Professional Documents

Culture Documents

FDA Validation Nonsterile 2013

FDA Validation Nonsterile 2013

Uploaded by

Jorge Humberto HerreraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FDA Validation Nonsterile 2013

FDA Validation Nonsterile 2013

Uploaded by

Jorge Humberto HerreraCopyright:

Available Formats

Working document QAS/13.

527

April 2013

RESTRICTED

1

PROPOSAL FOR REVISION OF THE 2

SUPPLEMENTARY GUIDELINES ON 3

GOOD MANUFACTURING PRACTICES: VALIDATION, 4

APPENDIX 7: NON-STERILE PROCESS VALIDATION 5

6

(APRIL 2013) 7

8

DRAFT FOR COMMENT 9

10

11

12

World Health Organization 2013 13

All rights reserved. 14

This draft is intended for a restricted audience only, i.e. the individuals and organizations having received this 15

draft. The draft may not be reviewed, abstracted, quoted, reproduced, transmitted, distributed, translated or 16

adapted, in part or in whole, in any form or by any means outside these individuals and organizations (including 17

the organizations' concerned staff and member organizations) without the permission of the World Health 18

Organization. The draft should not be displayed on any web site. 19

Please send any request for permission to: 20

Dr Sabine Kopp, Medicines Quality Assurance Programme, Quality Assurance and Safety: Medicines, 21

Department of Essential Medicines and Health Products, World Health Organization, CH-1211 Geneva 27, 22

Switzerland. Fax: (41-22) 791 4730; e-mail: kopps@who.int. 23

The designations employed and the presentation of the material in this draft do not imply the expression of any 24

opinion whatsoever on the part of the World Health Organization concerning the legal status of any country, 25

territory, city or area or of its authorities, or concerning the delimitation of its frontiers or boundaries. Dotted 26

lines on maps represent approximate border lines for which there may not yet be full agreement. 27

The mention of specific companies or of certain manufacturers products does not imply that they are endorsed 28

or recommended by the World Health Organization in preference to others of a similar nature that are not 29

mentioned. Errors and omissions excepted, the names of proprietary products are distinguished by initial capital 30

letters. 31

All reasonable precautions have been taken by the World Health Organization to verify the information 32

contained in this draft. However, the printed material is being distributed without warranty of any kind, either 33

expressed or implied. The responsibility for the interpretation and use of the material lies with the reader. In no 34

event shall the World Health Organization be liable for damages arising from its use. 35

This draft does not necessarily represent the decisions or the stated policy of the World Health Organization. 36

37

Please address any comments on this proposal by 24 May 2013 to Dr S. Kopp, Medicines Quality

Assurance Programme, World Health Organization, 1211 Geneva 27, Switzerland, fax: (+41 22) 791 4730

or e-mail: kopps@who.int with a copy to gaspardm@who.int.

We are sending out our working documents electronically only and they are also placed on the

Medicines web site for comment. If you do not already receive our documents please let us have your

e-mail address (to bonnyw@who.int) and we will add it to our electronic mailing list.

Working document QAS/13.527

page 2

SCHEDULE FOR THE PROPOSED ADOPTION PROCESS OF DOCUMENT QAS/13.527: 38

PROPOSAL FOR REVISION OF THE SUPPLEMENTARY GUIDELINE ON 39

GOOD MANUFACTURING PRACTICES: VALIDATION, APPENDIX 7: NON-STERILE 40

PROCESS VALIDATION 41

42

43

44

Need for revision of published good manufacturing

practices: validation identified by Prequalification of

Medicines Programme

March 2013

Wide circulation of draft document for comment April 2013

Compilation of feedback received June 2013

Discussion of feedback during informal consultation on

quality assurance guidelines

July 2013

Mailing of revision for comment August 2013

Presentation to forty-eighth meeting of the WHO Expert

Committee on Specifications for Pharmaceutical

Preparations

October 2013

Any further action as necessary

Working document QAS/13.527

page 3

PROPOSAL FOR REVISION OF THE SUPPLEMENTARY GUIDELINE ON 45

GOOD MANUFACTURING PRACTICES: VALIDATION, APPENDIX 7: NON-STERILE 46

PROCESS VALIDATION 47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

The Appendixes of the Supplementary Guideline on Good Manufacturing Practices: 66

Validation are currently as follows: 67

68

Appendix 1- Validation of heating, ventilation and air-conditioning systems 69

70

Appendix 2 -Validation of water systems for pharmaceutical use 71

72

Appendix 3 - Cleaning validation need for revision? 73

74

Appendix 4 - Analytical method validation 75

76

Appendix 5 - Validation of computerized systems 77

78

Appendix 6 - Qualification of systems and equipment 79

80

Appendix 7 - Non-sterile process validation proposed to be revised 81

82

Note from Secretariat:

The current text of the Supplementary Guideline on Good Manufacturing Practices:

Validation (Ref: World Health Organization, WHO Technical Report Series, No. 937,

2006, Annex 4) is available on the following web site:

http://www.who.int/medicines/areas/quality_safety/quality_assurance/production/en/index.html

Moreover, comments are being sought at the same time, if the Appendix 3 on Cleaning

validation be revised in line with the current developments on setting health based

exposure limits for use in risk identification in the manufacture of different medicinal

products in shared facilities; if yes concrete proposals for revision would be

appreciated.

Working document QAS/13.527

page 4

Proposal for revision of the 83

Supplementary Guideline on Good Manufacturing Practices: Validation, 84

Appendix 7: Non-sterile process validation 85

86

87

Contents 88

page 89

1. Background and scope 90

2. Glossary 91

3. Introduction 92

4. Phase I. Process design 93

5. Phase II. Qualification and process verification 94

6. Phase III. Continued process verification 95

7. Change control 96

References 97

98

1. BACKGROUND AND SCOPE 99

100

Further to the Supplementary Guideline on good manufacturing practices: validation, as 101

published in the World Health Organization (WHO) Technical Report, No. 937,

1

additional 102

guidelines to support current approaches in GMP are published herewith to further support 103

the scope of process validation (also referred to as process qualification) linked to quality risk 104

management and quality by design principles as described by WHO and the International 105

Conference on Harmonisation (ICH). 106

107

This guideline allows for different approaches in process validation. The principles described 108

in this guideline are applicable to non-sterile finished pharmaceutical dosage forms. 109

Thorough knowledge of product and process development studies; previous manufacturing 110

experience; and quality risk management (QRM) principles are essential in the all approaches 111

to process validation as the focus is now on the life-cycle approach. The life-cycle approach 112

1

Supplementary guidelines on good manufacturing practices: validation. In: WHO Expert Committee on

Specifications for Pharmaceutical Preparations. Fortieth report. Geneva, World Health Organization. WHO

Technical Report Series, No. 937 (Annex 5), 2006.

Working document QAS/13.527

page 5

links product and process development, validation of the commercial manufacturing process 113

and maintenance of the process during routine commercial production. 114

115

A risk based approach to validation is recommended, linked to in-line or on-line controls and 116

monitoring to ensure that a process is in a state of control during routine manufacture. 117

118

2. GLOSSARY 119

120

control strategy 121

A planned set of controls, derived from current product and process understanding that assures 122

process performance and product quality. The controls can include parameters and attributes related to 123

drug substance and pharmaceutical product materials and components, facility and equipment 124

operating conditions, in-process controls, finished product specifications, and the associated methods 125

and frequency of monitoring and control. 126

127

continued process verification (CPV) 128

Continued process verification (CPV) can be defined as continuous monitoring of 129

manufacturing performance by using extensive in-line, on-line or at-line monitoring and/or 130

controls to evaluate process performance. It is a science and risk-based real-time approach to 131

verify and demonstrate that a process that operates within the predefined specified parameters 132

consistently produces material which meets all its critical quality attributes (CQAs) and 133

control strategy requirements. 134

135

continuous process verification 136

An alternative approach to process validation in which manufacturing process performance is 137

continuously monitored and evaluated. 138

139

critical process parameter (CPP) 140

A process parameter whose variability has an impact on a critical quality attribute 141

and therefore should be monitored or controlled to ensure the process produces the 142

desired quality. 143

144

145

Working document QAS/13.527

page 6

critical quality attribute (CQA) 146

A physical, chemical, biological or microbiological property or characteristic that should be 147

within an appropriate limit, range or distribution to ensure the desired product quality. 148

149

life-cycle 150

All phases in the life of a product from the initial development through marketing until the 151

products discontinuation (ICH Q8). 152

153

pharmaceutical quality system (PQS) 154

Management system to direct and control a pharmaceutical company with regard to 155

quality. 156

157

process validation 158

Documented evidence which provides a high degree of assurance that a specific process will 159

consistently result in a product that meets its predetermined specifications and quality 160

characteristics. 161

162

3. INTRODUCTION 163

164

Process validation data should be generated for all products to demonstrate the adequacy of 165

the manufacturing process at each site of manufacture. The validation should be carried out in 166

accordance with good manufacturing practices (GMP) and data should be held at the 167

manufacturing location and made available for inspection. Manufacturers should confirm that 168

a manufacturing process is under control before a product is placed on the market. 169

170

Process validation is associated with the collection and evaluation of data, from the process 171

design stage through commercial production, which provides scientific evidence that a 172

process is capable of consistently delivering a quality product. Process validation provides 173

documented evidence that a process is capable of reliably and repeatedly rendering a product 174

of the required quality. 175

176

A risk assessment approach should be used to determine the scope and extent to which 177

process(es) and starting material variability may affect product quality. The critical steps and 178

Working document QAS/13.527

page 7

parameters (e.g. those that may have an impact on the quality of the product) in the process of 179

manufacturing a pharmaceutical product and other relevant studies demonstrating that the 180

process is capable of delivering the desired product, quality should be identified and 181

documented and be based on knowledge of the product or processes concerned, according to 182

the stage of the product life-cycle. Process validation should cover at least these critical steps 183

and parameters. 184

185

Where necessary, a flow diagram may be helpful, covering all operations and controls in the 186

process to be validated. When applying QRM to a given operation, the steps preceding and 187

following that operation should also be considered. Amendments to the flow diagram may be 188

made where appropriate and should be documented as part of the validation documentation. 189

190

Different approaches can be followed when validating a process. 191

192

Manufacturers should ensure that the principles of process validation described in this 193

guideline are implemented. These include and cover phases of validation during process 194

design, scale up, qualification of premises, utilities and equipment, process performance 195

verification and ongoing monitoring of batches manufactured for commercial supply to 196

ensure that the process remains in a state of control. 197

198

The objectives of process validation include ensuring that: 199

200

the process design is evaluated to show that it is reproducible, 201

the commercial manufacturing process is defined and controlled, 202

ongoing assurance is gained to show that the process remains in a state of control. 203

204

The validation should cover all manufactured strengths and all manufacturing sites used for 205

production of the marketed product. A matrix approach may be acceptable based on 206

appropriate risk assessment. 207

208

There are different approaches to process validation which include traditional process 209

validation with prospective and concurrent validation, continuous process performance 210

verification (where an enhanced approach to development has been employed or where a 211

Working document QAS/13.527

page 8

substantial amount of product and process knowledge and understanding has been gained 212

through historical data and manufacturing experience) and a combination of traditional 213

process validation and continuous process verification. 214

215

Continued process verification is considered as a third phase in process validation. 216

217

Manufacturers should plan towards implementing the new approach in process validation that 218

should consist of three phases in the product life-cycle. 219

220

Phase I. Process design 221

Phase II. Qualification and process verification 222

Phase IIA. Qualification 223

Phase IIB. Continuous process performance verification 224

Phase III. Continued process verification 225

226

4. PHASE I. PROCESS DESIGN 227

228

As part of the process validation life-cycle some process validation studies may be conducted 229

on pilot-scale batches (corresponding to at least 10% or 100 000 units whichever is the 230

greater) of the production scale. 231

232

In certain cases, however, it may be necessary to provide production-scale validation data. 233

The number of batches (minimum of three) should be based on the variability of the process, 234

the complexity of the process/product and the experience of the manufacturer. 235

236

The number of batches produced in this validation exercise should be sufficient to allow the 237

normal extent of variation and trends to be established and to provide sufficient data for 238

evaluation. Extensive testing should be performed on the product at various stages during the 239

manufacturing process of the batches. 240

241

Manufacturers should define the stage at which the product is considered to be validated and 242

the basis on which that decision was made. It should include a justification for the number of 243

batches used based on the complexity and expected variability of the process. 244

Working document QAS/13.527

page 9

245

Validation should be done in accordance with process validation protocols. Data should be 246

collected and reviewed against predetermined acceptance criteria, and reflected in process 247

validation reports. 248

249

The protocol should include: 250

a description of the process; 251

a description of the experiment; 252

details of the equipment and/or facilities to be used (including measuring or recording 253

equipment) together with its calibration status; 254

the variables to be monitored; 255

the samples to be taken where, when, how, how many and how much (sample size); 256

the product performance characteristics/attributes to be monitored, together with the test 257

methods; 258

the acceptable limits; 259

time schedules; 260

personnel responsibilities; 261

details of methods for recording and evaluating results, including statistical analysis. 262

263

The results should be documented in the validation report which reflects the validation 264

protocol. 265

266

A conclusion and recommendation should be made on the extent of monitoring and the in- 267

process controls necessary for routine production, on the basis of the results obtained. 268

269

The planned commercial production and control records, which contain the operational limits 270

and overall strategy for process control, should be carried forward to the next phase for 271

confirmation. 272

273

Working document QAS/13.527

page 10

5. PHASE II. QUALIFICATION AND PROCESS VERIFICATION 274

275

Process verification is divided into two phases. These phases include qualification of 276

premises, utilities and equipment where commercial scale batches will be manufactured and 277

continuous process performance verification. 278

279

Phase IIA. Qualification 280

281

Premises, utilities, support systems and equipment should be appropriately qualified before 282

process performance verification (as part of validation) is started. 283

284

In a traditional approach, stages of qualification may include design, installation, operational 285

and performance qualification. 286

287

In some cases process validation may be conducted concurrently with performance 288

qualification. 289

290

Phase IIB. Continuous process performance verification 291

292

After completion of qualification, commercial batches should be subjected to continuous 293

process performance verification as part of process validation. It should confirm that scale up 294

in batch size did not adversely affect the characteristics of a product. 295

296

CPV demonstrates that a process that operates within the predefined specified parameters 297

consistently produces a product which meets all its critical quality attributes (CQAs) and 298

control strategy requirements. 299

300

The process should be verified on commercial-scale batches prior to marketing of the product. 301

Extensive in-line or at-line controls should be used to monitor process performance and 302

product quality in a timely manner. Relevant process quality attributes of incoming materials 303

or components, in-process material and finished products should be collected. This should 304

include the verification of attributes, parameters and end points, and assessment of CQA and 305

Working document QAS/13.527

page 11

critical process parameter (CPP) trends. Process analytical technology applications and 306

multivariate statistical process control (MSPC) can be used. 307

308

The scope and extent of continuous process verification will be influenced by a number of 309

factors including: 310

prior development and manufacturing knowledge from similar products and/or processes; 311

the extent of process understanding gained from development studies and commercial 312

manufacturing experience; 313

the complexity of the product and/or manufacturing process; 314

the level of process automation and analytical technologies used; 315

process robustness and manufacturing history since point of commercialization as 316

appropriate. 317

318

Manufacturers should describe the appropriateness and feasibility of the CPV strategy 319

including the process parameters and material attributes that will be monitored as well as the 320

analytical methods that will be employed. 321

322

Continuous process verification can be introduced at any time of the life-cycle of the product: 323

it can be used to design process validation protocols for the initial commercial production; 324

to revalidate commercialized products as part of process changes; 325

to support continual improvement throughout the remainder of the life-cycle. 326

327

It is expected that additional monitoring for the first commercial batches should be done 328

where continuous process verification is implemented. 329

330

Manufacturers should define: 331

the number of batches for which additional monitoring is proposed; 332

the type of testing/monitoring to be performed; 333

the acceptance criteria to be applied; 334

how the data will be evaluated. 335

336

Statistical models or tools used should be described. 337

338

Working document QAS/13.527

page 12

6. PHASE III. CONTINUED PROCESS VERIFICATION 339

340

Manufacturers should monitor product quality of commercial batches after completion of 341

Phase I and Phase II of process validation. This will provide evidence that a state of control is 342

maintained throughout the product life-cycle. 343

344

Periods of enhanced sampling and monitoring may help to increase process understanding as 345

part of continuous improvement. 346

347

Process trends such as the quality of incoming materials or components, in-process and 348

finished product results and non-conformances should be collected and assessed in order to 349

verify the validity of the original process validation or to identify required changes to the 350

control strategy. 351

352

The extent and frequency of ongoing process validation should be reviewed periodically and 353

modified if appropriate throughout the product life-cycle. 354

355

Continued process validation (CdPV) should not be confused with product quality review. 356

357

Table 2 provides a summary of the new approach to process validation. 358

359

Table 2. New approach to process validation 360

Product life-cycle

Process validation

Phase I Phase II Phase III

Process design Qualification Continuous process

verification

Continued process

verification

- Pilot scale (and

scale-up batches

where appropriate)

- Risk assessment to

identify critical

quality attributes and

process control

parameters

- Premises

- Utilities

- Equipment

- Commercial-scale

batches

- In-line or on-line

monitoring (e.g. PAT)

- Defined number of

batches

- Periodic review of

trends

- May include

sampling and testing

Working document QAS/13.527

page 13

- Protocols and

reports

- Validate process

- Define CQA and

CPPs to be

monitored in Phase II

Change control

GMP

361

7. CHANGE CONTROL 362

363

Changes during the life-cycle of a product should be managed through a change control 364

procedure. Sufficient data should be generated to demonstrate that the revised process will 365

result in a product of the desired quality, consistent with the approved specification. 366

367

The change control procedure and records should ensure that all aspects are thoroughly 368

documented and approved including regulatory approval where appropriate (variation). 369

Manufacturers should follow change control procedures when changes are planned to 370

existing systems or processes. 371

372

Validation should be considered when changes are planned to production and/or control 373

procedures. 374

375

Changes that are likely to require revalidation may include: 376

changes in the manufacturing process (e.g. mixing times, drying temperatures); 377

changes in the equipment (e.g. addition of automatic detection systems); 378

production area and support system changes (e.g. rearrangement of areas or a new water 379

treatment method); 380

transfer of processes to another site; 381

unexpected changes (e.g. those observed during self-inspection or during routine analysis 382

of process trend data). 383

384

Based on risk assessment, revalidation should be considered in the case of: 385

changes in the master formula, methods, starting material manufacturer, equipment and/or 386

instruments; 387

Working document QAS/13.527

page 14

equipment calibrations and preventive maintenance carried out; 388

changes to standard operating procedures (SOPs); 389

changes to cleaning and hygiene programmes. 390

391

REFERENCES 392

393

1. Guideline on Process Validation, 29 March 2012 394

EMA/CHMP/CVMP/QWP/70278/2012-Rev1 , Committee for Medicinal Products for 395

Human Use (CHMP), Committee for Medicinal Products for Veterinary Use (CVMP) 396

www.ema.europa.eu/uideline/2012/04/WC500125399.pdf. 397

398

2. Guidance for Industry, Process Validation: General Principles and Practices, U.S. 399

Department of Health and Human Services, Food and Drug Administration, 400

Center for Drug Evaluation and Research (CDER), Center for Biologics Evaluation 401

and Research (CBER), Center for Veterinary Medicine (CVM), January 2011, 402

Current Good Manufacturing Practices (CGMP) Revision 1. 403

404

3. ICH Harmonised Tripartite Guideline, Pharmaceutical Development Q8(R2), Current 405

Step 4 version, dated August 2009. 406

407

4. ICH Harmonised Tripartite Guideline, Quality Risk Management, Q9, Current Step 4 408

version, dated 9 November 2005. 409

410

5. ICH Harmonised Tripartite Guideline, Pharmaceutical Quality System, Q10, Current 411

Step 4 version, dated 4 June 2008 412

http://www.ich.org/products/guidelines/quality/article/quality-guidelines.html 413

414

6. Quality Assurance of pharmaceuticals. WHO guidelines, related guidance and 415

GXP training materials. Geneva, World Health Organization, 2013 (CD-ROM). 416

417

418

Working document QAS/13.527

page 15

7. WHO good manufacturing practices: main principles for pharmaceutical products. In: 419

WHO Expert Committee on Specifications for Pharmaceutical Preparations. Forty- 420

fifth report. Geneva, World Health Organization. WHO Technical Report Series, No. 421

961 (Annex 3), 2011 (WHO good manufacturing practices: main principles for 422

pharmaceutical products). 423

424

8. WHO guidelines on quality risk management. In: WHO Expert Committee on 425

Specifications for Pharmaceutical Preparations. Forty-seventh report. Geneva, World 426

Health Organization. WHO Technical Report Series, No. 981 (Annex 2), 2013 (in 427

press). 428

429

*** 430

431

432

433

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LEED V4 ScorecardDocument1 pageLEED V4 ScorecardsubirmeNo ratings yet

- Employee Handbook: The Johns Hopkins Hospital/ Johns Hopkins Health System CorporationDocument34 pagesEmployee Handbook: The Johns Hopkins Hospital/ Johns Hopkins Health System CorporationMisbhasaeedaNo ratings yet

- New Monthly SHE ReportsDocument21 pagesNew Monthly SHE ReportsGIRI BISWAS100% (1)

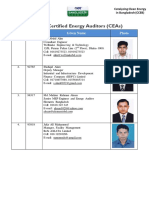

- CEA BangladeshDocument21 pagesCEA Bangladeshsubirme100% (1)

- HSA Cleaning Validation GuidelineDocument11 pagesHSA Cleaning Validation GuidelinesubirmeNo ratings yet

- LPG Vapour Liquefication SystemDocument1 pageLPG Vapour Liquefication SystemsubirmeNo ratings yet

- Sectional View of Turnnion Mounted Ball ValveDocument1 pageSectional View of Turnnion Mounted Ball ValvesubirmeNo ratings yet

- ISO 9606-1 Welder Qualification Download LinkDocument1 pageISO 9606-1 Welder Qualification Download LinksubirmeNo ratings yet

- ASHRAE 100 - Energy Conservation in Existing BuildingDocument1 pageASHRAE 100 - Energy Conservation in Existing BuildingsubirmeNo ratings yet

- Boiler Short GuideDocument6 pagesBoiler Short GuidesubirmeNo ratings yet

- Guideline On Air Handling On Food IndustryDocument6 pagesGuideline On Air Handling On Food IndustrysubirmeNo ratings yet

- List of Parts of Boiler BurnerDocument1 pageList of Parts of Boiler BurnersubirmeNo ratings yet

- Green in BrochurDocument1 pageGreen in BrochursubirmeNo ratings yet

- Safety Inherent DesignDocument68 pagesSafety Inherent Designsubirme100% (1)

- Motor Star Delta ConnectionDocument11 pagesMotor Star Delta ConnectionsubirmeNo ratings yet

- Allopathic Manufacturing Approval ChecklistDocument4 pagesAllopathic Manufacturing Approval ChecklistsubirmeNo ratings yet

- Dop TestDocument2 pagesDop TestsubirmeNo ratings yet

- Pharma WasteDocument1 pagePharma WastesubirmeNo ratings yet

- TabletDocument156 pagesTabletSiddharth Patel100% (2)

- Cleaning Validation Guideline (GUI 0028) Revision Draft 201201Document16 pagesCleaning Validation Guideline (GUI 0028) Revision Draft 201201Chang Woo JongNo ratings yet

- Tablet Tooling in Compression MachineDocument32 pagesTablet Tooling in Compression Machinesubirme0% (1)

- Cleaning Validation Guideline (GUI 0028) Revision Draft 201201Document16 pagesCleaning Validation Guideline (GUI 0028) Revision Draft 201201Chang Woo JongNo ratings yet

- Microbiological Monitoring Rodac PlateDocument2 pagesMicrobiological Monitoring Rodac PlatesubirmeNo ratings yet

- Basic GMP ChecklistDocument12 pagesBasic GMP Checklistsubirme50% (2)

- key đề thi hk2 khối 12 tự ôn tậpDocument17 pageskey đề thi hk2 khối 12 tự ôn tậpNgọc Khuê TrầnNo ratings yet

- Lecture 4 Urinary Data For K CalculationDocument29 pagesLecture 4 Urinary Data For K Calculationmahmoudnageh38No ratings yet

- Sierra de Pecho - EBS-1Document12 pagesSierra de Pecho - EBS-1cristian andres quiceno mayaNo ratings yet

- Clasification of Odontogenic Tumours A ReviewDocument6 pagesClasification of Odontogenic Tumours A ReviewJuan Carlos MeloNo ratings yet

- Neural Plasticity 2020Document11 pagesNeural Plasticity 2020ANo ratings yet

- Isst Distance Education CoursesDocument43 pagesIsst Distance Education CoursesDivik ShahNo ratings yet

- Reflection of Psychology 1010Document2 pagesReflection of Psychology 1010api-270635734No ratings yet

- Operation and Maintenance Manual: 854F-E34T and 854E-E34TA Industrial EnginesDocument120 pagesOperation and Maintenance Manual: 854F-E34T and 854E-E34TA Industrial EnginesRasheed SiddiquiNo ratings yet

- EOP ProposalDocument6 pagesEOP ProposalnatasyaNo ratings yet

- Chemical Company ProfileDocument13 pagesChemical Company ProfileRaghuram KrishnamurthyNo ratings yet

- Xtenso Moisturist Tech Guide A5Document40 pagesXtenso Moisturist Tech Guide A5Alexandra SNo ratings yet

- Configuration of Circle of Willis in Bangladeshi Population An Observational StudyDocument3 pagesConfiguration of Circle of Willis in Bangladeshi Population An Observational StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Saturated Fat - Villain and Bogeyman in The Development of Cardiovascular DiseaseDocument10 pagesSaturated Fat - Villain and Bogeyman in The Development of Cardiovascular DiseasedddNo ratings yet

- Home - Impanelled Hospital ListDocument20 pagesHome - Impanelled Hospital ListeffefefeNo ratings yet

- SPEAKING Definition of HIVDocument2 pagesSPEAKING Definition of HIVRijal QalbiNo ratings yet

- USMLE Step 2 CK Lecture Notes Pediatrics ATFDocument262 pagesUSMLE Step 2 CK Lecture Notes Pediatrics ATFkadirklnc.47No ratings yet

- 12 Haccp Baking PDFDocument32 pages12 Haccp Baking PDFMuzammal FarooqNo ratings yet

- C. Pasternatsky Symptom IsDocument11 pagesC. Pasternatsky Symptom IsareenNo ratings yet

- EPP Module 2 Assignment (Eng)Document8 pagesEPP Module 2 Assignment (Eng)anne.le6996No ratings yet

- BP Normal Pulse Rate ChartDocument3 pagesBP Normal Pulse Rate Chartzafri77No ratings yet

- Mombasa County ADP 2020 - 2021Document187 pagesMombasa County ADP 2020 - 2021Mombasa CountyNo ratings yet

- Dugayo Activity 1Document1 pageDugayo Activity 1Ozen YuNo ratings yet

- Applying The Chronic Care Model in Low-Resource Settings Ada Dec2013Document44 pagesApplying The Chronic Care Model in Low-Resource Settings Ada Dec2013Wawan JokoNo ratings yet

- Food Safety Research PaperDocument8 pagesFood Safety Research Papergz98szx1100% (1)

- 2° Consenso Mexicano de AQEDocument11 pages2° Consenso Mexicano de AQEFernando Vega RiverosNo ratings yet

- Commitment To Process Safety Pillars AIChEDocument2 pagesCommitment To Process Safety Pillars AIChEAnonymous orNHXM0f0No ratings yet

- Wastewater Treatment: P.O. Box 397-00242 Nairobi, Kenya. +254 721 279 688 Email: Info@ecosavetech - Co.keDocument1 pageWastewater Treatment: P.O. Box 397-00242 Nairobi, Kenya. +254 721 279 688 Email: Info@ecosavetech - Co.kevictorNo ratings yet

- Five Factor Narcissism InventoryDocument6 pagesFive Factor Narcissism Inventoryyashini_96No ratings yet