Professional Documents

Culture Documents

Ch39 NCandRobotics Wiley

Ch39 NCandRobotics Wiley

Uploaded by

Atul Bhagat0 ratings0% found this document useful (0 votes)

18 views49 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views49 pagesCh39 NCandRobotics Wiley

Ch39 NCandRobotics Wiley

Uploaded by

Atul BhagatCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 49

2002 John Wiley & Sons, Inc. M. P.

Groover, Fundamentals of Modern Manufacturing 2/e

NUMERICAL CONTROL AND

INDUSTRIAL ROBOTICS

Numerical Control

Industrial Robotics

Programmable Logic Controllers

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Numerical Control

A form of programmable automation in which the

mechanical actions of a piece of equipment are

controlled by a program containing coded

alphanumeric data

The data represent relative positions between a

workhead and a workpart

Workhead = tool or other processing element

Workpart = object being processed

NC operating principle is to control the motion of the

workhead relative to the workpart and to control the

sequence in which the motions are carried out

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Components of a Numerical Control System

Part program - the detailed set of commands to be

followed by the processing equipment

Machine control unit (MCU) - microcomputer that

stores and executes the program by converting each

command into actions by the processing equipment,

one command at a time

Processing equipment - accomplishes the sequence

of processing steps to transform starting workpart

into completed part

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

NC Coordinate System

Consists of three linear axes (x, y, z) of Cartesian

coordinate system, plus three rotational axes (a, b, c)

Rotational axes are used to orient workpart or

workhead to access different surfaces for

machining

Most NC systems do not require all six axes

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Figure 38.2 - Coordinate systems used in numerical control: (a)

for flat and prismatic work

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Figure 38.2 - Coordinate systems used in numerical control:

(b) for rotational work

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

NC Motion Control Systems

Two types:

1. Point-to-point

2. Continuous path

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Point-to-Point (PTP) System

Workhead (or workpiece) is moved to a programmed

location with no regard for path taken to get to that

location

Once the move is completed, some processing action

is accomplished by the workhead

Examples: drilling or punching a hole

Thus, the part program consists of a series of point

locations at which operations are performed

Also called positioning systems

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Continuous Path (CP) System

Continuous simultaneous control of more than one axis,

thus controlling path followed by tool relative to part

Permits tool to perform a process while axes are

moving, enabling the system to generate angular

surfaces, two-dimensional curves, or 3-D contours in

the workpart

Examples: many milling and turning operations,

flame cutting

Also called contouring in machining operations

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Two Types of Positioning

Absolute positioning

Locations are always defined with respect to origin

of axis system

Incremental positioning

Next location is defined relative to present location

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Figure 38.3 - Absolute vs. incremental positioning. The workhead is

presently at point (2,3) and is to be moved to point (6,8). In

absolute positioning, the move is specified by x = 6, y = 8; while in

incremental positioning, the move is specified by x = 4, y = 5

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Figure 38.4 - Motor and leadscrew arrangement in a NC

positioning system

NC Positioning System

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

NC Positioning System

Converts the coordinates specified in the NC part

program into relative positions and velocities between

tool and workpart during processing

Leadscrew pitch p - table is moved a distance

equal to the pitch for each revolution

Table velocity (e.g., feed rate in machining) is set

by the RPM of leadscrew

To provide x-y capability, a single-axis system is

piggybacked on top of a second perpendicular axis

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Two Basic Types of Control in NC

Open loop system

Operates without verifying that the actual position

is equal to the specified position

Closed loop control system

Uses feedback measurement to verify that the

actual position is equal to the specified location

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Precision in Positioning

Three critical measures of precision in positioning:

1. Control resolution

2. Accuracy

3. Repeatability

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Control Resolution (CR)

Defined as the distance separating two adjacent control

points in the axis movement

Control points are sometimes called addressable

points because they are locations along the axis to

which the worktable can be directed to go

CR depends on:

Electromechanical components of positioning

system

Number of bits used by controller to define axis

coordinate location

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Figure 38.7 - A portion of a linear positioning system axis, with

showing control resolution, accuracy, and repeatability

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Statistical Distribution of Mechanical Errors

When a positioning system is directed to move to a

given control point, the capability to move to that

point is limited by mechanical errors

Errors are due to a variety of inaccuracies and

imperfections, such as play between leadscrew

and worktable, gear backlash, and deflection of

machine components

It is assumed that the errors form an unbiased normal

distribution with mean = 0 and that the standard

deviation is constant over axis range

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Accuracy in a Positioning System

Maximum possible error that can occur between desired

target point and actual position taken by system

For one axis:

Accuracy = 0.5 CR + 3

where CR = control resolution; and = standard

deviation of the error distribution

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Repeatability

Capability of a positioning system to return to a given

control point that has been previously programmed

Repeatability of any given axis of a positioning

system can be defined as the range of mechanical

errors associated with the axis

Repeatability = 3

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

NC Part Programming Techniques

1. Manual part programming

2. Computer-assisted part programming

3. CAD/CAM- assisted part programming

4. Manual data input

Common features:

Points, lines, and surfaces of the workpart must

be defined relative to NC axis system

Movement of the cutting tool must be defined

relative to these part features

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Manual Part Programming

Uses basic numerical data and special alphanumeric

codes to define the steps in the process

Suited to simple point-to-point machining jobs, such

as drilling operations

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Manual Part Programming: Example

Example command for drilling operation:

n010 x70.0 y85.5 f175 s500

where n-word (n010) = a sequence number; x- and

y-words = x and y coordinate positions (x = 70.0

mm and y = 85.5 mm), and f-word and s-word =

feed rate and spindle speed (feed rate = 175

mm/min, spindle speed = 500 rev/min)

Complete part program consists of a sequence of

commands

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Computer-Assisted Part Programming

Uses a high-level programming language

Suited to programming of more complex jobs

First NC part programming language was APT =

Automatically Programmed Tooling

In APT, part programming is divided into two

basic steps:

1. Definition of part geometry

2. Specification of tool path and operation

sequence

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

APT Geometry Statements

Part programmer defines geometry of workpart by

constructing it of basic geometric elements such as

points, lines, planes, circles, and cylinders

Examples:

P1 = POINT/25.0, 150.0

L1 = LINE/P1, P2

where P1 is a point located at x = 25 and y = 150,

and L1 is a line through points P1 and P2

Similar statements are used to define circles,

cylinders, and other geometry elements

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

APT Motion Statements:

Point-to-Point (PTP)

Specification of tool path accomplished with APT

motion statements

Example statement for point-to-point operation:

GOTO/P1

Directs tool to move from current location to P1

P1 has been defined by a previous APT geometry

statement

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

APT Motion Statements (CP)

Use previously defined geometry elements such as

lines, circles, and planes.

Example command:

GORGT/L3, PAST, L4

Directs tool to go right (GORGT) along line L3 until it

is positioned just past line L4

L4 must be a line that intersects L3

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

CAD/CAM-Assisted Part Programming

Takes computer-assisted part programming further by

using a CAD/CAM system to interact with

programmer as part program is being prepared

In conventional use of APT, program is written and

then entered into the computer for processing

Programming errors may not be detected until

computer processing

With CAD/CAM, programmer receives immediate

visual verification as each statement is entered

Errors can be corrected immediately rather than

after entire program has been written

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Manual Data Input (MDI)

Machine operator enters part program at the machine

Involves use of a CRT display with graphics

capability at machine tool controls

NC part programming statements are entered

using a menu-driven procedure that requires

minimum training of machine tool operator

Because MDI does not require a staff of NC part

programmers, MDI is a way for small machine shops

to economically implement NC

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Applications of Numerical Control

Operating principle of NC applies to many

operations

There are many industrial operations in which the

position of a workhead must be controlled

relative to the part or product being processed

Two categories of NC applications:

1. Machine tool applications

2. Non- machine tool applications

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Machine Tool Applications

NC is widely used for machining operations such as

turning, drilling, and milling

NC has motivated the development of machining

centers, which change their own cutting tools to

perform a variety of machining operations under NC

Other NC machine tools:

Grinding machines

Sheet metal pressworking machines

Tube bending machines

Thermal cutting processes

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Non-Machine Tool Applications

Tape laying machines and filament winding machines

for composites

Welding machines, both arc welding and resistance

welding

Component insertion machines in electronics

assembly

Drafting machines

Coordinate measuring machines for inspection

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Benefits of NC Relative to Manually

Operated Equipment

Reduced non-productive time which results in shorter

cycle times

Lower manufacturing lead times

Simpler fixtures

Greater manufacturing flexibility

Improved accuracy

Reduced human error

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Industrial Robotics

An industrial robot is a general purpose programmable

machine that possesses certain anthropomorphic

features

The most apparent anthropomorphic feature of an

industrial robot is its mechanical arm, or manipulator

Robots can perform a variety of tasks such as

loading and unloading machine tools, spot welding

automobile bodies, and spray painting

Robots are typically used as substitutes for human

workers in these tasks

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Robot Anatomy

An industrial robot consists of a mechanical

manipulator and a controller to move it and perform

other related functions

The mechanical manipulator consists of joints and

links to position and orient the end of the

manipulator relative to its base

The controller operates the joints in a coordinated

fashion to execute a programmed work cycle

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Figure 38.8 -

The manipulator of a

modern industrial

robot

(photo courtesy of

Adept Technology,

Inc.)

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Manipulator Joints and Links

A robot joint is similar to a human body joint

It provides relative movement between two parts

of the body

Typical industrial robots have five or six joints

Manipulator joints: classified as linear or rotating

Each joint moves its output link relative to its input

link

Coordinated movement of joints gives the robot its

ability to move, position, and orient objects

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Manipulator Design

Robot manipulators can usually be divided into two

sections:

Arm-and-body assembly - function is to position

an object or tool

Wrist assembly - function is to properly orient the

object or tool

There are typically three joints associated with the

arm-and-body assembly, and two or three joints

associated with the wrist

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Manipulator Wrist

The wrist is assembled to the last link in any of these

arm-and-body configurations

The SCARA is sometimes an exception because it is

almost always used for simple handling and

assembly tasks involving vertical motions

A wrist is not usually present at the end of its

manipulator

Substituting for the wrist on the SCARA is usually

a gripper to grasp components for movement

and/or assembly

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

End Effectors

The special tooling that connects to the robot's wrist to

perform the specific task

Two general types:

1. Tools - used for a processing operation

Applications: spot welding guns, spray

painting nozzles, rotating spindles, heating

torches, assembly tools

2. Grippers - designed to grasp and move objects

Applications: part placement, machine

loading and unloading, and palletizing

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Figure 38.10 - A robot gripper:

(a) open and (b) closed to grasp a workpart

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Robot Programming

Robots execute a stored program of instructions

which define the sequence of motions and positions

in the work cycle

Much like a NC part program

In addition to motion instructions, the program may

include commands for other functions such as:

Interacting with external equipment

Responding to sensors

Processing data

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Two Basic Teach Methods in

Robot Programming

1. Leadthrough programming - "teach-by-showing" in

which manipulator is moved through the sequence

of positions in the work cycle and the controller

records each position in memory for subsequent

playback

2. Computer programming languages robot program

is prepared at least partially off-line for subsequent

downloading to computer

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Where Should Robots be

Used in the Workplace?

Work environment is hazardous for humans

Work cycle is repetitive

The work is performed at a stationary location

Part or tool handling is difficult for humans

Multi-shift operation

Long production runs and infrequent changeovers

Part positioning and orientation are established at the

beginning of work cycle, since most robots cannot

see

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Applications of Industrial Robots

Three basic categories:

1. Material handling

2. Processing operations

3. Assembly and inspection

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Programmable Logic Controller (PLC)

Microcomputer-based device that uses stored

instructions in programmable memory to implement

logic, sequencing, timing, counting, and arithmetic

control functions, through digital or analog

input/output modules, for controlling various

machines and processes

Introduced around 1969 in response to specifications

proposed by General Motors Corporation

Controls manufacturers saw a commercial

opportunity, and today PLCs are an important

industrial controls technology

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Why PLCs are Important

Many automated systems operate by turning on and

off motors, switches, and other devices to respond to

conditions and as a function of time

These devices use binary variables that have two

possible values, 1 or 0, which means ON or OFF,

object present or not present, high or low voltage

Common binary devices used in industrial control:

limit switches, photodetectors, timers, control relays,

motors, solenoids, valves, clutches, and lights

Some devices send a signal in response to a physical

stimulus, while others respond to an electrical signal

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

Figure 38.12 - Major components of a programmable logic controller

2002 John Wiley & Sons, Inc. M. P. Groover, Fundamentals of Modern Manufacturing 2/e

PLC Programming

Most common control instructions include logical

operations, sequencing, counting, and timing

Many control applications require additional

instructions for analog control, data processing, and

computations

A variety of PLC programming languages have been

developed, ranging from ladder logic diagrams to

structured text

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- You Data Career RoadmapDocument34 pagesYou Data Career RoadmapSWNo ratings yet

- Data Structures and Algorithms Cheat Sheet: by ViaDocument7 pagesData Structures and Algorithms Cheat Sheet: by Viaxuanbao2008No ratings yet

- Siemens PLCDocument2 pagesSiemens PLCmailme_vijuNo ratings yet

- Half Adder and Full AdderDocument16 pagesHalf Adder and Full AdderkusumNo ratings yet

- Authorization Letter For Disconnection PLDTDocument1 pageAuthorization Letter For Disconnection PLDTSANS NT5No ratings yet

- CATIA Drawings For Practice (Pune)Document36 pagesCATIA Drawings For Practice (Pune)Mr. Pradeep Wadkar91% (35)

- CATIA Drawings For Practice (Pune)Document36 pagesCATIA Drawings For Practice (Pune)Mr. Pradeep Wadkar91% (35)

- Asdfkj HDFH SHKJHSDKJFH Skajhf Ierahsf HSXDZKJHF Ierhaiu KHSKJDKJ Iaushrdkjhskjdh Aiusrh HSDKJ KiahrDocument1 pageAsdfkj HDFH SHKJHSDKJFH Skajhf Ierahsf HSXDZKJHF Ierhaiu KHSKJDKJ Iaushrdkjhskjdh Aiusrh HSDKJ KiahranandnilewarNo ratings yet

- Sasadf Sa Asdfsdf As Asdf Asdf SDXFG Asdf SDocument1 pageSasadf Sa Asdfsdf As Asdf Asdf SDXFG Asdf SanandnilewarNo ratings yet

- SR - No Name of Experiment Page No. Date Grade SignatureDocument60 pagesSR - No Name of Experiment Page No. Date Grade SignatureanandnilewarNo ratings yet

- Unit-I Introduction To DBMSDocument20 pagesUnit-I Introduction To DBMSanandnilewarNo ratings yet

- WWW Xenons CN X6090-Small-Flatbed-Printer-P00237p1 HTMLDocument4 pagesWWW Xenons CN X6090-Small-Flatbed-Printer-P00237p1 HTMLnanodocl50990% (1)

- In The Name of Allah, The Most Beneficent, The Most MercifulDocument22 pagesIn The Name of Allah, The Most Beneficent, The Most MercifulHamzaNo ratings yet

- Design Process and Prototyping Chapter 3 - Part 2: Sub-TopicDocument36 pagesDesign Process and Prototyping Chapter 3 - Part 2: Sub-TopicSandra Suriya A/l JayasuriNo ratings yet

- Question Bank Class 8 2015 2016 1Document44 pagesQuestion Bank Class 8 2015 2016 118 DEY ARGHYA 6CNo ratings yet

- Appium CommandsDocument3 pagesAppium Commandsveenus kumarNo ratings yet

- YMW820 Data Sheet enDocument38 pagesYMW820 Data Sheet envlstudiosincNo ratings yet

- Liberty Mills Limited: Job Card IssuanceDocument2 pagesLiberty Mills Limited: Job Card IssuanceFarrukh JamilNo ratings yet

- SVEN E-217b Headphone Manual EnglishDocument6 pagesSVEN E-217b Headphone Manual EnglishKevinNo ratings yet

- ATMEGA2560 Development Board Mini Integrated With Xbee/USB InterfaceDocument6 pagesATMEGA2560 Development Board Mini Integrated With Xbee/USB InterfaceNitin RajputNo ratings yet

- Optimal Operation of Electrical Distribution Networks Including Distributed Generation Units Using Trader Optimization AlgorithmDocument5 pagesOptimal Operation of Electrical Distribution Networks Including Distributed Generation Units Using Trader Optimization AlgorithmHamdy AhmedNo ratings yet

- Grade 12 Practical Exercise BookDocument64 pagesGrade 12 Practical Exercise BookmatlosanecatclassroomNo ratings yet

- Ebook Digital Information Age An Introduction To Electrical Engineering 2Nd Edition Roman Kuc Solutions Manual Full Chapter PDFDocument35 pagesEbook Digital Information Age An Introduction To Electrical Engineering 2Nd Edition Roman Kuc Solutions Manual Full Chapter PDFconnielopezpmdrzqcjbn100% (8)

- OnlinebookstorepdxDocument2 pagesOnlinebookstorepdxSushrita MeshramNo ratings yet

- Unit 2 Part 2Document41 pagesUnit 2 Part 2Abhishek SrivastavaNo ratings yet

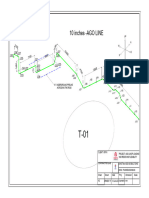

- AGO - As Built DrawingDocument1 pageAGO - As Built DrawingErnest S FelixNo ratings yet

- 19BCS2626 Crab GraphDocument3 pages19BCS2626 Crab GraphWhite WolfNo ratings yet

- Array ProgramsDocument10 pagesArray ProgramsMohak BhattacharyaNo ratings yet

- Both (A) and (B) ) Mimic The Human Intelligence in Non-Living Beings) All of The AboveDocument2 pagesBoth (A) and (B) ) Mimic The Human Intelligence in Non-Living Beings) All of The AboveVyankatesh AshtekarNo ratings yet

- FL - Piano RollDocument2 pagesFL - Piano RollJusAnothaSoulOnNotez64No ratings yet

- Bidi-Switch: Power Switch Bidirectional InterfaceDocument9 pagesBidi-Switch: Power Switch Bidirectional InterfaceSupuran RichardoNo ratings yet

- Fetal Monitor FM-3000 BrochureDocument4 pagesFetal Monitor FM-3000 BrochuretNo ratings yet

- BTD 300 DS Doc101267.10aDocument4 pagesBTD 300 DS Doc101267.10asagarnitishpirtheeNo ratings yet

- Elifas Levi - Masonske Legende: Everything Books Audiobooks Snapshots Articles Sheet Music PodcastsDocument8 pagesElifas Levi - Masonske Legende: Everything Books Audiobooks Snapshots Articles Sheet Music PodcastsTinamou0001No ratings yet

- Nero Burn RightsDocument17 pagesNero Burn RightsJenny AbramsNo ratings yet

- AdvanceServices BestPractices Nexus PDFDocument67 pagesAdvanceServices BestPractices Nexus PDFsebanadoNo ratings yet