Professional Documents

Culture Documents

Cylinder Block PDF

Uploaded by

victover0 ratings0% found this document useful (0 votes)

47 views2 pagesOriginal Title

Cylinder Block.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views2 pagesCylinder Block PDF

Uploaded by

victoverCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 17-60-98 1-3

1.1 CYLINDER BLOCK AND CYLINDER LINER

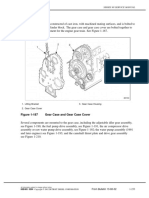

The cylinder block is the basic engine structure, establishing and maintaining the alignment of all

engine working parts. In the Series 60 Engine, the cylinder bores are not an integral part of the

block casting, but are in the form of replaceable, wet type cylinder liners. See Figure 1-1.

Flanges at the liner upper ends seat in counterbores in the block deck, and project slightly above

the deck to compress the head gasket for a good compression seal. Below the water jacket the

lower end of the cylinder liner has two D-shaped seal rings and a lipped crevice seal to prevent

leakage between the water jacket and crankcase.

1.Cylinder Block 4.Cylinder Liner

2.D-rings 5.Integral Coolant Inlet Manifold

3.Crevice Seal 6.Oil Galleries

Figure 1-1 Series 60 Cylinder Block and Liner

1.1 CYLINDER BLOCK AND CYLINDER LINER

All information subject to change without notice.

1-4 From Bulletin 17-60-98 6SE483 9610 1996 DETROIT DIESEL CORPORATION

An integral coolant inlet manifold is cored into the right side of the block. It distributes the water

pump output along the length of the block. Oil galleries are machined into the cooler side of the

block. See Figure 1-1.

The integral oil galleries direct the oil pump output through the external oil cooler and filters, to

the main oil gallery and to drilled passages in the crankcase webs which supply oil under

pressure to each main bearing. In the crankcase, five integral webs plus front and rear bulkheads

support the crankshaft in seven main bearings. See Figure 1-2.

Figure 1-2 Series 60 Cylinder Block Crankcase

An improved cylinder block has replaced the former block on all Series 60 engines. This change

took effect with unit serial number 6R210293, built November 30, 1994. The former cylinder

block was used on engines built prior to this serial number.

The Series 60 cylinder block was further improved by the addition of a drilled lubrication orifice

and bolt hole at the base of each cylinder bore. See Figure 1-2. The orifices are drilled into the

main oil gallery and are required for installation of bolt-on oil spray nozzles used with forged

steel pistons on premium engine. When blocks are used for non-premium engines with cast-iron

pistons, the lubrication orifices are closed with bolt-on steel plates. First usage of the drilled

block was on March 2, 1998, effective with engine serial number 6R408505.

You might also like

- Audi 4.2 V8-5v Engine Self Study GuideDocument52 pagesAudi 4.2 V8-5v Engine Self Study Guidesheba1023100% (2)

- Cummins L10 Engine FamiliarisationDocument16 pagesCummins L10 Engine FamiliarisationTariqMaqsood100% (2)

- D6a - D8a PDFDocument168 pagesD6a - D8a PDFduongpn63% (8)

- E5101d01 Engine Ls400Document237 pagesE5101d01 Engine Ls400Chad Cochran50% (6)

- Detroit 8.2 v8Document25 pagesDetroit 8.2 v8Jose Juan Davila100% (3)

- SECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyDocument35 pagesSECTION 303-01B: Engine - 4.6L and 5.4L 2000 F-150 Workshop Manual AssemblyHassan Vela VenegasNo ratings yet

- Motor KA24E PDFDocument32 pagesMotor KA24E PDFJose Pichinte100% (2)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNo ratings yet

- Figure 1-17 Location of Engine Serial and Model Numbers: Series 60 Service ManualDocument2 pagesFigure 1-17 Location of Engine Serial and Model Numbers: Series 60 Service ManualvictoverNo ratings yet

- Connecting Rod PDFDocument9 pagesConnecting Rod PDFvictoverNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Forged Steel Piston PDFDocument14 pagesForged Steel Piston PDFvictoverNo ratings yet

- 1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualDocument2 pages1.8.7.1 Inspection of Crankshaft Oil Seal: Series 60 Service ManualvictoverNo ratings yet

- Emd-Mi926 Filtracion de AceitesDocument7 pagesEmd-Mi926 Filtracion de AceitesVictor Raul Tobosque MuñozNo ratings yet

- Basic Engine: Systems OperationDocument3 pagesBasic Engine: Systems OperationTri WahyuningsihNo ratings yet

- 2.3L V5 Engine: ServiceDocument27 pages2.3L V5 Engine: ServiceEdidjo DarwinNo ratings yet

- Basic Engine: Systems OperationDocument2 pagesBasic Engine: Systems OperationMedo SowarNo ratings yet

- Engine Mechanical (D6A, D8A)Document168 pagesEngine Mechanical (D6A, D8A)Manuales De Maquinaria JersoncatNo ratings yet

- Series 60 Service Manual: From Bulletin 6-60-98 1-157bDocument2 pagesSeries 60 Service Manual: From Bulletin 6-60-98 1-157bvictoverNo ratings yet

- Gruppe 150 enDocument28 pagesGruppe 150 enMarco MaximilianoNo ratings yet

- Basic Engine: Systems OperationDocument2 pagesBasic Engine: Systems OperationNay SoeNo ratings yet

- DT466 Valve AdjustmentDocument15 pagesDT466 Valve Adjustmentחנניה מוסNo ratings yet

- Instructions For Main Engine: Doosan Engine Co., LTDDocument22 pagesInstructions For Main Engine: Doosan Engine Co., LTDLekembauerNo ratings yet

- Steel Piston PDFDocument14 pagesSteel Piston PDFvictoverNo ratings yet

- Basic EngineDocument2 pagesBasic Engineyoga_jpbmbmNo ratings yet

- Detroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00aDocument20 pagesDetroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00anguynthanhlongNo ratings yet

- 79-20-00 - Oil Distribution - Description and OperationDocument3 pages79-20-00 - Oil Distribution - Description and OperationCleber SouzaNo ratings yet

- Basic Engine: Operación de SistemasDocument5 pagesBasic Engine: Operación de SistemasLuis TepezanoNo ratings yet

- Figure 1-187 Gear Case and Gear Case CoverDocument32 pagesFigure 1-187 Gear Case and Gear Case CoverIvanovNo ratings yet

- Jake Brake 1998 PDFDocument10 pagesJake Brake 1998 PDFvictoverNo ratings yet

- Manual de Motor Honda Civic Ex 2000Document63 pagesManual de Motor Honda Civic Ex 2000David Emmanuel Turcios CarrilloNo ratings yet

- HidrolikDocument43 pagesHidrolikAli AtmacaNo ratings yet

- Series 60 Crank Seal11-60-04aDocument22 pagesSeries 60 Crank Seal11-60-04aKeyser SözeNo ratings yet

- Engine Overhaul 2.2LDocument29 pagesEngine Overhaul 2.2LalbertoNo ratings yet

- GEAR BOX Service ManualDocument66 pagesGEAR BOX Service ManualJon Mo86% (7)

- ENGINE OVERHAUL 2.6 4cylDocument24 pagesENGINE OVERHAUL 2.6 4cylalbertoNo ratings yet

- 300tdi Overhaul Manual Land RoverDocument103 pages300tdi Overhaul Manual Land RoverChikombe Jonathan ChelaNo ratings yet

- Diesel Engine TestDocument9 pagesDiesel Engine TestSamuel Blandes RwegasiraNo ratings yet

- Caterpillar Cat 226B Skid Steer Loader (Prefix MJH) Service Repair Manual (MJH00001-10574)Document26 pagesCaterpillar Cat 226B Skid Steer Loader (Prefix MJH) Service Repair Manual (MJH00001-10574)rpoy9396615No ratings yet

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Document113 pagesYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- 4l80e HD Shift Recalibration Kit InstructionsDocument8 pages4l80e HD Shift Recalibration Kit InstructionsGuntherMizen100% (1)

- AMTE-126 - Midterm Assignment#1Document5 pagesAMTE-126 - Midterm Assignment#1Maybelyn ConsignadoNo ratings yet

- Install Cylinder HeadDocument6 pagesInstall Cylinder Headrahmat sanusiNo ratings yet

- Hyundai-B&w 1Document201 pagesHyundai-B&w 1shujauddin84100% (1)

- S46MC-C, Edition 2Document168 pagesS46MC-C, Edition 2Nghia Duongdinh50% (2)

- Crankshaft Oil 2 PDFDocument2 pagesCrankshaft Oil 2 PDFvictoverNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7Document12 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7anony8103No ratings yet

- Sephia 1995 1.6LDocument46 pagesSephia 1995 1.6Lmiguel harciaNo ratings yet

- ManualDocument11 pagesManualDavid Antoine100% (1)

- Manual Reparación Turbo GARRETDocument24 pagesManual Reparación Turbo GARRETFelipe Lepe MattaNo ratings yet

- CSL 1082Document4 pagesCSL 1082oscar horacio floresNo ratings yet

- CPCBII 4B3.3 Engine Design FeaturesDocument26 pagesCPCBII 4B3.3 Engine Design FeaturesGowthaman NNo ratings yet

- Man-10-20220607-Paae058977 Update ManualDocument18 pagesMan-10-20220607-Paae058977 Update Manualrafael.eloidasilvaNo ratings yet

- Mantenimiento 6466 PDFDocument3 pagesMantenimiento 6466 PDFmarcosluna680% (3)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualFrom EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualRating: 3.5 out of 5 stars3.5/5 (2)

- Water Pump PDFDocument2 pagesWater Pump PDFvictoverNo ratings yet

- Steel Piston PDFDocument14 pagesSteel Piston PDFvictoverNo ratings yet

- Water Pump 2 PDFDocument2 pagesWater Pump 2 PDFvictoverNo ratings yet

- 6.4 TURBOCHARGER (Diesel) : Figure 6-9 TV45, TV51 Turbocharger AssemblyDocument2 pages6.4 TURBOCHARGER (Diesel) : Figure 6-9 TV45, TV51 Turbocharger AssemblyvictoverNo ratings yet

- Two-Bolt Camshaft 2 PDFDocument1 pageTwo-Bolt Camshaft 2 PDFvictoverNo ratings yet

- Series 60 Service Manual: From Bulletin 19-60-98 1-288cDocument2 pagesSeries 60 Service Manual: From Bulletin 19-60-98 1-288cvictoverNo ratings yet

- Figure 6-18A Checking Wastegate CalibrationDocument6 pagesFigure 6-18A Checking Wastegate Calibrationvictover100% (2)

- Two-Bolt Camshaft PDFDocument7 pagesTwo-Bolt Camshaft PDFvictoverNo ratings yet

- Figure 2-382 Jake Brake and DDC Bolt Identification: Series 60 Service ManualDocument2 pagesFigure 2-382 Jake Brake and DDC Bolt Identification: Series 60 Service Manualvictover100% (1)

- 8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionDocument2 pages8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionvictoverNo ratings yet

- Service Manual PDFDocument2 pagesService Manual PDFvictoverNo ratings yet

- Steel Piston 2 PDFDocument2 pagesSteel Piston 2 PDFvictoverNo ratings yet

- Jake Brake 1998 3 PDFDocument2 pagesJake Brake 1998 3 PDFvictoverNo ratings yet

- Jake Brake 1998 PDFDocument10 pagesJake Brake 1998 PDFvictoverNo ratings yet

- Guidelines Water Pump 2 PDFDocument2 pagesGuidelines Water Pump 2 PDFvictoverNo ratings yet

- Figure 2-12 Electronic Unit Injector Terminal InstallationDocument2 pagesFigure 2-12 Electronic Unit Injector Terminal InstallationvictoverNo ratings yet

- 13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service ManualDocument2 pages13.8.4.6 Stop Engine Light Did Not Illuminate: Series 60 Service ManualvictoverNo ratings yet

- Figure 12-9 Adjusting Leveling Screw: Series 60 Service ManualDocument2 pagesFigure 12-9 Adjusting Leveling Screw: Series 60 Service ManualvictoverNo ratings yet

- 13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualDocument2 pages13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualvictoverNo ratings yet

- Guidelines Water Pump 3 PDFDocument2 pagesGuidelines Water Pump 3 PDFvictoverNo ratings yet

- This Page Intentionally Left Blank.: Series 60 Service ManualDocument2 pagesThis Page Intentionally Left Blank.: Series 60 Service ManualvictoverNo ratings yet

- Figure 1-301 Gasket Eliminator Application: Series 60 Service ManualDocument2 pagesFigure 1-301 Gasket Eliminator Application: Series 60 Service ManualvictoverNo ratings yet

- Front Camshaft 2 PDFDocument2 pagesFront Camshaft 2 PDFvictoverNo ratings yet

- 1.16.1 Repair or Replacement of Flywheel HousingDocument2 pages1.16.1 Repair or Replacement of Flywheel HousingvictoverNo ratings yet

- Engine Coolant PDFDocument1 pageEngine Coolant PDFvictoverNo ratings yet

- Flywheel 2 PDFDocument4 pagesFlywheel 2 PDFvictoverNo ratings yet

- Tool Number Tool Name: Table 1-43 Engine-Cylinder BlockDocument2 pagesTool Number Tool Name: Table 1-43 Engine-Cylinder BlockvictoverNo ratings yet

- Engine Coolant 2 PDFDocument3 pagesEngine Coolant 2 PDFvictoverNo ratings yet

- Drain Water Pump PDFDocument2 pagesDrain Water Pump PDFvictoverNo ratings yet