Professional Documents

Culture Documents

Ais 67

Uploaded by

Ebru Önlü DuralOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ais 67

Uploaded by

Ebru Önlü DuralCopyright:

Available Formats

Glass Processing Days, 1821 June 2001

www.glassfiles.com

S

e

s

s

i

o

n

3

1

688

Conception of A New Notification of Building

Glass Design in Japan

31 meters titled Notification No. 109 had been

established in 1971. It was presented by using

numerous results obtained the wind pressure test

of large sized glass, however, it became necessary

to revise because of following four reasons;

1. Revision of glass manufacture process,

2. The strength data exceeding 19mm thickness

glass were not defined,

3. Effect of aspect ratio against the wind load was

not considered,

4. Allowable wind load of both laminated glass and

IG unit had been estimated assuming as the

layered glass.

A new notification No.1458 was published in

June 2000 to revise the mentioned defects.

Conception of notification No. 1458 is shown in

this paper. To determine the basis of mechanical

glass strength, coaxial double ring test is carried

out for annealed glass. The glass strength

depending on its thickness is recognized through

the test. Then, the allowable wind loads as the

cumulative failure probability=1/1000 are

determined by using the reliability design method

and its own strength data for each monolithic glass

thickness. The wind load resistance is evaluated

in several aspect ratios of glass panes. The

minimum wind load resistance is defined as the

allowable wind load to simplify the calculation

procedure in this notification. As the result, there

is no term of aspect ratio in this equation to

evaluate the wind load resistance.

Some new ideas evaluating the wind load

resistance are introduced in new notification No.

1458. For laminated glass, the resistance is not

evaluated as the layered glass, but calculated as

an equivalent monolithic glass. For IG units, the

resistance is estimated by using the accurate load

share factor and climatic effect. The simple

calculation method is shown in this new notification

No. 1458.

Masashi Kikuta*, Takahiro Murakami**, Shinichi Aratani***

* Nippon Sheet Glass Co. Ltd., Japan

** Asahi Glass Co. Ltd., Japan

***Central Glass Co. Ltd., Japan

Keywords

1 = Glass design 2 = Japan notification

Abstract

In June 2000, a new notification of glass

design for use in buildings was published in Japan.

The method of determining the equivalent wind

load and a safety application of glass type in

building are shown in the notification No.1458.

Allowable load of window glass subjected to wind

pressure is calculated by following simple

equation.

P=300k

1

k

2

(t+t

2

/4)/A

where, P : allowable wind load(N/m

2

), k1 :

glass strength factor, k

2

: glass type factor, t :

nominal thickness of glass(mm), A : aspect area

of glass(m

2

).

Glass strength factors were determined by

using a reliability design method, and they were

defined as a unique value with respect to each

monolithic glass panes having cumulative failure

probability=1/1000. Even a float glass, we obtained

the several glass strength factors depending on its

thickness.

Glass type factors were defined as unique

value for a monolithic glass, for a laminated glass

and for an IG unit, respectively. For a laminated

glass, glass type factor was determined by the

results obtained from a lot of measurements and

numerical analyses for stresses and displace-

ments. Effective thickness of a laminated glass

pane is also shown in this paper. For an IG unit,

we considered the climatic effect, (ex.

temperature, meteorological pressure, typhoon..),

and an accurate load share factors. Then, Glass

type factors were obtained as a function of each

glass thickness composed IG units.

This paper provides a simple method for

determining a glass type in safety use against a

design wind load.

Introduction

An old design code of building glass higher than

Glass Processing Days, 1821 June 2001

www.glassfiles.com 689

S

e

s

s

i

o

n

3

1

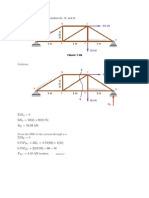

Calculating equation

Allowable wind load with respect to glass

thickness, glass strength and glass type can be

expressed by

(1)

Where, P is the allowable wind load (N/m

2

), k1

and k

2

denote glass strength factor and glass type

factor, respectively, A is aspect area of glass (m

2

)

and t is a nominal thickness of glass (mm).

Allowable wind load is defined as the cumulative

failure probability=1/1000 in a glass pane

subjected 6 seconds constant wind load[1]. The

outline of reliability design method is shown in

Fig.1. In this method, it is important to determine

the basis of glass strength and to estimate the

cumulative failure probability of glass panes by

using the statistical treatment and numerical

analysis, respectively.

of strength distribution, and the allowable

mechanical strength is decided for each glass

thickness. Fig.2 shows the testing apparatus.

(1) Annealed Glass

Table 1 shows the results obtained by coaxial

ring test in case of commercial float glass. It is

found that the strength of testing glass is depended

on its thickness.

Glass strength factor k

1

Coaxial double ring test was carried out with

respect to some glass thickness. Logarithmic

normal distribution was applied to treat as statistics

The relationship between the thickness ratio

and the strength ratio is shown in Fig.3, and it is

approximated as equation (2).

Using equation (2), the glass strength factors

of commercial float glass are defined as Table 2.

P =

300k

1

k

2

A

t +

t

2

4

1

=

t

2

t

1

1

4

Allowable

load

Relationship between load and

cumulative failure probability

Parameters obtained

by statistics treatment

Predicted failure

probability model

FEM

analysis

Stress

distribution

Fracture test of small

size specimens

Computer simulation

Figure 1 Reliability design method

Table 1 Glass Strength

Thickness

(mm)

Average Strength

(MPa)

Allowable Strength

(MPa)

6 95.1 42.2

8 93.3 40.9

10 91.5 39.7

12 89.7 38.4

15 87.0 36.5

19 83.4 34.0

22 80.7 32.2

25 78.0 30.3

Table 2 Strength Factor of Float Glass

Thickness Strength Factor

Thickness =< 8 mm 1.0

9 mm =< Thickness =< 12 mm 0.9

13 mm =< Thickness =< 20 mm 0.8

21 mm =< Thickness 0.75

Glass Processing Days, 1821 June 2001

www.glassfiles.com

S

e

s

s

i

o

n

3

1

690

(2) Heat strengthened (HS) and Fully tempered

(FT) Glass

Strength of HS and FT glass for several

thickness was also investigated as same way,

however the changing of strength depended on its

thickness was not found out because of the wide

variance of residual stress. Table 3 shows the

glass strength factor of HS and FT glass.

and Fig.5. Minimum glass thickness defined in JIS

R3202 is used in this calculation.

Table 3 Strength Factor of HS and FT Glass

Type of Glass Strength Factor

Heat Strengthened Glass 2.0

Tempered Glass 3.5

(3) The other glass

The glass strength factors of the others are

shown in Table 4.

Table 4 Strength Factor of the Other Glass

Type of Glass Strength Factor

Sheet Glass 1.0

Polished Glass 0.8

Polished Wired Glass 0.8

Figured Glass 0.6

Figured Wired Glass 0.6

Glass type factor k

2

(1) Monolithic glass

Allowable wind load values for various aspect

ratio of glass pane are obtained by using reliability

design method. Some results are shown in Fig.4

0

2

4

6

8

10

1 1.5 2 2.5

0.5m

2

0.6m

2

0.8m

2

1m

2

1.5m

2

2m

2

3m

2

4m

2

A

l

l

o

w

a

b

l

e

l

o

a

d

(

k

P

a

)

Aspect ratio (long/short)

Figure 4 Allowable load (thickness 6mm)

0

2

4

6

8

10

1 1.5 2 2.5

3m

2

4m

2

5m

2

6m

2

7m

2

8m

2

9m

2

10m

2

Aspect ratio (long/short)

Figure 5 Allowable load (thickness 19mm)

A

l

l

o

w

a

b

l

e

l

o

a

d

(

k

P

a

)

Minimum wind load value is introduced as a

allowable wind load for each glass thickness.

Glass type factor of monolithic glass is defined 1.0

as basis of this design code.

(2) Laminated glass

Polyvinyl butyral (PVB) interlayer is assumed as

the interlayer of laminated glass. The authors have

investigated the allowable wind load of laminated

glass composed two same thickness of glass pane

for several loading speed and temperature of PVB

interlayer[2,3]. It was found that the laminated

glass is not similar to layered glass but similar to

monolithic glass. For dynamic wind pressure,

allowable wind load of laminated glass was

0.941.05 times and 0.801.04 times of monolithic

glass having the total thickness of laminated glass

except for interlayer thickness when the

temperature of interlayer is 20C and 50C,

respectively. In the case of laminated glass

composed different glass thickness, the result was

obtained that the above magnification of laminated

glass becomes low which is approximately equal

to 0.75.

So, laminated glass is assumed as monolithic

glass having total glass thickness, and glass type

factor of laminated glass is defined 0.75 as

mentioned reasons. Effective thickness of

laminated glass would be able to express as

equation (3).

(3) IG units

In Fig. 6 and Fig. 7 are shown the calculated

load share factor of IG units for several glass

thickness ratio. This calculation was carried out by

t = 0.866 T 0.268

Glass Processing Days, 1821 June 2001

www.glassfiles.com 691

S

e

s

s

i

o

n

3

1

using FEM, and also examined[4]. In calculation

and examination, IG units was used as 1000mm

x 2000mm x (10mm glass thickness + 6mm

airspace + 10mm glass thickness). The results

show that the load share factor cannot be assumed

the layered glass. This phenomenon has been also

reported by David Chou et al.[5].

Next, the climatic effect should be considered

because it is easy to estimate that the

meteorological pressure is very low (approxima-

Figure 6 The Relationship between Thickness

Ratio and Load Share Factor

0.6

0.7

0.8

0.9

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

0 0.2 0.4 0.6 0.8 1

LOAD on Thicker Glass

W1000H2000t10-A6:Q1000kg/m2:ThickG-load on ThickG

W1000H2000t10-A6:Q1000kg/m2:ThinG-load on ThickG

W1000H2000t19-A6:Q1000kg/m2:ThickG-load on ThickG

W1000H2000t19-A6:Q1000kg/m2:ThinG-load on ThickG

W1000H1000t10-A6:Q1000kg/m2:ThickG-load on ThickG

W1000H1000t10-A6:Q1000kg/m2:ThinG-load on ThickG

L

o

a

d

S

h

a

r

e

F

a

c

t

o

r

:

L

a

y

e

r

e

d

=

1

.0

Thickness Ratio (=Thinner/Thicker)

Figure 7 The Relationship between Thickness

Ratio and Load Share Factor

0.6

0.7

0.8

0.9

1

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

0 0.2 0.4 0.6 0.8 1

LOAD on Thinner Glass

W1000H2000t10-A6:Q1000kg/m2:ThickG-load on ThinG

W1000H2000t10-A6:Q1000kg/m2:ThinG-load on ThinG

W1000H2000t19-A6:Q1000kg/m2:ThickG-load on ThinG

W1000H2000t19-A6:Q1000kg/m2:ThinG-load on ThinG

W1000H1000t10-A6:Q1000kg/m2:ThickG-load on ThinG

W1000H1000t10-A6:Q1000kg/m2:ThinG-load on ThinG

L

o

a

d

S

h

a

r

e

F

a

c

t

o

r

:

L

a

y

e

r

e

d

=

1

.0

Thickness Ratio ( =Thinner/Thicker)

tely, 940hPa) in Japan when typhoon attacked. If

IG unit is produced in normal pressure 1013hPa,

estimated load caused by inner pressure changing

would be 15% of its allowable wind load.

Considering both load share factor and climatic

effect, the glass type factor of IG units is defined

as following equations.

Discussion and Conclusions

A simple method for determining a glass

thickness and glass type in safety use against a

design wind load is provided as the notification No.

1458 of Japan. This design code is prepared with

numerous examinations and calculations, however

some restrictions remain for application of design

strength as follows,

(1) If the lateral deflection of the edges of the

glass exceed 1/150 of their length, calculated

allowable wind load cannot be confidence.

(2) For IG units, the accurate load share factor

cannot be obtained when the glass thickness ratio

(thicker glass/thinner glass) is greater than 2.5.

(3) For laminated glass, glass type factor should

be required except for PVB interlayer.

References

[1] Takehiro Miura, Satoru Kasagi and Shunji Miyoshi, Report

of the Research Laboratory,

Asahi Glass Co., Ltd., Vol.24, 1974

[2] Shinichi Aratani, Masashi Kikuta, Takahiro Murakami and

Masahiko Ida, Stress

measurement of laminated glass, 12th Fall Meeting of The

Ceramic Society of Japan, 1999

[3] Takahiro Murakami, Yukihito Oketani and Yoshinobu

Fujitani, Journal of architecture,

Architectural Institute of Japan, 2000

[4] Hidemi Kato,Taito Kinoshita and Masashi Kikuta, Summaries

of technical paper of annual

meeting, Architectural Institute of Japan, 2000

[5] G. David Chou, Joseph E. Minor and C. V. Girija Vallabhan,

The Structural-Mechanics

Behavior of Insulating Glass Units, 1986

+ =

3

1

2

1 , 2

1 75 . 0

t

t

k

+ =

3

2

1

2 , 2

1 75 . 0

t

t

k

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Delamination of Laminated GlassDocument4 pagesDelamination of Laminated Glassreagan_roy8177100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Table of Integrals: AppendixDocument30 pagesTable of Integrals: AppendixhabalilbaNo ratings yet

- Centers of Gravity - Centroids: NotationDocument5 pagesCenters of Gravity - Centroids: NotationEbru Önlü DuralNo ratings yet

- Table of Integrals: AppendixDocument30 pagesTable of Integrals: AppendixhabalilbaNo ratings yet

- Moment Inertia PDFDocument18 pagesMoment Inertia PDFSameOldHatNo ratings yet

- Centers of Gravity - Centroids: NotationDocument5 pagesCenters of Gravity - Centroids: NotationEbru Önlü DuralNo ratings yet

- Moment Inertia PDFDocument18 pagesMoment Inertia PDFSameOldHatNo ratings yet

- Fluid Equations, MagnetohydrodynamicsDocument21 pagesFluid Equations, MagnetohydrodynamicsEbru Önlü DuralNo ratings yet

- Moment Inertia PDFDocument18 pagesMoment Inertia PDFSameOldHatNo ratings yet

- Moment of InertiaDocument3 pagesMoment of InertiaSurya VenkatramanNo ratings yet

- Inertia FormulasDocument1 pageInertia FormulasrohitkapyarNo ratings yet

- Momi Table PDFDocument1 pageMomi Table PDFEbru Önlü DuralNo ratings yet

- Moment Inertia PDFDocument18 pagesMoment Inertia PDFSameOldHatNo ratings yet

- Regulating Glass For SafetyDocument3 pagesRegulating Glass For SafetyEbru Önlü DuralNo ratings yet

- Sudoku Number Fun 1Document1 pageSudoku Number Fun 1Ebru Önlü DuralNo ratings yet

- Gaussian Quad ProofDocument8 pagesGaussian Quad ProofFahmee TalibNo ratings yet

- Name: - Date: - Which Picture in Each Group Is The Odd One Out? Circle ItDocument1 pageName: - Date: - Which Picture in Each Group Is The Odd One Out? Circle ItEbru Önlü DuralNo ratings yet

- Solution:: 1. Determine The Force in Members BC, CE, and EFDocument9 pagesSolution:: 1. Determine The Force in Members BC, CE, and EFEbru Önlü DuralNo ratings yet

- Ais 67Document4 pagesAis 67Ebru Önlü DuralNo ratings yet

- 485 FullDocument28 pages485 FullEbru Önlü DuralNo ratings yet

- So Sweet Valentines Day Banner by Anna and Blue Paperie PDFDocument7 pagesSo Sweet Valentines Day Banner by Anna and Blue Paperie PDFEbru Önlü DuralNo ratings yet