Professional Documents

Culture Documents

A Pump FMEA Approach To Improve Reliability Centered Maintenance Procedure

A Pump FMEA Approach To Improve Reliability Centered Maintenance Procedure

Uploaded by

Finigan Joyce0 ratings0% found this document useful (0 votes)

31 views8 pagesOriginal Title

A Pump FMEA Approach to Improve Reliability Centered Maintenance Procedure

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views8 pagesA Pump FMEA Approach To Improve Reliability Centered Maintenance Procedure

A Pump FMEA Approach To Improve Reliability Centered Maintenance Procedure

Uploaded by

Finigan JoyceCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

A Pump FMEA Approach to Improve Reliability Centered

Maintenance Procedure: The Case of Centrifugal Pumps in

Onshore Industry

A. AZADEH *, V. EBRAHIMIPOUR, P. BAVAR

Department of Industrial Engineering and Center of Excellence for Intelligent

Experimental Mechanics, Faculty of Engineering University of Tehran, P.O. Box 11365-

4563, Tel: +9821 88021067. Tehran, Iran *Corresponding Author

aazadeh@ut.ac.ir, vebrahimi@ut.ac.ir, pbavar@ut.ac.ir

Abstract: - In the reliability centered maintenance (RCM) methodology, the reliability estimates

of the system are used to provide a cost-effective & satisfactory maintenance schedule. In this

paper, a new framework for improvement of the RCM procedure based on the failure mode and

effect analysis (FMEA) is developed. In order to achieve the objective, first based on the OREDA

handbook classification the critical failure modes of centrifugal pumps & causes of these failures

are identified. Then through the FMEA, the interactive impacts of these failure causes on both

hydraulic & mechanical operating parameters of the centrifugal pumps (e.g. flow rate, discharge

pressure, vibration) are indicated in linguistic variables. Next, based on the obtained failure

information, the linguistic rules for failure diagnosis are extracted, and moreover based on the

failure analysis the maintenance intervals are determined. The ability of the proposed approach to

identify and classify faults, which result in correct and timely diagnosis, will increase the

reliability of the system by maximizing the equipment availability, and consequently the system

performance is improved.

Keywords: - failure mode, FMEA, centrifugal pump, operating parameter, RCM

1- Introduction

In order to reduce total production costs

and increase the reliability of the

equipments, there has been a great

concentration on maintenance policies in

recent years, since maintenance costs are

major costs within the organizations [1].

Maintenance defines the set of activities

performed on an item to retain it in or to

restore it to a specific state. [2].

Reliability centered maintenance (RCM)

is one of the analytical methodologies,

which is oriented to the development of

component reliability to identify

preventive maintenance (PM)

requirements of complex systems. In

many industries such as aviation, steel

plant & ships, RCM is accepted as the

most frequent and effective technique

for maintenance [3,4].

The goal of RCM is minimization of

costs and down time with regard to

elimination of failures. RCM consists of

two tasks; the first one is to analyze

failure modes based on the effects of

failures on the performance of the

system. And, the second one is

evaluation of the impact of maintenance

schedules on the reliability of the

system. In order to achieve these

objectives, first all failure modes are

identified and categorized through a

Proceedings of the 6th WSEAS International Conference on FLUID MECHANICS (FLUIDS'09)

ISSN: 1790-5095 38 ISBN: 978-960-474-40-6

failure modes and effects analysis

(FMEA). Next, based on the

consequences and severity of the failure

modes maintenance decision are

prioritized [5]. In the recent studies,

different approaches are developed to

improve the efficiency of the reliability

centered maintenance analysis

[3,4,6,7,8]. In this paper, a new

framework for improvement of the RCM

procedure based on the failure mode and

effect analysis (FMEA) is developed.

The paper is organized as follows.

Section 2, describes the methodology of

the proposed approach. In section 3, the

proposed approach is implemented to

centrifugal pumps of the case study (a

petrochemical industry). And section 4,

includes the conclusion.

2- Methodology

In the Oil & Petrochemical industry,

there is a great attention on the concepts

of maintainability, reliability and safety,

and many analyses are used to estimate

the risk of hazards and damage to

equipments in order to improve

maintenance policies and reduce the

amount and frequency of maintenance

costs [9]. The major equipment failures

in a petrochemical plant are related to

pumps, compressors and piping, [10].

Pumps of all types are used in every

phase of petrochemical industry,

production, transportation and refinery.

In recent years, many petrochemical

plants utilize advanced methods to

enhance their knowledge and

understanding about the pump

performance and its impact on process

behavior to provide a practical and

structured approach for a satisfactory

maintenance strategy [11,12].

Centrifugal pumps are used in a wide

range of field & industrial applications.

Since they are varied in types, sizes,

designs, and materials of construction,

there is a vast range of operational

problems for these pumps [12]. But, due

to nonlinear, time-varying behavior &

imprecise measurement information of a

complex system such as a petrochemical

plant it is difficult to deal with pump

failures with precise mathematical

equations, and diagnosis of these

problems needs domain experts with

high experience or education. But, the

failure diagnosis process by human

operators is time consuming and human

error may lead to a faulty diagnosis,

which increases the repair time and

unnecessary expenditures for upgrades

and consequently the reliability of the

system is decreased.

The purpose of this study is to

develop a new framework for

improvement of the RCM procedure

based on the failure mode and effect

analysis (FMEA). In order to achieve the

objective, first based on the OREDA

handbook classification the critical

failure modes of centrifugal pumps &

causes of these failures are identified

[13]. Then, through a FMEA approach

based on the knowledge acquisition from

manufacturer pump troubleshooting,

field expert maintenance personnel, and

pump handbook [12], the interactive

impacts of these failure causes on both

hydraulic & mechanical operating

parameters of the centrifugal pumps (e.g.

flow rate, discharge pressure, vibration)

are indicated in linguistic variables.

Next, these failure information are used

to extract linguistic rules for pump

diagnosis, which provide correct and

timely diagnosis. Consequently, by

reduction of human error, reduction of

repair time, maintenance costs are

reduces and moreover based on the

failure analysis the maintenance

Proceedings of the 6th WSEAS International Conference on FLUID MECHANICS (FLUIDS'09)

ISSN: 1790-5095 39 ISBN: 978-960-474-40-6

intervals are determined to improve the

RCM methodology. The schematic

structure of the proposed approach is

illustrated in Figure 1.

DCS

OREDA

handbook

Development of

thepump FMEA to

definetheeffects

of thefailure

causes on the

operating

parameters

Extraction of

linguistic rules for

diagnosis fromthe

pump FMEA

Development of the

Specification

of

maintenance

interval

based on the

severity of

failuremodes

Improvement of

RCM methodology

Operating parameters

Knowledge acquisition

Failure mode

identification

Pump handbook

Field expert

maintenancepersonnel

Pump

troubleshooting

Figure 1: The schematic structure of the proposed FMEA approach for RCM improvement

2-1- OREDA classification

In this study, the equipment

classification is considered based on the

OREDA (Offshore Reliability Data)

handbook taxonomy [13]. The OREDA

handbook includes high quality

reliability data for offshore/onshore

equipment (which are collected from

offshore equipments of ten Oil & Gas

companies), and provides both

quantitative and qualitative information

as a basis for reliability, availability,

maintenance and safety (RAMS)

analysis [13]. In this taxonomy various

items are classified into equipment

classes based on one main function (e.g.

pumps, valves). The equipments being

studied in this research are centrifugal

pumps, from machinery category with

the oil processing service type.

In this step, the failure modes

associated with oil processing

centrifugal pumps based on the

classification of the OREDA handbook

are identified. The OREDA handbook

classifies the failure modes based on

their severity, in to the following four

categories: (1) critical failure, (2)

degraded failure, (3) incipient failure, (4)

unknown failure [14]. In this study,

without loss of generality, from all the

different failure modes associated with

the involved pump units according to

OREDA handbook, the critical failure

modes which have the highest failure

rate are considered. For example, for the

oil processing centrifugal pumps, the

External leakage-process medium, the

Spurious stop and Vibration failure

modes, (with the 49.8, 9.82 & 4.91

failure rates, respectively), are

considered as the most frequent critical

failure modes, Figure 2.

In the next step, based on the

OREDA classification, maintainable

items of the pump associating with these

failure modes are considered [13]. The

Proceedings of the 6th WSEAS International Conference on FLUID MECHANICS (FLUIDS'09)

ISSN: 1790-5095 40 ISBN: 978-960-474-40-6

failure data include the percentage of

occurrence of each failure mode due to

failure of each maintainable item of the

oil processing centrifugal pump and the

percentage of occurrence of each failure

mode due to each failure cause of oil

processing centrifugal pump.

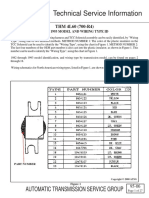

Figure 2: The failure and maintenance data of the oil processing centrifugal pumps based on OREDA

2-2- Pump FMEA

Failure mode and effect analysis is one

of the analytical tools by which the

critical components whose failure will

lead to undesirable outcomes are

identified [6,16]. FMEA prioritize the

potential failure modes by developing a

risk priority number (RPN) which helps

managers and engineers to identify the

failure modes and their cause during the

design and production stages. In the

RPN technique linguistic terms are used

to rank the severity of the failure effect

(S), the probability of occurrence of the

failure mode (O), and the probability of

detection of the failure mode (D) [7].

As previously mentioned, the

information about the critical failure

modes and the related failure causes

(based on the OREDA handbook

classification) are considered as inputs

for the pump FMEA. The novel strategy

of this study is that, through the pump

FMEA the impact of failure causes on

both the hydraulic & mechanical

operating parameters of the pump; flow

rate, discharge pressure, NPSHR (Net

Positive Suction Head Required), BHP

(Brake Horse Power), efficiency,

vibration, and temperature, are

identified.

In this stage the knowledge is

acquired to complete the FMEA. To

define the effects of failure causes on the

hydraulic operating parameters such as

flow rate & discharge pressure the

knowledge is acquired as linguistic

variables (variables whose values are

defined in linguistic terms) from:

process simulation of the plant, the

pump manufacturer troubleshooting, and

the field expert maintenance personnel.

And to identify the effects of failure

causes on the mechanical parameters

Proceedings of the 6th WSEAS International Conference on FLUID MECHANICS (FLUIDS'09)

ISSN: 1790-5095 41 ISBN: 978-960-474-40-6

such as vibration & temperature the

knowledge is acquired as linguistic

variables from: the pump manufacturer

troubleshooting, the field expert

maintenance personnel, and pump

handbook [12,17]. For example, the

effect of possible causes of the vibration

failure mode at low flows of oil

processing centrifugal pump on the

hydraulic & mechanical operating

parameters is depicted in Table 1. Since,

the disadvantages of the RPN analysis is

that RPN ranking may neglect the

relative importance of the RPN elements

(S,O,D) and as a result in some failure

modes although the RPN is lower than

the other failure modes, while potentially

the failure mode is more dangerous

[7,8], in this study, instead of the RPN

number, the weight number is

assigned to each failure cause. The

weight number is the product of the (O)

which is induced from the probability of

the contribution of each failure cause

and maintainable item to the failure

mode, based on OREDA data, and (S)

which is the severity of the failure cause

based on the expertise of field

maintenance experts. The weight

number is scaled between 0&1 and is

depicted in the last column of Table 3.

With regard to the assigned weights,

failure causes of each failure mode are

ranked prioritized and then based on

these ranks the preventive maintenance

is scheduled which will increase the

overall system reliability and help

maintenance managers to provide

suitable preventive actions.

Table 1. The pump FMEA/ In the form of linguistic variables and semiotic signs

Failure

mode

Possible cause of the

failure:

Q

( )

Disch.

Press.

( )

NPSHR

(m)

BHP

(kW)

Efficiency

(%)

Velocity

( )

Temp.

( )

Weight

1. Pump suction pipe not

completely filled with

liquid

Decrease

(--)

Decrease

(-)

-

- - Increase

(++)

Increase

(+)

0.5

2. Insufficient available

NPSH

Decrease

(-)

- - Decrease

(--)

Decrease

(--)

Increase

(++)

Increase

(+)

0.8

3. Selection of pump with

too high a suction specific

speed

Decrease

(-)

Increase

(+)

- Decrease

(--)

Decrease

(--)

Increase

(++)

- 0.6

4. Impeller selection with

abnormally high head

coefficient

Decrease

(-)

Increase

(++)

- - - - - 0.5

5. Running the pump

against a closed discharge

valve without opening a

by-pass

Decrease

(--)

Increase

(+)

- Decrease

(--)

Decrease

(--)

Increase

(++)

Increase

(+)

0.6

Pump

vibration

at low

flows

6. Operating pump below

recommended minimum

flow

Decrease

(-)

Decrease

(-)

increase Decrease

(-)

Decrease

(--)

Increase

(++)

Increase

(+)

0.9

Proceedings of the 6th WSEAS International Conference on FLUID MECHANICS (FLUIDS'09)

ISSN: 1790-5095 42 ISBN: 978-960-474-40-6

Table 2. The linguistic rules for vibration failure at low flows

Rule No. If (premise) Then (consequent)

Rule 1. Q is very low & Disch. Press. is low & Velocity is very high &

Temperature is high

Pump suction pipe not completely filled with liquid

Rule 2. Q is very low & BHP is very low & Efficiency is very low & Velocity is

very high & Temperature is high

Insufficient available NPSH

Rule 3. Q is low & Disch. Press. is high & BHP is low & Efficiency is very low

& Velocity is very high

Selection of pump with too high a suction specific speed

Rule 4. Q is low & Disch. Press. is very high, Impeller selection with abnormally high head coefficient

Rule 5. Q is very low & Disch. Press. is high & BHP is very low & Efficiency is

very low & Velocity is very high & Temperature is high

Running the pump against a closed discharge valve without

opening a by-pass

Rule 6. Q is low & Disch. Press. is low & NPSHR is high & BHP is low &

Efficiency is very low & Velocity is very high & Temperature is high

Operating pump below recommended minimumflow

Moreover, based on the pump

FMEA for the Leakage, Spurious stop

and Vibration failure modes, about 60

linguistic rules were extracted. For

example, the six diagnostic rules for the

Vibration failure mode (vibration at low

flows) based on the Table 1, are depicted

in Table 2. The extracted diagnostic

rules will provide correct and timely

diagnosis of the failures, which by

reduction of repair time & human error

will increase the reliability of the

system.

3- Case study

The equipments being studied in this

research are centrifugal pumps (with the

oil processing service) of an aromatic

plant of a petrochemical complex. In this

section, the proposed FMEA approach is

applied on a stripper column bottoms

centrifugal pump with the 250*200

UCWM type. The process under study is

the Sulfolane process in an Aromatic

plant of a petrochemical complex.

Products of the Aromatic plant are

Benzene, mixed Xylenes, and +

Raffainate. And, the Sulfolane process is

used to recover high purity aromatics

from hydrocarbon mixtures.

In order to define the set points, the

preferred, allowable, minimum &

maximum operating ranges for each of

the operating parameters of the pump,

with regard to the P&ID of the plant

(Piping and Instrumentation Diagram

which defines every mechanical aspect

of the plant regarding the process

equipment and their interconnections),

the Process Flow Diagram (PFD; which

defines operating conditions, material &

compositions and flow quantities) of the

plant is simulated by ASPEN HYSYS (a

chemical process simulation package).

Next, based on the pump datasheet,

process simulation set points, and the

interpretation of the field expert

maintenance personnel, the preferred,

allowable, minimum, & maximum

operating ranges for each of the

operating parameters of the pump (flow

Proceedings of the 6th WSEAS International Conference on FLUID MECHANICS (FLUIDS'09)

ISSN: 1790-5095 43 ISBN: 978-960-474-40-6

rate, discharge pressure, NPSHR, BHP,

efficiency, vibration, and temperature),

are defined. For example, for the flow

rate the four following ranges are

defined: the [0,324.1] as very low,

[324.1,370.4] as low, [370,509.3] as

normal, and [509.3,545] as high.

In this stage, the operating parameters of

the pump monitored by the distributed

control system (DCS) are considered as

the inputs for the extracted diagnostic

rules. Therefore, with regard to the

operating ranges of the operating

parameters discussed previously, the

consequence of the rules will provide the

correct diagnosis of the failure. In

another word, the output variable is

defined as the Failure cause.

4- Conclusion

In this paper, due to nonlinear, time-

varying behavior & imprecise

measurement information of a pump

system, through the proposed FMEA

approach the interactive impact of the

critical pump failure modes on the both

hydraulic & mechanical operating

parameters was specified. The ability of

the proposed approach to identify and

classify faults, which result in correct

and timely failure diagnosis, will

increase the reliability of the system by

maximizing the equipment availability.

Moreover based on the FMEA, faults

(failure causes) are ranked and

prioritized and with regard to this

analysis, the appropriate preventive

maintenance actions can be scheduled to

improve the RCM procedure and

increase the overall system reliability

and help maintenance managers to

provide suitable preventive actions. The

implementation of the proposed

approach would result in reduction of

repair time, reduction of human error,

reduction of unnecessary expenditures

for upgrades by providing the earlier

diagnosis of the faults and finally by

reduction of maintenance costs and

improvement of maintenance policies

will increase the reliability & safety of

the system, which plays an important

role in the Oil & Petrochemical industry.

In the further studies, we are to

implement fuzzy inference on the

proposed FMEA approach, in order to

improve the effectiveness of rules and

reduce the number of rules to provide a

more accurate diagnostic system.

Acknowledgement

*****Financial support from University

of Tehran, under grant number

(27775/1/02) is gratefully appreciated.

References

[1] M. Bevilacqua, M., Braglia, R.

Montanari, The classification and

regression tree approach to pump

failure rate analysis, Reliability

Engineering and System Safety, 79,

5967, (2003).

[2] A. Birolini, Reliability Engineering,

Theory and Practice, (4th edition).

Springer-Verlag Berlin Heidelberg.

(2004).

[3] D.J . Fonseca, G.M. Knapp, (2000). An

expert system for reliability centered

maintenance in the chemical industry.

Expert Systems with Applications 19,

4557.

[4] Zh. Cheng, X. J ia, P. Gao, S. Wu, J.

Wang, A framework for intelligent

reliability centered maintenance

analysis, Reliability Engineering and

System Safety 93, 784-792, (2008).

[5] R. Kothamasu, S.H. Huang Adaptive

Mamdani fuzzy model for condition-

Proceedings of the 6th WSEAS International Conference on FLUID MECHANICS (FLUIDS'09)

ISSN: 1790-5095 44 ISBN: 978-960-474-40-6

based maintenance, Fuzzy Sets and

Systems. 158, 2715-2733, (2007).

[6] R.K. Sharma, D. Kumar, P.Kumar,

Predicting uncertain behavior of

industrial system using FM-A practical

case, Applied Soft Computing, 8, 96-

109, (2008).

[7] S.M. Seyed-Hosseini, N. Safaei, M.J .

Asgharpour, Reprioritization of

failures in a system failure mode and

effects analysis by decision making

trial and evaluation laboratory

technique, Reliability Engineering and

System Safety 91, 872-881, (2006).

[8] R.k. Sharma, S. Kumar, Performance

modeling in critical engineering

systems using RAM analysis,

Reliability Engineering and System

Safety 93, 891-897, (2008).

[9] INTERNATIONAL STANDARD, ISO

14224, Petroleum and natural gas

industries-Collection and exchange of

reliability and maintenance data for

equipment, edition, International

Organization for Standardization,

(1999).

[10] F.P. Lees, Loss prevention in the

process industries, Reed Educational

and Professional Publishing Ltd,

Loughborough, Oxford, UK, (1996).

[11] V. Ebrahimipour, K. Suzukia, A.

Azadeh, An integrated off-on line

approach for increasing stability and

effectiveness of automated controlled

systems based on pump

dependabilitycase study: Offshore

industry, J ournal of Loss Prevention in

the Process Industries, 19, 542552,

(2006).

[12] I.J ., Karassik, J .P. Messina, P. Cooper,

Ch.C. Heald, Pump Handbook,

edition, McGraw-Hill, New York,

(2001).

[13] OREDA Participants, OREDA

Handbook, edition. Trondhim:

OREDA Participants, (2002).

[14] H. Langseth, K. Haugen, H. Sandtorv,

Analysis of OREDA data for

maintenance optimization, Reliability

Engineering and System Safety, 60,

103-110, (1998).

[15] M. Sahdev, Centrifugal Pumps: Basic

Concepts of Operation, Maintenance,

and Troubleshooting, Part I, Presented

at The Chemical Engineers Resource

Page, www.cheresources.com, Figure

B.01.

[16] C. Ebeling, An Introduction to

Reliability and Maintainability

Engineering, Tata McGraw-Hill

Company Ltd., New York, NY, (2000).

[17] A. Avallone, T. Baumeister III, A.

Sadegh, Marks Mechanical

Engineers Handbook, McGraw-Hill,

New York, (1996).

Proceedings of the 6th WSEAS International Conference on FLUID MECHANICS (FLUIDS'09)

ISSN: 1790-5095 45 ISBN: 978-960-474-40-6

You might also like

- Failure Modes and Effects AnalysisDocument90 pagesFailure Modes and Effects Analysisapi-3732848100% (6)

- Technical Service Information: Automatic Transmission Service GroupDocument27 pagesTechnical Service Information: Automatic Transmission Service GroupMario Mastronardi100% (1)

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreFrom EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreNo ratings yet

- Failure Mode and Effects Analysis (FMEA)Document37 pagesFailure Mode and Effects Analysis (FMEA)Charlie Tubaon100% (3)

- CMRP Exam Study ResourcesDocument2 pagesCMRP Exam Study Resourcesabdulrahman elsaiedNo ratings yet

- RCM TrainingDocument123 pagesRCM Trainingdodi alexander100% (1)

- Air Compressor FMEADocument32 pagesAir Compressor FMEAJitu Jena67% (6)

- Condition Based Maintenance PDFDocument3 pagesCondition Based Maintenance PDFjayaram432No ratings yet

- FIELD GUIDE Preventing Serious Injury & FatalitiesGO1965Document16 pagesFIELD GUIDE Preventing Serious Injury & FatalitiesGO1965ekoimampNo ratings yet

- Engineering ReliabilityDocument11 pagesEngineering Reliabilityernestaugustus5167No ratings yet

- FMEA - Condenser ADocument26 pagesFMEA - Condenser Aazisyuswandi100% (2)

- Airfield Pavement2Document12 pagesAirfield Pavement2molgarNo ratings yet

- ARP E Reliability Engineer CourseDocument4 pagesARP E Reliability Engineer CourseLyonelNo ratings yet

- Mechanical Engineering Failures The Role of ReliabilityDocument15 pagesMechanical Engineering Failures The Role of ReliabilityAbdulrahman AlkhowaiterNo ratings yet

- Tutoria Risk 2 Event Tree and Fault Tree SPRING 2011Document27 pagesTutoria Risk 2 Event Tree and Fault Tree SPRING 2011Lpthinh ThinhNo ratings yet

- Mock Board Examination For CriminologyDocument76 pagesMock Board Examination For CriminologyOdigirb Galapia Gumarang II100% (10)

- Weibull Statistic and Growth Analysis in Failure PredictionsDocument9 pagesWeibull Statistic and Growth Analysis in Failure PredictionsgmitsutaNo ratings yet

- Failure Analysis of 7500 HP MotorDocument6 pagesFailure Analysis of 7500 HP Motorgusgif100% (1)

- FmecaDocument43 pagesFmecaOsvaldo Jimenez100% (1)

- Fire ProtectionDocument120 pagesFire ProtectionTarik BenzinebNo ratings yet

- A Two-Stage Failure Mode and Effect Analysis of Offshore Wind Turbines - 2020Document24 pagesA Two-Stage Failure Mode and Effect Analysis of Offshore Wind Turbines - 2020johnNo ratings yet

- Failure Reporting, Analysis, Corrective Action System: Presented By: Ricky Smith, CMRPDocument55 pagesFailure Reporting, Analysis, Corrective Action System: Presented By: Ricky Smith, CMRPTeodora DobricăNo ratings yet

- Compressor Failure Mode - CHAPTER13Document26 pagesCompressor Failure Mode - CHAPTER13zona amrulloh100% (2)

- Maintenance Data AnalysisDocument15 pagesMaintenance Data AnalysisRaju Ramaswami100% (1)

- Failure Analysis: Basic ConceptsDocument72 pagesFailure Analysis: Basic Conceptsbrucemartin3100% (1)

- Root Cause Analysis Example Slurry Pump FULLDocument11 pagesRoot Cause Analysis Example Slurry Pump FULLarifin rizalNo ratings yet

- RCM PresentationDocument10 pagesRCM PresentationnicoartNo ratings yet

- Fault TreeDocument45 pagesFault Treerusticrage2883100% (2)

- Computerised Maintenance Management SystemsDocument12 pagesComputerised Maintenance Management SystemsNeng AmnadNo ratings yet

- Reliability Centered MaintenanceDocument15 pagesReliability Centered MaintenanceEdmund YoongNo ratings yet

- Reliability Centered Maintenance-GaryDocument15 pagesReliability Centered Maintenance-GaryAshwin80% (5)

- Basics For FMEA and FMECADocument35 pagesBasics For FMEA and FMECAchameera82No ratings yet

- Kingsburry 1Document28 pagesKingsburry 1sumantabal_uceNo ratings yet

- Fmeca ProcedureDocument11 pagesFmeca Procedurewarigiyatno100% (1)

- 3 Reliability Concepts and CalculationsDocument56 pages3 Reliability Concepts and CalculationstitoNo ratings yet

- Exam 13 P PDFDocument3 pagesExam 13 P PDFAnonymous RRTcbwU100% (1)

- Reliability in Maintenance: Source: Chapter 8 From Maintenance Engineering and Management by R.C.MishraDocument20 pagesReliability in Maintenance: Source: Chapter 8 From Maintenance Engineering and Management by R.C.Mishranikitanath23No ratings yet

- Introduction To Reliability and MaintenanceDocument48 pagesIntroduction To Reliability and MaintenanceTong Bbm100% (4)

- Condation MonitoringDocument19 pagesCondation MonitoringFadooollNo ratings yet

- Availability Analysis of Gas TurbinesDocument10 pagesAvailability Analysis of Gas TurbinesEman ZabiNo ratings yet

- RCM Made EasyDocument55 pagesRCM Made EasyAlAli EmirZayd Burj Khalifah100% (4)

- Maintenance Planning and SchedullingDocument3 pagesMaintenance Planning and SchedullingAnnisa MarlinNo ratings yet

- Hydrocom - For RecipcompressorDocument18 pagesHydrocom - For Recipcompressorsumantabal_uce50% (2)

- Designing The Best Maintenance OrganizationDocument5 pagesDesigning The Best Maintenance Organizationmanu_chatNo ratings yet

- SMRP Metric 5.5.38 Storeroom Maintenance Material CostDocument5 pagesSMRP Metric 5.5.38 Storeroom Maintenance Material CostJorge FracaroNo ratings yet

- Failure Mode Effects and Criticality Analysis PDFDocument2 pagesFailure Mode Effects and Criticality Analysis PDFMacNo ratings yet

- Hazard Analysis and Risk Assessments For Industrial Processes Using FMEA and Bow-Tie MethodologiesDocument13 pagesHazard Analysis and Risk Assessments For Industrial Processes Using FMEA and Bow-Tie MethodologiesratrihaningdsNo ratings yet

- Centered Maintainance ReliabilityDocument8 pagesCentered Maintainance ReliabilityKifayat Ullah100% (1)

- FMEA 4th BOOK PDFDocument151 pagesFMEA 4th BOOK PDFLuis Cárdenas100% (2)

- API Plan 53-Accumulator Bladder ChargingDocument11 pagesAPI Plan 53-Accumulator Bladder Chargingsumantabal_uceNo ratings yet

- Introduction To RCMDocument27 pagesIntroduction To RCMMariadelosangeles Mata Ramos67% (3)

- Questions of Reliability Centered MaintenanceDocument15 pagesQuestions of Reliability Centered Maintenancemariana100% (1)

- RCM Process RCM ProcessDocument58 pagesRCM Process RCM Processgoldu18100% (2)

- Presentation of RCMDocument35 pagesPresentation of RCMAbdulNo ratings yet

- Application of Reliability Centred Maintenance To Dynamic PlantDocument13 pagesApplication of Reliability Centred Maintenance To Dynamic Plantgvc1No ratings yet

- 03 - Advance Maintenance StartegiesDocument105 pages03 - Advance Maintenance StartegiesMuhammad Amru Yazid100% (1)

- SRCM ApproachDocument28 pagesSRCM Approachdefian50% (2)

- SSP267 The 6.0 L W12 Engine in The Audi A8 - Part 1Document64 pagesSSP267 The 6.0 L W12 Engine in The Audi A8 - Part 1ccordobestexano100% (1)

- The Basic Reliability CalculationsDocument30 pagesThe Basic Reliability CalculationsAbdulyunus AmirNo ratings yet

- FMEA For BlowerDocument19 pagesFMEA For Blowerxtremewhiz100% (3)

- RCM Handbook 2007Document105 pagesRCM Handbook 2007checho_mdzNo ratings yet

- Data Sheet Daniel Model 788 Digital Control Valve en 43714Document16 pagesData Sheet Daniel Model 788 Digital Control Valve en 43714dreyko77No ratings yet

- Maintenance Planning and Scheduling PPT 2Document9 pagesMaintenance Planning and Scheduling PPT 2Sunday Paul100% (1)

- Reliability GrowthDocument32 pagesReliability Growths.b.v.seshagiri1407No ratings yet

- RCM Alan PrideDocument16 pagesRCM Alan PrideambuenaflorNo ratings yet

- Reliability Analysis For Refinery Plants: February 2017Document11 pagesReliability Analysis For Refinery Plants: February 2017DilipSinghNo ratings yet

- RAM Analysis Applied To Centrifugal Gas Compressors "Case Study of An Oil and Gas Company"Document10 pagesRAM Analysis Applied To Centrifugal Gas Compressors "Case Study of An Oil and Gas Company"Muhammad RosihanNo ratings yet

- 10.2478 - Pomr 2022 0047Document8 pages10.2478 - Pomr 2022 0047fgadshfdjfhgNo ratings yet

- Reliability Centered Maintenance in Schedule Improvement of Automotive Assembly IndustryDocument5 pagesReliability Centered Maintenance in Schedule Improvement of Automotive Assembly IndustryflavianosamelNo ratings yet

- 04 Actuator EnglDocument14 pages04 Actuator Englsumantabal_uceNo ratings yet

- 03 Hydraulic Unit of Step Less Capacity Control of Reciprocating Compressors.Document5 pages03 Hydraulic Unit of Step Less Capacity Control of Reciprocating Compressors.sumantabal_uceNo ratings yet

- 01 Genera Lover View of Step Less Capacity Control of Reciprocating CompressorDocument15 pages01 Genera Lover View of Step Less Capacity Control of Reciprocating Compressorsumantabal_uceNo ratings yet

- 03 Design PhilosophiesDocument11 pages03 Design PhilosophiesAudrey Joyce A. WakatNo ratings yet

- Chapter 2 Modeling in The Frequency Domain Example 2.17 Part 1Document5 pagesChapter 2 Modeling in The Frequency Domain Example 2.17 Part 1Joy Rizki Pangestu DjuansjahNo ratings yet

- AVLDocument32 pagesAVLZECHARIAH TAMUNONIMENo ratings yet

- Panalex Led E-Catalogue (NewDocument4 pagesPanalex Led E-Catalogue (Newcristina tovarNo ratings yet

- Product Catalogue: Imi Norgren Buschjostgmbh Co - KGDocument210 pagesProduct Catalogue: Imi Norgren Buschjostgmbh Co - KGgbr.moreira12No ratings yet

- .......Document5 pages.......anggoenzNo ratings yet

- M.R.Barakat CVDocument2 pagesM.R.Barakat CVMohammad Rashad BarakatNo ratings yet

- BesselDocument10 pagesBesselSeptian MambrasarNo ratings yet

- QBDocument6 pagesQBPethurajNo ratings yet

- R9 Regular Without Late Fee PDFDocument585 pagesR9 Regular Without Late Fee PDFNithin NiceNo ratings yet

- Datasheet Radox RADOX MFH-SDocument2 pagesDatasheet Radox RADOX MFH-SnichoNo ratings yet

- Project Report On Design and Fabrication of Miniature of Continuously Variable TransmissionDocument56 pagesProject Report On Design and Fabrication of Miniature of Continuously Variable TransmissiondeveshtiksNo ratings yet

- Stepien KfullpaperDocument5 pagesStepien KfullpaperRahul ChavanNo ratings yet

- Chapter 2 Electronic StructureDocument62 pagesChapter 2 Electronic StructureLivan TuahNo ratings yet

- Salt TestDocument16 pagesSalt Testم.ذكى فضل ذكى100% (1)

- A New Simulation Framework For Soil-Root Interaction, Evaporation, Root Growth, and Solute TransportDocument21 pagesA New Simulation Framework For Soil-Root Interaction, Evaporation, Root Growth, and Solute TransportJulfahHawaryNo ratings yet

- Temperature ControlDocument18 pagesTemperature ControlgopikrishnaraoNo ratings yet

- Ass AsDocument5 pagesAss AsMukesh BishtNo ratings yet

- The Adventure Important Extra Questions and AnswerDocument5 pagesThe Adventure Important Extra Questions and AnswerSiddharth ThakurNo ratings yet

- Load Management SystemDocument40 pagesLoad Management Systematul mishraNo ratings yet

- Centripetal Force Grade 12 PhysicsDocument15 pagesCentripetal Force Grade 12 Physicssrinidhi innaniNo ratings yet

- High Voltage EngineeringDocument38 pagesHigh Voltage EngineeringMohsin Iqbal0% (1)

- ELECTROPHRESISDocument66 pagesELECTROPHRESISM.PRASAD NAIDU100% (1)