Professional Documents

Culture Documents

Emi in Modern Ac

Emi in Modern Ac

Uploaded by

Ioan Ţilea0 ratings0% found this document useful (0 votes)

6 views6 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views6 pagesEmi in Modern Ac

Emi in Modern Ac

Uploaded by

Ioan ŢileaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

53 2009 IEEE

in that year, where he was engaged in the research and development

of communication network architectures and communication switch-

ing software. He joined the Division of Medical Informatics, Shi-

mane University Hospital, in 2004. He moved to the Department of

Medical Informatics, Shimane University School of Medicine, in

2005. His research interests include information processing systems

in hospitals as well as computational learning theory and its appli-

cation. He is a member of the Institute of Electronics, Information

and Communication Engineers of Japan, the Japanese Society for

Artificial Intelligence, the Japan Society for Health Care Manage-

ment, and the Japanese Society for Clinical Pathway.

Takato Kudou was born in Oita, Japan, in

1963. He received his B.Eng., M.Eng. and D.

Eng. degrees in communication engineering, all

from Kyushu University, Fukuoka, Japan, in

1985, 1987 and 1990, respectively. From 1990

to 1994, he was a Research Associate of the

Department of Computer Science and Communica-

tion Engineering, Kyushu University. In 1994,

he joined the Department of Electrical and Electronic Engineering, Oita

University, and is currently an Associate Professor of the same Univer-

sity. His research interests have been on electromagnetic direct/inverse

scattering and FDTD analysis of the electromagnetic environment. Dr.

Kudou is a member of the IEICE of Japan, the IEE of Japan and the

Japanese Society of Medical and Biomedical Engineering.

Takashi Kano was born in Tokyo, Japan, in

1949. He received his B.Eng. degrees from

Sophia University, Tokyo, Japan, in 1973. He

received his Ph.D. degree from Toa University,

Yamaguchi, Japan, in 2004. Since 1973, he

has worked at the Department of Medical Engi-

neering Service in Mitsui Memorial Hospital for

32 years. Since 2006, he has been working at

the Department of Biomedical Engineering, Faculty of Health and

Medical Care, Saitama Medical University. Prof. Kano is a member

of the Japanese Society of Medical and Biomedical Engineering, the

Healthcare Engineering Association of Japan and the Japanese Society

of Medical Instrumentation. EMC

EMI in Modern AC Motor Drive Systems

Firuz Zare, Queensland University of Technology Brisbane, QLD,

Australia Email: f.zare@qut.edu.au

AbstractIn this paper, several aspects of high frequency related

issues of modern AC motor drive systems, such as common mode

voltage, shaft voltage and resultant bearing current and leakage

currents, have been discussed. Conducted emission is a major prob-

lem in modern motor drives that produce undesirable effects on

electronic devices. In modern power electronic systems, increasing

power density and decreasing cost and size of system are market

requirements. Switching losses, harmonics and EMI are the key

factors which should be considered at the beginning stage of a

design to optimise a drive system.

Introduction

Nowadays, more than 60 percent of the worlds energy is used

to drive electric motors. Due to growing requirements of speed

control, pulse width modulated inverters are used in adjustable

speed drives. Rapid developments in semiconductor technolo-

gy have increased the switching speed and frequency of power

switches dramatically. In a motor drive system, a voltage source

converter with hard switches generates high dv/dt, which

causes leakage currents due to stray capacitances in an electric

motor. As shown in Fig.1, a modern power electronic drive

consists of a filter, a rectifier, a DC link capacitor, an inverter

and an AC motor. Many small capacitive couplings exist in the

motor drive systems which may be neglected at low frequency

analysis but the conditions are completely different at high

frequencies.

Electromagnetic Interference (EMI) is a major problem in

recent motor drives that produces undesirable effects on elec-

tronic devices. In modern power electronic systems, increasing

power density and decreasing cost and size of a system are mar-

ket requirements. Switching losses, harmonics and EMI are the

key factors which should be considered at the beginning stage

of a design to optimise a drive system.

Common mode voltage creates shaft voltage through electro-

static couplings between a rotor and stator windings and the ro-

tor and a frame which can cause bearing currents when the shaft

voltage exceeds a breakdown voltage level of the bearing grease.

An increase in the carrier frequency of voltage-source Pulse

Width Modulated (PWM) inverters based on high-speed

switching devices has improved operating characteristics of the

inverters. High speed switching can generate the following se-

rious problems due to high dv/dt:

Ground current escaping to earth through stray capacitors

inside a motor

Conducted and radiated noises

Shaft voltage and bearing current

Models of parasitic couplings and high frequency com-

ponents for an inverter fed induction motor drive system

are investigated to determine suitable models to predict

54 2009 IEEE

bearing currents and shaft voltage over a wide frequency

range. A high frequency model of an electric motor is an

important issue for power electronic engineers, which helps

them to analyse leakage and bearing currents and to design

EMI filters. At low frequency, an equivalent circuit of an

electric motor consists of inductances and resistances with-

out considering stray capacitances and skin effect. These

issues become more important at high speed switching ap-

plications due to high dv/dt.

Fig.2 shows the capacitive cou-

plings of an induction motor and a

view of stator slot, where:

C

wr

is the capacitive coupling be-

tween the stator winding and rotor

C

ws

is the capacitive coupling be-

tween the stator winding and stator

frame

C

rs

is the capacitive coupling be-

tween the rotor and stator frame

C

ww

is the capacitive coupling

between turns of stator winding

C

ball

is the capacitive coupling of

ball bearing

Fig.3 shows a general structure of

a ball bearing and shaft in an AC ma-

chine. As shown in this figure there

are some balls between outer and in-

ner races with lubricated grease be-

tween the balls and the races. There

are capacitive couplings between the

outer and inner races. During opera-

tion, the distances between the balls

and races may be changed and will

vary the capacitance values and resul-

tant electric field between the races

and balls. Due to this fact, this capac-

itance has a nonlinear value. Lubricat-

ed grease in the ball bearing cannot

withstand a high voltage and a short

circuit through the lubricated grease

may happen, thus this phenomenon

can be modelled as a switch.

PWM inverters have been found

to be a major cause of motor bearing

failures in inverter motor drive sys-

tems. All inverters generate common

mode voltages relative to the ground,

which make bearing current through

motor parasitic capacitances.

According to Fig.4.a, phase volt-

ages and a common mode voltage (V

n

)

can be derived based on the power

converter voltages (V

a

, V

b

,V

c

). Each

leg voltage of a three phase inverter

is given by:

V

a

5V

an

1V

n

V

b

5V

bn

1V

n

(1)

V

c

5V

cn

1V

n

And then:

V

a

1V

b

1V

c

5 1 V

an

1V

bn

1V

cn

2 13V

n

(2)

It is clear that in a three-phase system:

V

an

1V

bn

1V

cn

50 (3)

So, the common mode voltage can be calculated as:

V

n

5 1 V

a

1V

b

1V

c

2 /3 (4)

Fig. 1. A power electronic motor drive system with capacitive couplings.

Filter

Voltage

Supply

Filter

Diode

Rectifier Inverter

dc-Link

Capacitor Cables Motor

PE

Fig. 3. (a) general structure of a ball bearing (b) a view of ball, outer and inner

races and capacitive couplings (c) simple model of a ball bearing.

Shaft

Inner Race

Ball

Outer Race

C

BO

d

BO

d

BI

C

BI

Outer Race

Inner Race

Ball

S C

(a) (b) (c)

Fig. 2. A view of stator slot and capacitive coupling in an induction motor.

Stator (s)

Winding (w)

Rotor (r)

Stator

Stator

End

Winding

End

Winding

Motor

Frame

Ballbearing

Ballbearing

C

ww

C

ws

C

wr

C

ball

C

ball

C

wr

C

ww

C

rs

Rotor

Shaft

55 2009 IEEE

In a three phase power inverter, a

DC voltage is converted to three

phase voltages with 120 phase

shift. Fig.4.b shows three phase leg

voltages of an inverter with common

mode voltage.

The trend in increasing switch-

ing frequency improves the quality

of current waveforms in motor drive

systems but due to short switching

time, a high dv/dt is produced across

the motor terminal. The leakage

current is created by a high voltage

stress during switching time and ca-

pacitive coupling in an AC motor.

Fig.5 shows a simple equiva-

lent model of an induction motor

which contains main capacitances

between the windings, rotor and

the stator frame.

Analysis of an Electric

Motor at High Frequency

The stray capacitance between the

windings and the stator frame is the

most significant parasitic compo-

nent compared to the other stray

capacitances which generate signifi-

cant conducted emission noise. At

high frequency, an electric motor

can be modeled as distributed capac-

itors, inductors and resistors as

shown in Fig.6 and the maximum

frequency can be determined using

the standing waves equation. We consider one v section to

model the motor at high frequency as shown in Fig.6.b and

only the stray capacitance between the windings and the stator

has been considered. Each motor has different high frequency

parameters due to its structure, size and materials.

Calculation of C

ws

The first step is to measure the magnitude and the phase values

of the impedance in terms of frequency based on two different

connections of the windings.

The first measurement is based on Fig.7.a where three phas-

es are connected to each other at the terminal sides. Thus, the

impedance between the phases and the stator (phase and mag-

nitude values) can be measured in terms of the frequency using

an impedance analyzer.

Based on this configuration, the impedance of the stray ca-

pacitance, C

ws

, is much higher than the impedance of L

s

and

R

loss

at low frequencies and the model can be simplified as two

parallel stray capacitances.

Fig.8 shows measurement results of the impedance between

the phases and the stator frame of a 5.5 KW motor. According

to Fig.8, the phase value is around 90 at ,40 KHz which

addresses the fact that the two capacitors are connected to each

other in parallel. The stray capacitance of the electric motor has

been calculated using the magnitude and the phase values from

10 kHz up to 40 kHz and the result shows that C

ws

is almost

around 0.9 nF. The capacitance value is calculated based on the

measurement results and 0 Z

c

ws

0 51/vC

ws

.

Calculation of L

s

and R

loss

The second measurement is based on Fig.7.b where three

phases are connected to each other and the impedance between

the phases and star point is measured. Based on this configura-

tion, the impedance of the stray capacitance is much higher

than the impedance of L

s

and R

loss

(Fig.9.a) at low frequencies

Fig. 4. (a) three phase voltage source inverter (b) PWM voltage.

V

a

V

an

V

bn

V

cn

V

b

V

c

V

n

(a)

(b)

60

40

20

0

20

40

60

Fig. 5. A high frequency model of an induction motor.

C

ws

C

rs

C

wr

C

ball

Rotor

Stator Frame

Winding

56 2009 IEEE

and it can be simplified as an induc-

tive and a resistive load as shown in

Fig.9.b.

Fig.10 shows measurement re-

sults of the impedance between the

phases and the star point. The in-

ductance and resistance values can

be calculated using the measure-

ment results and based on the cir-

cuit diagram shown in Fig.9.b. The

inductance value is decreased from

5.77 mH down to 5.56 mH when

L

s

L

s

c

ws

c

ws

R

Loss

R

Loss

(a) (b)

Fig. 9. Circuit diagram for measurement between phases

and star point (a) a model of motor (b) simplified model for

low frequency range.

1

10

100

718

4.73

100

50

0

50

100

72.2

85.5

1 10

3

1 10

4

1 10

4

1 10

7

1 10

5

1 10

6

1 10

7

Z1

0

Z1

1

(a)

1 10

4

1 10

4

1 10

7

1 10

5

1 10

6

1 10

7

P1

0

(b)

P1

1

Fig. 10. Measurement results (a) magnitude and

(b) phase values between the phases-star point

of a 5.5 KW motor.

Fig. 6. (a) a distributed model of an electric motor at high frequency (b) a simple

model of an electric motor.

C

C C

R-L

stator

R-L

stator

R-L

stator

R

loss

L

s

Phase

C C C C

ws

C

ws

C C

1 2 n

n

(a) (b)

Fig. 7. Two different connections to measure the impedance between

(a) the phases and the stator (b) the phases and the star point.

Phase Phase

Stator

n n

(a) (b)

Fig. 8. Measurement results (a) magnitude and (b) phase

values between the phases and the stator of a 5.5 KW motor.

1

10

100

1 10

4

1 10

4

1 10

5

1 10

6

1 10

7

1 10

3

Z2

1

Z2

0

100

50

0

50

100

(a)

1 10

4

1 10

5

1 10

6

1 10

7

P2

0

(b)

P2

1

57 2009 IEEE

the frequency is increased from 10 kHz up to 40 kHz. At low

frequency (below 100 kHz), the input impedance of the wind-

ings (according to Fig.9.b) is Z

RL

5R

loss

3jvL

s

/jvL

s

1R

loss

.

The magnitude and phase values of this configuration, which

are used to extract the resistance and inductance values, are

given in Fig.10.

The simulations have been carried out based on the follow-

ing equations driven from the above figures:

Z

stator_winding

5

Z

C

ws

1 Z

RL

1Z

C

ws

2

2 3 Z

C

ws

1Z

RL

Z

winding_winding

5

Z

C

ws

2

1 Z

RL

2

Z

C

ws

2

1Z

RL

Where Z

RL

5R

loss

3

jvL

s

/jvL

s

1R

loss

and 0 Z

c

ws

0 51/vC

ws

There is a short cable from the motor terminals to

the impedance analyzer, which can be modeled as a R_L

in series with the motor as shown in Fig.11. The second

resonance frequency shown in Fig.10 is associated with

this inductance and the first stray capacitance, C

ws

. Thus

the inductance value of the cable can be calculated using

L

cable

51/ 1 2pf 2

2

C

ws

5378 nH. The resistance value of the

cable can be calculated at the second resonance frequency.

Based on this analysis, the parameters of the 5.5 kW motor

have been extracted as follow:

L

s

5 5.56 mH; C

ws

5 0.9 nF; R

loss

5 2215 V; L

cable

5 378 nH;

R

cable

5 3 V

The 5.5 kW motor is modeled based on this analysis and the

simulation and experimental results are shown in Fig.12. The

cable impedance is negligible at frequencies below 4-5 MHz

but it becomes significant above that frequency range.

Active EMI Filters

The use of Active EMI filters based on current injection is a

proper solution to cancel common mode high frequency cur-

rents. Fig.13 shows a block diagram of an active EMI filter

with a common mode transducer.

The filter composes of an emitter follower using complemen-

tary transistors and a common mode transformer to measure the

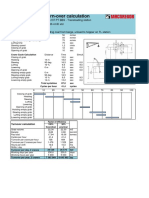

Fig. 12. Experimental and simulation results of a 5.5 kW motor; (a) magnitude (b) phase values between phases-stator

(c) magnitude (d) phase values between phases-star point.

1

10

100

1 10

4

100

78.3

91.1

50

0

0

50

100

100

79.087

85.5

50

50

100

1 10

3

1 10

4

1 10

4

3.1 10

3

2.79

1 10

7

1 10

5

1 10

6

1 10

7

Z_exp

0

,

f

(a)

1 10

4

1 10

4

1 10

7

1 10

5

1 10

6

1 10

7

Z_exp

0

,

f

(c)

1 10

4

1 10

4

1 10

7

1 10

5

1 10

6

1 10

7

Phase_exp

0

,

f

(b)

1 10

4

1 10

4

1 10

7

1 10

5

1 10

6

1 10

7

Phase_exp

0

,

f

(d)

Z_exp

1

Zsimul(f )

Z_exp

1

Zsimul(f )

1

10

100

1 10

3

741.102

3.378

Phase_exp

1

arg(Zsimul(f ))

180

Phase_exp

1

arg(Zsimul(f ))

180

Fig. 11. A high frequency model of a motor with a short cable.

R

cable

L

cable

L

s

n

R

loss

C

ws

C

ws

Stator

58 2009 IEEE

leakage current. A high frequency amplifier generates the same

current and injects it into the motor drive circuit in order to by-

pass the current as shown in Fig.13. In this case, the leakage cur-

rent generated by dv/dt is circulated through the active filter.

There are few issues to design an active EMI filter which

should be considered:

A high band width power amplifier to generate the leakage

current

A three-phase or a single-phase current transducer with sym-

metrical configuration to measure current accurately

A separate power supply for the active EMI filter.

Conclusions

A high frequency model of an electric motor has been analyzed

in this paper. One of the advantages of the high frequency

model of the electric motor is to estimate and analyze the leak-

age and bearing currents to design EMI filters using simula-

tions. This paper addresses a simple method to extract high

frequency parameters of an electric motor based on the mea-

surement results. It is recommended to estimate the behavior

of the motor in a frequency range, when the motor acts as a

capacitive or an inductive load according to the phase values of

the impedance. Then, the parameters can be calculated directly

from the magnitude and the phase values of the impedance.

In this paper several aspects of high frequency related issues

of modern AC motor drive systems, such as common mode

voltage, shaft voltage and resultant bearing current and leak-

age currents, have been discussed. Conducted and radiated

emissions are major problems in modern motor drives that pro-

duce undesirable effects on electronic devices. In modern pow-

er electronic systems, increasing power density and decreasing

cost and size of system are market requirements. Switching

losses, harmonics and EMI are the key factors which should

be considered at the beginning stage of a design to optimise

a drive system. In most power electronic designs, EMI issues

have not been taken into account as one of the main factors;

and mitigation techniques for EMI are considered at the last

stage of design!

References

[1] Firuz Zare, Power Electronics E-Book, www.peeeb.com; from this web-

site, you can virtually attend lectures and tutorials and also access to lecture

notes and computer Labs.

[2] Firuz Zare, High frequency model of an electric motor based on measure-

ment results, Australian Journal of Electrical & Electronics Engineering

(AJEEE), Vol 4, No 1, 2008, page 17-24.

Biography

Dr. Firuz Zare received his B.Eng degree in

Electronic Engineering from Gilan University,

his MSc degree in Power Engineering from K.N

Toosi University and his Ph.D. degree in Power

Electronics from Queensland University of Tech-

nology in 1989, 1995 and 2001, respectively.

He spent several years in industry as a team

leader and development engineer where he was

involved in electronics and power electronics projects. Dr. Zare won a

student paper prize at the Australian Universities Power Engineering

Conference (AUPEC) conference in 2001 and was awarded a Sym-

posium Fellowship by the Australian Academy of Technological Sci-

ence and Engineering in 2001. He received the Vice Chancellors

Award in research in 2009 and faculty excellence award in research

as an early career academic from Queensland University of Technol-

ogy in 2007. Dr. Zare has published over 60 journal and conference

papers and technical reports in the area of Power Electronics. He has

been invited as a reviewer and technical chair of national and inter-

national conferences and presented several seminars and workshops. He

presented a half-day tutorial at the 2007 IEEE International Sym-

posium on EMC in Hawaii, at the EMC Asia Pacific Workshop in

Singapore in May 2008 and at the 2008 IEEE International Sym-

posium on EMC in Michigan. Dr. Zare is a senior lecturer at the

Queensland University of Technology, Australia and a senior member

of the IEEE. EMC

Vs

Active

EMI Filter

Motor

I

leakage

Fig. 13. An active EMI filter.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Saudi Aramco Steam Turbine Training CourseDocument45 pagesSaudi Aramco Steam Turbine Training CourseDhananjay B K100% (2)

- Advances in Vehicle DesignDocument187 pagesAdvances in Vehicle Designsayed92% (13)

- Electricity and MagnetismDocument16 pagesElectricity and MagnetismHazel Riyenzi100% (1)

- Solution Manual Antenna Theory by Balanis Edition2 Chapter3Document6 pagesSolution Manual Antenna Theory by Balanis Edition2 Chapter3m_mahdiroodi100% (2)

- Zero CrossingDocument16 pagesZero CrossingAryan KapsNo ratings yet

- Testing Precommissioning & Commissioning of FCUsDocument7 pagesTesting Precommissioning & Commissioning of FCUsFinito TheEndNo ratings yet

- Astm E1827 - Blower DoorDocument12 pagesAstm E1827 - Blower DoormuhammadsuhaibNo ratings yet

- PHYSICAL SCIENCE MODULE 13-EditedDocument24 pagesPHYSICAL SCIENCE MODULE 13-EditedEricha Solomon88% (8)

- Item Emcdirectory-Design 2008Document262 pagesItem Emcdirectory-Design 2008naver01No ratings yet

- DMO 200 Data Sheet Rev0aDocument2 pagesDMO 200 Data Sheet Rev0anaver01No ratings yet

- The Transmission-Line Modeling (TLM) Method in ElectromagneticsDocument132 pagesThe Transmission-Line Modeling (TLM) Method in ElectromagneticsRafael CoelhoNo ratings yet

- Friction FactorDocument79 pagesFriction FactorahmedNo ratings yet

- Correl 2 Until MidtermsDocument23 pagesCorrel 2 Until MidtermsKimberly TacaisanNo ratings yet

- Turnover and Load Cycle - Transloading Station 2xK3030 + SULDocument1 pageTurnover and Load Cycle - Transloading Station 2xK3030 + SULafandybaharuddinNo ratings yet

- Multiple Choice Question (MCQ) - Mass Transfer - Multiple Choice Question (MCQ) For Chemical Engineering PDFDocument20 pagesMultiple Choice Question (MCQ) - Mass Transfer - Multiple Choice Question (MCQ) For Chemical Engineering PDFMuthu KumarNo ratings yet

- Oriental Motor RK SeriesDocument28 pagesOriental Motor RK SeriesShahrul IznanNo ratings yet

- Technical Details ENDocument8 pagesTechnical Details ENjaelNo ratings yet

- Chapter 6 ThermochemistryDocument6 pagesChapter 6 ThermochemistryKevin HuangNo ratings yet

- (Junoon-e-JEE) - (3.0) - Electrostatics (Part-2) - 29th September.Document140 pages(Junoon-e-JEE) - (3.0) - Electrostatics (Part-2) - 29th September.Siyasha Singh0% (1)

- Mikroommetras RMO200 enDocument4 pagesMikroommetras RMO200 enparu0509No ratings yet

- Venturimeter ExperimentDocument11 pagesVenturimeter ExperimentMuhammad Naveed 952-FET/BSME/F20No ratings yet

- Bare Aluminium Conductors, ACSR and ABC Cables: Cables (M) Sdn. BHDDocument24 pagesBare Aluminium Conductors, ACSR and ABC Cables: Cables (M) Sdn. BHDgosalhs9395No ratings yet

- Chapter 4,5,6 and 7Document10 pagesChapter 4,5,6 and 7Pixel AragamiNo ratings yet

- Displacer LT CalibrationDocument11 pagesDisplacer LT CalibrationChristianNo ratings yet

- PHYF111 MIDSem QuestPaperDocument3 pagesPHYF111 MIDSem QuestPaperf20231045No ratings yet

- Chemical Engineering & Processing: Process Intensi Fication: ArticleinfoDocument12 pagesChemical Engineering & Processing: Process Intensi Fication: ArticleinfoRohan PrajapatiNo ratings yet

- Dmr's Physics Notes - Oersted's ExperimentDocument4 pagesDmr's Physics Notes - Oersted's ExperimentyashNo ratings yet

- Torque Follower Setup Rev 1Document7 pagesTorque Follower Setup Rev 1NelsonNo ratings yet

- XS1250-ND Data SheetDocument3 pagesXS1250-ND Data SheetMamadou djibril BaNo ratings yet

- NEE+311-intro+part+2Document18 pagesNEE+311-intro+part+2Arrianna AngelesNo ratings yet

- Harbor Freight 14 Function Professional Digital Multimeter With Sound Level and Luminosity Product Manual 723998Document27 pagesHarbor Freight 14 Function Professional Digital Multimeter With Sound Level and Luminosity Product Manual 723998Hayato IkedaNo ratings yet

- Class XI Physics DPP Set (22) - Previous Chaps - Rotational Motionb.Document13 pagesClass XI Physics DPP Set (22) - Previous Chaps - Rotational Motionb.Ashish RanjanNo ratings yet

- Section 6: Magnetostatics: Magnetic Fields in MatterDocument11 pagesSection 6: Magnetostatics: Magnetic Fields in MatterrizwanNo ratings yet

- Punjab College of Excellence Seet Pur: Question No# 1 Attempt Any 5 Short QuestionsDocument2 pagesPunjab College of Excellence Seet Pur: Question No# 1 Attempt Any 5 Short Questionsmehdi.mehdi15121472No ratings yet

- Induction Motor (Asynchronous Motor) : Electrical MachinesDocument41 pagesInduction Motor (Asynchronous Motor) : Electrical MachinesNAITIKNo ratings yet