Professional Documents

Culture Documents

Warehousing Management Final

Uploaded by

Sai Indrakaran Reddy CherabuddiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Warehousing Management Final

Uploaded by

Sai Indrakaran Reddy CherabuddiCopyright:

Available Formats

WAREHOUSING

MANAGEMENT

Gaurav Narkhede | Josue Servalis | Mike Macas |

Praneetha Boda

Part of firms logistics system that stores

products at and between point of origin and

point of consumption.

Term Warehousing is referred as

transportation at zero miles per hour

Warehousing provides time and place utility for

raw materials, industrial goods, and finished

products, allowing firms to use customer service

as a dynamic value-adding competitive tool.

THE ROLE OF THE WAREHOUSE IN

THE LOGISTICS SYSTEM

The warehouse is where the supply chain holds

or stores goods.

Functions of warehousing include

Transportation consolidation

Product mixing

Docking

Service

Protection against contingencies

TYPE OF WAREHOUSING

Public Warehousing

Private Warehousing

Contract Warehousing

Multi-client Warehousing

DESIGN CONSIDERATION

Ideal Facility for Pure Supplier

Consolidation

(Full Pallet Movement)

Warehouse Space

Requirements

PRINCIPLES OF WAREHOUSE

LAYOUT DESIGN

Use one-story

facilities

Move goods in a

straight line

Use efficient

materials-

handling

equipment

Use an effective

storage plan

Minimize aisle

space

Use maximum

height of the

building

WAREHOUSE PROCESS

Put-away

Identify Product

Identify Product Location

Move Products

Update Records

Storage

Equipment

Stock Location

Popularity

Unit Size

Cube

Shipping Preparation

Packing

Labeling

Stacking

Order Picking

Information

Walk & Pick

Batch Picking

Shipping

Schedule Carrier

Load Vehicle

Bill of Loading

Record Update

RECEIVING

Schedule Carrier

Unload Vehicle

Inspect for damage

INP

UT

OUT

PUT

OBJECTIVES OF EFFICIENT

WAREHOUSE OPERATIONS

Provide timely customer service.

Keep track of items so they can be found readily &

correctly.

Minimize the total physical effort & thus the cost of

moving goods into & out of storage.

Provide communication links with customers

Benefits of Warehouse Management

Provide a place to store & protect inventory

Reduce transportation costs

Improve customer service levels

Complexity of warehouse operation depends on the

number of SKUs handled & the number of orders

received & filled.

Most activity in a warehouse is material handling.

Capital costs

Costs of space & materials handling

equipment

Operating costs

Cost of labor

Measure of labor productivity is the number of

units that an operator can move in a day

COSTS OF OPERATING A WAREHOUSE

WAREHOUSE ACTIVITIES

Receive goods

Identify the goods

Dispatch goods to

storage

Hold goods

Pick goods

Marshal shipment

Dispatch shipment

Operate an information

system

Accepts goods from

Outside transportation or attached factory &

accepts responsibility

Check the goods against an order & the bill of

loading

Check the quantities

Check for damage & fill out damage reports if

necessary

Inspect goods if required

Receive goods

items are identified with the appropriate stock-

keeping unit (SKU) number (part number) &

the quantity received recorded

Identify the goods

Dispatch goods to storage

goods are sorted & put away

Hold goods

goods are kept in storage & under proper

protection until needed

Pick goods

items required from stock must be selected

from storage & brought to a marshalling area

Marshal the shipment

goods making up a single order are brought

together & checked for omissions or errors; order

records are updated

Dispatch the shipment

orders are packaged, shipping documents are

prepared, & goods loaded on the vehicle

Operate an information system

a record must be maintained for each item in

stock showing the quantity on hand, quantity

received, quantity issued, & location in the

warehouse

Maximize productivity & minimize

cost, warehouse management must

work with the following

Maximize use of space

space is the largest capital cost

Effective use of labor & equipment

labor is the largest operating cost

material handling equipment is the second

largest capital cost

FACTORS INFLUENCING EFFECTIVE

USE OF WAREHOUSES

Cube utilization and accessibility

Stock location

Order picking and assembly

Physical Control & Security - Elements

Cube utilization and

accessibility

Goods stored not just on the floor, but in the

cubic space of the warehouse; warehouse

capacity depends on how high goods can be

stored

Accessibility means being able to get at the

goods wanted with a minimum amount of

work

Cube utilization and accessibility

continued

Stock Location

Objectives

To provide the required customer

service

To keep track of where items are stored

To minimize effort to receive, put away,

and retrieve items

Basic Stock Locating Systems

Group functionally related items

together

Group fast-moving items together

Group physically similar items together

Locate working stock and reserve stock

separately

Fixed Location

SKU assigned a permanent location, & no other

items are stored there

Fixed-location systems usually have poor cube

utilization

Usually used in small warehouses; throughput is

small, & there are few SKUs

Floating (Random) Location

Goods stored wherever there is appropriate

space

Advantage is improved cube utilization

It requires accurate and up-to-date information

Warehouses using floating-location systems are

usually computer-based

Stock Location

continued

Stock Location

continued

Two other systems sometimes used are

Point-of-use storage

Inventory stored close to where it will be

needed

Used in repetitive manufacturing & JIT

systems

Central storage

Contains all inventory in one central location

Advantages of Point-of-use Storage

Materials are readily accessible to users

Material handling is reduced or eliminated

Central storage costs are reduced

Material is accessible all the time

Stock Location

continued

Advantages of Central Storage

Ease of control

Inventory record accuracy is easier to

maintain

Specialized storage can be used

Reduced safety stock, since users do not

need to carry their own safety stock

Stock Location

continued

Order Picking and

Assembly

When an order is received, items must

be obtained from the warehouse,

grouped, & prepared for shipment,

systems used

Area system

Zone system

Multi-order system

Area system

Order picker circulates throughout

warehouse selecting items on an order --

order is ready to ship when order picker is

finished

Zone system

Warehouse is divided into zones, & each

picker works only in an assigned zone --

order is divided by zone, & the items from

each zone are sent to the marshaling

area

Order Picking and

Assembly continued

Multi-order system

Same as the zone system, except that

each picker collects items for a number of

orders at the same time

Order Picking and

Assembly continued

PHYSICAL CONTROL & SECURITY -

ELEMENTS

Good part numbering system

Simple, well-documented transaction system

Identify the item

Verify the quantity

Record the transaction

Physically execute the transaction

Limited access

Inventory must be kept in a safe, secure

(locked) place with limited general access

Well-trained workforce

VIDEO

http://www.youtube.com/watch?v=

Cbj2d_0w24E

Questio

ns ?

THANK

YOU

You might also like

- Warehousing Management: Gaurav Narkhede - Josue Servalis - Mike Macas - Praneetha BodaDocument31 pagesWarehousing Management: Gaurav Narkhede - Josue Servalis - Mike Macas - Praneetha Bodahr chemtek100% (1)

- Warehouse ManagementDocument31 pagesWarehouse ManagementASHOK SUTHARNo ratings yet

- 06.01.2021.warehouse ManagementDocument29 pages06.01.2021.warehouse ManagementArham OrbNo ratings yet

- 4.2.1warehouse ManagementDocument29 pages4.2.1warehouse ManagementhimmNo ratings yet

- Chapter 7 Warehouse Operations & ManagementDocument69 pagesChapter 7 Warehouse Operations & ManagementKhánh Đoan Lê Đình100% (1)

- Warehousing Management FinalDocument31 pagesWarehousing Management FinalSalah AnayaNo ratings yet

- Warehousing Management: Gaurav Narkhede - Josue Servalis - Mike Macas - Praneetha BodaDocument31 pagesWarehousing Management: Gaurav Narkhede - Josue Servalis - Mike Macas - Praneetha BodaNataraja Sekhar Reddy VaddamaniNo ratings yet

- WAREHOUSING MANAGEMENT FinalDocument22 pagesWAREHOUSING MANAGEMENT FinalPulkit MarwahNo ratings yet

- TRISEM252023-24 BMT6188 ETH VL2023240300005 2024-01-09 Reference-Material-IDocument32 pagesTRISEM252023-24 BMT6188 ETH VL2023240300005 2024-01-09 Reference-Material-ImrinfiniousNo ratings yet

- Warehousing Management: Gaurav Narkhede - Josue Servalis - Mike Macas - Praneetha BodaDocument32 pagesWarehousing Management: Gaurav Narkhede - Josue Servalis - Mike Macas - Praneetha Bodashahzaib aghaNo ratings yet

- Warehousing Unit - 1Document41 pagesWarehousing Unit - 1pramav2411No ratings yet

- (Mr.P.V.Bapat) 731 SCM Warehouse Management-Converted-CompressedDocument28 pages(Mr.P.V.Bapat) 731 SCM Warehouse Management-Converted-CompressedTayseer EltayebNo ratings yet

- Warehousing Management FinalDocument30 pagesWarehousing Management FinalMritunjay YadavNo ratings yet

- Inventory Management Chapter 5 Warehouse and Supply Chain ManagementDocument78 pagesInventory Management Chapter 5 Warehouse and Supply Chain ManagementPhương DungNo ratings yet

- Chapter 7 WarehouseDocument76 pagesChapter 7 Warehousenkminh19082003No ratings yet

- Warehousing ManagementDocument22 pagesWarehousing Managementdeepthikundan100% (1)

- Warehouse Management & LogisticsDocument28 pagesWarehouse Management & LogisticsShamsa Noorallah BudhwaniNo ratings yet

- Warehouse ManagementDocument89 pagesWarehouse ManagementSadeep SasankaNo ratings yet

- Warehousing ManagementDocument8 pagesWarehousing ManagementPoornika AwasthiNo ratings yet

- Warehouse ManagementDocument36 pagesWarehouse ManagementMochamad Sulaiman100% (5)

- Essentials of Warehouse ManagementDocument33 pagesEssentials of Warehouse ManagementXoanor Kluger100% (1)

- WarehousingDocument33 pagesWarehousingMervyn Joe Sebastian100% (2)

- Definition of WarehouseDocument14 pagesDefinition of WarehouseHímà SumânthNo ratings yet

- Angielski ZawodowyDocument35 pagesAngielski ZawodowyEgzoNNNNo ratings yet

- SAP EWM An IntroductionDocument26 pagesSAP EWM An Introductiondbabu7100% (2)

- Warehousing OperationsDocument24 pagesWarehousing OperationsRavi KumarNo ratings yet

- Warehousing ManagementDocument24 pagesWarehousing ManagementFrans N PandjaitanNo ratings yet

- Warehouse ManagementDocument28 pagesWarehouse ManagementRavi Singh100% (2)

- Warehousing & Storage Techniques - Lecture 5Document38 pagesWarehousing & Storage Techniques - Lecture 5Muhammad AhsanNo ratings yet

- Warehousing ConceptDocument68 pagesWarehousing ConceptJohana MiraflorNo ratings yet

- Chapter Five Cont'd : Warehousing and Matériels ManagementDocument27 pagesChapter Five Cont'd : Warehousing and Matériels ManagementTamratAfeworkNo ratings yet

- Logistics & WarehousingDocument27 pagesLogistics & WarehousingManasi PatilNo ratings yet

- Good Warehousing Practices (GWP)Document36 pagesGood Warehousing Practices (GWP)erikaoktavianipurba100% (1)

- Warehouse Management - PIM 1dayDocument21 pagesWarehouse Management - PIM 1dayIbrahimshoaibNo ratings yet

- Chapter 1Document9 pagesChapter 1Firdaus LasnangNo ratings yet

- CH 1 MaerialDocument47 pagesCH 1 MaerialBacha AyanaNo ratings yet

- Warehouse & Storage Techniques - Lecture 3Document29 pagesWarehouse & Storage Techniques - Lecture 3Muhammad AhsanNo ratings yet

- Warehousing 2Document17 pagesWarehousing 2abubakar arshadNo ratings yet

- Warehouse SpaceplanningDocument16 pagesWarehouse SpaceplanningShahrukh Ghulam Nabi0% (1)

- Lecture 7 - WAREHOUSING MANAGEMENTDocument51 pagesLecture 7 - WAREHOUSING MANAGEMENTsamwel100% (1)

- WAREHOUSING & STORAGE TECHNIQUES - Lecture 2Document31 pagesWAREHOUSING & STORAGE TECHNIQUES - Lecture 2Muhammad AhsanNo ratings yet

- C H A P T E R 9 Storage and Warehouse SystemsDocument114 pagesC H A P T E R 9 Storage and Warehouse SystemsKhaled SamaraNo ratings yet

- Store KeepingDocument60 pagesStore KeepingHaritha Mugunthan100% (2)

- Air Cargo Warehousing and Inventory ManagementDocument25 pagesAir Cargo Warehousing and Inventory Managementvageesha100% (1)

- Unit 2 Production MGTDocument63 pagesUnit 2 Production MGTVaish VarshNo ratings yet

- I I T T M: Warehousing ManagementDocument23 pagesI I T T M: Warehousing ManagementMoonka Ankit100% (1)

- Purchasing Plan Is Prepared As Per The Output From The MarketingDocument2 pagesPurchasing Plan Is Prepared As Per The Output From The MarketingArun SathyanNo ratings yet

- Chapter 7 - OPER8030Document44 pagesChapter 7 - OPER8030srinivas saiNo ratings yet

- An Introduction To Warehousing and The Underlying Facility Design IssuesDocument54 pagesAn Introduction To Warehousing and The Underlying Facility Design IssuesGabriele LorussoNo ratings yet

- Manh Warehouse Management Brochure enDocument8 pagesManh Warehouse Management Brochure enTanweer AlamNo ratings yet

- Warehousing and Storage in Supply Chain Management: Group MembersDocument58 pagesWarehousing and Storage in Supply Chain Management: Group MembersMuhamad Abi HaykalNo ratings yet

- Warehousing and Storage in Supply Chain ManagementDocument58 pagesWarehousing and Storage in Supply Chain ManagementGilles100% (1)

- Odoo WMS - Warehouse Management SystemDocument19 pagesOdoo WMS - Warehouse Management Systemanton widodo100% (1)

- Inventory Control and Types of Inventery PDFDocument19 pagesInventory Control and Types of Inventery PDFsreekanth3185No ratings yet

- Ome 664: Project Procurement and Contracting: Lecture Three: Warehouse ManagementDocument35 pagesOme 664: Project Procurement and Contracting: Lecture Three: Warehouse ManagementYonas Alemayehu100% (1)

- Material Handling Systems:: Submitted By: SWATI DUBEY (PG2018-P053) Logistics and Warehousing ManagementDocument23 pagesMaterial Handling Systems:: Submitted By: SWATI DUBEY (PG2018-P053) Logistics and Warehousing ManagementSwati DubeyNo ratings yet

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityFrom Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityRating: 5 out of 5 stars5/5 (3)

- Dec 2022Document8 pagesDec 2022John CNo ratings yet

- Jun SMSDocument43 pagesJun SMSgallardo0121No ratings yet

- Rankel Engine.Document16 pagesRankel Engine.Divya Prakash SrivastavaNo ratings yet

- MET Till DEC 2018 PDFDocument171 pagesMET Till DEC 2018 PDFt.srinivasanNo ratings yet

- Manual Construction Standards Completo CorregidozDocument240 pagesManual Construction Standards Completo CorregidozJose DiazNo ratings yet

- ANSYS Mechanical Basic Structural NonlinearitiesDocument41 pagesANSYS Mechanical Basic Structural NonlinearitiesalexNo ratings yet

- VX-1700 Owners ManualDocument32 pagesVX-1700 Owners ManualVan ThaoNo ratings yet

- 2015 Audi q5 sq5 71153 PDFDocument302 pages2015 Audi q5 sq5 71153 PDFPraveen100% (1)

- Technical Data For Elevator Buckets - Bucket ElevatorDocument1 pageTechnical Data For Elevator Buckets - Bucket ElevatorFitra VertikalNo ratings yet

- VAPORISERDocument62 pagesVAPORISERAshish ChavanNo ratings yet

- 01 Cone Winding Study (Calculation)Document4 pages01 Cone Winding Study (Calculation)Hasan Istiaque Ahmed60% (5)

- REE Copy PDFDocument9 pagesREE Copy PDFJake ZozobradoNo ratings yet

- Ruckus Wired Accreditation ExamDocument15 pagesRuckus Wired Accreditation ExamDennis Dube25% (8)

- Black Invention MythsDocument16 pagesBlack Invention MythsjoetylorNo ratings yet

- En 12604 (2000) (E)Document7 pagesEn 12604 (2000) (E)Carlos LanzillottoNo ratings yet

- (Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)Document66 pages(Ebook - Electronics) - Principles of PLL - Tutorial (Kroupa 2000)양종렬No ratings yet

- Droop Vs Iso Control Modes For Gas TurbinesDocument3 pagesDroop Vs Iso Control Modes For Gas TurbinesArdvark100% (1)

- Meitrack Gprs Protocol v1.6Document45 pagesMeitrack Gprs Protocol v1.6monillo123No ratings yet

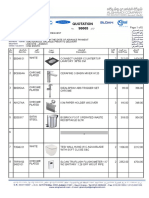

- Quotation 98665Document5 pagesQuotation 98665Reda IsmailNo ratings yet

- PB Hydro en PDFDocument86 pagesPB Hydro en PDFWahyu Tirta NugrahaNo ratings yet

- Vertical Take Off and LandingDocument126 pagesVertical Take Off and LandingMukesh JindalNo ratings yet

- Error Number Mentor GraphicsDocument30 pagesError Number Mentor GraphicsMendesNo ratings yet

- VarPlus Can - BLRCH104A125B48Document2 pagesVarPlus Can - BLRCH104A125B48Achira DasanayakeNo ratings yet

- Alloc 150 DMDocument301 pagesAlloc 150 DMSheik Mohamed ImranNo ratings yet

- (WWW - Manuallib.com) - MOELLER EASY512&Minus AB&Minus RCDocument8 pages(WWW - Manuallib.com) - MOELLER EASY512&Minus AB&Minus RCErik VermaakNo ratings yet

- Elvax 460Document3 pagesElvax 460ingindjorimaNo ratings yet

- Transfer Action in Sap HRDocument3 pagesTransfer Action in Sap HRKarthi MrvkNo ratings yet

- Toyota Vios Ecu Wiring DiagramDocument4 pagesToyota Vios Ecu Wiring DiagramSri Yuniati17% (6)

- Wastewater Treatment Options For Paper Mills Using Waste Paper/imported Pulps As Raw Materials: Bangladesh PerspectiveDocument4 pagesWastewater Treatment Options For Paper Mills Using Waste Paper/imported Pulps As Raw Materials: Bangladesh PerspectiveKool LokeshNo ratings yet

- BEC198 (Finals)Document180 pagesBEC198 (Finals)Lorenz BerroyaNo ratings yet