other flaws may be present in the work piece.

At the same time the increase in temperature also needs to be controlled to insure that the

temperature does not increase beyond the melting point in materials with low melting point such

as aluminium. Stirring at the plastic region also plays an important role in determining the

quality of weld.

Tool Rotation and welding speed

The rotation of tool causes stirring and mixing of material along the rotating pin. Higher tool

rotation generates higher temperature because of higher frictional heating and results in more

intense stirring and mixing of material. The translation of the tool moves the stirred material

from front to back of the pin. With constant rotational speed, high welding speed results in lower

heat input per unit length of the weld, causing lack of stirring in the friction stir processing zone

leading to poor tensile properties.

Tool Design

Tool design is also an important welding parameter as a good tool design can not only improve

the quality of the weld but also the maximum possible welding speed. Material selection,

shoulder diameter and tool pin height are some of the aspects that need to me considered while

selecting a tool. In the initial stage of the tool plunge, heating is a result of friction between the

10

work piece and tool pin. Thus the relative size of the pin plays an important role. The tool

shoulder not only provides a confinement for the heated volume of the material but also stirs and

moves the material as stated above. The uniformity of the micro-structural properties is governed

by the tool design.

Micro-structural changes

The welding parameters plays very significant role in deciding the temperature distribution

which produce a number of micro structural changes. These changes include diffusion and

diffusion less phase transformations, grain refinement, coarsening, and recrystallization. These

properties significantly alter the microstructure, thereby changing the properties of the material

near the weld zone.

There is an inverse relationship between delta yield strength and grain size, given by [11]

where is the strengthening coefficient and both and are material specific.

The relation between yield stress and grain size is described mathematically by Hall-Petch

equation [12]

Where

is the yield stress,

is a materials constant for the starting stress for dislocation

movement (or the resistance of the lattice to dislocation motion),

is the strengthening

coefficient (a constant unique to each material), and is the average grain diameter.

The yield doesnt keep increasing with decrease in grain size because at very small grain size

grain boundary sliding is observed.

11

The micro-structure can be broken into the following zones [1,13-14]

Dynamically recrystallized zone (DXZ) or stir zone: the high temperatures and high levels of

deformation result in full dynamic recrystallization and the formation of a fine-grain equiaxed

microstructure. This zone is indicative of hot-working produced by the combination of heat

induced by the rotating tool as well as the forging action produced by the shoulder of the tool as

it traverses along the joint. This is in contrast to a fusion-welded joint, which shows a dendritic

structure representative of a solidification process. Several concentric rings, called the onion

rings, are observed, the precise origin of which has not been completely understood.

Thermo mechanically affected zone (TMZ): This region occurs on either side of the stir zone

where the deformation is sufficient to cause grain reorientation and rotation; however, the grains

are not recrystallized.

Heat-affected zone (HAZ): A well-defined HAZ is present in heat-treatable alloys; this zone is

adjacent to the TMZ. In this zone, only thermal effects are present; no deformation is observed

during welding. However the temperature may have significant effect if the microstructure is

unstable.

Flow arm zone: It consists of material that is dragged by the shoulder from the retreating side

and deposited on the advancing side.

12

Literature survey

Weld Characteristics

James and Mahoney [ 16 ] measured the residual stresses of friction stir welds by means of X-ray

diffraction. It was observed that the residual stresses in all the FSW welds were quite low

compared to those generated by fusion welding. This was attributed to the low heat input. Peel et

al [17] observed that the nugget zone was in tension both in longitudinal and transverse

directions. Moreover, the longitudinal stress increased with increasing tool traverse speed

whereas the transverse residual stresses do not exhibit any dependence on transverse speed.

For heat treatable alloys, Sato et al [18] examined the hardness profiles associated with the

microstructure in friction stir welding of 6063Al-T5. The hardness profile was fouond to be

strongly affected by precipitate distribution rather than grain size in the weld. For solid-solution-

hardened aluminium alloys, FSW does not result in softening of welds [19, 20].

Mahoney et al [21] investigated the effect of FSW on room-temperature tensile properties of Al

7074-T651. The weld samples showed a reduction in yield and ultimate strengths in the weld

nugget, while elongation was unaffected. This reduced strength was attributed to reduction in

pre-existing dislocations and elimination of the very fine hardening precipitates. Biallas et al [22]

observed that for a constant ratio of tool traverse speed/rotation rate, both yield and ultimate

strengths increase with increasing tool rotation rate.

Elangovan et al [23] studied the effect of tool pin profiles and welding speed on the formation of

friction stir processing zone in AA2219 aluminium alloy. It was observed that square pin profile

tool produced defect free FSP region irrespective of the welding speed. Zhou et al [24] observed

that the fatigue life of 5083 aluminium alloy was longer than that of MID-pulse welds. The

fatigue characteristic value of each weld increased from 39.8MPa for MIG to 67.3MPa for FSW.

13

Process Optimization

Rajakumar et al [25] studied the influence of friction stir welding process and tool parameters on

strength properties of AA7075-T6 aluminium alloy joints. The strength properties of square butt

joints were evaluated and correlated with microstructure and micro-hardness of the weld nugget.

It was observed that the joint fabricated with tool RPM as 1400, welding speed of 60mm/min

and axial force of 8kN, using tool of 15mm shoulder diameter and 5 mm pin diameter yielded the

best strength properties.

Hans et al [26] evaluated the mechanical characteristics of friction stir welds for aluminium 5082

alloy. A tunnel type void was observed from an early stage to the end point at 1800 RPM. These

defects are rough with imperfect joining due to excessive rotation speed and high physical force.

The optimum FSW conditions were observed when the welding speed was 124 mm/min and

rotation speed was 800 RPM. A systematic approach to optimizing FSW process parameters

through consideration of power input was presented by Lombard et al. [27] Frictional power

governs the tensile strength and fatigue life of 5083 aluminium alloy through its effect on plastic

flow processes in the thermo-mechanically affected zone (TMAZ)

Design of experiments has been found to an effective tool for parameter optimization during

friction stir welding. Two level factorial design was used by Grover et al [28] to investigate the

interaction effects of parameters on the required response. Nourani et al[29] used Taguchi

optimization to minimize the HAZ distance to the weld line and peak temperatures. Rotational

speed was observed to be the most significant parameter among axial force, rotational speed and

welding speed based on ANOVA analysis.

Temperature Measurement Techniques

Since the temperature distribution within and around the stirred zone directly influences the

Micro structure of the welds, the range of maximum temperature within the stirred zone can be

estimated form the microstructure of the weld. [30-31] In most cases the temperatures generated

in the FSW zone exceeded the precipitate solvus temperatures. As a result, precipitate dissolution

and re-precipitation was observed in some specific alloys. An investigation of micro-structural

evolution in 7075Al-T651 during FSW by Rhodes et al. [30] showed dissolution of larger

14

precipitates and re-precipitation in the weld center. Therefore, they concluded that maximum

process temperatures are between about 400 and 480C in FSW 7075Al- T651. On the hand,

Murr et al [31] indicated that some of the precipitates were not dissolved during welding and

suggested that the temperature rises to roughly 400C in FSW 6061Al. Sato et al. [18] estimated

the peak temperatures at different distances away from the weld center by studying the micro

structural evolution of 6063Al during FSW using transmission electron microscopy (TEM) and

comparing it with the simulated weld thermal cycles.

Another technique used for measuring the temperatures during welding is by using embedded

thermocouples in the region to be welded. Tang et al. [33] measured the heat input and

temperature distribution within friction stir weld of 6061Al-T6 aluminum plates with a thickness

of 6.4 mm using this technique. The thermocouples were embedded into the back surface of the

work piece at three different depths. It was found that the thermocouples were not destroyed by

the pin during welding but changed position due to plastic flow of the material ahead of the pin.

Further, the weld temperature was found to increase with increase in weld pressure and tool

rotation. Kwon et al. [34] and Hashimoto et al. [35] also measured the temperature rise in the

weld zone by embedded thermocouple technique. Kwon et al. reported that in FSW 1050Al, the

peak temperature in the FSP zone increased linearly from 190 to 310C with increasing tool

rotation rate from 560 to 1840 rpm at a constant tool traverse speed of 155 mm/min. Hashimoto

et al reported that the peak temperature in the weld zone increases with increasing the ratio of

tool rotation rate/traverse speed for FSW of 2024Al-T6, 5083Al-O and 7075Al-T6. A peak

temperature >550C was observed in FSW 5083Al-O at a high ratio of tool rotation rate/traverse

speed.

Another technique for temperature measurement which has gained prominence over the last few

years is the use of infra red (IR) thermal imager. Many commercially available IR imaging

systems now support excellent temperature precision for fast frame rates and small spatial

resolutions. Hamilton et al [36] used a Mikron M7815 thermal imaging camera to record the

temperature profile using welding. The thermal emissivity was calibrated by heating the

aluminium surface to 460C and adjusting the emissivity value till the recorded temperature of

the camera matched the reference temperature. The emissivity was determined to be .285. FSW

15

research team from National R&D Institute for Welding and Material Testing ISIM Timisoara,

demonstrated the possibilities of using infrared thermo graphic technique for monitoring friction

stir welding process (FSW) [37]

Typical friction Stir Welding Defects

The process parameters in FSW cause too hot or too cold welds. Too cold weld condition lead to

insufficient material flow and gives rise to defects like void formation and nonbonding. Too hot

weld condition may lead to liquation of low melting point phase or material expulsion with flash

formation and the collapse of the nugget within the stir zone. [37]

Defects from too hot welds

The defects which are generated under such processing conditions are visually identified through

the surface appearance of the welded joint. The improper parameter settings cause too much

thermal softening. The surface of welded joint appears to contain blisters or surface galling.

Furthermore, excessive heat generation can lead to thermal softening in the work piece material

beyond the boundary of tool shoulder. Therefore, the tool shoulder, rather than actively

participating as a means for material containment, gives rise to material expulsion in the form of

excessive flash formation. This leads to the thinning of the work piece material. The work piece

material below the tool shoulder may reaches a point where it is no longer able to support the

axial load placed upon it, which causes production of excessive flash.

A weld nugget collapse under too hot welding condition is another serious defect in FSW joints.

It is not always expected that the increase of tool rotational speed at constant tool travel speed

will increase the size of weld nugget.[38]

Colegrove et al [39] has observed that the nugget region for an Al-Cu-Mg-Mn 2024 alloy can

actually decrease in size rather than increase in size when tool rotational speed is sufficiently

increased. The thermal softening brought about by very hot processing condition can lead to slip

between the tool pin and the workpiece material, and thus decreases strain rates within the

immediate vicinity of the tool pin. The weld nugget appears distorted. This weld nugget collapse

is generally occurred in the retreating side of the stir zone.

16

Defects from too cold welds

Too cold welding condition results in work hardening of the workpiece material. This causes dry

slip between the tool pin and the workpiece material. The lack of surface fills or voids and

channel defect are the main defects arising due to insufficient heat generation. The insufficient

heat generation causes improper material mixing and thus responsible for non-bonding.

Cavaliere et al [40] studied FSW joint cross-sections and SEM observations of the fractured

surfaces to characterize the weld performances. He studied the effect of the welding speed on the

fractured surface of the tensile and fatigue tested specimens. The work-piece material

investigated was AA 6082. The fractured surface appeared populated with very fine dimples

revealing a very ductile behavior of the material before failure. All the fatigue tested specimens

were observed to fracture in the advancing side of the tool. It was observed that, at higher

stresses the fatigue cracks started from the surface. Such big defects were often associated with

the vortex formed in the material in the advancing side where a more chaotic flow is formed

leading to the presence of voids of the mean dimension of hundreds of microns that represent the

site of fatigue cracks initiation. By decreasing the stress amplitude a strong change in the crack

behaviour was detected, the crack appear to start from the forging defects inside the joints which

are always present in this kind of welding. The failure was also related to the coalescence of

many small voids and defects in the material. The presence of dimples on the surface revealed a

local ductile behaviour of the material prior to fracture. This is the case of such conditions in

which the optimal solution between material mixing and grain refinement is obtained. By

increasing the advancing speed of the tool the material is extruded too fast (high strain rates) and

do not reached the conditions for the optimal mixing. The coupling of a high rotation speed and

high advancing speed leads to a good material mixing but to a non-optimal grain structure.

17

Objective

Friction stir welding process involves hot-working due to heat produced by the combination of

friction at the rotating shoulder and plastic deformation produced by the tool pin as it traverses

along the joint. The variation in weld quality with changing parameter could be understood by

analyzing the temperature variation during various weld parameters and further analysis of weld

properties.

The objectives of this research project are as follows:

Development of temperature isotherms for various weld parameters during friction stir

welding by careful temperature measurements using infrared imaging, and correlating

these measurements with the experimental results of tensile strength

Designing a new tool for friction stir welding, with different shoulder geometry, and

comparing the variation in weld properties between the welds obtained by this tool and

the conventional FSW tool.

To sum it up the research aims to understand how the thermal fields produced during FSW

influences the physical properties of FSW joints. The variation in tensile strength and micro-

hardness would be used study the effect of change in parameters on the friction stir welds.

18

Experimental Setup

Machines/Instruments used during experiments

VF3.5 Knee Type Milling Machine

Friction stir welding was performed in the VF3.5 Knee Type Milling Machine shown in the

figure. The friction stir welding setup was mounted over this knee type milling Machine. The

machine has a RPM range from 50 to 1800 RPM and traverse speed range from 16 to 800

mm/min.

Figure 3 FSW Setup

19

Power Sensor

The power input to the VF3.5 Knee Type Milling Machine during the welding procedure was

measured by the power sensor PS100-DGM as shown in figure 4. The PS100-DGM is a power

sensor with on-board microprocessor controlled gain, offset, and non-linear filtering.

Sensor Type Active power sensor

Range of Measurements Current supply: 4.2A to 100A

Voltage supply: 230 to 460VAC

Range of input frequency: 0 1000Hz

Output Signal 0-10V DC analog

Dimensions 114 x 232 x 33

Temperature Range Operation: up to 55 C

Storage: -40 to 100 C

Relative Humidity 0 to 95 %, non-condensing

Diameter Cable Lead-trough 16mm

National Instrument and LABview Software

A NI card was used for data acquisition for the measurement of power during welding

experiment. Power sensor was connected to a personal computer through one channel of a data

acquisition system.

The experimental set up for power measurement, acquisition system and computer LabVIEW are

displayed in figure 5 and figure 6.

Table 1. Technical data of Power Sensor

Figure 4 NI card

20

FLIR A-320 camera for Thermal Imaging

An Infrared camera measures and images the emitted radiation from an object. The fact that

radiation is a function of object surface temperature makes it possible for the camera to calculate

and display this temperature.

FLIR R&D software was used to analysis the video feed from the camera. A sample image taken

during the welding process is shown in the figure. The FLIR A320 camera has optimum

resolution of 320x240, frequency of 30Hz and 8X interpolating zoom. The object temperature

range was set as 200

C to 1200

C

The radiation measured by the camera does not only depend on the temperature of the object but

is also a function of the emissivity. This was calculated as 0.28. For calculating this a black

Figure 5 Power Sensor circuit Figure 6 Capturing the reading by using LabVIEW

Figure 7 FLIR A320 Camera Figure 8 Sample video feed

21

coating with known high emissivity was used and the temperature of aluminium plate was

calibrated to this temperature.

LEICA DFC-295 for Macrostructure

Macrostructure analysis was carried out using light optical microscope (LEICA DFC-295). The

images were analyzed in QWin-V3 software.

Figure 9 LEICA DFC-295

22

Vickers micro-hardness testing apparatus

A diamond indenter was used to make micro-indentations on the polished aluminium surface.

The indentations were measured optically and converted to hardness value. Test load of 50 gf

and 15s dwell tome was used.

INSTON (Universal Testing Machine)

Tensile tests were carried out on a computer controlled universal tensile testing machine

INSTRON at a crosshead speed of 2 mm/min. Transverse tensile test specimen were prepared

and tested according to ASTM E8M-04 guidelines.

Figure 10 Leco LM-700 Micro-indenter Figure 11 Universal Testing

23

Experimental Procedure

Experimental work

The rolled plates of 2.5 mm thickness, aluminium alloy, were cut into the required size

(200mm100mm2.5mm) by power hacksaw cutting. The initial joint configuration is obtained

by securing the plates in position using mechanical clamps. The direction of welding is normal to

the rolling direction. Single pass welding procedure has been used to fabricate the joints. No

special treatment was carried out before welding and testing. Non-consumable tool made of

stainless steel SS316 was used to as the machining tool. The chemical composition of work piece

material was analysed by energy dispersive X-ray spectroscopy.

Chemical Composition of the work-piece material (AA1100)

Composition Weight Percentage

Silicon 0.76

Iron 0.850

Copper 0.01

Manganese 0.006

Aluminium 98.3

Chemical Composition of the tool material (SS316)

Composition Weight Percentage

Iron 72.01

Chromium 16.29

Manganese 8.95

Silicon 2.13

Phosphorus 0.27

Nickel 0.20

Table 2 Composition of the workpiece material

Table 3 Composition of the tool material

24

Mechanical properties of the work piece material

Properties Value

Ultimate tensile strength 106.27 MPa

Yield strength 94.25 MPa

Percentage elongation 21.27

Vickers micro hardness 50

Figure 12 and figure 13 show the tools which were used for FSW, the dimensions for the same

are given in table 5.

Experiments were performed at 3 different RPM and feed rates. The RPM that were selected

were 900, 1400 and 1800 and the feed rates were 16mm/min, 31.5mm/min and 63mm/min.

Tool Dimensions Value

Tool Shoulder Diameter(D), mm 16

Tool Pin Diameter(d), mm 5

Tool Pin length(L), mm 2.1

D/d ratio 3.2

Table 5 FSW Tool Specifications

Table 4 Mechanical Properties of work piece

Figure 12 Tools used for Friction stir Figure 13 Top View Cylindrical Tool Ribs and Flat Cylindrical

tool

25

Micro-hardness

The micro-hardness profiles of friction stir welding joints were measured in the cross sections in

order to evaluate the material behavior as a function of the different welding parameters. The

specimen for the same was prepared by grinding the specimen cross section using emery paper

and then using a diamond paste to polish the samples

Temperature Measurements

While conducting experiments FLIR A320 camera was used to obtain the temperature

distribution over the entire field of view. The camera was placed on a tripod stand and placed in

a stable position in front of the milling machine bed. This camera was connected to a laptop to

capture the video feed and further process it in propriety FLIR software.

The thermal image thus obtained was analyzed in MATLAB to obtain temperature isotherms.

Tensile Strength

Test specimens for tensile testing were produced by wire EDM. Tensile tests were performed in

100 KN; electro-mechanical controlled Universal Testing Machine (INSTRON). The specimen

fails with necking and various data such as yield strength, ultimate tensile strength and

percentage elongation are recorded. The specimen is loaded at the strain rate of 2mm/min as per

ASTM specification and extensometer is attached to the specimen.

Figure 14 FLIR Camera on Tripod

Stand

Figure 15 Field of view of the camera

26

Results and discussion

Thermal Analysis

In FSW heat is generated by combination of friction and plastic dissipation during deformation

of the metal. The dominating heat generation mechanism is influenced by weld parameters,

thermal conductivities of the work piece, pin tool, backing anvils and the weld tool geometry.

Hotter welds are generated with high rpm and low weld speed and colder welds with low rpm

and high weld speed. A too-low temperature around the joint line will make it difficult for the

pin to traverse the work piece, which can result in breaking of the pin. A higher temperature can

decrease the flow stress of the work piece and make the work piece material stick.

During plunging and dwelling there is rapid increase in the temperature w. r. t. time. As the

temperature increases during plunging and dwelling, the metal softens and friction between tool

and work piece reduces, this results in decrease of rate of temperature increase during tool

traverse i.e. during actual welding. The max temperature reduces after a while as the heat loss

due to conduction increases. Similarly, as the tool reaches the other end of the work piece there

is yet another sharp rise in the temperature as the area for the heat loss by conduction around the

tool decreases. The temperature versus time graph for cylindrical tool weld speed of 16 mm/min

and rotational speed of 1800pm is shown in Graph 1.

0

100

200

300

400

500

600

700

0 2 4 6 8 10 12

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Time (min)

Temperature Vs Time

Graph 1 Variation in for cylindrical tool with RPM 1800 & feed

rate 16mm/min

27

It was found that as the RPM increases the surface temperature increases. The percentage

increase in temperature from 900 RPM to 1400 RPM is greater than the corresponding increase

from 1400 to 1800 RPM. This is because as the temperature of the weld metal rises, the metal

softens, torque is reduced, and less heat is imparted to the metal by mechanical work, friction

phenomenon gets replaced by stick-slide phenomenon between tool and work piece.

The steady state temperature recorded for each welding process is given in table 6

Experimental Parameters Steady state temperature for

plain cylindrical tool

Steady state temperature of

cylindrical tool with ribs

Feed Rate : 16 mm/min

RPM

900 320 300

1400 400 480

1800 440 500

Feed Rate: 31.5 mm/min

RPM

900 330 320

1400 380 430

1800 420 480

Feed Rate: 63 mm/min

RPM

900 320 330

1400 360 410

1800 400 470

Table 6 Steady state temperature readings

28

200

250

300

350

400

450

500

700 900 1100 1300 1500 1700 1900

T

e

m

p

e

r

a

t

u

r

e

RPM

For Cylindrical Tool

Average Temperature VS RPM

16

31.5

63

Graph 2 Variation in temperature with RPM for Flat

Cylindrical Tool

The variation in temperature for both tools is shown in the following graphs.

200

250

300

350

400

450

500

550

700 900 1100 1300 1500 1700 1900

T

e

m

p

e

r

a

t

u

r

e

RPM

For Tool woth Ribs

Average Temperature VS RPM

16

31.5

63

Graph 3 Variation in temperature with RPM for Cylindrical

Tool with Ribs

29

The temperature readings obtained were processed in MATLAB to obtain temperature isotherms

for various weld parameters.

Measurement of power

The FSW process consists of several steps i.e. plunging and dwelling, actual welding and pulling

the tool out of work piece. During the plunge stage a non-consumable rotating tool is slowly

plunged into the joint line between the two materials to be welded. Once the tool reaches the

required depth it is held in position for some time while still rotating, this is called the dwell

stage. The purpose of this stage is to soften the work piece material ahead of the tool before

welding. During the translational stage the tool traverses along the joint line of the two work

piece plates leaving behind a fully consolidated weld. The power used during FSW of aluminium

alloy plate of 2.5 mm thickness with cylindrical tool with ribs at weld speed of 16 mm/min and

rotational speed 1800 RPM as recorded is shown in Graph 4. Power reaches to peak values

during the plunging and dwelling of the tool into the work piece when the shoulder reaches the

target depth. The power then reaches a relatively steady state during translation motion of the

tool. Further, the input power decreases sharply when the welding is completed and the tool is

withdrawn.

Figure 16 Temperature isotherm for Cylindrical tool with RPM

1800 and feed rate 16mm/min

30

Graph 4 Variation in Power Consumed

RPM:- 1800 Feed Rate:- 16 mm/min for flat cylindrical tool with ribs

The power consumption for varying RPMs and at a feed rate of 16mm/min was calculated while

welding. The results have been tabulated below

Experiment Parameters Steady state power measurement

for tool with ribs (in Watts)

Steady state power measurement

for flat cylindrical tool ( Watts)

Feed Rate: 16 mm/min

RPM

900 2275 2000

1400 2750 2500

1800 3500 3000

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

0 100 200 300 400 500 600 700

P

o

w

e

r

(

W

a

t

t

)

Time (seconds)

Power Vs Time

Table 7 Variation of power with RPM at

16mm/min feed rate

31

From the table it can observed that the power consumption for cylindrical tool with ribs is greater

than that for the flat cylindrical tool. This can be attributed to the greater plastic deformation

produced while using the cylindrical tool with ribs. The power consumption also increases with

increase in RPM. Graph 5 shows the variation in power consumption with changing RPM.

0

500

1000

1500

2000

2500

3000

3500

4000

0 500 1000 1500 2000

P

o

w

e

r

(

W

a

t

t

)

RPM

Power Vs RPM

Cylindrical tool with

ribs

Flat cylindrical tool

Graph 5 Variation of power with RPM at 16mm/min feed rate for

both tools

32

Tensile properties

The parent material was machined by wire EDM to prepare a sample for tensile testing.

American Society for testing materials (ASTM E8M-04) guidelines was followed for preparing

the test specimens.

Figure 17 Tensile test specimen

The Ultimate tensile strength and yield strength was obtained as 106.27 MPa and 94 MPa

respectively. The percentage elongation for the aluminium alloy was recorded as 21.27%.

0

20

40

60

80

100

120

0 0.05 0.1 0.15 0.2 0.25

T

e

n

s

i

l

e

S

t

r

e

s

s

(

M

p

a

)

Tensile Strain

Stress Vs Strain

Graph 6 Stress-strain curve for AA1120

33

Influence of tool rotational speed and shoulder geometry on tensile properties

Traverse tensile properties of Friction stir welds such as yield strength and ultimate tensile

strength were obtained for a constant feed rate of 16mm/min and varying RPM. The values

obtained are given in table 8.

Feed Rate: 16 mm/min

RPM

UTS (MPa) Yield Strength

(MPa)

UTS (MPa) Yield Strength

(MPa)

900 90 71 75 71

1400 90.24 57.89 98 65

1800 91 58 93 54

A plot of UTS Vs RPM at 16mm/min shows that for cylindrical tool with ribs a sharp

increase in UTS is observed when the RPM is increased from 900 to 1400, thereafter the

value of UTS decreases as the RPM is further increased to 1800. Not much variation in UTS

is observed for flat cylindrical tool at a feed rate of 16mm/min

50

60

70

80

90

100

110

700 900 1100 1300 1500 1700 1900

U

T

S

(

M

P

a

)

RPM

UTS Vs RPM

Flat

Ribs

Experiment Parameters Flat cylindrical tool Cylindrical tool with Ribs

Table 8 UTS and Yield Strength at feed rate of

16mm/min

Graph 7 Variation of UTS with RPM for a constant feed

rate of 16mm/min

34

The yield strength for the weld samples shows a decrease with increase in RPM. At higher

RPM the steady state temperature is more, this leads to a larger grain size which in turn

causes decrease in yield strength. Moreover, the increase in grain size is also accompanied

by decrease in elongation, i.e. the ductility of the welded material. The values for the

elongation percentage are given in table 9

40

45

50

55

60

65

70

75

700 900 1100 1300 1500 1700 1900

Y

i

e

l

d

S

t

r

e

n

g

t

h

(

M

P

a

)

RPM

Yield Strength Vs RPM

Flat

Ribs

Experiment Parameters Percentage Elongation for Flat

Cylindrical tool

Percentage Elongation for

Cylindrical tool with ribs

Feed Rate: 16 mm/min

RPM

900 14 7

1400 17.53 18

1800 18 21

Graph 8 Variation of yield strength with RPM for

a constant feed rate of 16mm/min

Table 9 Variation in % elongation with

varying RPM

35

Influence of weld speed and shoulder geometry on tensile properties

Table 10 shows the variation in ultimate tensile strength (UTS) and yield strength at a

constant RPM of 900 and varying feed rate.

RPM: 900

Feed Rate:

UTS (MPa)

Yield Strength

(MPa)

UTS (MPa)

Yield Strength

(MPa)

16 mm/min 90 71 75 71

31.5 mm/min 91 86 94 90

63 mm/min 95 71.94 83 78.29

It was observed that the yield strength increases with feed rate as it increases from

16mm/min to 31.5mm/min, but with further increase in feed rate the yield strength again

decreases. Moreover, the yield strength for cylindrical tool with ribs was found to be greater

than flat cylindrical tool. However, since UTS is depends on both yield strength and

hardness no specific trend is observed in UTS for the two given tools at constant RPM and a

varying feed rate. A plot for yield strength Vs feed rate at a RPM of 900 is shown below.

50

55

60

65

70

75

80

85

90

95

0 10 20 30 40 50 60 70

Y

i

e

l

d

S

t

r

e

n

g

t

h

(

M

P

a

)

Feed Rate (mm/min)

Yield Strength Vs Feed Rate

Flat

Ribs

Experiment Parameters Flat cylindrical tool Cylindrical tool with Ribs

Graph 9 Variation of Yield strength with feed rate for

a constant RPM of 900

Table 10 UTS and Yield Strength at 900 RPM

36

Optical macrograph for weld cross section and tensile test specimen

Friction stir welds are prone to defects such as pin hole, tunnel defect, etc. The ultimate tensile

strength of the weld shows dependence on yield strength as well as the quality of the weld. Table

11 shows macrograph for weld cross section and tensile test specimen obtained using flat

cylindrical tool, at a constant feed rate of 31.5 mm/min and varying RPM.

RPM Macrostructure

Cross section

Macrostructure

Tensile specimen

Quality and Defect

900

No defects

No necking, fracture

along the centre line

Yield Strength:

86MPa

Elongation: 7%

1400

Tunnel defect found

on the weld cross

section

Fractured by necking

from retreating side

Yield Strength:

64MPa

Elongation: 15 %

1800

Pin hole defect.

Fractured by necking

from retreating side

Yield Strength:

57MPa

Elongation: 16%

Table 11 Macrographs of weld cross section &

tensile specimen: Flat Cylindrical tool

37

For a given feed rate the yield strength decreases with increase in RPM, as the welding

temperature increases, leading to increase in grain size as explained earlier. Further, it was

observed that most of the welds failed from the retreating side during tensile loading.

Table 12 shows macrographs for weld cross section and tensile test specimen obtained using

cylindrical tool with ribs, at a constant feed rate of 16 mm/min and varying RPMs. As in the

previous case, very small elongation is observed for welds obtained at 900 RPM which

ultimately leads to low UTS.

RPM Macrostructure :

Cross section

Macrostructure :

Tensile specimen

Quality and Defect

900

Tunnel Defect

No necking, fracture

along the centre line

Yield Strength:

71MPa

Elongation: 7%

Very low UTS of

75MPa

1400

No defects

Fractured by necking

from retreating side

Yield Strength:

65Mpa

Elongation: 18%

High UTS of 98

1800

No macroscopic

defects.

Fractured by necking

from retreating side

Yield Strength:

54MPa

Elongation: 21%

Table 12 Macrographs of weld cross section & tensile

specimen: Cylindrical tool with Ribs

38

20

25

30

35

40

45

50

-4 -2 0 2 4

H

a

r

d

n

e

s

s

Distance from weld center (mm)

Flat Cylindrical Tool; Feed Rate :

31.5mm/min

1400

1800

900

20

25

30

35

40

45

50

-3 -2 -1 0 1 2 3

H

a

r

d

n

e

s

s

Distance from weld center (mm)

Cylindrical Tool with Ribs; Feed Rate :

16mm/min

1800 RPM

1400 RPM

900 RPM

Micro-hardness

Micro-hardness values were obtained for the polished weld cross sections. Graph 10 shows the

variation of hardness across the cross section of weld joint obtained using cylindrical tool with

ribs at a feed rate of 16mm/min. It was observed that the hardness in the nugget zone did not

show much variation with change in RPM at constant feed rate. However, in the TMAZ and

HAZ it was observed that the hardness decreases with increase in RPM. This increase in

hardness at lower RPM is accompanied by decrease in % elongation during tensile testing as

show previously.

Graph 10 Variation of Micro-hardness, Feed rate: 16mm/min

(Cylindrical tool with Ribs)

Graph 11 Variation of Micro-hardness, Feed rate: 31.5 mm/min

(Flat Cylindrical tool )

39

20

25

30

35

40

45

50

-4 -3 -2 -1 0 1 2 3 4

H

a

r

d

n

e

s

s

Distance from weld center (mm)

RPM 900 and Feed rate 31.5mm/min

Flat Cylindrical Ribs

Graph 11 shows the effect of change in RPM when the feed rate is kept constant at 31.5mm/min.

As in the case of Cylindrical tool with ribs the hardness in the nugget zone did not show much

variation with change in RPM. Small variation in hardness across the cross section was observed

at 1400 RPM and 1800 RPM. At 900 RPM maximum hardness was observed.

Graph 12 shows the variation in micro-hardness for welds obtained at 900 RPM and

31.5mm/min feed rate using the two tools. The hardness obtained using cylindrical tools with

ribs was found to be greater.

Graph 12 Effect of shoulder geometry on

micro-hardness

40

Conclusion

From the experimental data it was observed that the maximum temperature during friction stir

welding increases with corresponding increase in the rotational speed of the tool for a constant

feed rate. Further a sudden rise in temperature was observed at the end of each pass, this was due

to the fact that the area for heat loss by conduction around the tool had reduced, and as a result

the temperature increase is greater. Melting point temperature of aluminium alloy is greater than

~640C. Temperature measured during experiments ranges from 250 to 550 C. The cylindrical

tool with ribs (tool 2) showed greater temperature variation as well as greater temperature at

steady state as compared to the flat cylindrical tool (tool 1).

The temperature isotherms were plotted from the thermal images obtained by the infrared

camera. These isotherms can give an idea, how the heat is dissipated in and around the weld

zone.

The power consumption in case of tool 2 was found to be more than tool 1 when the welding

parameters were kept same. This result can be attributed to the fact that the energy for plastic

deformation and the frictional heat generated are both greater in case of the second tool.

The tensile strength of welds obtained using the cylindrical tool with ribs was found to be greater

than those with flat cylindrical tool. For cylindrical tool with ribs the ultimate tensile strength

was found to be highest at 1400 RPM.

For both the tools it was observed that the yield strength was highest at 31.5mm/min among the

three feed rate. When the feed rate was kept constant, the value of yield strength decreases with

increase in RPM. Thus, maximum value of yield strength was obtained at an RPM of 900 and

feed rate of 31.5mm/min and is equal to 86MPa and 94MPa for flat cylindrical tool and tool with

ribs respectively.

41

References

[1] R.S. Mishra, Z.Y. Ma, Friction stir welding and processing, Materials Science and

Engineering: R: Reports, Volume 50, Issues 1-2, 31 Pages 1-78 (2005)

[2] Chao, Y. J., Qi, X., and Tang, W., Heat transfer in friction stir welding Experimental

and numerical studies, Transaction of the ASME, pp. 125, 138145 (2003)

[3] Effect of friction stir welding parameters (rotation and transverse) speed on the transient

temperature distribution in Friction stir welding of AA 7020-T53, ARPN Journal of Engineering

and Applied Sciences

[4] http://www.hitachi.com/rd/hrl/interview/monozukuri_platform-ks.html.

[5] K. Jata, S. Semiatin, Scripta Mater. 43,743 (2000)

[6]W. J. Arbegast and P. J. Hartley, "Friction Stir Weld Technology Development at Lockheed

Martin Michoud Space System - An Overview," 5th International Conference

on Trends in Welding Research, ASM International, Materials Park, OH, 541-546 (1999).

[7] C. J. Dawes and W. M. Thomas. TWI Bulletin, 6,124-127 (1995)

[8] C. J. Dawes and W. M. Thomas. Welding Journal, 75(3), 41-46 (1996)

[9] W. Thomas, C. Dawes, M. Gittos, and D. Andrews. TWI Bulletin, 3,44-50 (1998).

[10] http://en.wikipedia.org/wiki/Friction_stir_welding

[11] http://en.wikipedia.org/wiki/Grain_boundary_strengthening

[12] Smith, William F.; Hashemi, Javad, Foundations of Materials Science and Engineering (4th

ed.), McGraw-Hill, ISBN 0-07-295358-6 (2006)

[13] W. Thomas, C. Dawes, M. Gittos, and D. Andrews. TWI Bulletin, 3,44-50 (1998)

[14] J.-Q. Su, T. W. Nelson, R. Mishra, M. Mahoney. Ada Materialia, 51, 713-729 (2003)

[15] I.Charit, R.S. Mishra, Abnormal Grain growth in Friction stir processed alloys, Scripta

Mater. 58,367-371 (2008)

[16] M. James, M. Mahoney, in: Proceedings of the First International Symposium on Friction

Stir Welding, Thousand Oaks, CA, USA, June 1416 (1999)

[17] M. Peel, A. Steuwer, M. Preuss, P.J. Withers, Acta Materials 51, 4791 (2003)

[18] Y.S. Sato, H. Kokawa, M. Enmoto, S. Jogan, Metall. Mater. Trans. A 30, 2429 (1999)

[19] Y.S. Sato, S.H.C. Park, H. Kokawa, Metall. Mater. Trans. A 32, 3023 (2001)

42

[20] L.E. Svesson, L. Karlsson, H. Larsson, B. Karlsson, M. Fazzini, J. Karlsson, Microstructural

and mechanical properties of friction stir weld aluminium alloys with special reference to AA

5053 and AA 6082 Aluminium,Science Technol.Weld. Joining 5, 285 (2000)

[21] M.W. Mahoney, C.G. Rhodes, J.G. Flintoff, R.A. Spurling, W.H. Bingel, Properties of

Friction Stir Welded 7075 T651 Aluminium, Metallurgical and Materials Transaction A, 29 A,

1955-1964 (1998)

[22] G. Biallas, R. Braun, C.D. Donne, G. Staniek,W.A. Kaysser, in: Proceedings of the First

International Symposium on Friction Stir Welding, Thousand Oaks, CA, USA (1999)

[23] K.Elangovan, V.Balasubramaninan, Influences of tool pin profile and welding speed on the

formation of friction stir processing zone in AA2219 aluminium alloy, Volume 200, Issue 1-3,

163-175 (2008)

[24] Zhou, C., X. Yang, and G. Luan, Effect of root flaws on the fatigue property of friction stir

welds in 2024-T3 aluminum alloys. Materials Science and Engineering: A, 418(1-2): p. 155-160

(2006)

[25] S. Rajakumar, C. Muralidharan, V. Balasubramanian; Influence of friction stir welding

process and tool parameters on strength properties of AA7075-T6 aluminium alloy joints,

Materials and Design 32, 535549 (2011)

[26] M. Han, S. Lee, J. Park, S. Ko, Y. Woo, S. Kim; Optimum condition by mechanical

characteristic evaluation in friction stir welding for 5083-O Al alloy, Trans. Nonferrous Met.

Soc. China 19, s17-s22 (2009)

[27] H. Lombard, D. Hattingh , A. Steuwer, M. James, Optimising FSW process parameters to

minimise defects and maximise fatigue life in 5083-H321 aluminium alloy, Engineering Fracture

Mechanics 75, 341354 (2008)

[28] H. Grover, H.Tripathi, R.Sharma, Experimental study of FSW process parameters on

tensile strength of the Al-Si alloy, IJAET/Vol.II/ Issue 3,164-170 (2011)

[29] M. Nourami, A. S. Milani, S. Yannacopoulos, Taguchi Optimization of Process Parameters

in Friction Stir Welding of 6061 Aluminum Alloy: A Review and Case Study, Engineering, 3,

144-155 (2011)

[30]C.G. Rhodes, M.W. Mahoney, W.H. Bingel, R.A. Spurling, C.C. Bampton, Effect of

Friction Stir Welding on micro-structure of 7075 aluminium Scripta Mater. 36, 69-75 (1997)

43

[31] G. Liu, L.E. Murr, C.S. Niou, J.C. McClure, F.R. Vega, Micro-structural aspects of friction

stir welding of 6061-T6 aluminium, Scripta Mater. Issue 37, 355 (1997)

[32] M. Strangwood, J. E. Berry, D. P. Cleugh, A. J. Leonard, and P. L. Threadgill, in

Proceedings of International Symposium on Friction Stir Welding, Thousand Oaks, CA, USA

(1999)

[33] W. Tang, X. Guo, J.C. McClure, L.E. Murr, Heat input and Temperature distribution in

Friction Stir Welding, Journal of Material Processing and Manufacturing Science, 7-21 (1998)

[34] Y.J. Kwon, N. Saito, I. Shigematsu, Friction stir process as a new manufacturing technique

of ultrafine grained aluminium alloy, Journal of Materials Science Letters 21 1473-1476 (2002)

[35] T. Hashimoto, S. Jyogan, K. Nakata, Y.G. Kim, M. Ushio, Proceedings of the First

International Symposium on Friction Stir Welding, Thousand Oaks, USA, (1999)

[36]C.Hamilton, S.Dymek, A.Sommers, Characteristic Temperature Curves for Aluminum

Alloys during Friction Stir Welding, Welding Journal, Volume 89, 189s-194s (2010)

[37] Application of Thermography in Materials Science and Engineering

[38] Kimand YG, Fujii H, Tsumura T, Komazaki T, Nakata K. Three defect types in friction stir

welding of aluminium die casting alloys. Material Science Engineering A ;415:2504 (2006)

[39] Colegrove P., M. Painter, D. Graham and T.Miller, Modeling of Friction Stir Welding

Process, 2nd International Symposium on Friction Stir Welding, Gothenburg Sweden (2000)

[40] P. Cavalierea, A. Squillaceb, F. Panellaa, Effect of welding parameters on mechanical and

micro-structural properties of AA6082 joints produced by friction stir welding journal of

materials processing technology 200 364372 ( 2008 )

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Friction Stir Welding Twin Tool Twin Tool SideaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool SideaxlerobertalhaNo ratings yet

- The Simultaneous Use of Two or More Friction Stir Welding ToolsDocument6 pagesThe Simultaneous Use of Two or More Friction Stir Welding ToolsrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ViewsDocument1 pageFriction Stir Welding Twin Tool Twin Tool ViewsrobertalhaNo ratings yet

- Friction Stir WeldingDocument43 pagesFriction Stir WeldingrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ToolDocument1 pageFriction Stir Welding Twin Tool Twin Tool ToolrobertalhaNo ratings yet

- Friction Stir Welding-Process Developmentannd VariantDocument21 pagesFriction Stir Welding-Process Developmentannd VariantrobertalhaNo ratings yet

- Friction Stir Welding Shridhar Rev-1Document26 pagesFriction Stir Welding Shridhar Rev-1robertalhaNo ratings yet

- Friction Stir Welding Twin Tool GearDocument1 pageFriction Stir Welding Twin Tool GearrobertalhaNo ratings yet

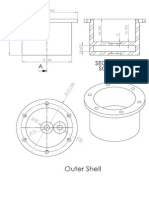

- Friction Stir Welding Twin Tool Twin Tool Outer ShellDocument1 pageFriction Stir Welding Twin Tool Twin Tool Outer ShellrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool ColletDocument1 pageFriction Stir Welding Twin Tool ColletrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool FlywheelDocument1 pageFriction Stir Welding Twin Tool FlywheelrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool ColletDocument1 pageFriction Stir Welding Twin Tool ColletrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool MainaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool MainaxlerobertalhaNo ratings yet

- Friction Stir Welding Twin Tool 1020ball BearingDocument1 pageFriction Stir Welding Twin Tool 1020ball BearingrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool Outer ShellDocument1 pageFriction Stir Welding Twin Tool Twin Tool Outer ShellrobertalhaNo ratings yet

- The Simultaneous Use of Two or More Friction Stir Welding ToolsDocument6 pagesThe Simultaneous Use of Two or More Friction Stir Welding ToolsrobertalhaNo ratings yet

- Friction Stir Welding ThesisDocument63 pagesFriction Stir Welding Thesisrobertalha80% (5)

- Friction Stir Welding Twin Tool Twin Tool ToolDocument1 pageFriction Stir Welding Twin Tool Twin Tool ToolrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool ViewsDocument1 pageFriction Stir Welding Twin Tool Twin Tool ViewsrobertalhaNo ratings yet

- Friction Stir WeldingDocument43 pagesFriction Stir WeldingrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool MainaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool MainaxlerobertalhaNo ratings yet

- Friction Stir Welding Twin Tool GearDocument1 pageFriction Stir Welding Twin Tool GearrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool FlywheelDocument1 pageFriction Stir Welding Twin Tool FlywheelrobertalhaNo ratings yet

- Friction Stir Welding-Process Developmentannd VariantDocument21 pagesFriction Stir Welding-Process Developmentannd VariantrobertalhaNo ratings yet

- Friction Stir Welding Twin Tool Twin Tool SideaxleDocument1 pageFriction Stir Welding Twin Tool Twin Tool SideaxlerobertalhaNo ratings yet

- Friction Stir Welding Shridhar Rev-1Document26 pagesFriction Stir Welding Shridhar Rev-1robertalhaNo ratings yet

- Friction Stir Welding Twin Tool 1020ball BearingDocument1 pageFriction Stir Welding Twin Tool 1020ball BearingrobertalhaNo ratings yet

- Friction Stir Welding ThesisDocument63 pagesFriction Stir Welding Thesisrobertalha80% (5)

- Friction Stir Welding RS REPORT-1 (17th April 13)Document52 pagesFriction Stir Welding RS REPORT-1 (17th April 13)robertalha100% (1)

- Friction Stir Welding Report Ent111Document45 pagesFriction Stir Welding Report Ent111robertalhaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)