Professional Documents

Culture Documents

Ec2 5 3 2 1

Uploaded by

khairulhakam0 ratings0% found this document useful (0 votes)

21 views2 pagesec2

Original Title

EC2 5 3 2 1

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentec2

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views2 pagesEc2 5 3 2 1

Uploaded by

khairulhakamec2

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

BS EN 1992-1-1:2004

EN 1992-1-1:2004 (E)

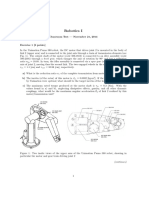

5.3.2 Geometric data

5.3.2.1 Effective width of flanges (all limit states)

(1)P In T beams the effective flange width, over which uniform conditions of stress can be

assumed, depends on the web and flange dimensions, the type of loading, the span, the

support conditions and the transverse reinforcement.

(2) The effective width of flange should be based on the distance l

between points of !ero

moment, which may be obtained from "igure #.2.

57

BS EN 1992-1-1:2004

EN 1992-1-1:2004 (E)

Note: The length of the cantilever, l$, should be less than half the ad%acent span and the ratio of ad%acent

spans should lie between 2&$ and 1,#.

($) The effective flange width b

eff

for a T beam or ' beam may be derived as(

b b b b

w

i ,

eff eff

+ =

(#.))

where

o o i i , eff

l 2 , 0 l 1 , 0 b 2 , 0 b + =

(#.)a)

and

i i , eff

b b

(#.)b)

(for the notations see "igure #.2 above and #.$ below).

(*) "or structural analysis, where a great accuracy is not re+uired, a constant width may be

assumed over the whole span. The value applicable to the span section should be adopted.

5.3.2.2 Effective span of eams and slas in !ildings

Note: The following provisions are provided mainly for member analysis. "or frame analysis some of these

simplifications may be used where appropriate.

(1) The effective span, leff, of a member should be calculated as follow(

2 1 n eff

a a l l + + =

(#.,)

where(

l

n

is the clear distance between the faces of the supports-

values for a

1

and a

2

, at each end of the span, may be determined from the appropriate a

i

values in "igure #.* where t is the width of the supporting element as shown.

5"

#ig!re 5.2 $efinition of l

%

& for calc!lation of effective flange width.

l

1

l

2

l

3

l

0

= 0,8l

1

l

0

=

0,15(l

1

+ l

2

) l

o

. 0,7l

2

l

o

= 0,15l

2

+ l

3

#ig!re 5.3 Effective flange width parameters

b

1

b

1

b

2

b

2

b

1

b

1

b

eff 1

b

eff 2

b

w

b

eff

b

w

b

You might also like

- EuroDocument4 pagesEuroxiangyong duanmuNo ratings yet

- MATH Reinforced Concrete Design 02Document14 pagesMATH Reinforced Concrete Design 02Ellen Bumal-oNo ratings yet

- 3.1 Width CalculationDocument7 pages3.1 Width CalculationSarath TejaNo ratings yet

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- AISC LRFD Column DesignDocument4 pagesAISC LRFD Column Designwinlugue3059No ratings yet

- Article: Stepped Hss T-And Cross - Connections Under Branch In-Plane and Out - Of-Plane BendingDocument5 pagesArticle: Stepped Hss T-And Cross - Connections Under Branch In-Plane and Out - Of-Plane Bendinggv Sathishkumar KumarNo ratings yet

- CE371A Quiz8Document2 pagesCE371A Quiz8Pravesh KumarNo ratings yet

- Flange Lateral Bending Stress Under Wind PressureDocument44 pagesFlange Lateral Bending Stress Under Wind Pressuremgonelli14No ratings yet

- 8.3.5 Moment Resistance To Lateral-Torsional Buckling: 8.3.5.1 Limiting SlendernessDocument1 page8.3.5 Moment Resistance To Lateral-Torsional Buckling: 8.3.5.1 Limiting SlendernessAlex LoNo ratings yet

- Introductory InformationDocument7 pagesIntroductory InformationSarath TejaNo ratings yet

- Handout CE523 Lecture Week 3 Tension MembersDocument45 pagesHandout CE523 Lecture Week 3 Tension MembersehabNo ratings yet

- Optimal Mapped Mesh On The Circle: Doc. Ing. Jaroslav Štigler, PH.DDocument8 pagesOptimal Mapped Mesh On The Circle: Doc. Ing. Jaroslav Štigler, PH.Dpablo_escobar27475No ratings yet

- Lecture 8Document18 pagesLecture 8Cyrus HongNo ratings yet

- Application Design of Thin Aerofofl Theory of Double Flap Controls Small ChordDocument10 pagesApplication Design of Thin Aerofofl Theory of Double Flap Controls Small ChordkarthipriyaNo ratings yet

- 4.2 Effective Lengths and Critical Loads: CHAPTER 4: Reinforced Concrete ColumnsDocument19 pages4.2 Effective Lengths and Critical Loads: CHAPTER 4: Reinforced Concrete ColumnsNacho ValenteNo ratings yet

- Bandwidth Minimization Algorithm For Finite Element MeshDocument13 pagesBandwidth Minimization Algorithm For Finite Element MeshSyed MustafaNo ratings yet

- CorreDocument6 pagesCorregeo84No ratings yet

- IJRAR19J5837Document6 pagesIJRAR19J5837sreelakshmi.ece eceNo ratings yet

- Crack Width Example Problem SolvedDocument8 pagesCrack Width Example Problem SolvedSuhail Ahamed100% (1)

- Geometric Dimensioning and TolerancingDocument105 pagesGeometric Dimensioning and TolerancingMohammad UmairNo ratings yet

- Fardis - USJ Hakone FinalDocument13 pagesFardis - USJ Hakone FinalductilityNo ratings yet

- Emz310 Prac2 09Document5 pagesEmz310 Prac2 09crazybilalNo ratings yet

- Robotics I: Jt2 Motor 506-1612Document8 pagesRobotics I: Jt2 Motor 506-1612asalifew belachewNo ratings yet

- Apmc 2000 926072Document4 pagesApmc 2000 926072Mylavarapu SriprithamNo ratings yet

- The Strength of Struts: A C K eDocument21 pagesThe Strength of Struts: A C K eLênon Guimarães Silva AlípioNo ratings yet

- Calc Bend Radii Tensile Elong DataDocument7 pagesCalc Bend Radii Tensile Elong Dataritesh_4luv7679No ratings yet

- Aperture Antenna DéignDocument4 pagesAperture Antenna DéignCuongNo ratings yet

- Naca Tech - Criticalstressof PlatecolumnsDocument17 pagesNaca Tech - Criticalstressof PlatecolumnsPedro GalvaniNo ratings yet

- LRFD Aashto 4-22-39Document18 pagesLRFD Aashto 4-22-39Eduardo SilvaNo ratings yet

- Pulse-Forming Networks: in Order To Circumvent These Disadvantages, Lumped Constant NetworksDocument18 pagesPulse-Forming Networks: in Order To Circumvent These Disadvantages, Lumped Constant NetworksМилица МијатовићNo ratings yet

- Introduction To Phased Array Ultrasonic Technology Applications 106-110Document5 pagesIntroduction To Phased Array Ultrasonic Technology Applications 106-110Kevin HuangNo ratings yet

- Slab Deflection and DepthDocument10 pagesSlab Deflection and Depthsyed AffanNo ratings yet

- Chapter D Design of Members For Tension: D.3 Area Determination D.3.1 Net Area D.1 General ProvisionsDocument1 pageChapter D Design of Members For Tension: D.3 Area Determination D.3.1 Net Area D.1 General ProvisionsAbdullah NajjarNo ratings yet

- Bolted End Plate Connection Design ExampleDocument20 pagesBolted End Plate Connection Design ExampleJames CENo ratings yet

- Design of Ridged Waveguides by Hofer PDFDocument10 pagesDesign of Ridged Waveguides by Hofer PDFవేలుసామి లింగాసామిNo ratings yet

- Discrete and Microstrip Coupler Design: ObjectiveDocument10 pagesDiscrete and Microstrip Coupler Design: Objectivep.mallikarjunaNo ratings yet

- Tbeam PhilosophySDocument4 pagesTbeam PhilosophySWhitney MannNo ratings yet

- Iso ASME Surface AnalysisDocument8 pagesIso ASME Surface AnalysisnilavanmuthuNo ratings yet

- Chapter 2Document24 pagesChapter 2joshuajoseph3No ratings yet

- Birla Institute of Technology and Science, Pilani Hyderabad CampusDocument2 pagesBirla Institute of Technology and Science, Pilani Hyderabad Campusmanish mehtaNo ratings yet

- Corrugadas GranetDocument9 pagesCorrugadas GranetKevs SsmNo ratings yet

- 3.4 Linear Arrays: 3.4.1 Active ApertureDocument5 pages3.4 Linear Arrays: 3.4.1 Active ApertureKevin HuangNo ratings yet

- IGJ - 17 - 03 - 249-258 Ramasamy Gopal Ranjan Modifications To The IS Method For Lateral Capacity of PileDocument10 pagesIGJ - 17 - 03 - 249-258 Ramasamy Gopal Ranjan Modifications To The IS Method For Lateral Capacity of Pileu19n6735No ratings yet

- Article9 Annular BottomDocument3 pagesArticle9 Annular Bottommohamed abd eldayemNo ratings yet

- 1-1.design Criterion of The Dual-Bell Nozzle Contour PDFDocument6 pages1-1.design Criterion of The Dual-Bell Nozzle Contour PDFSandeep AjaykumarNo ratings yet

- 2Document15 pages2rakesh biswasNo ratings yet

- SN017 (NCCI - Shear Resistance of A Fin Plate Connection)Document13 pagesSN017 (NCCI - Shear Resistance of A Fin Plate Connection)Hamati Rami100% (2)

- Practical Advanced Analysis ForDocument16 pagesPractical Advanced Analysis ForAndre YPNo ratings yet

- Syntesgripen EnglishDocument18 pagesSyntesgripen EnglishcristianNo ratings yet

- Al+ - :::F::L: BS EN 1992-1-1:2004 EN 1992-1-1:2004 (E)Document4 pagesAl+ - :::F::L: BS EN 1992-1-1:2004 EN 1992-1-1:2004 (E)alexNo ratings yet

- Parametric Study of Flexibility Factor For Curved Pipe and Welding ElbowsDocument9 pagesParametric Study of Flexibility Factor For Curved Pipe and Welding Elbowsbam_1962No ratings yet

- © Association For Scientific Research: Mathematical and Computational Applications, Vol. 16, No. 1, Pp. 77-86, 2011Document10 pages© Association For Scientific Research: Mathematical and Computational Applications, Vol. 16, No. 1, Pp. 77-86, 2011Marcos Delgado LópezNo ratings yet

- A Rapid Solution of Vierendeel Frames: D' Fid D I)Document3 pagesA Rapid Solution of Vierendeel Frames: D' Fid D I)Steven SebastianNo ratings yet

- A CPW-fed Inductively Modified Bow-Tie Slot Antenna: CoupledDocument4 pagesA CPW-fed Inductively Modified Bow-Tie Slot Antenna: CoupledPhí Mạnh ToànNo ratings yet

- Design in Timber To Ms 544 Part2: Week 5Document40 pagesDesign in Timber To Ms 544 Part2: Week 5Muhd FaridNo ratings yet

- 2.simply Supported Beam - IC 2 (Exp-2)Document8 pages2.simply Supported Beam - IC 2 (Exp-2)Nikhil KautilyaNo ratings yet

- Radio Frequency Identification and Sensors: From RFID to Chipless RFIDFrom EverandRadio Frequency Identification and Sensors: From RFID to Chipless RFIDNo ratings yet

- Lighting Fittings Performance and Design: International Series of Monographs in Electrical EngineeringFrom EverandLighting Fittings Performance and Design: International Series of Monographs in Electrical EngineeringNo ratings yet

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- Universiti Malaysia Perlis Teaching Plan: Pusat Pengajian/Pusat/ Institut: Fakulti Teknologi KejuruteraanDocument3 pagesUniversiti Malaysia Perlis Teaching Plan: Pusat Pengajian/Pusat/ Institut: Fakulti Teknologi KejuruteraankhairulhakamNo ratings yet

- Soil MechanicsDocument2 pagesSoil MechanicskhairulhakamNo ratings yet

- Soils QuestionDocument3 pagesSoils QuestionkhairulhakamNo ratings yet

- Soil MechanicsDocument2 pagesSoil MechanicskhairulhakamNo ratings yet

- ConclusionDocument5 pagesConclusionkhairulhakam50% (2)

- Water DistributionDocument5 pagesWater DistributionkhairulhakamNo ratings yet

- DiscussionDocument2 pagesDiscussionkhairulhakamNo ratings yet

- Construction Material Wast1Document7 pagesConstruction Material Wast1khairulhakamNo ratings yet

- BS1881 110 Method For Making Test Cylinders From Fresh ConcreteDocument12 pagesBS1881 110 Method For Making Test Cylinders From Fresh ConcretekhairulhakamNo ratings yet

- Relative HumidityDocument6 pagesRelative HumiditykhairulhakamNo ratings yet

- Soil MechanicsDocument2 pagesSoil MechanicskhairulhakamNo ratings yet

- Chapter 2Document15 pagesChapter 2khairulhakamNo ratings yet

- BS 1881 116 1983 Testing Concrete. Method For Determination of Compressive Strength of Concrete CubesDocument10 pagesBS 1881 116 1983 Testing Concrete. Method For Determination of Compressive Strength of Concrete Cubeskhairulhakam100% (1)

- Appendix 4 Industrial Training Final ReportDocument3 pagesAppendix 4 Industrial Training Final ReportkhairulhakamNo ratings yet

- Borang Penilaian Pembentangan LIDocument1 pageBorang Penilaian Pembentangan LIzalNo ratings yet

- CCFT Studentactivities TrafficengineeringDocument9 pagesCCFT Studentactivities TrafficengineeringkhairulhakamNo ratings yet

- Method of JoinDocument45 pagesMethod of JoinkhairulhakamNo ratings yet

- DemolitionDocument7 pagesDemolitionkhairulhakamNo ratings yet

- 5 Planning 1 PDFDocument6 pages5 Planning 1 PDFChanaka PereraNo ratings yet

- Demolition Techniques - Case StudyDocument18 pagesDemolition Techniques - Case Studybasanth_71298296% (23)

- DefinitionsDocument9 pagesDefinitionskhairulhakamNo ratings yet

- Application For Machinist or Foundry Technician With SchlumbergerDocument1 pageApplication For Machinist or Foundry Technician With SchlumbergerkhairulhakamNo ratings yet

- B B + B B For Monolithic Cast Beam-Slab. Orb L Is The Distance Between Points of Zero MomentsDocument3 pagesB B + B B For Monolithic Cast Beam-Slab. Orb L Is The Distance Between Points of Zero MomentskhairulhakamNo ratings yet

- E3 Mini Research RubricDocument2 pagesE3 Mini Research RubrickhairulhakamNo ratings yet

- CCFT Studentactivities TrafficengineeringDocument9 pagesCCFT Studentactivities TrafficengineeringkhairulhakamNo ratings yet

- 351 01Document11 pages351 01smithams90No ratings yet

- CHAPTER 2-Water PollutionDocument18 pagesCHAPTER 2-Water PollutionkhairulhakamNo ratings yet

- CC605 Dka5c S1Document1 pageCC605 Dka5c S1khairulhakamNo ratings yet

- Rms Cc605 (Ec2) June 2k14Document8 pagesRms Cc605 (Ec2) June 2k14khairulhakamNo ratings yet

- B B + B B For Monolithic Cast Beam-Slab. Orb L Is The Distance Between Points of Zero MomentsDocument3 pagesB B + B B For Monolithic Cast Beam-Slab. Orb L Is The Distance Between Points of Zero MomentskhairulhakamNo ratings yet