Professional Documents

Culture Documents

MD-12 Spur Gear Design

MD-12 Spur Gear Design

Uploaded by

Asela BollegalaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MD-12 Spur Gear Design

MD-12 Spur Gear Design

Uploaded by

Asela BollegalaCopyright:

Available Formats

1

P N RAO 1

12. Spur Gear Design and

selection

Objectives

Applyprinciples learned in Chapter 11 to actual design and selection of spur

gear systems.

Calculate forces on teeth of spur gears, including impact forces associated with

velocityand clearances.

Determine allowable force on gear teeth, including the factors necessarydue to

angle of involute of tooth shape and materials selected for gears.

Design actual gear systems, including specifying materials, manufacturing

accuracy, and other factors necessary for complete spur gear design.

Understand and determine necessary surface hardness of gears to minimize or

prevent surface wear.

Understand howlubrication can cushion the impact on gearing systems and cool

them.

Select standard gears available fromstocking manufacturers or distributors.

P N RAO 2

Standard proportions

American Standard Association (ASA)

American Gear Manufacturers Association

(AGMA)

Brown and Sharp

14 deg; 20 deg; 25 deg pressure angle

Full depth and stub tooth systems

P N RAO 3

Specifications for standard gear

teeth

1.157/P 1.2/P + 0.002 1.250/P 1.250/P Dedendum

(in.)

1/P 1.0/P 1.0/P 1.0/P Addendum

(in.)

14 20 25 20 Pressure

angle

14 full

depth

Full depth &

pitches finer

than 20

Full depth & pitches

coarser than 20

Item

P N RAO 4

Forces on spur gear teeth

F

t

= Transmitted force

F

n

= Normal force or separating

force

F

r

= Resultant force

= pressure angle

F

n

= F

t

tan

cos

F

F

t

r

=

P N RAO 5

Forces on spur gear teeth

Power, P; or

Torque, T = F

t

r and r = D

p

/2

Combining the above we can write

63,000

n T

P =

p

t

D

T 2

F =

n

P 63,000

T =

P N RAO 6

20-tooth, 8 pitch, 1-inch-wide, 20 pinion

transmits 5 hp at 1725 rpm to a 60-tooth gear.

Determine driving force, separating force, and

maximum force that would act on mounting

shafts.

Example Problem 12-1: Forces on Spur Gear Teeth

2

P N RAO 7

(2-6)

P =

Tn

63,000

T =

63,000P

n

T =

(63,000)5

1725

= 183 in-lb

Find pitch circle:

(11-4)

Dp =

Np

Pd

Dp =

20 teeth

8 teeth/in diameter

= 2.5 in

20-tooth, 8 pitch, 1-inch-wide, 20 pinion transmits 5 hp at 1725 rpmto a 60-tooth gear.

Determine driving force, separating force, and maximumforce that would act on

mounting shafts.

Example Problem 12-1: Forces on Spur Gear Teeth

P N RAO 8

Find transmitted force:

(12-3)

Ft =

2T

Dp

Ft =

(2)183 in-lb

2.5 in

= 146 lb

Find separatingforce:

(12-1)

Fn = Ft tan

Fn = 146 lb tan 20

Fn = 53 lb

Find maximumforce:

(12-2)

Fr =

Ft

cos

Fr =

146 lb

cos 20

Fr = 155 lb

Example Problem 12-1: Forces on Spur Gear Teeth (contd.)

P N RAO 9

Surface Speed

Surface speed (V

m

) is often referred to as

pitch-line speed

V

m

= ft/min

V

m

= m/min -- Metric units

12

n D

p

1000

n D

p

P N RAO 10

(12-7)

Vm = D n

or

(12-5)

Vm =

Dp n

12

Vm = 2.5 in 1725 rpm

ft

12 in

Vm = 1129 ft/min

Example Problem 12-2: Surface Speed

In previous problem, determine the surface speed:

P N RAO 11

Strength of Gear Teeth

Lewis form factor method

P N RAO 12

Forces on Gear Tooth

1998 McGraw-Hill, Hamrock,

Jacobson and Schmid

Figure 14.20 Forces acting

on individual gear tooth.

3

P N RAO 13

Lewis equation

F

s

= Allowable dynamic bending force (lb)

S

n

= Allowable stress (lb/in

2

). Use

endurance limit and account for the fillet as

the stress concentration factor

b = Face width (in.)

Y = Lewis form factor (Table 12.1)

P

d

= Diametral pitch

d

n

s

P

b Y S

F =

P N RAO 14

Table 12.1 Lewis form factors (Y)

P N RAO 15

Pinion:

Sn = .5 Su = .5 (95 ksi) = 47.5 ksi

(12-9)

Fs =

Sn b Y

Pd

Find Lewis formfactor (Y) fromTable 12-1, assuming full-depth teeth:

Y = .320

Fs =

47,500 (1) .320

8

Fs = 1900 lb

In Example Problem12-1, determine the force allowable (F

s

) on these teeth if the

pinion is made froman AISI 4140 annealed steel, the mating gear is made fromAISI

1137 hot-rolled steel, and long life is desired.

Example Problem 12-3: Strength of Gear Teeth

P N RAO 16

Gear:

Sn = .5 (88 ksi) = 44 ksi

(Table 12-1)

Y = .421

Fs =

44,000 (1) .421

8

Fs = 2316 lb

Use Fs = 1900 lb for design purposes.

Example Problem 12-3: Strength of Gear Teeth (contd.)

P N RAO 17

Classes of Gears

Transmitted load depends on the accuracy of the

gears

Gear Manufacture

Casting

Machining

Forming

Hobbing

Shaping and Planing

Forming

stamping

P N RAO 18

Force Transmitted

Transmitted load depends on the accuracy of the

gears

A dynamic load factor is added to take care of

this.

F

t

= Transmitted force

F

d

= Dynamic force

Commercial

t

m

d

F

600

V 600

F

+

=

4

P N RAO 19

Classes of Gears

Carefully cut

Precision

Hobbed or shaved

t

m

d

F

1200

V 1200

F

+

=

t

0.5

m

d

F

78

V 78

F

+

=

t

0.5

m

d

F

50

V 50

F

+

=

P N RAO 20

Design Methods

Strength of gear tooth should be greater

than the dynamic force; F

s

F

d

You should also include the factor of safety,

N

sf

d

sf

s

F

N

F

P N RAO 21

Table 12.2 Service Factors

Heavy shock 1.75 < N

sf

< 2

Moderately heavy shock 1.5 < N

sf

< 1.75

Medium shock, frequent starts 1.25 < N

sf

< 1.5

Uniform load without shock 1 < N

sf

< 1.25

P N RAO 22

Face width of Gears

Relation between the width of gears and the

diametral pitch

d d

P

12.5

P

8

< < b

P N RAO 23

If, in Example Problem12-1, the gears are commercial grade, determine dynamic load

and, based on force allowable fromExample Problem12-3, would this be an acceptable

design if a factor of safety of 2 were desired?

Use surface speed and force transmitted fromExample Problems 12-2 and 12-3.

Dynamic load:

Example Problem 12-4: Design Methods

This design meets the criteria.

lb F

lb F

F

V

F

d

d

t

m

d

421

) 146 (

600

1129 600

600

600

=

+

=

+

=

Comparing to force allowable:

lb lb

lb

F

N

F

d

sf

s

421 950

421

2

1900

>

(12-10)

P N RAO 24

Therefore:

Sn = .5 Su

Sn = .5 (55 ksi) = 27.5 ksi

Find Dp :

(11-4)

Dp =

Np

Pd

Dp =

24

12

= 2 in

Spur gears fromthe catalog page shown in Figure 12-3 are made froma .2% carbon

steel with no special heat treatment.

What factor of safetydo theyappear to use in this catalog?

Try a 24-tooth at 1800 rpmgear for example purposes.

FromAppendix 4, an AISI 1020 hot-rolled steel would have .2% carbon with an S

y

=30

ksi and S

u

=55 ksi.

Example Problem 12-5: Design Methods

5

P N RAO 25

Find Vm :

(12-5)

Vm =

Dp n

12

Vm = 2 in (1800 rpm)

ft

12 in

Vm = 942 ft/min

Find Fs :

(12-9)

Fs =

Sn b Y

Pd

(fromTable 12-1)

Y = .302

Fs =

27,500 () .302

12

Fs = 519 lb

Example Problem 12-5: Design Methods (contd)

P N RAO 26

Set Fs = Fd and solve for Ft :

Fd = Fs =

600 + Vm

600

Ft

519 lb =

600 + 942

600

Ft

Ft = 202 lb

(12-3)

T = F

Dp

2

T = 202 lb

2 in

2

T = 202 in-lb

(2-6)

P =

Tn

63,000

=

202 (1800)

63,000

= 5.8 hp

or

(12-6)

P =

Ft Vm

33,000

=

202 (942)

33,000

= 5.8 hp

Example Problem 12-5: Design Methods (contd)

P N RAO 27

Compared to catalog:

Nsf =

hp - calculated

hp - catalog

Nsf =

5.8

4.14

= 1.4

Example Problem 12-5: Design Methods (contd)

Appears to be reasonable value.

Manufacturer may also have reduced its rating for wear purposes as these

are not hardened gears.

P N RAO 28

Miscellaneous properties:

(11-4)

Dp =

Np

Pd

=

48

12

= 4 in

Ng = Np Vr = 48(3) = 144 teeth

Pair of commercial-grade spur gears is to transmit 2 hp at a speed of 900 rpmof the

pinion and 300 rpmfor gear.

If class 30 cast iron is to be used, specifya possible design for this problem.

The following variables are unknown: P

d

, D

p

, b, N

t

, N

sf

, .

As it is impossible to solve for all simultaneously, try the following:

P

d

=12, N

t

=48, =14, N

sf

=2

Solve for face width b.

Example Problem 12-6: Design Methods

P N RAO 29

Surface speed:

(12-5)

Vm =

Dp n

12

Vm =

4 in 900 rpm

12 in/ft

Vm = 943 ft/min

Finding force on teeth:

(12-6)

Ft =

33,000 hp

Vm

Ft =

33,000 (2)

943

Ft = 70 lb

Example Problem 12-6: Design Methods (contd.)

P N RAO 30

Example Problem 12-6: Design Methods (contd.)

lb F

F

F

V

F

d

d

t

m

d

180

70

600

943 600

600

600

=

+

=

+

= Dynamic force

Since width b is the unkown:

d

d sf

n

d

n

s

d

sf

s

F

P N

Y b S

P

Y b S

F

and

F

N

F

=

=

Class 30 CI; S

u

=30 ksi; S

n

=.4 S

u

(.4 is used because cast iron):

S

n

=12 ksi

Y =.344

(12-10)

(12-8)

(Table 12-1)

6

P N RAO 31

Substituting:

(12-9)

Sn b Y

Nsf Pd

= Fd

12,000 b .344

2 (12)

= 180

b = 1.0 inches

Check ratio of width to pitch:

(12-14)

8

Pd

< b <

12.5

Pd

8

12

< 1 <

12.5

12

.66 < 1 < 1.04

Example Problem 12-6: Design Methods (contd.)

This is an acceptable design.

Manyother designs are also possible.

P N RAO 32

To increase the dynamic beam strength of

the gear

Increase tooth size by decreasing the

diametral pitch

Increase face width upto the pitch diameter

of the pinion

Select material of greater endurance limit

Machine tooth profiles more precisely

Mount gears more precisely

Use proper lubricant and reduce

contamination

P N RAO 33

Buckingham Method of Gear Design

It offers greater flexibility

Expected error is based on different-pitch

teeth

More conservative design

P N RAO 34

Fig. 12.4 Expected error in tooth profiles

P N RAO 35

Table 12.3 Values of C for e = 0.001 inch

830

1,140

1,660

800

1,100

1,600

Gray iron and Gray iron

Gray iron and steel

Steel and steel

20 deg 14 deg Material

P N RAO 36

Buckingham Method of Gear Design

0.5

t m

t m

t d

) F C (b V 0.05

) F C (b V 0.05

F F

+ +

+

+ =

7

P N RAO 37

Fig. 12.5 Recommended maximum error in gear teeth

P N RAO 38

(Appendix 4)

Su = 95 ksi

Sn = .5 Su = .5(95 ksi) = 47.5 ksi

(11-4)

Dp =

Np

Pd

=

24

16

= 1.5 in

A pair of steel gears is made fromannealed AISI 3140.

Each gear has a surface hardness of BHN =350.

The pinion is a precision, 16 pitch, 20 involute, with 24 teeth 1 inch wide.

The gear has 42 teeth.

To transmit 3 hp at a speed of 3450 rpmfor a safetyfactor of 1.4, is this a

suitable design?

Example Problem 12-7: Buckingham Method of Gear

Design and Expected Error

P N RAO 39

Find torque:

(2-6)

P =

Tn

63,000

T =

P (63,000)

n

T =

3 (63,000)

3450

T = 55 in-lb

Find force transmitted:

(12-3)

Ft =

2T

Dp

Ft =

2(55 in-lb)

1.5 in

Ft = 73 lb

Example Problem 12-7: Buckingham Method of Gear

Design and Expected Error (contd.)

P N RAO 40

Find surface speed:

(12-5)

Vm =

Dp n

12

Vm =

1.5 in 3450 rpm

12 ft/in

Vm = 1355 ft/min

Find force allowable (Fs):

(12-9)

Fs =

Sn b Y

Pd

(fromTable 12-1)

Y = .337

Fs =

47,500 (1) .337

16

Fs = 1000

Example Problem 12-7: Buckingham Method of Gear

Design and Expected Error (contd.)

P N RAO 41

Example Problem 12-7: Buckingham Method of Gear

Design and Expected Error (contd.)

Expected error fromFigure 12-4:

e = .0005

The value of C fromTable 12-3 for steel and steel and 20 involute angle gears is 1660:

C = .0005 (1000) 1660

C = 830

Solve for dynamic load using Buckinghams equation:

This meets the criteria.

699 714

699

4 . 1

1000

699

) 73 830 1 ( ) 1355 ( 05 .

) 73 830 1 ( ) 1355 ( 05 .

73

) ( 05 .

) ( 05 .

2 / 1

2 / 1

>

=

+ +

+

+ =

+ +

+

+ =

d

sf

s

d

d

t m

t m

t d

F

N

F

lb F

F

F bC V

F C b V

F F

(12-15)

P N RAO 42

Wear strength (Buckingham)

+

=

g p

g

g P W

D D

D 2

K b D F

F

w

=tooth wear strength (lb)

D

p

=diametral pitch of pinion (in.)

D

g

=diametral pitch of gear (in.)

b =face width (in.)

K

g

=load stress factor (Appendix 13)

8

P N RAO 43

Wear formula:

(12-16)

Fw = Dp b Q Kg

Find Q :

(12-17)

Q =

2 Ng

Ng + Np

Q =

2 (42)

42 + 24

Q = 1.27

(from Appendix 13)

Kg = 270

In prior example problem, verify the surface is suitable for wear considerations.

For wear use N

ss

=1.2

Example Problem 12-8: Wear of Gears

P N RAO 44

Example Problem 12-8: Wear of Gears (contd.)

Substituting into equation 12-16:

This would not be suitable. Try if surfaces each had a BHN =450.

514

) 270 ( 27 . 1 ) 1 ( 5 . 1

=

=

w

w

F

F

699 746

699

2 . 1

895

895

) 470 ( ) 27 . 1 ( ) 1 ( 5 . 1

470

>

>

=

=

=

d

sf

w

w

w

g

F

N

F

F

F

K

This would now be acceptable if the gear teeth were hardened to a BHN of 450.

(fromAppendix13)

You might also like

- Sheet Metal Design-Handbook-Rev3 PDFDocument12 pagesSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- TiKi TaKa CK Preventive MedicineDocument3 pagesTiKi TaKa CK Preventive MedicinenonsNo ratings yet

- Gear CorrectionDocument17 pagesGear CorrectionMurugesanNo ratings yet

- Alan Titchmarsh How To Garden - Garden DesignDocument422 pagesAlan Titchmarsh How To Garden - Garden DesignJosip MilinkovićNo ratings yet

- 5 - Threaded Fasteners PDFDocument60 pages5 - Threaded Fasteners PDFPradyunn HoraNo ratings yet

- GD&T IntroductionDocument147 pagesGD&T IntroductionPrithviraj Daga100% (6)

- Standard Actuator BrochureDocument20 pagesStandard Actuator BrochuretranquangtrungxdNo ratings yet

- Radio Frequency Transistors: Principles and practical applicationsFrom EverandRadio Frequency Transistors: Principles and practical applicationsRating: 4 out of 5 stars4/5 (3)

- Spring CalculationDocument24 pagesSpring Calculationmahaprabhu78100% (1)

- IrisDocument7 pagesIrisPrithviraj DagaNo ratings yet

- GearboxesDocument24 pagesGearboxesPrithviraj Daga100% (2)

- ProE Wildfire 4 Tutorial 4-3D AnnotationsDocument26 pagesProE Wildfire 4 Tutorial 4-3D AnnotationsPrithviraj Daga100% (3)

- WM D ProcessDocument70 pagesWM D Processkumar N100% (1)

- MRP2019Document680 pagesMRP2019bhupendra patelNo ratings yet

- Polyurethane (PU) : HistoryDocument28 pagesPolyurethane (PU) : HistoryPrithviraj Daga83% (12)

- Gear EquationsDocument71 pagesGear EquationsMickloSoberan50% (2)

- Tractive Effort PDFDocument8 pagesTractive Effort PDFPrithviraj DagaNo ratings yet

- Machine DesignDocument15 pagesMachine DesignYaNo ratings yet

- A.tcharkhtchi-Simulation of Roto Molding ProcessDocument28 pagesA.tcharkhtchi-Simulation of Roto Molding ProcessPrithviraj Daga100% (1)

- Drug Study: Francisco Tampos JRDocument37 pagesDrug Study: Francisco Tampos JRCarlmeister Ambray JudillaNo ratings yet

- Railways Technical InformationDocument88 pagesRailways Technical InformationPrithviraj Daga100% (2)

- Design of Power ScrewsDocument13 pagesDesign of Power ScrewstogibabusNo ratings yet

- Turbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandTurbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (4)

- Spur Gear Design and Selection Standard Proportions: ObjectivesDocument2 pagesSpur Gear Design and Selection Standard Proportions: Objectivesrak9797No ratings yet

- Friction Devices 19Document36 pagesFriction Devices 19mahaveer dasNo ratings yet

- Gears PresentationDocument33 pagesGears PresentationNaveen YadavNo ratings yet

- Machine Design-Ii: GearsDocument50 pagesMachine Design-Ii: Gearsmuhammad hamzaNo ratings yet

- Analysis of Spur and Helical Gears: Prepared by Wayne Book Based On Norton, Machine Design and Mischke and ShigleyDocument33 pagesAnalysis of Spur and Helical Gears: Prepared by Wayne Book Based On Norton, Machine Design and Mischke and ShigleyMadya LangitNo ratings yet

- FLI Bases of Calculation For Trapezoidal ScrewDocument5 pagesFLI Bases of Calculation For Trapezoidal ScrewEnquiry SgNo ratings yet

- Lect 5Document14 pagesLect 5MunyahNo ratings yet

- Shaft Design LongDocument5 pagesShaft Design LongAmeeh TorionNo ratings yet

- Handouts MD Day 2Document7 pagesHandouts MD Day 2Obane Ordnael P.No ratings yet

- Spur Gear CalculationsDocument7 pagesSpur Gear Calculationsaniket patilNo ratings yet

- Gears Presentation BubuDocument37 pagesGears Presentation BubuAbebaw AyeleNo ratings yet

- Top Machinery Catalogue PDFDocument11 pagesTop Machinery Catalogue PDFShariq KhanNo ratings yet

- 7 Gear KinematikDocument19 pages7 Gear KinematikiwenNo ratings yet

- Mechanical Engineering Handbook 96 105Document10 pagesMechanical Engineering Handbook 96 105basaricaNo ratings yet

- Technical GearsDocument19 pagesTechnical GearsM.NatarajanNo ratings yet

- Spur GearDocument80 pagesSpur GearLutfhi HanafiNo ratings yet

- Shear DesignDocument25 pagesShear DesignPhạm Tiến ĐạtNo ratings yet

- A A A D N L A: Company DateDocument6 pagesA A A D N L A: Company Datechemical509No ratings yet

- Gears KinematicsDocument19 pagesGears Kinematicsavinashn12No ratings yet

- Handouts MD Day 2Document7 pagesHandouts MD Day 2Cantera, Cris Bryan E.No ratings yet

- Engelhardt Steel Notes VI - Connections PDFDocument29 pagesEngelhardt Steel Notes VI - Connections PDFPauccar Rhp HpNo ratings yet

- 10.3 Calculation For Cylindrical Worm Gear Pair StrengthDocument7 pages10.3 Calculation For Cylindrical Worm Gear Pair StrengthNandaKumarPNo ratings yet

- Langston Model 380SS Automatic Slitter Scorer Retrofit - CISA - Panama - Rack and Pinion Mechanism PDFDocument9 pagesLangston Model 380SS Automatic Slitter Scorer Retrofit - CISA - Panama - Rack and Pinion Mechanism PDFeacondeNo ratings yet

- Extrusion Process and Die Design ConsiderationDocument62 pagesExtrusion Process and Die Design ConsiderationMun JiwonNo ratings yet

- RBD SRBD PF: Elastic Couplings Single Pump Drive PtoDocument7 pagesRBD SRBD PF: Elastic Couplings Single Pump Drive PtococorakoNo ratings yet

- Symbols For Rules & FormulasDocument3 pagesSymbols For Rules & FormulasBudiman SupomoNo ratings yet

- MD Module 2 Shaft DesignDocument6 pagesMD Module 2 Shaft DesignCllyan ReyesNo ratings yet

- Friction Clutches - LongDocument4 pagesFriction Clutches - LongAmeeh TorionNo ratings yet

- Spur Gear: Speed Input Speed Output R R R R R VDocument12 pagesSpur Gear: Speed Input Speed Output R R R R R Vprakash tyagiNo ratings yet

- Theory of Gears r3Document53 pagesTheory of Gears r3gamini ranaweeraNo ratings yet

- Disk BrakesDocument18 pagesDisk BrakesArif KaziNo ratings yet

- ClutchDocument4 pagesClutchtisha revillaNo ratings yet

- Gears: Transmits Rotary Motion TorquesDocument24 pagesGears: Transmits Rotary Motion Torquessamurai7_77No ratings yet

- Spur Gear For I PDocument40 pagesSpur Gear For I PVenkatagiri Srinivas MurthyNo ratings yet

- Calculation of Gear Dimensions - KHK Gears - Bevel Gears PDFDocument10 pagesCalculation of Gear Dimensions - KHK Gears - Bevel Gears PDFPrasad PatilNo ratings yet

- Ch7 Gear Second HalfDocument22 pagesCh7 Gear Second HalfM. ZoubaNo ratings yet

- EX1001Document7 pagesEX1001igualdi53No ratings yet

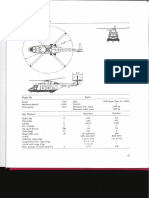

- Westland Model 30Document1 pageWestland Model 30Jurriën PltNo ratings yet

- Unit 1 Module 2 PDFDocument26 pagesUnit 1 Module 2 PDFKaradam Patel0% (1)

- Technical Drawing With Engineering Graphics - (732-735)Document4 pagesTechnical Drawing With Engineering Graphics - (732-735)mont21No ratings yet

- Horizontal Alignment IDocument31 pagesHorizontal Alignment IAravind KumarNo ratings yet

- Power Screws: ME 147P Machine Design IDocument23 pagesPower Screws: ME 147P Machine Design IJohn Karl De BelenNo ratings yet

- Lec02 ElectricMotors PDFDocument12 pagesLec02 ElectricMotors PDFAnonymous 9pUwwvsoNo ratings yet

- Vehicle DynamicsDocument24 pagesVehicle Dynamicssviggnesh_hpNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- MaglevDocument21 pagesMaglevPrithviraj DagaNo ratings yet

- Electrodynamic Suspension SystemDocument88 pagesElectrodynamic Suspension SystemPrithviraj Daga100% (1)

- BT PresentationDocument34 pagesBT PresentationPrithviraj DagaNo ratings yet

- Bombardier TraxxDocument12 pagesBombardier TraxxPrithviraj DagaNo ratings yet

- Contact Stress Analysis of Spur Gear Teeth PairDocument6 pagesContact Stress Analysis of Spur Gear Teeth PairPrithviraj DagaNo ratings yet

- Gear DesignDocument18 pagesGear DesignJitendra BagalNo ratings yet

- Gear StressDocument12 pagesGear StressPrithviraj Daga100% (1)

- Transient Stress Analysis On Spur GearDocument8 pagesTransient Stress Analysis On Spur GearPrithviraj DagaNo ratings yet

- Consumer Product Design WP ENGDocument8 pagesConsumer Product Design WP ENGPrithviraj DagaNo ratings yet

- Shipping, Logistics Management - Container Dimensions, Container Capacity, Rating, Tare Mass and Payload of ContainersDocument4 pagesShipping, Logistics Management - Container Dimensions, Container Capacity, Rating, Tare Mass and Payload of ContainersPrithviraj Daga80% (5)

- Sheet Metal Bend AllowanceDocument3 pagesSheet Metal Bend AllowancePrithviraj DagaNo ratings yet

- Analysis Guide Machine Design WP ENGDocument10 pagesAnalysis Guide Machine Design WP ENGPrithviraj Daga100% (3)

- Tutorials For Pro Engineer Wildfire 2.0Document101 pagesTutorials For Pro Engineer Wildfire 2.0shuklahouseNo ratings yet

- Pro/E - Efficient Wall Thickness Analysis Methods For Optimal Design of Casting PartsDocument9 pagesPro/E - Efficient Wall Thickness Analysis Methods For Optimal Design of Casting PartsPrithviraj DagaNo ratings yet

- ProCNC - Design Guide ForCost Effective Machined Parts - IVDocument4 pagesProCNC - Design Guide ForCost Effective Machined Parts - IVPrithviraj DagaNo ratings yet

- Heteroskedasticity in Regression: Paul E. JohnsonDocument55 pagesHeteroskedasticity in Regression: Paul E. JohnsonadonovanxNo ratings yet

- Lesson Plan: Lesson: Carboxylic Acids (II)Document3 pagesLesson Plan: Lesson: Carboxylic Acids (II)MarcTnnNo ratings yet

- Agriculture TLE TG Grade 6Document7 pagesAgriculture TLE TG Grade 6hotel transelvanyia pleaseNo ratings yet

- Resiliency in Complete DenturesDocument4 pagesResiliency in Complete DenturesYassinSalahNo ratings yet

- Frequently Asked Questions (FAQ) On Wastewater - Sewage Treatment Plants (STP)Document11 pagesFrequently Asked Questions (FAQ) On Wastewater - Sewage Treatment Plants (STP)Krishna SrikanthNo ratings yet

- GeographyDocument11 pagesGeographyNarmatha BalachandarNo ratings yet

- Elements of Poetry Structure and FormsDocument43 pagesElements of Poetry Structure and FormsJulie Marie BalabatNo ratings yet

- Diseño Y Chequeo Muros Pantalla de Concreto Bloque 2: Table: Shear Wall Pier Design Summary - ACI 318-14, Part 1 of 5Document2 pagesDiseño Y Chequeo Muros Pantalla de Concreto Bloque 2: Table: Shear Wall Pier Design Summary - ACI 318-14, Part 1 of 5Uriel Vélez OrejuelaNo ratings yet

- Hexanes: Chemical Names Chemical Formula Formula WeightDocument6 pagesHexanes: Chemical Names Chemical Formula Formula WeightRustika SafitriNo ratings yet

- Tetanus NCPDocument3 pagesTetanus NCPMarc Jayson TobiasNo ratings yet

- 3516a Cat Engine Moh Part List Sheet1Document4 pages3516a Cat Engine Moh Part List Sheet1Shubham KhandelwalNo ratings yet

- 1 VHF DSC RM2042 PDFDocument76 pages1 VHF DSC RM2042 PDFchemasanchizNo ratings yet

- Math Grade 10Document3 pagesMath Grade 10MAYLENE VILLAROSANo ratings yet

- Hydrothermal Liquefaction and HydroprocessingDocument36 pagesHydrothermal Liquefaction and HydroprocessingcemilNo ratings yet

- WELCOME!!!!!: Six-Day Skills Enhancement Training For The TLE, TVL, ALS & Mobile TeachersDocument65 pagesWELCOME!!!!!: Six-Day Skills Enhancement Training For The TLE, TVL, ALS & Mobile TeachersErma JalemNo ratings yet

- Strongest Quarter Helped by Low Base: 3Q FY07 Results PreviewDocument24 pagesStrongest Quarter Helped by Low Base: 3Q FY07 Results PreviewIndushekhar JhaNo ratings yet

- PT124B 121 (英文)Document2 pagesPT124B 121 (英文)Jose Villalobos CoralNo ratings yet

- Buxton and Its Medicinal WatersDocument32 pagesBuxton and Its Medicinal WatersMotea IoanaNo ratings yet

- Determinants of Green Competitive AdvantageDocument23 pagesDeterminants of Green Competitive AdvantageInsiya AbbasNo ratings yet

- Preload Type of Precision Ball Screw: φ d φ D φ dp φ d φ dc φ Dg6 φ dDocument2 pagesPreload Type of Precision Ball Screw: φ d φ D φ dp φ d φ dc φ Dg6 φ dKshitij SharmaNo ratings yet

- Series N170-M3 and LFN170-M3 Installation InstructionsDocument12 pagesSeries N170-M3 and LFN170-M3 Installation InstructionsWattsNo ratings yet

- History of The TelephoneDocument16 pagesHistory of The TelephonedondonNo ratings yet

- Tax Types QuestionsDocument5 pagesTax Types QuestionsJoseph Tinio CruzNo ratings yet

- Technip3-Petroleum Refining 3 Conversion Processes PDFDocument650 pagesTechnip3-Petroleum Refining 3 Conversion Processes PDFNhat Cao100% (2)

- The Najd Fault System, Arabian ShieldDocument28 pagesThe Najd Fault System, Arabian Shieldgeo ghallabNo ratings yet