Professional Documents

Culture Documents

Damping Properties of Materials

Damping Properties of Materials

Uploaded by

Andi MakmurCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Damping Properties of Materials

Damping Properties of Materials

Uploaded by

Andi MakmurCopyright:

Available Formats

1

DAMPING PROPERTIES OF MATERIALS Revision C

By Tom Irvine

Email: tomirvine@aol.com

November 8, 2004

________________________________________________________________________

The purpose of this tutorial is to give typical damping values for various materials and

systems.

The data in Tables 1 and 2 is taken from Reference 1.

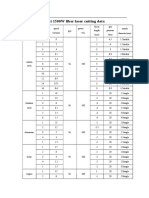

Table 1.

Static Properties of Materials under Standard Conditions

(approx. 20 C).

Material

Density

(kg/m

3

)

Elastic

Modulus

(N/m

2

)

Shear

Modulus

(N/m

2

)

Poissons

Ratio

Aluminum 2700

72 (10

9

) 27 (10

9

)

0.34

Lead 11,300

17 (10

9

) 6 (10

9

)

0.43

Iron 7800

200 (10

9

) 77 (10

9

)

0.30

Steel 7800

210 (10

9

) 77 (10

9

)

0.31

Gold 19,300

80 (10

9

) 28 (10

9

)

0.423

Copper 8900

125 (10

9

) 46 (10

9

)

0.35

Magnesium 1740

43 (10

9

) 17 (10

9

)

0.29

Brass 8500

95 (10

9

) 36 (10

9

)

0.33

Nickel 8900

205 (10

9

) 77 (10

9

)

0.30

Silver 10,500

80 (10

9

) 29 (10

9

)

0.37

Bismuth 9800

3.3 (10

9

) 1.3 (10

9

)

0.38

Zinc 7130

13.1(10

9

) 5 (10

9

)

0.33

Tin 7280

4.4 (10

9

) 1.6 (10

9

)

0.39

2

Table 2.

Dynamic Properties of Materials under Standard Conditions (approx. 20 C)

Material

Propagation

Velocity of

Longitudinal

Wave in a Rod

(meters/sec)

Propagation

Velocity of

Torsional

Wave

(meters/sec)

Longitudinal Loss

Factor

Flexural Loss

Factor

Aluminum 5200 3100

( )

5

10 10 to 3 . 0

4

10

Lead

(pure) 1250 730

( )

2

10 30 to 5

( )

2

10 2

Lead

(including

antimony)

( )

3

10 4 to 1

Iron 5050 3100

( )

4

10 4 to 1

( )

4

10 6 to 2

Steel 5100 3100

( )

4

10 3 to 2 . 0

Gold 2000 1200

( )

4

10 3

Copper

(polycrystalline) 3700 2300

( )

3

10 2

( )

3

10 2

Copper

(single crystal)

( )

4

10 7 to 2

Magnesium 5000 3100

4

10

Brass 3200 2100

( )

3

10 1 to 2 . 0

3

10

<

Nickel 4800 2900

3

10

<

Silver 2700 1600 !

"

#

$

%

&

4

10 4

( )

3

10 3

<

Bismuth 580 360

( )

4

10 8

Zinc 1350 850

( )

4

10 3

Tin 780 470

( )

4

10 20

Notes:

1. Some loss factors are unavailable.

2. The relationship between the loss factor and the viscous damping ratio is:

= 2 .

3

The data in Table 3 is taken from Reference 2.

Table 3. Representative Damping Ratios

System

Viscous Damping

Ratio

Metals (in elastic range) <0.01

Continuous Metal Structures 0.02 to 0.04

Metal Structure with Joints 0.03 to 0.07

Aluminum / Steel Transmission Lines 0.0004

Small Diameter Piping Systems 0.01 to 0.02

Large Diameter Piping Systems 0.02 to 0.03

Auto Shock Absorbers 0.30

Rubber 0.05

Large Buildings during Earthquakes 0.01 to 0.05

Prestressed Concrete Structures 0.02 to 0.05

Reinforced Concrete Structures 0.04 to 0.07

The data in Tables 4 through 6 is taken from Reference 3.

Table 4. Material Damping Ratios (Bare Structure)

System

Viscous Damping

Ratio

Reinforced Concrete

Small Stress Intensity (uncracked)

Medium Stress Intensity (fully cracked)

High Stress Intensity

(fully cracked but no yielding of reinforcement)

0.007 to 0.010

0.010 to 0.040

0.005 to 0.008

Prestressed Concrete (uncracked) 0.04 to 0.07

Partially Prestressed Concrete (slightly cracked) 0.008 to 0.012

Composite 0.002 to 0.003

Steel 0.001 to 0.002

C.1

4

Table 5. Footbridge Damping

Construction Type Viscous Damping Ratio

Min. Mean Max.

Reinforced Concrete 0.008 0.013 0.020

Prestressed Concrete 0.005 0.010 0.017

Composite 0.003 0.006 -

Steel 0.002 0.004 -

1.1

Table 6. Building Damping

Construction Type Viscous Damping Ratio

Min. Mean Max.

Tall Buildings ( h > ~100 m)

Reinforced concrete 0.010 0.015 0.020

Steel 0.007 0.010 0.013

Buildings ( h ~ 50 m)

Reinforced concrete 0.020 0.025 0.030

Steel 0.015 0.020 0.025

3.1

5

The data in Table 7 is taken from Reference 1.

Table 7.

Mechanical Properties of Building Materials under Standards Conditions

Material

Density

(g/cm

3

)

Elastic

Modulus

(dyne/cm

2

)

Longitudinal

Wavespeed

(cm/sec)

Loss Factor

Asbestos

Concrete

2.0 28e+10 3.7e+05 0.7-2e-02

Asphalt 1.8 - 2.3 7.7e+10 1.9e+05 0.38

12e+10 2.4e+05 0.21

21e+10 3.2e+05 0.055

Oak 0.7 1.0 2-10e+10 1.5-3.5e+05 1e-02

Fiber Mats 0.08 0.3 1.4-3e+10 - 0.1

Fir 0.4 0.7 1-5e+10 2.5e+05 8e-03

Felt - 0.03e+10 - 6e-02

Gypsum Board 1.2 7e+10 2.4e+05 6e-03

Glass 2.5 60e+10 4.9e+05 0.6-2e-03

Pressed-wood

Panels

0.6 0.7 4.6e+10 2.7e+05 1 - 3e-02

Plaster 1.7 4.4e+10 1.6e+05 2 - 5e-02

Cork 0.12 0.25 0.025e+10 0.43e+05 0.13 - 0.17

Light Concrete 1.3 3.8e+10 1.7e+05 1.5e-02

Plexiglas 1.15 5.6e+10 2.2e+05 2 - 4e-02

Porous,

Concrete

0.6 2e+10 1.7e+05 1e-02

Sand, dry 1.5 0.03e+10 0.1-0.17e+05 0.06-0.12

Dense

Concrete

2.3 26e+10 3.4e+05 4 - 8e-03

Plywood 0.6 5.4e+10 3e+05 1.3e-02

Brick 1.9 2.2 2.5-3e+10 2.5-3e+05 1 2e-02

6

The damping values in the tables should be used with caution. There are many types of

damping, such as viscous, hysteresis, acoustic coupling, air pumping at joints, energy

radiation to the soil, etc. Also, boundaries and bearings contribute damping.

Furthermore, structures have many modes. Each mode may have a unique damping

value.

References

1. L. Cremer and M. Heckl, Structure-Borne Sound, Springer-Verlag, New York,

1988.

2. V. Adams and A. Askenazi, Building Better Products with Finite Element

Analysis, OnWord Press, Santa Fe, N.M., 1999.

3. H. Bachmann, et al., Vibration Problems in Structures, Birkhauser Verlag, Berlin,

1995.

You might also like

- Visconti G., Ruggieri P. Fluid Dynamics. Fundamentals and Applications 2020 PDFDocument337 pagesVisconti G., Ruggieri P. Fluid Dynamics. Fundamentals and Applications 2020 PDFCrystal Nguyen100% (5)

- Electroplating Costs CalculationDocument19 pagesElectroplating Costs CalculationmosesNo ratings yet

- Solution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Document8 pagesSolution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Alberto Sullivan100% (41)

- Electroplating Cost Calculation - RefDocument12 pagesElectroplating Cost Calculation - RefJitendra PatilNo ratings yet

- C 45Document10 pagesC 45mohsen_267No ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Earthing Resistance Calculations IEEE-80Document19 pagesEarthing Resistance Calculations IEEE-80ANANDNo ratings yet

- Transmission Line ParameterDocument75 pagesTransmission Line Parameteraregawi weleabezgi100% (1)

- Astm A781 PDFDocument13 pagesAstm A781 PDFIslam Fawzy100% (6)

- 1 4571 PDFDocument7 pages1 4571 PDFSiis IngenieriaNo ratings yet

- Properties of Engineering Material - Waleed NassefDocument1 pageProperties of Engineering Material - Waleed NassefWaleed NassefNo ratings yet

- Die Casting AlloysDocument6 pagesDie Casting AlloyskeeblerkhanNo ratings yet

- Plating RateDocument20 pagesPlating RateFrancisco BocanegraNo ratings yet

- Mat 07000-07149 200411Document5 pagesMat 07000-07149 200411Ronaldo Bandeira RodriguesNo ratings yet

- Appendix E Mechanical Properties of Engineering MaterialsDocument3 pagesAppendix E Mechanical Properties of Engineering MaterialsBrhane W YgzawNo ratings yet

- Soft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdDocument10 pagesSoft Magnetic Iron-Cobalt Alloy Hiperco 27: Xi'An Gangyan Special Alloy Co.,LtdMohammadehsan SalarpourNo ratings yet

- Aluminium Diecasting MaterialDocument2 pagesAluminium Diecasting MaterialzainudinNo ratings yet

- Influence of Molybdenum, Vanadium, and Niobium On The Abrasion PDFDocument4 pagesInfluence of Molybdenum, Vanadium, and Niobium On The Abrasion PDFFàtí ĐCNo ratings yet

- PWHT TempDocument1 pagePWHT TempVKT TiwariNo ratings yet

- E SolDocument7 pagesE SolPeter ZubarikNo ratings yet

- Elastic Constants and Theri RelationshipsDocument4 pagesElastic Constants and Theri RelationshipsrchallahaliNo ratings yet

- Technical Info About Die CastingDocument5 pagesTechnical Info About Die CastingSanoj KumarNo ratings yet

- 1.4435 - C Stainless Steel DetailsDocument3 pages1.4435 - C Stainless Steel DetailsmeenakshiNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- Eos Stainless Steel 316 LDocument5 pagesEos Stainless Steel 316 LsameeraNo ratings yet

- Requerimientos ABS Pruebas MecanicasDocument7 pagesRequerimientos ABS Pruebas MecanicasGilberto ZamudioNo ratings yet

- Effect of Tio Nanoparticles On Mechanical Properties of Epoxy-Resin SystemDocument9 pagesEffect of Tio Nanoparticles On Mechanical Properties of Epoxy-Resin SystemDhananjay ShimpiNo ratings yet

- Hot-Rolled - Plate: Data SheetDocument2 pagesHot-Rolled - Plate: Data SheetRichard Vica CalvoNo ratings yet

- Forged Engineering DataDocument4 pagesForged Engineering DataretrogradesNo ratings yet

- Hole Punch CalculationDocument7 pagesHole Punch Calculationvikash kumarNo ratings yet

- Casting Aluminum: Die Casting, A Brief DescriptionDocument7 pagesCasting Aluminum: Die Casting, A Brief Descriptionanon_124372987No ratings yet

- Tabla de MaterialesDocument2 pagesTabla de MaterialesAlan Mauricio InsaustiNo ratings yet

- Iso 13715 PDFDocument2 pagesIso 13715 PDFnovkovic1984No ratings yet

- Duplex Ss Welding PDF FreeDocument8 pagesDuplex Ss Welding PDF Freeel_sharkawy2011No ratings yet

- Reci 1500W Fiber Laser Cutting Data 30um)Document2 pagesReci 1500W Fiber Laser Cutting Data 30um)morteza hamishegiNo ratings yet

- Electrical or Thermal CondutivityDocument1 pageElectrical or Thermal CondutivityDan SabadusNo ratings yet

- Main Formulas and Ultrasonic Reference Data: 2.1 Physics of Ultrasonics-DefinitionsDocument5 pagesMain Formulas and Ultrasonic Reference Data: 2.1 Physics of Ultrasonics-DefinitionsKevin HuangNo ratings yet

- Review of Industrial Engineering Letters: Hydrogen Sulphide, Corrosion Rate, Stainless Steel. Nickel, Water, EnvironmentDocument9 pagesReview of Industrial Engineering Letters: Hydrogen Sulphide, Corrosion Rate, Stainless Steel. Nickel, Water, EnvironmentPrasad ChakkrapaniNo ratings yet

- SilcoTek Coatings For High Purity ApplicationsDocument30 pagesSilcoTek Coatings For High Purity ApplicationsKommu RohithNo ratings yet

- Product Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 48.00: E 'Manual Metal-Arc Welding'wangshengfffNo ratings yet

- Case Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackDocument3 pagesCase Hardening Alloy Steel Bar 6587 Atlas 6587: Colour Code: Signal Red (Band) - BlackCelsoNo ratings yet

- Rules For Materials and Welding 2021 AmendmentsDocument29 pagesRules For Materials and Welding 2021 AmendmentsSUEZSHIPYARD QCNo ratings yet

- ALLOY 7075 Plate and Sheet: All Around Consistent PerformanceDocument4 pagesALLOY 7075 Plate and Sheet: All Around Consistent PerformanceSarat SrinivasNo ratings yet

- 1000 Info About SSDocument8 pages1000 Info About SSzahirshah1436923No ratings yet

- Bola Tash Vili 2009Document4 pagesBola Tash Vili 2009Vikyath PopuriNo ratings yet

- Material Yield Stress COMPARITIVE DATADocument4 pagesMaterial Yield Stress COMPARITIVE DATAshNo ratings yet

- Weor, 50 145: 0043-1648/78/0050-0145$2.25 0 Elsevier Sequoia S.A., Lausanne/Rinted in The NetherlandsDocument9 pagesWeor, 50 145: 0043-1648/78/0050-0145$2.25 0 Elsevier Sequoia S.A., Lausanne/Rinted in The NetherlandsAswar ATSNo ratings yet

- Curtain Wall Manual - Section 6 Material Properties: Approved Via Ballot #808-15 Out For Ballot (16-1006)Document12 pagesCurtain Wall Manual - Section 6 Material Properties: Approved Via Ballot #808-15 Out For Ballot (16-1006)philipNo ratings yet

- Permeability of MaterialDocument5 pagesPermeability of Materialankesh_ghoghariNo ratings yet

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pages36CrB4 Rod - Wire Rev4 PDFKarthi KeyanNo ratings yet

- Phe GSR - 2023Document245 pagesPhe GSR - 2023Neil AgshikarNo ratings yet

- jp3054857 Si 001Document10 pagesjp3054857 Si 001odunmoolorun dorcasNo ratings yet

- C7025 (英文) ver1 6Document11 pagesC7025 (英文) ver1 6顏健軒No ratings yet

- 00-Material Properties TableDocument4 pages00-Material Properties TableNgân TrịnhNo ratings yet

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocument2 pagesAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamNo ratings yet

- MSE 227 HW9 F10 SolutionsDocument5 pagesMSE 227 HW9 F10 Solutionsputri nur shahidaNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- Table of Resistivity - For Loss Calculation - MATERIAL RESISTIVITYDocument1 pageTable of Resistivity - For Loss Calculation - MATERIAL RESISTIVITYprakashNo ratings yet

- Casting - Solidification.Document3 pagesCasting - Solidification.__Caro26__No ratings yet

- Yellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloyDocument3 pagesYellow: LM6 (EN 1706 AC-44100) Aluminium Casting AlloySohail ShaikhNo ratings yet

- HR Plate AS3678300Document1 pageHR Plate AS3678300ABHISHEKNo ratings yet

- TABLE 1 Characteristics of The Interlaboratory Wear Test SpecimensDocument1 pageTABLE 1 Characteristics of The Interlaboratory Wear Test SpecimensBayu AmartaNo ratings yet

- Cas React ReactionsDocument16 pagesCas React ReactionstrewNo ratings yet

- Sci - Test Questions in SciG9Document4 pagesSci - Test Questions in SciG9Ibe Mae Collera ViovicenteNo ratings yet

- Structure of Atom: NEET/JEE: 2020-21Document3 pagesStructure of Atom: NEET/JEE: 2020-21shantinath123gmailcoNo ratings yet

- Proracun Grejanja BazenaDocument4 pagesProracun Grejanja Bazenaduje_raftmanNo ratings yet

- CV Fla Mar 19Document25 pagesCV Fla Mar 19Farzana Latif AnsariNo ratings yet

- Consumer Chemistry q3 PPT For Cot 1Document41 pagesConsumer Chemistry q3 PPT For Cot 1Allynn JunioNo ratings yet

- Disolusi Ambroxol (30 MNT, Min 80%)Document9 pagesDisolusi Ambroxol (30 MNT, Min 80%)Katarina KatarinaNo ratings yet

- CLS JEEAD-19-20 XI Phy Target-3 Level-1 Chapter-6 PDFDocument31 pagesCLS JEEAD-19-20 XI Phy Target-3 Level-1 Chapter-6 PDFRupak100% (1)

- Board's Question Papers 2021Document19 pagesBoard's Question Papers 2021subtractnewNo ratings yet

- Savant Speedvac Concentrators: Quick and Efficient Sample PreparationDocument18 pagesSavant Speedvac Concentrators: Quick and Efficient Sample Preparationmmeneses07No ratings yet

- MAX H20 Desalter BrochureDocument2 pagesMAX H20 Desalter BrochureAnonymous fj9ypF83No ratings yet

- Flores Chapter 7-8Document65 pagesFlores Chapter 7-8Reinzo GallegoNo ratings yet

- 1.industrial Management - R5Document42 pages1.industrial Management - R5Manav IsraniNo ratings yet

- Sample Board Paper 2011Document4 pagesSample Board Paper 2011Saravanan VenkataNo ratings yet

- Chen 3009 - Tutorial 6 2020Document22 pagesChen 3009 - Tutorial 6 2020Rosario QFNo ratings yet

- Psyche and Singularity - Timothy DesmondDocument366 pagesPsyche and Singularity - Timothy DesmondAlexa CosimaNo ratings yet

- Learning Activity Sheet in Science 7: A. Practice TasksDocument8 pagesLearning Activity Sheet in Science 7: A. Practice TasksJonash Miguel LorzanoNo ratings yet

- Assignment 01 Rectillinear Motion AJN Sir-2921Document3 pagesAssignment 01 Rectillinear Motion AJN Sir-2921iitforumNo ratings yet

- LAB Plug FlowDocument24 pagesLAB Plug FlowZalina SamsuddinNo ratings yet

- Aquaflo HV - TDS (En)Document5 pagesAquaflo HV - TDS (En)frankNo ratings yet

- MOF Bimetalicos Producción BiodieselDocument9 pagesMOF Bimetalicos Producción BiodieselHilson ValdezNo ratings yet

- SHORT REPORT - 606 - Liner DisplacementDocument26 pagesSHORT REPORT - 606 - Liner DisplacementwongpeisenNo ratings yet

- Kimia ProteinDocument12 pagesKimia ProteinFajar RyamizardNo ratings yet

- Lecture20-Fluid Mechanics PDFDocument5 pagesLecture20-Fluid Mechanics PDFSata AjjamNo ratings yet

- Nuclgauges Form 1Document5 pagesNuclgauges Form 1kirandevi1981No ratings yet

- Thermal Properties of Matter PDFDocument33 pagesThermal Properties of Matter PDFGAMES TECHNo ratings yet