Professional Documents

Culture Documents

2856 - OMB Orientation To Valves - Part 4

2856 - OMB Orientation To Valves - Part 4

Uploaded by

roscillaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2856 - OMB Orientation To Valves - Part 4

2856 - OMB Orientation To Valves - Part 4

Uploaded by

roscillaCopyright:

Available Formats

Introduction to

Valve Technology

Presented by

prepared by Simone Brevi

rev 0 April 2006

s.brevi@ombvalves.com

OMB valves s.p.a. - 2006

Part 4 Standards

Presented by

Design

Standard

Standards & Codes

The valve business has been regulated by a number of

standards issued primary by national bodies, with a

prevalence of American institutions (API, NACE,

ANSI, ASME).

In the past few years ISO is incorporating all international

standards into a uniform body of rules.

The ISO denomination is still not used widely.

In the following page we identify traditionally used standards

even if already superseded by an ISO standard.

A red code indicate a superseded standard

OMB Valves : Intrudction to Valves - Standard

Design

Standard

Standards & Codes

ISO International Standardization Organization

API American Petroleum Institute

ASTM American Society for Testing and Material

ASME American Society of Mechanical Engineers

ANSI American National Standard Institute

MSS Manufacturers Standardization Society of the Valve

and Fitting Industry

NACE National Association of Corrosion Engineers

BS British Standards Institute

OMB Valves : Intrudction to Valves - Standard

Design

Standard

ISO International Standard Org. www.iso.org

ISO 5208:1993 Industrial valves -- Pressure testing of valves

ISO 5209:1977 General purpose industrial valves -- Marking

ISO 5752:1982 Metal valves for use in flanged pipe systems

Face-to-face and centre-to-face dimensions

ISO 5996:1984 Cast iron gate valves

ISO 6002:1992 Bolted bonnet steel gate valves

ISO 12149:1999 Bolted bonnet steel globe valves for general-purpose applications

ISO 7121:1986 Flanged steel ball valves

ISO 7259:1988 Predominantly key-operated cast iron gate valves for underground use

ISO 10434:2004 Bolted bonnet steel gate valves for the petroleum, petrochemical and

allied industries

ISO 10497:2004 Testing of valves -- Fire type-testing requirements

ISO 10631:1994 Metallic butterfly valves for general purposes

ISO 12149:1999 Bolted bonnet steel globe valves for general-purpose applications

ISO 15761:2002 Steel gate, globe and check valves for sizes DN 100 and smaller,

for the petroleum and natural gas industries

ISO 15848-1:2006 Industrial valves - Measurement, test and qualification procedures

for fugitive emission

Part 1: Classification system and qualification procedures

for type testing of valves

ISO 17292:2004 Metal ball valves for petroleum, petrochemical and allied industries

Design

Standard

ISO International Standard Org.

ISO 10423:2003

Petroleum and natural gas industries - Drilling and production equipment -

Wellhead and christmas tree equipment

specifies requirements and gives recommendations for the performance,

dimensional and functional interchangeability, design, materials, testing,

inspection, welding, marking, handling, storing, shipment, purchasing,

repair and remanufacture of wellhead and christmas tree equipment for

use in the petroleum and natural gas industries.

eq. API 6A

www.iso.org

Design

Standard

ISO International Standard Org.

ISO 14313:1999

Petroleum and natural gas industries -- Pipeline transportation systems --

Pipeline valves

eq. API 6D

www.iso.org

Design

Standard

ISO International Standard Org.

ISO 15156

NACE MR0175, Petroleum and natural gas industriesMaterials for

use in H2S-containing environments in oil and gas production

Includes new addenda for 2005! NACE MR0175/ISO 15156 gives requirements and recommendations for the

selection and qualification of carbon and low-alloy steels, corrosion-resistant alloys, and other alloys for service

in equipment used in oil and natural gas production and natural gas treatment plants in H2S-containing

environments, whose failure could pose a risk to the health and safety of the public and personnel or to the

environment. It can be applied to help to avoid costly corrosion damage to the equipment itself. NACE

MR0175/ISO 15156 consists of three standards and four technical corrigenda (addenda), available through

NACE as a complete package: Part 1: General principles for selection of cracking-resistant materials Part 2:

Cracking-resistant carbon and low alloy steels, and the use of cast irons Part 3: Cracking-resistant CRAs

(corrosion-resistant alloys) and other alloys Part 1, Technical Corrigendum1 Part 2, Technical Corrigendum 1

Part 3, Technical Corrigendum 1 Part 3, Technical Corrigendum 2 Key words: aluminumalloys, austenitic

stainless steels, bolts, carbon steels, cast iron, ceramic coatings, cobalt alloys, cold working, copper alloys,

fabrication, ferritic stainless steels, free-machining steels, hardness, hydrogen sulfide, identification marking,

low-alloy steels, martensitic stainless steels, metals, oilfield production equipment, overlays, precipitation-

hardening steels, pressure gauges, protective coatings, sealing rings, shot peening, sour environments, springs,

stainless steels, sulfide stress cracking, valves, welding.

www.iso.org

Design

Standard

API - American Petroleum Institute

API 6D Specification for Pipeline Valves

API 6A Specification for Wellhead and Christmas Tree Equipment

API 6FA Specification for Fire Test for Valves

API 591 User Acceptance of Refinery Valves

API 598 Valve Inspection and Testing

API 600 Steel Gate Valves

API 602 Compact Carbon Steel Gate Valves

API 603 Cast, Corrosion Resistant Gate Valves

API 17D Specification for Subsea Wellhead and Christmas Tree

Equipment

www.api.org

Design

Standard

API - American Petroleum Institute

Spec 6A

Specification for Wellhead and Christmas Tree Equipment

(includes Errata dated September 2004)

Specifies requirements and gives recommendations for the performance,

dimensional and functional interchangeability, design, materials,

testing, inspection, welding, marking, handling, storing, shipment

and purchasing, of wellhead and christmas tree equipment for use in

the petroleum and natural gas industries.

This edition of API Spec 6A is the modified national adoption of ISO

10423:2003. An informative annex is included covering the requirements

of the API Monogram Program for equipment covered in the

specification.

19th Edition / J uly 2004 / Effective Date: February 2005

www.api.org

Design

Standard

API - American Petroleum Institute

Spec 6A718

Specification of Nickel Base Alloy 718 (UNS N07718) for Oil and Gas

Drilling and Production Equipment

Provides specification requirements for Nickel Base Alloy 718 (UNS

N07718) that are intended to supplement the existing requirements of

API Spec 6A and ISO 10423. These additional specification requirements

include detailed process control requirements and detailed testing

requirements. Pages: 17

1st Edition / March 2004 / Product Number: G6A7181

www.api.org

Design

Standard

API - American Petroleum Institute

Spec 6D / ISO 14313

Specification for Pipeline Valves

Petroleum and Natural Gas IndustriesPipeline Transportation

SystemsPipeline Valves

API Specification 6D is the (proposed) national adoption of ISO 14313:

1999 MOD. This Standard specifies requirements and gives

recommendations for the design, manufacturing, testing and

documentation of ball, check, gate and plug valves for application in

pipeline systems.

Valves for pressure ratings exceeding PN 420 (Class 2500) are not covered

by this Standard. Annex A of this Spec 6D provides guidelines to

assist the purchaser with valve type selection and specification of specific

requirements when ordering valves. Annex E provides information on

API Monogram Licensing requirements. Annex F includes the technical

modifications and editorial changes.

22nd Edition / J anuary 2002 / Effective Date: J uly 1, 2002

www.api.org

Design

Standard

API - American Petroleum Institute

Spec 6FA

Fire Test for Valves

Covers the requirements for testing and evaluating the performance of

API Spec 6A and Spec 6D valves when exposed to specifically defined

fire conditions.

3rd Edition / April 1999 /

www.api.org

Design

Standard

API - American Petroleum Institute

RP 591

Process Valve Qualification Procedure

Provides recommendations for evaluation of a manufacturers valve

construction and quality assurance program for the purpose of

determining

a manufacturers capability to provide new valves manufactured

in accordance with the applicable API standards listed in Section 2.

Qualification of valves under this recommended practice is manufacturing

facility specific and does not cover valves manufactured by

other manufacturing facilities, whether owned by the same manufacturer

or a third party. Pages: 9

3rd Edition / September 2003

www.api.org

Design

Standard

API - American Petroleum Institute

Std 598

Valve Inspection and Testing

Covers inspection, examination, supplementary examinations, and

pressure test requirements for resilient-seated, nonmetallic-seated (for

example, ceramic), and metal-to-metal-seated valves of the gate, globe,

plug, ball, check, and butterfly types.

API Std 598 supplements the API standards that reference it, but it may

also be applied to other types of valves by agreement between the

purchaser

and the valve manufacturer.

8th Edition / May 2004

www.api.org

Design

Standard

API - American Petroleum Institute

API 600/ ISO 10434

Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas

IndustriesModified National Adoption

(ANSI/API Std 600-2001)

ANSI/API Standard 600 specifies the requirements for a heavy duty

series of bolted bonnet steel gate valves for petroleum refinery and

related applications where corrosion, erosion and other service conditions

indicate a need for full port openings, heavy wall sections and

extra large stem diameters.

11th Edition / October 2001

www.api.org

Design

Standard

API - American Petroleum Institute

Std 602/ ISO 15761

Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for

the Petroleum and Natural Gas Industries

Covers threaded-end, socket-welding-end, butt-welding-end, and

flanged-end compact carbon steel gate valves in sizes NPS 4 and

smaller.

8th Edition / J anuary 2005

www.api.org

Design

Standard

API - American Petroleum Institute

Std 607/ ISO 10497

Fire Test for Soft-Seated Quarter-Turn Valves

Specifies fire type-testing requirements and a fire type-test method for

confirming the pressure-containing capability of a valve under pressure

during and after the fire test. It does not cover the testing

requirements for valve actuators other than manually operated gear

boxes or similar mechanisms when these form part of the normal

valve assembly. Other types of valve actuators (e.g. electrical, pneumatic

or hydraulic) may need special protection to operate in the

environment considered in this valve test, and the fire testing of such

actuators is outside the scope of this Standard. Pages: 16

5th Edition / J une 2005

www.api.org

Design

Standard

API - American Petroleum Institute

Std 608

Metal Ball ValvesFlanged, Threaded and Butt-Welding Ends

Covers metal ball valves used in on-off service that have butt-welding of

flanged ends for nominal pipe size NPS 1/2 through NPS 12 and

threaded or socket-welding ends for sizes NPS 1/2 through NPS 2,

corresponding

to the nominal pipe sizes in ASME B36.10M. Also covers additional

requirements for ball valves that are otherwise in full

conformance to the requirements of ASME B16.34, Standard Class.

Pages: 6

3rd Edition / August 2002

www.api.org

Design

Standard

API - American Petroleum Institute

Std 622

Type Testing of Process Valve Packing for Fugitive Emissions

This API Standard specifies the requirements for comparative testing of

block valve stem packing for process applications where fugitive emissions

are a consideration. Packing(s) shall be suitable for use at 20

degrees F. to 1000 degrees F. (29 degrees C. to 538 degrees C). Factors

affecting fugitive emissions performance that are considered by

this Standard include temperature, pressure, thermal cycling and

mechanical cycling.

1st Edition / to be published Q1, 2006

www.api.org

Design

Standard

ASME American Society of Mech. Eng.

Section II Materials

Section III Rules for Construction of Nuclear Power Plant

Components

Section V Non-destructive Examination

Section VIII Rules for Construction of Pressure Vessels

Section IX Welding and Brazing Qualifications

Section XI Rules for In-service Inspection of Nuclear Power Plant

Components

Boiler and Pressure Vessel Code

Design

Standard

ANSI American Natl Standards Ins.

B16.34 Valves 2 Flanged, Threaded, and Buttwelded End

B16.10 Face-to-Face and End-to-End Dimensions of Valves

B16.5 Pipe Flanges and Flanged Fittings

B16.25 Buttwelded Ends

B16.11 Forged Fittings, Socket Welding and Threaded

ASME ANSI

www.ansi.org

Design

Standard

BSI British Standards Institution

BS 1414 Steel Wedge Gate Valves

BS 1868 Steel Check Valves

BS 1873 Steel Globe Valves

BS 5351 Steel Ball Valves

BS 5352 Steel Wedge Gate, Globe, Check Valves, 50mm

and Smaller

BS 6364 Valves for Cryogenic Service

BS 6755 Testing of Valves

ISO15761

Design

Standard

MSS Manufacturers Standardization

Society of the Valve and Fitting Industry

MSS SP-6 Contact Faces of Pipe Flanges

MSS SP-25 Standard Marking System for Valves, Fittings, Flanges

MSS SP-55 Quality Standard for Steel Castings (visual method)

MSS SP-61 Pressure Testing of Steel Valves

MSS SP-72 Ball Valves with Flanged or BW Ends for General Service

MSS SP-117 Bellows Seals for Globe and Gate Valves

Design

Standard

MSS Manufacturers Standardization

Society of the Valve and Fitting Industry

MSS SP-6

Standard finishes for contact faces of pipe flanges of valves and fittings

MSS SP-9

Spot facing for bronze , iron and steel flanges

MSS SP-25

Standard marking system for valves, fittings, flanges and unions

MSS SP-42

Class 150 corrosion resistant gate, globe, angle and check valves with flanged and butt

weld ends

MSS SP-54

Quality standard for steel castings - radiographic inspection method for valves , flange,

fittings and other piping components

MSS SP-55

Quality standard for steel castings for valves, flanges and fittings and other piping

components

MSS SP-60

Connecting flange joint between tapping sleeves and tapping valves

Design

Standard

MSS Manufacturers Standardization

Society of the Valve and Fitting Industry

MSS SP-61

Hydrostatic testing of steel valves

MSS SP-67

Butterfly valves

MSS SP-70

Cast iron gate valves , flanged and threaded ends

MSS SP-71

Cast iron swing check valves, flanged and threaded ends

MSS SP-72

Ball valves with flanged or butt - welding ends for general service

MSS SP-78

Cast iron plug valves

MSS SP-80

Bronze Gate, globe angle and check valves

MSS SP-82

Valves pressure testing methods

MSS SP-84

Steel valves socket welding and threaded ends

MSS SP-86

Metric data in standards for valves, flanges and fittings

Design

Standard

NACE National Association of Corrosion

Engineers

MR0175 Petroleum and natural gas industriesMaterials for

use in H2S-containing environments in oil and gas

production

Includes new addenda for 2005! NACE MR0175/ISO 15156 gives requirements and recommendations for the selection and

qualification of carbon and low-alloy steels, corrosion-resistant alloys, and other alloys for service in equipment used in oil and

natural gas production and natural gas treatment plants in H2S-containing environments, whose failure could pose a risk to the

health and safety of the public and personnel or to the environment. It can be applied to help to avoid costly corrosion damage

to the equipment itself. NACE MR0175/ISO 15156 consists of three standards and four technical corrigenda (addenda),

available through NACE as a complete package: Part 1: General principles for selection of cracking-resistant materials Part 2:

Cracking-resistant carbon and low alloy steels, and the use of cast irons Part 3: Cracking-resistant CRAs (corrosion-resistant

alloys) and other alloys Part 1, Technical Corrigendum 1 Part 2, Technical Corrigendum 1 Part 3, Technical Corrigendum 1 Part

3, Technical Corrigendum 2 Key words: aluminumalloys, austenitic stainless steels, bolts, carbon steels, cast iron, ceramic

coatings, cobalt alloys, cold working, copper alloys, fabrication, ferritic stainless steels, free-machining steels, hardness,

hydrogen sulfide, identification marking, low-alloy steels, martensitic stainless steels, metals, oilfield production equipment,

overlays, precipitation-hardening steels, pressure gauges, protective coatings, sealing rings, shot peening, sour environments,

springs, stainless steels, sulfide stress cracking, valves, welding.

MR0103 MR0103-2005 Materials Resistant to Sulfide Stress

Cracking in Corrosive Petroleum Refining

Environments

Revised in 2005. Defines material requirements for resistance to sulfide stress cracking (SSC) in sour refinery process

environments (i.e., environments that contain wet hydrogen sulfide [H2S]). The term "wet H2S cracking" as used in the

refining industry covers a range of damage mechanisms that can occur due to the effects of hydrogen charging in wet H2S

refinery or gas plant process environments. One of the types of material damage that can occur as a result of hydrogen

charging is sulfide stress cracking (SSC) of hard weldments and microstructures, which is addressed by this standard. This

standard is intented to be utilized by refineries, equipment manufacturers, engineering contractors, and construction

contractors. Key words: aluminumalloys, austentic stainless steels, carbon steels, cast iron, ceramic coatings, cobalt alloys,

copper alloys, ferritic stainless steels, free-machining steels, hydrogen sulfide, low-alloy steels, martensitic stainless steels,

metals, nickel alloys, oilfield production equipment, precipitation-hardening steels, sour environments, stainless steels, sulfide

stress cracking.

www.nace.org

ISO 15156

You might also like

- Bearing Design in MachineryDocument640 pagesBearing Design in MachineryDavid Amachree100% (1)

- Class 7 Imo 4 Years Sample Paper & ANSWERSDocument9 pagesClass 7 Imo 4 Years Sample Paper & ANSWERSvmktpt43% (7)

- ABCO - Hammer UnionsDocument2 pagesABCO - Hammer UnionsOman Baptist ChurchNo ratings yet

- IEC Motor StandardsDocument9 pagesIEC Motor Standardssubramanyanvenkat6185100% (1)

- Seal Self Study Guide PDFDocument114 pagesSeal Self Study Guide PDFhalder_kalyan9216No ratings yet

- RCA - Mechanical Component Failure Analysis - Part 1Document73 pagesRCA - Mechanical Component Failure Analysis - Part 1sgupta_615796No ratings yet

- RCA - Mechanical Component Failure Analysis - Part 1Document73 pagesRCA - Mechanical Component Failure Analysis - Part 1sgupta_615796No ratings yet

- American and British and Indian Codes and Standards: Benadict Subhash 7/8/2019Document10 pagesAmerican and British and Indian Codes and Standards: Benadict Subhash 7/8/2019Karthikeyan ParthasarathyNo ratings yet

- Hybrid Safety and Service Procedures: Automotive Technology, Fifth EditionDocument40 pagesHybrid Safety and Service Procedures: Automotive Technology, Fifth EditionSkyAnimal ChannelNo ratings yet

- BPV ThreadDocument1 pageBPV ThreadRicardo Paz Soldan100% (1)

- Valve Standards ISO API ASMEDocument1 pageValve Standards ISO API ASMEGohilakrishnan Thiagarajan100% (1)

- API 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingDocument10 pagesAPI 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingQuality controller0% (1)

- Metal Expansion Joints PDFDocument32 pagesMetal Expansion Joints PDFlishiqian100% (1)

- Figure Union Identification Instructions-NEWDocument4 pagesFigure Union Identification Instructions-NEWArgonauta_navegadorNo ratings yet

- Woodco: Catalog For Inside Blowout PreventersDocument13 pagesWoodco: Catalog For Inside Blowout PreventersJairo PuentesNo ratings yet

- Running Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGDocument16 pagesRunning Procedure: Voestalpine Tubulars GMBH & Co KG Voestalpine Tubulars GMBH & Co KGSumesh DethanNo ratings yet

- API 6A Spec Flange Bolt+ Ring Chart PDFDocument1 pageAPI 6A Spec Flange Bolt+ Ring Chart PDFAlan JuanNo ratings yet

- TenarisCatalogue Casing&Tubing PDFDocument118 pagesTenarisCatalogue Casing&Tubing PDFHenry Carreno MesaNo ratings yet

- Steel Flanges Ansi Stnd1Document36 pagesSteel Flanges Ansi Stnd1Harshvardhan MishraNo ratings yet

- Data Sheet of Double Studded Adapter FlangeDocument3 pagesData Sheet of Double Studded Adapter FlangeAGSMotoVlog 06100% (1)

- API Slide Rule (Flange & Hub)Document3 pagesAPI Slide Rule (Flange & Hub)didikhartadiNo ratings yet

- API 6a Flanges CatalogueDocument37 pagesAPI 6a Flanges CatalogueSend MailNo ratings yet

- Octg Division: Date:19/02/2016 Reference: MD-15-XXX Rev 0Document2 pagesOctg Division: Date:19/02/2016 Reference: MD-15-XXX Rev 0Jenny100% (1)

- Cortec Choke CatalogDocument8 pagesCortec Choke Catalogamjath584100% (1)

- H135-155XL (G006) : 1559719 ©2009 Hyster Company 10/2009Document456 pagesH135-155XL (G006) : 1559719 ©2009 Hyster Company 10/2009Fabricio Félix100% (1)

- API 6A, 16A, BX Ring Gaskets, BX Ring Gasket DimensionsDocument1 pageAPI 6A, 16A, BX Ring Gaskets, BX Ring Gasket DimensionsKaleem UllahNo ratings yet

- Mud Gate ValveDocument16 pagesMud Gate ValvesudhisnairNo ratings yet

- Compressors 1Document11 pagesCompressors 1sgupta_615796No ratings yet

- Gear PumpDocument58 pagesGear Pumpsgupta_615796100% (5)

- Grid Coupling PDFDocument6 pagesGrid Coupling PDFsgupta_615796100% (1)

- VWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Document20 pagesVWS Pump Manual (Varat Pump & Machinery Pvt. LTD.)Kaushik ChakrabortyNo ratings yet

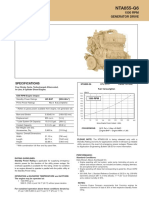

- NTA855-G6: 1500 RPM Generator DriveDocument2 pagesNTA855-G6: 1500 RPM Generator DriveUnit Alkal100% (1)

- Building Services ReportDocument108 pagesBuilding Services ReportBrian WilliamsNo ratings yet

- Kop Flex Coupling Paper 2 PDFDocument4 pagesKop Flex Coupling Paper 2 PDFsgupta_615796No ratings yet

- Tech Manual 1222B: Booster Cylinder Assembly EH34-BC03Document21 pagesTech Manual 1222B: Booster Cylinder Assembly EH34-BC03jose perozoNo ratings yet

- Hammer UnionsDocument16 pagesHammer Unionsram_river808100% (2)

- 5 CTDocument5 pages5 CTDileep KumarNo ratings yet

- Api RP 5a3Document4 pagesApi RP 5a3maruc08100% (1)

- Casar Steel Wire RopesDocument32 pagesCasar Steel Wire Ropessgupta_615796No ratings yet

- Check Valve: High Pressure Dart StyleDocument6 pagesCheck Valve: High Pressure Dart StyleGenard Sabenacio GarciaNo ratings yet

- Heshka Oil Catalog 2019Document16 pagesHeshka Oil Catalog 2019Michael PerschkeNo ratings yet

- Asme b16.20 StandardsDocument1 pageAsme b16.20 StandardsJakir HossainNo ratings yet

- 6 44 0005 Rev5 PDFDocument439 pages6 44 0005 Rev5 PDFprasadNo ratings yet

- Tenaris BlueDock BrochureDocument19 pagesTenaris BlueDock BrochureSudish BhatNo ratings yet

- Cameron EB3040BDocument1 pageCameron EB3040Bgplese0No ratings yet

- Hydril 523 Integral Casing Connection: Hydril 523 Efficiency and Torque ValuesDocument4 pagesHydril 523 Integral Casing Connection: Hydril 523 Efficiency and Torque ValuestheislandboyNo ratings yet

- Codes and Standards: What Is A CodeDocument7 pagesCodes and Standards: What Is A CodeRushikesh TawareNo ratings yet

- MRP1000 - Ops ManualDocument62 pagesMRP1000 - Ops Manualjose abaNo ratings yet

- Grant Prideco™ Mechanical Property Requirements For Drill PDFDocument4 pagesGrant Prideco™ Mechanical Property Requirements For Drill PDFChristian Matteo100% (1)

- 2011 Boiler Feed Pumps Thermosolar Conference V3 PDFDocument27 pages2011 Boiler Feed Pumps Thermosolar Conference V3 PDFjrri16No ratings yet

- Welding SymbolsDocument21 pagesWelding Symbolstuna61No ratings yet

- Cameron Fully Welded Ball Valves BrochureDocument36 pagesCameron Fully Welded Ball Valves BrochureBalderas Rosas WilibaldoNo ratings yet

- Design of Blowout Preventer Lifting FrameDocument10 pagesDesign of Blowout Preventer Lifting FrameSisu StefanNo ratings yet

- NORD Gear Box ManualDocument216 pagesNORD Gear Box Manualsgupta_615796100% (5)

- So2 BlowerDocument1,647 pagesSo2 Blowersgupta_615796No ratings yet

- Fan Source BookDocument92 pagesFan Source Bookapi-3808778100% (10)

- CODES and STANDARDS PDFDocument10 pagesCODES and STANDARDS PDFemnptn2667No ratings yet

- 04b Anti CollisionDocument30 pages04b Anti CollisionAli BoubeniaNo ratings yet

- Ball MillDocument2 pagesBall Millsgupta_615796No ratings yet

- Buttress Run-Out - API ConnectionDocument2 pagesButtress Run-Out - API ConnectionEDWIN M.PNo ratings yet

- Chemical Cleaning and Degassing Refinery EquipmentDocument4 pagesChemical Cleaning and Degassing Refinery EquipmentWilfred OzerecNo ratings yet

- Ariens ST924 ManualDocument42 pagesAriens ST924 Manualw_christopher_miller@gmail_comNo ratings yet

- TN GopinathDocument299 pagesTN GopinathNaresh Sharma0% (1)

- Codes and StanDocument6 pagesCodes and StanVikramNo ratings yet

- Component Handbook Rev.3 Dated 20 Sept 2010Document319 pagesComponent Handbook Rev.3 Dated 20 Sept 2010jaime cerdaNo ratings yet

- Chain CalculationsDocument3 pagesChain CalculationsTeguh Nugraha KusnanNo ratings yet

- Bore and Keyway TolerancesDocument8 pagesBore and Keyway TolerancesIgor San Martín PeñalozaNo ratings yet

- Sample - Belt Bucket Elevator DesignDocument7 pagesSample - Belt Bucket Elevator Designmfhasnain100% (1)

- CEIC2000 Exam 2016 MainDocument18 pagesCEIC2000 Exam 2016 MainMeena LochniNo ratings yet

- Operation Manual Komatsu Wa 70-5Document253 pagesOperation Manual Komatsu Wa 70-5MTK201667% (6)

- Stahl New Operating Instruction Manual-Chain HoistDocument32 pagesStahl New Operating Instruction Manual-Chain Hoistsgupta_61579633% (3)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- API FlangesDocument31 pagesAPI FlangesSharun SureshNo ratings yet

- TECH003 Hammer Union MismatchDocument1 pageTECH003 Hammer Union MismatchKBCNo ratings yet

- Grasa para Tuberia Bestolife 2000Document4 pagesGrasa para Tuberia Bestolife 2000Haiber BurgosNo ratings yet

- API 6A Type 6B & 6BX FlangesDocument32 pagesAPI 6A Type 6B & 6BX Flangeszulaydejesus100% (1)

- Date Description ECR Rev. BY: Revision/Changes: SCALE: 0.500 B AS-0001 ADocument1 pageDate Description ECR Rev. BY: Revision/Changes: SCALE: 0.500 B AS-0001 APetrotrim ServicesNo ratings yet

- API Spec 16C - Union Connections 20140103Document2 pagesAPI Spec 16C - Union Connections 20140103Deby PristantoNo ratings yet

- Carbon Steel Spiralweld Pipe Miter Bends - NaylorPipe-Catalog PDFDocument16 pagesCarbon Steel Spiralweld Pipe Miter Bends - NaylorPipe-Catalog PDFanescobar0001No ratings yet

- TSH WTDocument1 pageTSH WTHomero NavarroNo ratings yet

- Api Flange Bolt & Ring Chart: PO BOX 639 - Bakersfield, CA 93302Document1 pageApi Flange Bolt & Ring Chart: PO BOX 639 - Bakersfield, CA 93302Prasetiyo SholehNo ratings yet

- Stronger Supply Chain With API Spec Q1 Addendum 2Document4 pagesStronger Supply Chain With API Spec Q1 Addendum 2jaymuscatNo ratings yet

- Engineering Bulletin - EB 99013-A: Multiple Position Lock System UpgradeDocument3 pagesEngineering Bulletin - EB 99013-A: Multiple Position Lock System UpgradeJean Dubois0% (1)

- New Catalgue-Fittings PDFDocument128 pagesNew Catalgue-Fittings PDFdeaaNo ratings yet

- Reference Standards PDFDocument3 pagesReference Standards PDFAsghar AliNo ratings yet

- Standards & Codes: Design StandardDocument25 pagesStandards & Codes: Design StandardQASWA ENGINEERING PVT LTDNo ratings yet

- Objasnjenje - NACE, TEMA, NORSK, ASME VIII, ....Document4 pagesObjasnjenje - NACE, TEMA, NORSK, ASME VIII, ....Nebojsa MirkovicNo ratings yet

- Piping Engineering All Codes and StandardDocument17 pagesPiping Engineering All Codes and Standardomkar parab100% (1)

- Valve Standards in The Petrochemical & Refining IndustryDocument4 pagesValve Standards in The Petrochemical & Refining Industryutut yfhgNo ratings yet

- Iso Code PDFDocument37 pagesIso Code PDFJP WayNo ratings yet

- Valve Standards ANSI ASME PDFDocument6 pagesValve Standards ANSI ASME PDFChi JoyNo ratings yet

- Dsic Coupling Vs Gear CouplingDocument4 pagesDsic Coupling Vs Gear Couplingsgupta_615796No ratings yet

- BCW CouplingDocument1 pageBCW Couplingsgupta_615796No ratings yet

- Blackmer Tx15 To Tx4aDocument24 pagesBlackmer Tx15 To Tx4aedwinramonNo ratings yet

- Chapter 02Document64 pagesChapter 02Muizz Zainuddin86% (7)

- Turbomachanies & ClassificationDocument7 pagesTurbomachanies & ClassificationVinay ChandwaniNo ratings yet

- Internship ReportDocument22 pagesInternship ReportAli Syed0% (1)

- Portable Fuel Tanks Bonding and Grounding PDFDocument3 pagesPortable Fuel Tanks Bonding and Grounding PDFSmart LauNo ratings yet

- Einhell BC-BG 43 AsDocument16 pagesEinhell BC-BG 43 AsCristiana LaviniaNo ratings yet

- Ehv 2015 PDFDocument4 pagesEhv 2015 PDFOsama AwwadNo ratings yet

- RempeyekDocument7 pagesRempeyekelyasliaNo ratings yet

- IC Engines Lab ReportDocument7 pagesIC Engines Lab ReportnewUserNo ratings yet

- LPG Vialle LiquidSi 2527-7EN-LiquidSiDocument6 pagesLPG Vialle LiquidSi 2527-7EN-LiquidSiFerenc VelezNo ratings yet

- Data Sheet: Hydraulic Fluid P. 854Document16 pagesData Sheet: Hydraulic Fluid P. 854aries_fransischoNo ratings yet

- Lubrication NotesDocument31 pagesLubrication NotesRishab SharmaNo ratings yet

- ExxonmobilDocument2 pagesExxonmobilapi-267116420No ratings yet

- Diaphragm AFGlobal High-PressureDocument8 pagesDiaphragm AFGlobal High-PressureAnonymous nw5AXJqjdNo ratings yet

- Sulfur HexafluorideDocument12 pagesSulfur HexafluorideRick JordanNo ratings yet

- Rotan GP: General Purpose PumpsDocument2 pagesRotan GP: General Purpose PumpsFerhat KahveciNo ratings yet

- Cn31 13 - 2013 07Document26 pagesCn31 13 - 2013 07leeNo ratings yet