Professional Documents

Culture Documents

Aw 450

Uploaded by

ruslan15800 ratings0% found this document useful (0 votes)

144 views36 pagesOriginal Title

AW-450

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

144 views36 pagesAw 450

Uploaded by

ruslan1580Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 36

AW 450-43LE

Preliminary Information About a

Transmission Youll Be Seeing Soon!

Produced by AAMCO Transmissions Inc.

Technical Services Department

AW 450-43LE KWIK NOTES

34

Table of Contents

AW 450-43LE TRANSMISSION................................................. 1

Construction.................................................................................. 2

Electrical Diagnosis ...................................................................... 3

Typical TCM Connector Pin Layout......................................... 11

Clutch & Solenoid Application Chart ...................................... 12

Specifications ............................................................................... 13

Torque Specifications.................................................................. 16

Component Parts ........................................................................ 17

Oil Pump...................................................................................... 20

Overdrive Planetary Gear ......................................................... 21

Overdrive Brake ......................................................................... 22

Continued......

AW 450-43LE KWIK NOTES

35

Table of Contents

Front Clutch................................................................................ 23

Rear Clutch ................................................................................. 24

Second Brake............................................................................... 25

Planetary Gears, One-Way Clutch and Output Shaft ............. 26

First and Reverse Brake............................................................. 27

Extension Housing ...................................................................... 28

Valve Body ................................................................................... 29

AW 450-43LE KWIK NOTES

1

AW 450-43LE TRANSMISSION

AW 450-43LE KWIK NOTES

2

e g n a R

d e e p S e n i g n E

g n i l d I g n i l l a t S

D

4 8 7 - 9 2 5

) 4 1 1 - 7 7 (

0 8 4 1 - 0 9 9

) 5 1 2 - 4 4 1 (

R

7 2 1 1 - 5 5 7

) 4 6 1 - 0 1 1 (

7 0 1 2 - 1 0 4 1

) 6 0 3 - 3 0 2 (

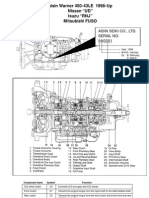

Construction

Line Pressure Test

Line Pressure Test Port

kPa(PSI)

1. Torque Converter Housing

2. Torque Converter

3. Transmission Case

4. Overdrive Direct Clutch

5. Overdrive Brake

6. Overdrive One-way Clutch

7. Overdrive Planetary gear

8. Front Clutch

9. 2nd Brake

10. Rear Clutch

11. Front Planetary Gear

12. No. 2 One-way Clutch

13. 1st and Reverse Brake

14. Rear Planetary Gear

15. Parking Lock Gear

16. Output Shaft

17. Overdrive Input Shaft

18. Oil Pump

19. Oil Pan

20. Valve Body

21. Input Shaft

22. PTO Drive Gear

23. Intermediate Shaft

24. Extension Housing

25. Speedmeter Drive Gear

AW 450-43LE KWIK NOTES

3

Electrical Diagnosis

Isuzu NPR, GMC Tiltmaster 1999

Checking Codes

Locate the green 3-pin Data Link Connector (DLC) under the left side of the dash near the brake

master cylinder (See Figure 1). You may also find a 16-pin OBD II type DLC. In either case use

the green 3-pin connector. To retrieve trouble codes use a suitable jumper to connect the two

outside terminals of the DLC. With the jumper in place any trouble codes present will be displayed

on the CHECK TRANS light (See Figure 3). The codes will appear as groups of short flashes.

For example a code 31 would look like this: flash-flash-flash pause flash = 31. Each code will be

displayed three times. If no faults are present code 1 will flash repeatedly.

Clearing Codes

1. Turn the ignition switch on but do not start the engine.

2. Connect a suitable jumper wire between the two outside terminals of the green 3-pin DLC.

3. Shift the transmission to the NEUTRAL position.

4. Depress the brake pedal fully.

5. Depress the accelerator pedal fully.

4. If memory is clear the CHECK TRANS light will flash rapidly for 10 seconds.

Isuzu NPR, GMC Tiltmaster 2000-2003

Checking Codes

Locate the 16 pin OBD II type Data Link Connector (DLC) under the left side of the dash near the

brake master cylinder. Connect a suitable jumper wire between terminal 11 and terminal 4 or 5 of

the DLC (See Figure 2). Flashes of the CHECK TRANS light will display any trouble codes

present (See Figure 3). The codes will appear as groups of short flashes. For example a code 31

would look like this: Flash-flash-flash pause flash = 31. Each code will be displayed three times. If

no faults are present code 1will flash repeatedly.

Clearing Codes

1. Turn the ignition switch on but do not start the engine.

2. Connect a suitable jumper wire between terminal 11 and terminal 4 or 5 of the DLC.

3. Shift the transmission to the NEUTRAL position.

4. Depress the brake pedal fully.

5. Depress the accelerator pedal fully.

4. If memory is clear the CHECK TRANS light will flash rapidly for 10 seconds.

AW 450-43LE KWIK NOTES

4

1 2 4 6 7 8

1516 13 9 1112

Green 3-Pin Diagnostic Connector Location

Isuzu, Tiltmaster

Figure 1

Figure 2

OBDII Diagnostic Connector Location

Isuzu, Tiltmaster

14

3 5

10

AW 450-43LE KWIK NOTES

5

Figure 3 Check Trans Light

Isuzu, Tiltmaster

99-03

AW 450-43LE KWIK NOTES

6

Electrical Diagnosis

Checking Codes

Locate the group of diagnostic connectors under the left side of the dash near the drivers kick panel.

Using a suitable jumper connect diagnostic connector I-14 (blue/yellow wire) and 1-15 (black

wire) together (See Figure 4). Flashes of the ATM warning light will display any trouble codes

present (See Figure 5). The codes will appear as groups of short flashes. For example a code 31

would look like this: Flash-flash-flash pause flash = 31. Each code will be displayed three times. If

no faults are present code 1will flash repeatedly.

Clearing Codes

1. Turn the ignition switch on but do not start the engine.

2. Connect diagnostic connectors 1-14 and 1-15 together.

3. Place the shift lever in the PARK position.

4. Depress the brake pedal fully.

5. Depress the accelerator pedal fully.

6. When the memory is cleared the ATM warning indictor will flash rapidly for 10 seconds.

7. If the memory is not cleared repeat procedure as necessary.

Nissan UD 1999-2003

Code list Isuzu, GMC Tiltmaster, Nissan UD

Code Description

11. Vehicle Speed Sensor #1 (on transmission)

13. Engine Revolution Sensor

15. ATF Temperature Sensor

17. Inhibitor Switch

21. Accelerator Sensor

24. Vehicle Speed Sensor #2 (on transmission)

31. Shift Solenoid A

32. Shift Solenoid B

33. Timing Solenoid

34. Lock-up Solenoid

35. Line Pressure Solenoid

37. Exhaust Brake System

38. Engine Warm-up Cut System*

* Isuzu, Tiltmaster Only

AW 450-43LE KWIK NOTES

7

Figure 5

ATM Warning Light

Nissan UD

Manual Code Retrieval

AW 450-43LE KWIK NOTES

8

Electrical Diagnosis

Mitsubishi Fuso 1999-2003

Checking Codes

Turn the ignition switch on but do not start the engine. Disconnect the Diagnosis Switch connector

located under the dash to the left of the steering column (See Figure 6). The Diagnosis Switch

connector will have a green/blue wire one side and a black wire on the other. Flashes of the auto

matic transmission warning light will display any trouble codes present (See Figure 7). Long flashes

indicate tens and short flashes indicate ones. For example code 24 would look like this:

long-long-short-short-short-short = 24. Each code will be displayed three times. If no faults are

present code 1 will flash repeatedly.

Clearing Codes MO35A4

1. Keep the Diagnosis Switch connector connected

2. Turn the ignition key on but do not start the engine.

3. Disconnect the Memory Clear Switch (See Figure 6) connector located under the dash to the left

of the steering column. The Memory Clear Switch connector will have a black/white wire

on one side and a black wire on the other.

4. After more than one second reconnect the Memory Clear Switch connector.

5. After three seconds the codes will be cleared.

Code List Mitsubishi Fuso

Code Description

11 Abnormal Power Supply Voltage

12 Vehicle Speed Sensor #1

13 ATF Temperature Sensor

15 Engine Revolution Sensor

24 Accelerator Sensor

25 Vehicle Speed Sensor #2

31 Shift Solenoid A

32 Shift Solenoid B

34 Line Pressure Solenoid

35 Lock-Up Solenoid

43 Inhibitor Switch

50 PTO Solenoid

51 Timing Solenoid

54 Exhaust bake system

58 PWM Signal

AW 450-43LE KWIK NOTES

9

Diagnosis

Switch

Memory

Clear

Switch

Fuso 1999-2003

Automatic Transmission Warning Light

Figure 6

Diagnostic Switch Connector

Mitsubishi Fuso 99-03

Figure 7

Mitsubishi Fuso 99-03

AW 450-43LE KWIK NOTES

10

B-79

B-79

B-79

B-79

Data

Link

Connector

Green 3 Pin

J-19 (3) Relay; Eng Warm Cut2

J-19 (4) Relay; Eng Warm Cut 2

V-2 (1) VSV; FISD

B-233 (14) ECM

J-18 (2) Relay; EXH Brake Cont

B-110 (7) EBCM

F-10 10A

Stop Light

1

B-66

0.5G/Y

SW; Stop Light

B-66

F-12 10A

MeterBack (1) ECM

0

. 5

B

/

Y

H-12

9

3

B

/ Y

3

B

67

B-51

8

O

F

F

A

C

C

O

N

S

T

STARTER

SWITCH

5

W

2

B

B

67

3

W

/B

1

H

7

2

H

6

5

W

3

W

/ B

0

.5

B

/

Y

FL-2 50A

KEYSW

8

W

FL-1

80A

MAIN

8

B

2

L

B-233

1 3

0

.

3

O

H

12

0.5LG/R

2

H 12

Relay;Tail

B-22 (5)

0.3O

B-51

B-51

5 0.3O/B

9

B-51

2 20

H-4

1

J-129

0.5Y/G 0.5Y/G

OD OFF

CHECKTRANS

ATOILTEMP

P

.

1

P

.

3

P

.

4

P

.

5

FRAME

0.5B/Y

J-12 (5) RELAY;STARTER

0.5B/Y

1

B-231

Illum. Cont

(3)

H-12

5

0.5LG/B

2

N

1

N

1

N

1

N

1

0

.5

B

4

S

W

;

O

D

O

F

F

0.3O 6

B-230

8

9

B-229

15

B-230

SW;ATF

TCM

B-160

5

4

7

11

0.5B

0.5B

0.3Y

0.5B/W

2

8

B-229

B-230

0.5LG/W

18

H-4

0.5LG/W 12

B-230

0.5B/R 19

H-4

0.5B/R 23

B-229

0.5L/G 8

H-4

0.5L/G

B-230

4

0.5L/G

1

B-230

0.5B/G 24

H-5

0.5B/G 22

B-229

0.5R/B 11

B-230

Stop Light

2 0.5G 0.5G 12

B-231

0.3LG

B-232

4 9

0.5L/O

1

B-229

Joint Connector2

B-233 (7) ECM

0.5B/G 16

B-230

J-71

B-229

25

0.5BR/G

H-4

0.5BR/G

5

B-229

13 0.5BR/Y

H-4

0.5BR/Y

4

J-71

B-229

12 0.5BR/R

4

H-4

0.5BR/R

J-71

B-229

11

0.5BR/B

H-4

0.5BR/B 2

J-71

B-229

24 0.5BR/W

H-4

0.5BR/W 8

J-71

VEHICLE

LOCKUP SOL

TIMINGSOL

SHIFT SOL S2

SHIFT SOL S1

12

3

9

13

5

H-4

7

3

B-229

H-4

0.5L/Y

0.5L/G

J-73

J-73

2 0.5P 16

B-229

B-229

15

B-229

B-229

6

0.5L/Y

0.5L/Y

6

J-71

20 0.5Y 0.5Y

J-71

B-229

26 0.5BR 0.5BR 1

J-71

3

0.5L

10

2

6

14

H-4

1

H-4

H-4

H-4

SP2

LINEPRRESSSOL

OILTEMPSENSOR

0

. 5

B

B-229

4

B-55 (2) METER

18 1

B-80

B-80

B-80

B-229

B-229

5

2

19 3 GND

5V

THROTTLE

SENSOR

SW;KICKDOWN

B-230

7

B-231

8

3

B-229

B-231

0.5B 1

B-76 B-76

2

2

0.5R/W

0.5L/Y

0.5B

0.5GR/L 7

0.3W

JOINT

CONNECTOR

2

0.5R/G

B-29

J-69 B-231

0.5L/W 2

0.5L/R 3

0.5L/O 4

H-4

0.5W/R 6

9 0.5R/L

H-5

29 0.5R/L 7

3 0.5W/R 7 0.5W/R 5

J-69

BACKUP LIGHT SW;INHIBITOR

J-69 B-231

B-231

6 0.5L/W

H-4

11 0.5L/R

H-4

16

J-69

10 0.5L/O

H-4

17

J-69

4 0.5W/R 11

J-69

15

B-231

B-231

B-231

0

.5

B

B-7

3

B

P

R

N

D

2

1

J-9

P

.

2

0.5B/R 12

J-69

8 0.5B/Y 22

H-5

J-69

B

C

P

J-69

9

2

B

N N 0.5B

H-4

1

8

2

B

Typical Wiring Diagram

AW 450-43LE KWIK NOTES

11

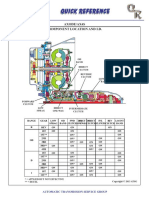

Typical TCM Connector Pin Layout

B229 B230 B231

13 12 11 10 9 8 7 6 5 4 3 2 1

26 25 24 23 22 21 20 19 18 17 16 15 14

8 7 6 5 4 3 2 1

16 15 14 13 12 11 10 9

6 5 4 3 2 1

12 11 10 9 8 7

(26 pin)

(16 pin)

(12 pin)

Pin No. Function

B231-1 Ignition signal

B231-2 Battery Ground

B231-3 Shift position; P range signal

B231-4 Shift position; N range signal

B231-5 Not used

B231-6 Shift position; 1 range signal

B231-7 Not used

B231-8 Battery ground

B231-9 Shift position; R range signal

B231-10 Shift position; D range signal

B231-11 Shift position; 2 range signal

B231-12 Brake Switch

B230-1 Exhaust brake signal

B230-2 Not used

B230-3 Not used

B230-4 Idle up signal

B230-5 Not used

B230-6 O/D OFF switch

B230-7 Kick-down switch

B230-8 Diagnostic enable signal

B230-9 Idle Switch UD only

B230-10 Not used

B230-11 ABS (Anti-lock brake system) signal

B230-12 QWS (Engine warming up system)

signal (Not used UD)

B230-13 Not used

B230-14 Not used

B230-15 ATF Temperature switch

B230-16 Idle signal (Not used UD)

Pin No. Function

B229-1 Engine speed sensor

B229-2 Not used

B229-3 Vehicle speed sensor (Transmission/+)

B229-4 Vehicle speed sensor (Speedometer)

B229-5 Throttle position sensor

B229-6 ATF Thermosensor (+)

B229-7 Not used

B229-8 Engine over-running light (Not used UD)

B229-9 Check trans indicator light (ATM)

B229-10 Not used

B229-11 Timing solenoid (ST)

B229-12 No. 2 shift solenoid (S2)

B229-13 No. 1 shift solenoid (S1)

B229-14 Not used

B229-15 Shield for No. B229-3

B229-16 Vehicle speed sensor (Transmission/-)

B229-17 Not used

B229-18 Throttle position sensor voltage

B229-19 Throttle position sensor ground

B229-20 ATF Thermosensor (-)

B229-21 Serial data (Scan tool)

B229-22 Exhaust brake cut signal

B229-23 QWS (Engine warming up system) cut

signal (Not used UD)

B229-24 Lock-up solenoid

B229-25 Line pressure solenoid (-)

B229-26 Line pressure solenoid (+)

AW 450-43LE KWIK NOTES

12

Clutch & Solenoid Application Chart

t f i h S

n o i t i s o P

n u r r e v O

h c t u l C

d r a w r o F

h c t u l C

4 - 3

h c t u l C

e v i r d r e v O

e k a r B

d n o c e S

e k a r B

e s r e v e R / w o L

e k a r B

t u p n I

g a r p S

w o L

g a r p S

t f i h S

1 d i o n e l o S

t f i h S

2 d i o n e l o S

P

o o

R

o o o x

N

o o

D

t s 1

o o x x o

d n 2

o o x o o

d r 3

o o o x o

D / O

o o o

2

t s 1

o o x x o

d n 2

o o o x o o

d r 3

o o o x o

L

t s 1

o o o x x o

d n 2

o o o x o o

d r 3

o o o x o

o - Applied

x - Applied when accelerating

AW 450-43LE KWIK NOTES

13

Specifications

AW 450-43LE KWIK NOTES

14

Specifications

AW 450-43LE KWIK NOTES

15

Specifications

e p y T d i u l F y t i c a p a C

I I I n o r t x e D ) S T Q 5 . 4 1 ( L 5 . 3 1

Transmission Fluid

AW 450-43LE KWIK NOTES

16

Torque Specifications

d e n e t h g i T t r a P m . N ) n i . b l ( t f - b l

y d o b p m u p l i O o t r e v o c p m u p l i O 1 2 5 1

y d o b e v l a v r e w o L o t y d o b e v l a v r e p p U 5 . 5 4

y d o b e v l a v r e w o L o t g n i r p s t n e t e d l a u n a M 5 . 5 ) 7 4 (

g n i s u o h n o i s n e t x E o t t e k c a r b l w a p k c o l g n i k r a P 9 1 4 1

e s a c n o i s s i m s n a r T o t r e v o c r o t a l u m u c c a 1 C 8 ) 9 6 (

g n i s u o h n o i s n e t x E o t e s a c n o i s s i m s n a r T 7 3 7 2

t l o b t e s t r o p p u s r e t n e C 5 2 8 1

e s a c n o i s s i m s n a r T o t n a p l i O 7 ) 1 6 (

g n i s u o h n o i s s i m s n a r T o t e s a c n o i s s i m s n a r T 4 6 7 4

e s a c n o i s s i m s n a r T o t r o s n e s e r u t a r e p m e t F T A 5 2 8 1

e s a c n o i s s i m s n a r T o t n o i n u r e l o o c l i O 9 2 2 2

e s a c n o i s s i m s n a r T o t h c t i w s r o t i b i h n I 5 . 2 1 ) 8 7 (

t f a h s e v l a v l a u n a M o t h c t i w s r o t i b i h n I 7 ) 1 6 (

e s a c n o i s s i m s n a r T o t t f a h s l o r t n o C 5 . 2 1 ) 8 7 (

e s a c n o i s s i m s n a r T o t p m u p l i O 5 2 8 1

e s a c n o i s s i m s n a r T o t y d o b e v l a V 0 1 ) 7 8 (

y d o b e v l a V o t e v l a v d i o n e l o S 0 1 ) 7 8 (

y d o b e v l a V o t r e n i a r t s l i O 0 1 ) 7 8 (

n a p l i O o t g u l p n i a r D 7 2 0 2

e s a c n o i s s i m s n a r T o t e t a l p k c o l e v e e l s r e t e m o d e e p S 5 . 2 1 ) 8 7 (

e s a c n o i s s i m s n a r T o t r o s n e s d e e p S 8 ) 9 6 (

e s a c n o i s s i m s n a r T o t e r i w d i o n e l o S 8 ) 9 6 (

e s a c n o i s s i m s n a r T o t r e v o c O T P 5 1 1 1

AW 450-43LE KWIK NOTES

17

Component Parts

1. O-ring

2. Oil Cooler Union

3. Clip

4. Hose

5. Clip

6. ATF Temperature Switch

7. O-ring

8. Oil Cooler Union

9. O-ring

10. Transmission Solenoid Wire

11. Bolt

12. O-ring

13. Parking Lock Gear

14. Speedometer Drive Gear

15. Spacer

16. Torque Converter Housing

17. Nut

18. Nut

19. Control Shaft Lever

20. Bolt

21. Gasket

22. PTO cover

23. Bolt

24. Bolt

25. Lock Plate

26. O-ring

27. Speedometer Drive Gear

28. Speedometer Sleeve

29. Clip

30. Gasket

31. Vehicle Speed Sensor 1

32. Bolt

33. Oil Seal

34. Companion Flange

35. O-ring

36. Lock Nut

37. Extension Housing

38. Bolt

39. Inhibitor Switch

40. Bolt

41. Grommet

42. Lock Washer

43. Nut

AW 450-43LE KWIK NOTES

18

Component Parts

1. Spring

2. O-ring

3. C1 Accumulator

4. O-ring

5. Gasket

6. Plate

7. Front Clutch Accumulator Cover

8. Bolt

9. Transmission Case

10. Center Support Apply Gasket

11. Spring

12. O-ring

13. B0 Accumulator Piston

14. O-ring

15. O-ring

16. Spring

17. C2 Accumulator Piston

18. B1 Accumulator Piston

19. O-ring

20. Spring

21. Valve Body Assembly

22. Bolt

23. Oil Seal

24. Magnet

25. Oil Stainer

26. Bolt

27. Manual Valve Lever Shaft

28. Spacer

29. Parking Lock Rod

30. Oil Pan

31. Drain Plug

32. Gasket

33. Bolt

34. Pin

35. Manual Valve Lever

36. Oil Seal

AW 450-43LE KWIK NOTES

19

Component Parts

1. Bolt

2. Oil Pump

3. O-ring

4. Gasket

5. Race

6. Thrust Bearing

7. O/D Planetary Gear,

O/D Direct Clutch and

One-way Clutch Assembly

8. Thrust Bearing

9. O/D Ring Gear assembly

10. Race

11. Thrust Bearing

12. Race

13. O/D Case Assembly

14. O-ring

15. Race

16. Thrust Bearing

17. Race

18. Spacer

19. Oil Seal ring

20. Front Clutch Assembly

21. Thrust Bearing

22. Race

23. Rear Clutch Assembly

24. Center Support assembly

25. Bolt

26. Thrust Washer

27. Snap Ring

28. Planetary Gear,

One-Way Clutch and

Output Shaft Assembly

29. O-ring

AW 450-43LE KWIK NOTES

20

Oil Pump

1. Oil Seal

2. Oil Pump Body

3. Oil Pump Driven Gear

4. Oil Pump Drive Gear

5. Oil Pump Cover

6. Bolt

7. Oil Seal Ring

8. Check Ball

9. Spring

10. Spring Seat

AW 450-43LE KWIK NOTES

21

Overdrive Planetary Gear and

Direct Clutch

. o N . n i s s e n k c i h T . o N . n i s s e n k c i h T

A 1 8 1 . 0 C 4 9 1 . 0

B 8 8 1 . 0 D 1 0 2 . 0

Selective Pressure Plates

O/D Direct Clutch Clearance .071-.081 in.

Sprag Rotation

1. O/D Direct Clutch Drum

2. O-ring

3. O/D Direct Clutch Piston

4. Piston Return Spring

5. Snap Ring

6. Plate

7. Disc

11. Thrust washer

12. One-way Clutch Outer Race

13. Retainer

14. One-way Clutch

8. Flange (Selective)

9. Snap Ring

10 . Snap Ring

15. Thrust Washer

16. O/D Planetary Gear

17. Thrust washer

18. Planetary Ring Gear

19. Ring Gear Flange

20. Snap Ring

21. Oil Seal Ring

AW 450-43LE KWIK NOTES

22

Overdrive Brake

OD Brake Clearance .049-.073 in. Not Adjustable

1. Snap Ring

2. Flange

3. Disc

4. Plate

5. Snap Ring

6. Piston Return Spring

7. O/D Brake Piston

8. O-ring

9. O/D Case

10. Ring Retainer

11. Oil Seal Ring

AW 450-43LE KWIK NOTES

23

Front Clutch

Front Clutch Clearance .155-.166 in

. n i s s e n k c i h T . n i s s e n k c i h T

1 7 0 . 0 7 8 0 . 0

9 7 0 . 0 4 9 0 . 0

NOTICE: P = This plate is used to

adjust clutch clearance.

Selective Clutch Plates

1. Front Clutch Drum

2. O-ring

3. Front Clutch Piston

4. Piston return spring

5. Snap Ring

6. Cushion Plate

7. Plate

8. Disc

9. Race

10. Thrust Bearing

11. Front Clutch Hub

12. Rear Clutch Hub

13. Snap Ring

AW 450-43LE KWIK NOTES

24

Rear Clutch

Rear Clutch Clearance 0.79 - .087 in

Selective Pressure Plates

. o N . n i s s e n k c i h T . o N . n i s s e n k c i h T

A 7 9 1 . 0 E 1 8 1 . 0

B 5 0 2 . 0 F 9 8 1 . 0

1. Snap Ring

2. Flange (Selective)

3. Disc

4. Plate

5. Snap Ring

6. Piston Return Spring

7. Rear Clutch Piston

8. O-ring

9. Rear Clutch Drum

AW 450-43LE KWIK NOTES

25

Second Brake

Second Brake Clearance .073 - .081 in.

. o N . n i s s e n k c i h T . o N . n i s s e n k c i h T

A 7 9 1 . 0 C 3 1 2 . 0

B 5 0 2 . 0 D 0 2 2 . 0

Selective Pressure Plates

1. Flange (Selective)

2. Plate

3. Snap Ring

4. Disc

5. Snap Ring

6. Piston return Spring

7. Second Brake Piston

8. O-ring

9. Snap Ring

10. Oil Seal Ring

11. Center Support

12. Front Planetary Sun Gear

13. Retainer

AW 450-43LE KWIK NOTES

26

Planetary Gears, One-Way Clutch

and Output Shaft

Sprag Rotation

1. One-way Clutch

2. Front Planetary Gear

3. No. 1 Thrust Washer

4. Front Planetary Ring Gear

5. Snap Ring

6. No. 2 Thrust washer

7. O-ring

8. Rear Planetary Gear

9. Rear Planetary Sun Gear

10. Thrust Bearing

11. Oil Seal Ring

12. Intermediate Shaft

13. Snap Ring

14. Rear Planetary Ring Gear

15. Ring Gear Flange

16. Snap Ring

17. Thrust Bearing

18. Output Shaft

19. Snap Ring

AW 450-43LE KWIK NOTES

27

First and Reverse Brake

First and Reverse Brake Clearance .130 - .150 in.

Selective Pressure Plates

. o N s s e n k c i h T

E 8 1 6 2 . 0

F 6 7 7 2 . 0

G 3 3 9 2 . 0

in.

1. Snap Ring

2. Flange (Selective)

3. Disc

4. Plate

5. Cushion Plate

6. Snap Ring

7. Piston Return Spring

8. First and Reverse Brake Piston

9. O-ring

10. Output Shaft Front Bearing

AW 450-43LE KWIK NOTES

28

Extension Housing

1. Oil Seal Ring

2. Bearing

3. Snap Ring

4. Bracket

5. Torsion Spring

6. Washer

7. Parking Lock Pawl Shaft

8. Parking Lock Pawl

AW 450-43LE KWIK NOTES

29

Valve Body

Upper Valve Body:

1. 2-3 Shift Valve

2. Reverse Inhibitor Valve

3. Modulator Valve

4. Throttle Valve

5. Secondary Regulator Valve

6. Reducing Valve

7. Lock-up Signal Valve

8. Accumulator Control Valve

9. Low Coast Modulator Valve

10. Orifice Control Valve

11. Low Inhibitor Valve

12. Check Valve

Lower Valve Body:

1. Manual Valve

2. 1-2 Shift Valve

3. 3-4 Shift Valve

4. Pressure Relief Valve

5. Primary Regulator Valve

6. Lock-up Control Valve

7. C0 Exhaust Valve

8. 2-3 Timing Valve

9. Cut-back Valve

AW 450-43LE KWIK NOTES

30

Valve Body

1. Pressure Relief Valve

2. Case

1. Strainer

AW 450-43LE KWIK NOTES

31

NOTICE: Each bolt length is indicated in the

illustration.

Bolt length:

A . n i 0 1 . 1

B . n i 6 2 . 1

C r e h s a w h t i w . n i 2 4 . 1

D . n i 7 5 . 1

Upper Valve Body Bolts

NOTICE: Each bolt length is indicated in the

illustration.

Bolt length:

A . n i 7 9 . 1

B . n i 5 6 . 1

C r e h s a w h t i w . n i 7 9 . 1

D . n i 7 9 . 1

E . n i 9 0 . 2

Lower Valve Body Bolts

NOTICE: Each bolt length is indicated in the

illustration.

Bolt length:

A . n i 5 6 . 1

B . n i 7 9 . 1

Plate Installation

Torque All Bolts: 5.5 N.m (48 lb.in.)

Valve Body

AW 450-43LE KWIK NOTES

32

Valve Body

Accumulator Installation

NOTICE: Each bolt length is indicated in the

illustration.

Bolt length:

A . n i 7 8 . 0 E . n i 7 5 . 1

B . n i 0 1 . 1 F . n i 1 6 . 1

C . n i 6 2 . 1 G . n i 7 7 . 1

D . n i 8 4 . 1 H . n i 5 0 . 2

I . n i 4 2 . 2

Torque 10 N m (88 lb in.)

h t g n e l e e r F r e t e m a i D r o l o C

0 - B ) 3 7 6 . 2 ( ) 1 3 8 . 0 ( e t i h W

) r e p p U ( 1 - B ) 7 9 1 . 1 ( ) 3 3 4 . 0 ( w o l l e Y

) w o L ( 1 - B ) 8 9 5 . 2 ( ) 8 8 9 . 0 ( w o l l e Y

2 - C ) 0 2 2 . 3 ( ) 2 8 8 . 0 ( e g i e B

Spring diameter and free length in.

Valve Body Bolt

Bolt length:

A . n i 3 6 . 0

B . n i 8 2 . 1

Torque 10 N m (88 lb-in)

Oil Strainer Installation

Accumulator Installation

h t g n e L e e r F 3 7 6 . 3

r e t e m a i D 7 9 6 . 0

r o l o C d e R

Spring Diameter in.

.

.

AW 450-43LE KWIK NOTES

33

Produced By AAMCO Transmissions, Inc.

Technical Service Department

For exclusive use of licensed AAMCO dealers ONLY.

Any Unauthorized use or reproduction, by any means, of the

illustrations or text in this book is a copyright violation and a

criminal offense punishable by fine, imprisonment or both

2005 AAMCO Transmissions, Inc.

All Rights Reserved. Printed in U. S. A. 80A-5270

You might also like

- Aisin Warner 450-43LE 1998-Up - Nissan UD - Isuzu RNJ - Mitsubishi FUSO 94628 TransmissionDocument8 pagesAisin Warner 450-43LE 1998-Up - Nissan UD - Isuzu RNJ - Mitsubishi FUSO 94628 Transmissionchente_b100% (2)

- AW450 43LE ManualDocument6 pagesAW450 43LE ManualEnrique Villamizar Laguado0% (1)

- Nissan 4N71B Transmission Checkball LocationsDocument104 pagesNissan 4N71B Transmission Checkball LocationsFSR1407No ratings yet

- Index: Technical Service InformationDocument96 pagesIndex: Technical Service Informationjose alvarezNo ratings yet

- 30 80le PDFDocument120 pages30 80le PDFJhonnyNo ratings yet

- A541e Automatic TransaxleDocument132 pagesA541e Automatic TransaxleHuey_7480% (10)

- Honda Px4bDocument101 pagesHonda Px4bRoberto Perez100% (1)

- Automatic Transmission - IsuzuDocument256 pagesAutomatic Transmission - Isuzumangyan100% (3)

- Aw450 43 Tech InfoDocument8 pagesAw450 43 Tech Infomasakp0% (1)

- Isuzu JR403E - ATSG Automatic Transmission Service GroupDocument120 pagesIsuzu JR403E - ATSG Automatic Transmission Service GroupElisio Marques100% (2)

- U151E ComponentsDocument203 pagesU151E ComponentsAndres Chavez Barrios100% (3)

- KM 175 PDFDocument96 pagesKM 175 PDFJhonny100% (2)

- Aisin As68rc Tech Info PDFDocument5 pagesAisin As68rc Tech Info PDFtambache69100% (1)

- 2014 Automatic V11 ECat CompleteDocument966 pages2014 Automatic V11 ECat Completesasha21123100% (2)

- Abbreviations Used in This ManualDocument126 pagesAbbreviations Used in This ManualSteve Fisher100% (6)

- Nissan RE4F04AV Overhaul PDFDocument91 pagesNissan RE4F04AV Overhaul PDFpedro melendez100% (2)

- KM171Document96 pagesKM171Cambio Automático do BrasilNo ratings yet

- Manual de Caja V4a51 PDFDocument141 pagesManual de Caja V4a51 PDFFrank Solano100% (1)

- Toyota Corolla A-131L OVERHAULDocument61 pagesToyota Corolla A-131L OVERHAULgerber damian100% (2)

- 6T40 Internal: Presented By: Bill Brayton ATRA Senior Research TechnicianDocument45 pages6T40 Internal: Presented By: Bill Brayton ATRA Senior Research TechnicianAntonio Del Angel80% (5)

- JR405EDocument8 pagesJR405ELalo Barajas Garcia100% (2)

- 2001 Honda Odyssey Transm. B7TA B7XADocument62 pages2001 Honda Odyssey Transm. B7TA B7XAAgustin Chaparro Tirado86% (14)

- Atra PDFDocument146 pagesAtra PDFRenan100% (3)

- GEARS August 2016Document68 pagesGEARS August 2016Rodger Bland100% (3)

- Toyota A40a41 A43da43de Aw70 Aw71 Atsg Automatic Transmission Service GroupDocument112 pagesToyota A40a41 A43da43de Aw70 Aw71 Atsg Automatic Transmission Service Groupanon_575426223100% (2)

- Gearbox M-A PDFDocument98 pagesGearbox M-A PDFLeonel AlvarezNo ratings yet

- Toyota U151E U151F Automatic Transmission Repair Manual RM1021UDocument151 pagesToyota U151E U151F Automatic Transmission Repair Manual RM1021UGary100% (2)

- RE5R05A Overview 2007Document4 pagesRE5R05A Overview 2007Alfonso100% (1)

- Toyota Ab60e and Ab60f Automatic TransmissionDocument52 pagesToyota Ab60e and Ab60f Automatic Transmissioncfi2834657100% (10)

- CVTDocument240 pagesCVTمحمد جاسم100% (2)

- Technical Bulletin Toyota Atf 2004 PDFDocument2 pagesTechnical Bulletin Toyota Atf 2004 PDFanon_5754262230% (1)

- C68RCDocument67 pagesC68RCYovani Gamaliel100% (5)

- 6l BulletinDocument18 pages6l BulletinFSR1407100% (1)

- Code False Akpp 5r55Document7 pagesCode False Akpp 5r55VobsStrongNo ratings yet

- Import Checkball Vol III 82-92 PDFDocument11 pagesImport Checkball Vol III 82-92 PDFJulio Chalbaud100% (1)

- HondaDocument4 pagesHondaErick Garcia Calvario100% (4)

- Mitsubishi S Valve BodiesDocument4 pagesMitsubishi S Valve BodiesReydeEspa1100% (1)

- 6R80 Updates PDFDocument41 pages6R80 Updates PDFIsaac Galvez Escudero100% (7)

- Gm4l30e 1Document6 pagesGm4l30e 1Juan GarciaNo ratings yet

- Bulletin 6l90 PDFDocument4 pagesBulletin 6l90 PDFAnonymous WzR5h9g8VNo ratings yet

- 1 4906800698873610302 PDFDocument112 pages1 4906800698873610302 PDFGabrielNo ratings yet

- Dokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFDocument5 pagesDokumen - Tips - Technical Service Information Atsg Toyotalexus U150u250 Preliminary Information PDFAleksandr Kuznichenko0% (1)

- 5R55S Cooler Thermal Bypass FixDocument4 pages5R55S Cooler Thermal Bypass FixDon Jenkins100% (2)

- GM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandGM 4L80E Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WFrom EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WRating: 4.5 out of 5 stars4.5/5 (6)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildFrom EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildRating: 5 out of 5 stars5/5 (1)

- Muncie 4-Speed Transmissions: How to Rebuild & ModifyFrom EverandMuncie 4-Speed Transmissions: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (7)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- Aw03 PDFDocument15 pagesAw03 PDFamazonagirl19No ratings yet

- G - Tests W/Codes - 1.6L Tbi Article TextDocument25 pagesG - Tests W/Codes - 1.6L Tbi Article TextAlexandros KastanakisNo ratings yet

- Auto Trans Diagnosis - Aw03-72Le Article TextDocument15 pagesAuto Trans Diagnosis - Aw03-72Le Article TextLeonardo SilvaNo ratings yet

- Auto Trans Diagnosis - Aw03-72Le Article TextDocument15 pagesAuto Trans Diagnosis - Aw03-72Le Article TextCarlos Andres Campos TorresNo ratings yet

- P Johnstone: Jackaroo TipsDocument5 pagesP Johnstone: Jackaroo TipsJimmy Brian KaifitiNo ratings yet

- ABS & VSC Diagnostics for 2002 Lexus LX470Document10 pagesABS & VSC Diagnostics for 2002 Lexus LX470Gabriel BalcazarNo ratings yet

- Câmbio Automático Vitara - AW03-72LEDocument15 pagesCâmbio Automático Vitara - AW03-72LELeandro Grassmann100% (2)

- Vitara DiagnosticosDocument117 pagesVitara DiagnosticosCoromoto Melendez83% (6)

- BMW Motronic Fault CodesDocument4 pagesBMW Motronic Fault CodesChris Palmer100% (1)

- 2JZ-GE Transmission Diagnostics PDFDocument55 pages2JZ-GE Transmission Diagnostics PDFJesus Cheremo100% (3)

- Fe05a PDFDocument72 pagesFe05a PDFvette512No ratings yet

- US Gears Overdrive ManualDocument23 pagesUS Gears Overdrive ManualNuman2100% (2)

- VihtovioriDocument58 pagesVihtovioripoisonknivesNo ratings yet

- Sonnax TF60SN Spring Adjuster15741-48K InstDocument2 pagesSonnax TF60SN Spring Adjuster15741-48K InstNuman2No ratings yet

- 4L60E Plate Drilling InstructionsDocument1 page4L60E Plate Drilling InstructionsNuman2No ratings yet

- Superior 4L80E InstructionsDocument4 pagesSuperior 4L80E InstructionsNuman267% (3)

- 4L60E Plate Drilling InstructionsDocument1 page4L60E Plate Drilling InstructionsNuman2No ratings yet

- Sonnax 340E 2k Up Zipkit Long InstructionsDocument8 pagesSonnax 340E 2k Up Zipkit Long InstructionsNuman2No ratings yet

- ZF6HP Solenoid InstructionsDocument1 pageZF6HP Solenoid InstructionsNuman2100% (1)

- SUPERIOR 4F27E InstructionsDocument3 pagesSUPERIOR 4F27E InstructionsNuman2No ratings yet

- Sonnax 340E 2k Up Zipkit InstructionsDocument2 pagesSonnax 340E 2k Up Zipkit InstructionsNuman2No ratings yet

- 09G TF60SN Transgo InstructionsDocument7 pages09G TF60SN Transgo InstructionsNuman289% (9)

- SK Awf21 Tf-81sc Aw6a-El InstructionsDocument8 pagesSK Awf21 Tf-81sc Aw6a-El InstructionsNuman2100% (3)

- B&M AOD Shiftkit InstructionsDocument16 pagesB&M AOD Shiftkit InstructionsNuman2No ratings yet

- Recover, recycle and recharge A/C systemsDocument24 pagesRecover, recycle and recharge A/C systemsNuman2No ratings yet

- VBX 55-50 Solenoid WiringDocument1 pageVBX 55-50 Solenoid WiringNuman2No ratings yet

- Mercedes Benz Fault Code ManualDocument107 pagesMercedes Benz Fault Code ManualAnthony75% (53)

- Zf6hp26 InfoDocument10 pagesZf6hp26 InfoNuman2100% (1)

- ATRA 41TE Rebuild (Chrysler A 604)Document115 pagesATRA 41TE Rebuild (Chrysler A 604)Patricio Bacigalupi100% (4)

- AW 55-50 Linear Solenoid: 2519 Dana, DR., Laurinburg, NC 28352 800-782-3379Document2 pagesAW 55-50 Linear Solenoid: 2519 Dana, DR., Laurinburg, NC 28352 800-782-3379Numan2No ratings yet

- 09g Ring Support FixDocument2 pages09g Ring Support FixNuman2No ratings yet

- 6F35 GearspdfDocument6 pages6F35 GearspdfNuman283% (12)

- 4l30e Pump ConversionDocument6 pages4l30e Pump ConversionNuman2100% (1)

- dps-1200 HP Power Supply Pin Assignment PDFDocument1 pagedps-1200 HP Power Supply Pin Assignment PDFNuman2No ratings yet

- 4l30e Gaskets Od Housing TASC TIP 11 04Document2 pages4l30e Gaskets Od Housing TASC TIP 11 04Numan2No ratings yet

- 4l30e Gaskets Od Housing TASC TIP 11 04Document2 pages4l30e Gaskets Od Housing TASC TIP 11 04Numan2No ratings yet

- 1990 ATRA Seminar Manual PDFDocument188 pages1990 ATRA Seminar Manual PDFwilderNo ratings yet

- 5 R 110 WDocument4 pages5 R 110 WNuman2100% (1)

- 4l30e Pump ConversionDocument6 pages4l30e Pump ConversionNuman2100% (1)

- Automatic Transmisson Aw55-50 SN - Volvo XC 90 Opel VectraDocument16 pagesAutomatic Transmisson Aw55-50 SN - Volvo XC 90 Opel VectraNovacovici Dorel100% (1)

- 400kV Circuit Breaker - O&MDocument109 pages400kV Circuit Breaker - O&MAMIT BISWASNo ratings yet

- Owners ManualDocument61 pagesOwners ManualThom StevensNo ratings yet

- 407 MM CH12 PDFDocument50 pages407 MM CH12 PDFVin VilleNo ratings yet

- Gepida - 2015 (Kerékpár, Kiegészítő)Document108 pagesGepida - 2015 (Kerékpár, Kiegészítő)Norbert PappNo ratings yet

- 01V Auto Trans SSPDocument66 pages01V Auto Trans SSPGolub MarkoNo ratings yet

- TF 0195 GS 050 AaaaDocument4 pagesTF 0195 GS 050 AaaaCristian AlonsoNo ratings yet

- Diesel Engine Starting SystemDocument25 pagesDiesel Engine Starting SystemAbrar Hussain100% (1)

- Ae 1013 Helicopter Maintenance NewDocument16 pagesAe 1013 Helicopter Maintenance NewAeronaughtycs Hamdan100% (1)

- XJ40 1991-92 3,2L 4L Boite Vitesse AutoDocument59 pagesXJ40 1991-92 3,2L 4L Boite Vitesse AutoTACHONNo ratings yet

- 00052706820-5-Speed Manual Gearbox 02D Four-Wheel Drive PDFDocument455 pages00052706820-5-Speed Manual Gearbox 02D Four-Wheel Drive PDFDavid Pit Fermiere100% (1)

- Freewheel Clutches: Ringspann CorporationDocument16 pagesFreewheel Clutches: Ringspann CorporationZahir KhiraNo ratings yet

- DSGDocument66 pagesDSGTM12550% (2)

- Torque Converter Clutch TCCDocument21 pagesTorque Converter Clutch TCCmarsh2002100% (2)

- Piaggio MP3 250 I.E. (EN)Document365 pagesPiaggio MP3 250 I.E. (EN)Manualles50% (2)

- Campus Mobility For The Future: The Electric BicycleDocument12 pagesCampus Mobility For The Future: The Electric BicycleIzza AnshoryNo ratings yet

- Grasshopper Classic Manual enDocument16 pagesGrasshopper Classic Manual enGustavs KrievkalnsNo ratings yet

- Over Running ClutchDocument96 pagesOver Running ClutchSUKhanNo ratings yet

- HI Tec - DRSUPS Presentation V3Document71 pagesHI Tec - DRSUPS Presentation V3safie147100% (1)

- Power Train: SERV1817 - 131 - Text Reference 04/06Document105 pagesPower Train: SERV1817 - 131 - Text Reference 04/06Wesley Gonzalo YupanquiNo ratings yet

- Manual Series 1 Land RoverDocument136 pagesManual Series 1 Land RoverKelly BenderNo ratings yet

- Electric Bicycle Mechanical EngineeringDocument22 pagesElectric Bicycle Mechanical EngineeringChirag Jadaun100% (1)

- Tailor your Volvo FM with endless optionsDocument18 pagesTailor your Volvo FM with endless optionsLuqman Cuopreakt'zNo ratings yet

- NAG 1/W5A580 Auto Transmission Diagnosis and RepairDocument42 pagesNAG 1/W5A580 Auto Transmission Diagnosis and RepairKamerom CunninghamNo ratings yet

- Quick Reference: Component Location and I.D. Axode/Ax4SDocument12 pagesQuick Reference: Component Location and I.D. Axode/Ax4SAyhan ÜmitNo ratings yet

- SincoTec - News - 2021 - English Brochure TribometersDocument6 pagesSincoTec - News - 2021 - English Brochure Tribometershugo vignoloNo ratings yet

- A960e VB BreakdownDocument15 pagesA960e VB BreakdownDavid Chalker0% (2)

- 01V 01L Automatic Transmissions PDFDocument80 pages01V 01L Automatic Transmissions PDFPeric Pero100% (1)

- 6hp19 26 PDFDocument92 pages6hp19 26 PDFВиталий Черненко100% (7)

- PPOO201 Poulan Pro PPX19H46 Operators ManualDocument56 pagesPPOO201 Poulan Pro PPX19H46 Operators ManualRon OstbergNo ratings yet

- Quick Reference: 45/545RFE Component Location and I.DDocument8 pagesQuick Reference: 45/545RFE Component Location and I.DAyhan ÜmitNo ratings yet