Professional Documents

Culture Documents

79-20-00 - Oil Distribution - Description and Operation

Uploaded by

Cleber SouzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

79-20-00 - Oil Distribution - Description and Operation

Uploaded by

Cleber SouzaCopyright:

Available Formats

MAINTENANCE MANUAL 79-20-00 - OIL DISTRIBUTION - DESCRIPTION AND OPERATION

Manual Part No.3043512 Rev. 35.0 - 23/JUL/18

79-20-00

Engine Model(s): MODEL(S)PT6A-114/-114A/-135/-135A

OIL DISTRIBUTION - DESCRIPTION AND OPERATION

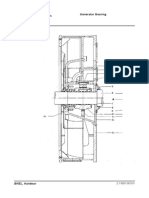

1. Description and Operation (Ref. Fig. 1)

Figure 1 Accessory Gearbox Diaphragm and Oil Pump

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 1

Printed on 25/SEP/18 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 79-20-00 - OIL DISTRIBUTION - DESCRIPTION AND OPERATION

Manual Part No.3043512 Rev. 35.0 - 23/JUL/18

c482b

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 2

Printed on 25/SEP/18 P&WC Proprietary – subject to restrictions in Technical Data Agreement

MAINTENANCE MANUAL 79-20-00 - OIL DISTRIBUTION - DESCRIPTION AND OPERATION

Manual Part No.3043512 Rev. 35.0 - 23/JUL/18

A. Oil Tank

The oil tank is an integral part of the compressor inlet case and is located in front of the

accessory gearbox. The tank is provided with a filler neck and an integral quantity dipstick and

cap located at the 11 o'clock position on the accessory gearbox housing. The cap and dipstick

are fastened to the filler neck, which passes through the gearbox housing and accessory

diaphragm and into the oil tank. The markings on the dipstick correspond to US quarts, and

indicate the amount of oil required to fill the tank to the full mark. An anti-flooding device and

breather arrangement, located at the 12 o'clock position on the compressor inlet case, prevents

foaming when scavenged oil is returned to the tank during engine operation. The tank is vented

to the top of the accessory gearbox, where the air/oil mist is passed through a centrifugal

breather. The breather separates the oil from the air and returns the oil to the bottom of the

accessory gearbox. The relatively oil free air is discharged overboard via a cored passage in the

accessory diaphragm and transfer tube, to a breather boss located at the 2 o'clock position on

the gearbox housing. Draining of the oil tank is done by removal of a plug located at the 6

o'clock position of the compressor inlet case (Ref. 72-00-00).

B. Oil Pump

Pressure oil is circulated from the integral oil tank and through the engine lubricating system by

a self-contained gear-type pump mounted at the bottom of the oil tank. The oil pump consists of

two gears contained in a cast housing bolted to the front of the AGB diaphragm. The pump

gears are driven by an accessory gearshaft which also drives the internal scavenge pump. A

removable inlet screen is fitted at the oil pump. The pump housing incorporates a support boss

at the pump for the oil filter housing, and is counterbored to accommodate the check valve

which is mounted at the inner end of the filter housing. The lubrication system pressure relief

valve (Ref. 72-60-00) is installed on a pad located at the upper end of the housing. An internal

cored passage connects the relief valve to pump outlet.

C. Oil Filter

The oil filter, installed in the pressure line downstream of the oil pump, consists of cartridge

type filter element, a spring loaded bypass valve, and a check valve mounted in a removable

alloy housing. Depending on installation requirements, the filter element may be of the

cleanable (reusable) or non-cleanable (disposable) type.

D. Centrifugal Breather

The centrifugal breather consists of an aluminum alloy, shrouded impeller housing attached to

the rear face of the starter generator gearshaft by a retaining ring. Rotational torque is

transmitted from the gearshaft to the impeller by three equi-distant pins. Breather air flows

radially inward through the rotating impeller housing where oil particles in the breather air are

separated by centrifugal force, and drain freely into the gearbox sump. The relatively oil-free air

passes inward and into the hollow rear section of the gearshaft. The air flows forward and into a

cored passage in the accessory diaphragm. From the cored passage, the air passes through a

transfer tube to a breather boss on the accessory gearbox housing at the 2 o'clock position.

Export Classification: ECCN=Contains 1025% 9E991;ECL=NSR Page 3

Printed on 25/SEP/18 P&WC Proprietary – subject to restrictions in Technical Data Agreement

You might also like

- WRV-WRVi Service Manual - September 2012Document64 pagesWRV-WRVi Service Manual - September 2012frigoremont79% (24)

- Cummins L10 Engine FamiliarisationDocument16 pagesCummins L10 Engine FamiliarisationTariqMaqsood100% (2)

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 1Document80 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 1anony810386% (7)

- 039-292 Stop Major 23XLDocument167 pages039-292 Stop Major 23XLJames Murray100% (1)

- C13 Oil SystemDocument6 pagesC13 Oil Systemjeddo2005100% (1)

- Detroit Series 60 EPA07 Engine Service ManualDocument945 pagesDetroit Series 60 EPA07 Engine Service ManualLarry100% (2)

- Capitol 5HD200-service-manual PDFDocument46 pagesCapitol 5HD200-service-manual PDFlabatea100% (1)

- Dcam PT 66 Training Module 15.10 Lubrication Systems PDFDocument73 pagesDcam PT 66 Training Module 15.10 Lubrication Systems PDFarif sulaimanNo ratings yet

- Torque Converter Clutch TCCDocument21 pagesTorque Converter Clutch TCCmarsh2002100% (2)

- Maintenance Manual (MM) : BO 105 (Not Applicable For BO 105 LS)Document772 pagesMaintenance Manual (MM) : BO 105 (Not Applicable For BO 105 LS)Cleber SouzaNo ratings yet

- Eclipse 500 Aircraft Systems Manual PDFDocument460 pagesEclipse 500 Aircraft Systems Manual PDFCleber Souza0% (1)

- Astm E1575 Water JetDocument10 pagesAstm E1575 Water JetHenry100% (1)

- 79-20-02 - Oil Filter, Housing and Check Valve - Description and OperationDocument3 pages79-20-02 - Oil Filter, Housing and Check Valve - Description and OperationCleber SouzaNo ratings yet

- 79-20-01 - External Oil Tubes - Description and OperationDocument1 page79-20-01 - External Oil Tubes - Description and OperationCleber SouzaNo ratings yet

- vnx.su transit 1976-1986 Часть2 PDFDocument543 pagesvnx.su transit 1976-1986 Часть2 PDFscodavnxNo ratings yet

- Generator AuxiliariesDocument4 pagesGenerator AuxiliariesNilesh KumarNo ratings yet

- GEAR BOX Service ManualDocument66 pagesGEAR BOX Service ManualJon Mo86% (7)

- Manual Reparación Turbo GARRETDocument24 pagesManual Reparación Turbo GARRETFelipe Lepe MattaNo ratings yet

- TFE 731 Chap 79Document24 pagesTFE 731 Chap 79Egor8550% (2)

- Image Server HandlerDocument12 pagesImage Server Handlerbobcat1810No ratings yet

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- Installation and Operating InstructionsDocument20 pagesInstallation and Operating InstructionsArtūrs CeimersNo ratings yet

- ManualDocument11 pagesManualDavid Antoine100% (1)

- Sistema de Lubricacion Emd 645Document21 pagesSistema de Lubricacion Emd 645Adriana Rojas VerasteguiNo ratings yet

- 1980 Dual Jet E2 MDocument40 pages1980 Dual Jet E2 MNestor CastilloNo ratings yet

- AMTE-126 - Midterm Assignment#1Document5 pagesAMTE-126 - Midterm Assignment#1Maybelyn ConsignadoNo ratings yet

- Elecon Scoop Coupling Installation Maintenance ManualDocument21 pagesElecon Scoop Coupling Installation Maintenance ManualVignesh VenkatasubramanianNo ratings yet

- Aircraft Maintenance Manual: Print Date: 2021-03-25Document8 pagesAircraft Maintenance Manual: Print Date: 2021-03-25CHIMONo ratings yet

- CSL 1082Document4 pagesCSL 1082oscar horacio floresNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7Document12 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7anony8103No ratings yet

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342Document10 pagesPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342EstebanNo ratings yet

- GenauxDocument135 pagesGenauxSoumya Ranjan SethyNo ratings yet

- Instruction Manual For SSP-70D-ACMEVACDocument15 pagesInstruction Manual For SSP-70D-ACMEVACParjanya MandalNo ratings yet

- Torque Converter C-300 OWI - Service ManualDocument12 pagesTorque Converter C-300 OWI - Service Manualaldino020203100% (3)

- 777F MG SistemasDocument118 pages777F MG SistemasDenerMendozaLayza100% (6)

- English - 420E Sistema Hidraulico - All Whell DriveDocument4 pagesEnglish - 420E Sistema Hidraulico - All Whell DriveAron Benito Pari MachacuayNo ratings yet

- SM 03 BDocument34 pagesSM 03 BMark OreschnickNo ratings yet

- Instruction - Flushing Gas Turbine Lubricant Oil SystemDocument5 pagesInstruction - Flushing Gas Turbine Lubricant Oil SystemRicky Hendra Silalahi100% (1)

- Emd-Mi926 Filtracion de AceitesDocument7 pagesEmd-Mi926 Filtracion de AceitesVictor Raul Tobosque MuñozNo ratings yet

- WRV ManualDocument52 pagesWRV ManualJacinto Morales100% (7)

- Compressore Tu-Flo 501Document21 pagesCompressore Tu-Flo 501Sauro GordiniNo ratings yet

- MAV Lube Oil SystemDocument9 pagesMAV Lube Oil SystemMurali Krishna GbNo ratings yet

- 4G63 ManualDocument34 pages4G63 Manualfrinliwigo100% (4)

- Seal Oil System 2Document31 pagesSeal Oil System 2Raga Lasya100% (8)

- Lubrication System, Description: Service InformationDocument6 pagesLubrication System, Description: Service Informationwidanto0apriawanNo ratings yet

- The Turbine Lubricating Oil System: ObjectivesDocument23 pagesThe Turbine Lubricating Oil System: Objectivesefmaggio100% (2)

- 912 Oil ChangeDocument4 pages912 Oil ChangeGaberNo ratings yet

- Jacking Oil SystemDocument15 pagesJacking Oil SystemSarah Frazier100% (1)

- Unit 5.oil System 16112019Document45 pagesUnit 5.oil System 16112019motores4297100% (1)

- 11.lube Oil SystemDocument22 pages11.lube Oil Systempepenapao1217100% (1)

- Instruction ManualDocument36 pagesInstruction ManualJoséNo ratings yet

- Sistema de Operacion Transmision 980f 3Document47 pagesSistema de Operacion Transmision 980f 3DiegoMenaNo ratings yet

- TransmisionntDocument11 pagesTransmisionntEdgardo Alfonso Ilabaca Saez100% (3)

- Tu-Flo 300 Compressor: Important! Please ReadDocument23 pagesTu-Flo 300 Compressor: Important! Please ReadOdai AlsaafinNo ratings yet

- TT Oil Flooded Rotary Air CompressorDocument2 pagesTT Oil Flooded Rotary Air Compressorajo2402No ratings yet

- Caterpillar Crawler Operators Manual CT o d9Document7 pagesCaterpillar Crawler Operators Manual CT o d9Tommy JunNo ratings yet

- Guide To The EJC 65 Hydraulic System: GeneralDocument50 pagesGuide To The EJC 65 Hydraulic System: GeneralSanti Al ElricNo ratings yet

- Powerplant King 350Document22 pagesPowerplant King 350stive100% (2)

- Bendix BA-921 Compressor: DescriptionDocument36 pagesBendix BA-921 Compressor: DescriptionEstebanMongeAlvaradoNo ratings yet

- Section 7 Engine: Maintenance 7.1Document26 pagesSection 7 Engine: Maintenance 7.1Jan HendriksNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 3 - Record of RevisionsDocument2 pages3 - Record of RevisionsCleber SouzaNo ratings yet

- ManualDocument29 pagesManualCleber SouzaNo ratings yet

- Maintenance Manual MBB B0Document48 pagesMaintenance Manual MBB B0Cleber SouzaNo ratings yet

- Y Librar Y Librar Y: Miscellaneous Products Used On HelicoptersDocument6 pagesY Librar Y Librar Y: Miscellaneous Products Used On HelicoptersCleber SouzaNo ratings yet

- 92 Electrical Systems: Maintenance Manual Bo 105Document244 pages92 Electrical Systems: Maintenance Manual Bo 105Cleber SouzaNo ratings yet

- Location AC Power System: Effectivity: ALL Static InverterDocument2 pagesLocation AC Power System: Effectivity: ALL Static InverterCleber SouzaNo ratings yet

- General Description Instrument Cooling System: Effectivity: ALLDocument2 pagesGeneral Description Instrument Cooling System: Effectivity: ALLCleber SouzaNo ratings yet

- General Description Heating System: Effectivity: ALLDocument5 pagesGeneral Description Heating System: Effectivity: ALLCleber SouzaNo ratings yet

- Configuration / Function Passenger Cabin Ventilation System: Effectivity: ALL Ventilation ControlDocument2 pagesConfiguration / Function Passenger Cabin Ventilation System: Effectivity: ALL Ventilation ControlCleber SouzaNo ratings yet

- Configuration / Function Pelican Rack Cooling System: Effectivity: ALL FCDS ControlDocument2 pagesConfiguration / Function Pelican Rack Cooling System: Effectivity: ALL FCDS ControlCleber SouzaNo ratings yet

- General Description Instrument Cooling System: Effectivity: ALLDocument2 pagesGeneral Description Instrument Cooling System: Effectivity: ALLCleber SouzaNo ratings yet

- Configuration / Function Instrument Cooling System: Effectivity: ALL Ventilation ControlDocument2 pagesConfiguration / Function Instrument Cooling System: Effectivity: ALL Ventilation ControlCleber SouzaNo ratings yet

- Eurocopter Maintenance Manual B 0Document16 pagesEurocopter Maintenance Manual B 0Cleber SouzaNo ratings yet

- 2116W Parts Manual 514018 R0Document434 pages2116W Parts Manual 514018 R0lrodr_guez_1100% (1)

- Project References: Clients Project Desription Location Period StatusDocument4 pagesProject References: Clients Project Desription Location Period StatusDiane Joy Fojas PanganibanNo ratings yet

- Lorentz Ps2-100 Product BrochureDocument3 pagesLorentz Ps2-100 Product BrochureSINES FranceNo ratings yet

- CV LinkedinDocument3 pagesCV LinkedinSamir ChaudharyNo ratings yet

- V05 Manual Pellet Classic Eng 1016Document24 pagesV05 Manual Pellet Classic Eng 1016Zarija AleksoskiNo ratings yet

- SPE-185485-MS Deliquification in A Mature Gas Field: Comparison of Predicted and Observed Rates After Well Workover To Install Velocity StringsDocument22 pagesSPE-185485-MS Deliquification in A Mature Gas Field: Comparison of Predicted and Observed Rates After Well Workover To Install Velocity StringsJamshed SoomroNo ratings yet

- Caterpillar G3500 Top End Overhaulesek PDFDocument18 pagesCaterpillar G3500 Top End Overhaulesek PDFMargaret Daugherty75% (4)

- BC-5800 Liquid SystemDocument114 pagesBC-5800 Liquid SystemДмитрийNo ratings yet

- Artificial Lift DudeDocument145 pagesArtificial Lift DudeA A Ichsan CrNo ratings yet

- Accu-Spray User's ManualDocument2 pagesAccu-Spray User's ManualInsetmax DedetizadoraNo ratings yet

- Operating and Maintenance Instructions: Oil Filter UnitDocument17 pagesOperating and Maintenance Instructions: Oil Filter UnitAlanNo ratings yet

- 301-302 Flanged BAA SUCT DIFFUSER SDIDocument2 pages301-302 Flanged BAA SUCT DIFFUSER SDIIan OsorioNo ratings yet

- A6vm250 Catalogo GeralDocument88 pagesA6vm250 Catalogo GeralPatrick GarciaNo ratings yet

- Alfa Laval PurifiersDocument4 pagesAlfa Laval PurifiersNasim AbbasNo ratings yet

- Maximum Total Head - Important Installation InformationDocument3 pagesMaximum Total Head - Important Installation InformationWijaya Cipta SolusindoNo ratings yet

- Water PumpsDocument15 pagesWater PumpsMohammad Mustafa MirzadNo ratings yet

- BYZ-810 Veterinary Stackable Single Syringe Pump: Features & FunctionsDocument3 pagesBYZ-810 Veterinary Stackable Single Syringe Pump: Features & FunctionsUchiha AatacheNo ratings yet

- تشغيل محطة بخارية مهم ورائع PDFDocument157 pagesتشغيل محطة بخارية مهم ورائع PDFelsayed100% (1)

- Fluid Power Design Data SheetDocument2 pagesFluid Power Design Data Sheetshahrol effendy rodziNo ratings yet

- BAUER Trench Cutter Systems PDFDocument32 pagesBAUER Trench Cutter Systems PDFShreedharNo ratings yet

- Lube Oil System PDFDocument18 pagesLube Oil System PDFHuỳnh Phan Ngọc100% (1)

- PZX Large PresentationDocument67 pagesPZX Large PresentationAnonymous yjK3peI7100% (3)

- Manual: MH500 Series Servo-Hydraulic System For Injection Molding MachinesDocument195 pagesManual: MH500 Series Servo-Hydraulic System For Injection Molding Machineshome madeNo ratings yet

- Condensing Unit: ASE-18AH, ASE-24AH, ASE-36AH, ASE-48AH, ASE-60AHDocument41 pagesCondensing Unit: ASE-18AH, ASE-24AH, ASE-36AH, ASE-48AH, ASE-60AHMilton UrrozNo ratings yet

- Crimson Star Series Transformer PumpersDocument8 pagesCrimson Star Series Transformer PumpersPaoloFregonaraNo ratings yet

- Customer - GID-208-CI-EAC-BS-54131 - R2 - PF Control PhilosophyDocument9 pagesCustomer - GID-208-CI-EAC-BS-54131 - R2 - PF Control Philosophysivasakti chp2No ratings yet

- Florencio Favila III Updated ResumeDocument5 pagesFlorencio Favila III Updated ResumeBibamz SanchezNo ratings yet

- Catalogo S20Document25 pagesCatalogo S20Jaime Zzaa100% (1)

- Cooling TowerDocument6 pagesCooling Towerbbmoksh100% (1)