Professional Documents

Culture Documents

Caliberation of Ceramic Servo Accelorometer

Caliberation of Ceramic Servo Accelorometer

Uploaded by

resmivlOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Caliberation of Ceramic Servo Accelorometer

Caliberation of Ceramic Servo Accelorometer

Uploaded by

resmivlCopyright:

Available Formats

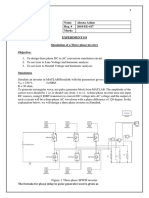

CALIBERATION OF CERAMIC SERVO ACCELOROMETER (CSA)

AIM

To calibrate ceramic servo accelerometer

OPERATORS/

1. Agilent 34401A 6 Digit Multimeter(DVM)

2. Laboratory DC power supply

3. CSA

4. Dividing head

5. Probes and connecting wires

CONNECTIONS

Pin 6-power supply channel 1 positive terminal (+15v)

Pin 2-power supply channel 2 negative terminal (-15v)

Pins 3&4-ground of power supply.

Pin 5- output torque connected to gr ound through 470 resistance.output across

resistance is connected to DVM.

PROCEDURE

1. Set the power supply output of channel 1 and 2 to +15v. Now short the positive

terminal of channel 1 and positive terminal of channel 2.this will act as ground.

2. Reading t +0g (EO)

Adjust dividing head to 0 degree position (0g input condition).

Wait for approximately 3 minute for sensor output stabilization.

Repeat this to get 5 sets of readings.

Similarly take average of 250 samples using DVM.

Repeat the procedure for taking readings of +1g(90),-0g(180),-1g(270)

Before taking readings at each position a wait period of 3 minutes is

required.

At positions 45, 135, 225, 315, 250 sample average from DVM to be

note down.

3. Caliberation coefficients

Formula for Scale factor(SF),Bias at 0g,1g,Bias Discrepancy,Misallignment

Parameters Equations Specifications

Scale factor(mA/g)

SF

(E90-E270)/2 4.2mA/g to 5.2mA/g

Bias at 0g(g)

B0

(E0+E180)*10^6/(2*SF)

1500g

Bias at 1g(g)

B1

(E90+E270)*10^6/(2*SF)

1500g

Bias Discrepancy(g)

BD

Bias at 1g-Bias at 0g

100g

Misallignment(Arc.s)

Mis

(E0-E180)*10^6/(2*SF)

700 arcSec

For computing calibration coefficient use 250 sample average.

4. Linearty plot

Plot g vs. output voltage (mV) using 250 sample average for 8 positions.

5. Standard deviation computation

Formula, = [(x-)/n] ^

=250 sample average

X=50 sample average(x1-x5:5 sets)

n=5

SD is computed for bias @ 0g, 1g and SF

You might also like

- Ad 811Document16 pagesAd 811srboghe651665No ratings yet

- SG1731/SG2731/SG3731: Features DescriptionDocument5 pagesSG1731/SG2731/SG3731: Features DescriptionRavindra MaraweeraNo ratings yet

- Pe Lab 8 2018-EE-417Document8 pagesPe Lab 8 2018-EE-417Ali Hassan RazaNo ratings yet

- Integrated Circuit Silicon Bilateral Switch (SBS)Document2 pagesIntegrated Circuit Silicon Bilateral Switch (SBS)Ramesh PagidipalliNo ratings yet

- RVDTDT SDocument4 pagesRVDTDT SFon Vui Lai0% (1)

- 1525AJDocument7 pages1525AJSalim BlognetNo ratings yet

- Two Stage Single Ended Output OP Amp With High GainDocument30 pagesTwo Stage Single Ended Output OP Amp With High GainPARIKSHIT SHAKTAWAT100% (1)

- SK250MS 180kVA Technical Data Sheets 10 01Document7 pagesSK250MS 180kVA Technical Data Sheets 10 01Sergio Marín SalasNo ratings yet

- R 11 KeyDocument12 pagesR 11 KeyKiran Kumar NallamekalaNo ratings yet

- Lab3 - ENGB035Document8 pagesLab3 - ENGB035haneinNo ratings yet

- 7805TDocument7 pages7805TGoti TorcalNo ratings yet

- Datasheet LF 353Document14 pagesDatasheet LF 353Anggridho MeilandanuNo ratings yet

- Anjali Shah. Instrumentationlab Report1Document6 pagesAnjali Shah. Instrumentationlab Report1Anurag SahNo ratings yet

- Transducers TrainerDocument11 pagesTransducers TrainerEsh-war RajNo ratings yet

- ZN409Document5 pagesZN409Sue RidgepipeNo ratings yet

- Fluke 80TK ThermoCouple ModuleDocument4 pagesFluke 80TK ThermoCouple ModuleRenjithpr RaviNo ratings yet

- Analog and Digital VLSI Design Analog AssignmentDocument12 pagesAnalog and Digital VLSI Design Analog AssignmentAdrian ChaseNo ratings yet

- 3.5.10. Directional Inverse Time Overcurrent Protection (Dircurrentinv)Document11 pages3.5.10. Directional Inverse Time Overcurrent Protection (Dircurrentinv)chichid2008No ratings yet

- Experiment 1: Transducer Trainer KitDocument22 pagesExperiment 1: Transducer Trainer KitSamarthNo ratings yet

- True RMS 3-Phase Voltage and Frequency Monitoring Relay: BenefitsDocument11 pagesTrue RMS 3-Phase Voltage and Frequency Monitoring Relay: BenefitsMohamedNo ratings yet

- DatasheetDocument7 pagesDatasheetjamalludin jamal jamalNo ratings yet

- Application Bulletin: Diode-Based Temperature MeasurementDocument6 pagesApplication Bulletin: Diode-Based Temperature Measurementsas999333No ratings yet

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- Data Sheet: MGA-425P8Document15 pagesData Sheet: MGA-425P8Aparna BhardwajNo ratings yet

- MAG3 SMT Datasheet RevD1Document4 pagesMAG3 SMT Datasheet RevD1lgrome73No ratings yet

- Ee2304 Lab ManualDocument49 pagesEe2304 Lab ManualSohail KhanNo ratings yet

- Power Electronics Lab ManualDocument49 pagesPower Electronics Lab ManualNeelakanth BenakalNo ratings yet

- Characterization of V Curve: Channel SP AnalysisDocument11 pagesCharacterization of V Curve: Channel SP AnalysisAnik JjNo ratings yet

- SEMIKRON DataSheet SKHE 3500 1550 2 0 05603650Document3 pagesSEMIKRON DataSheet SKHE 3500 1550 2 0 05603650Clovis GajoNo ratings yet

- Application Bulletin: Diode-Based Temperature MeasurementDocument5 pagesApplication Bulletin: Diode-Based Temperature MeasurementAlam TanweerNo ratings yet

- 5855292-Avr Users Manual Ea63-5 CDocument8 pages5855292-Avr Users Manual Ea63-5 CAbhoe StankNo ratings yet

- Opa381 PDFDocument19 pagesOpa381 PDFVictoria Guerrero100% (1)

- YTA70PDocument3 pagesYTA70PjamesrickynNo ratings yet

- AD590Document16 pagesAD590Trantan CdtNo ratings yet

- Texas Advanced Optoelectronic Solutions Inc.: DescriptionDocument8 pagesTexas Advanced Optoelectronic Solutions Inc.: DescriptionLý Thành ViênNo ratings yet

- Thuc Hanh 1Document7 pagesThuc Hanh 1tuantu007100% (1)

- PSP Lab ManualDocument21 pagesPSP Lab Manualakhil100% (1)

- AD8495Document16 pagesAD8495Миша СорокинNo ratings yet

- Bridge MeasureDocument19 pagesBridge MeasureThanh Nhan LeNo ratings yet

- Temperature Rise Test Procedure - Rev-01Document3 pagesTemperature Rise Test Procedure - Rev-01Soumya ranjan BasuriNo ratings yet

- LF151 LF251 LF351Document11 pagesLF151 LF251 LF351bl19cm7No ratings yet

- lm35 PDFDocument15 pageslm35 PDFRogers Ferreras BenitezNo ratings yet

- Syy155415 CPDocument3 pagesSyy155415 CPdanutzugheNo ratings yet

- SVERKER 900 Testing Directional Earth Fault An enDocument8 pagesSVERKER 900 Testing Directional Earth Fault An enFredrikNo ratings yet

- 2.5V and 4.096V Voltage References: Features DescriptionDocument20 pages2.5V and 4.096V Voltage References: Features Descriptionikaro181083No ratings yet

- LCD Thermocouple IndicatorDocument3 pagesLCD Thermocouple IndicatorHhelenaaNo ratings yet

- Performance of Cts in PowergridDocument61 pagesPerformance of Cts in PowergridS ManoharNo ratings yet

- RHV Lab Mannual 2020-21 RCNDocument39 pagesRHV Lab Mannual 2020-21 RCNVeershett MetreNo ratings yet

- Applications FeaturesDocument12 pagesApplications FeatureseduardofelisNo ratings yet

- Puente de WhistoneDocument10 pagesPuente de WhistoneAngie BarreraNo ratings yet

- TLP250 Mosfet Gate DriverDocument38 pagesTLP250 Mosfet Gate DriverKien Trung50% (2)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Op Amps: Design, Application, and TroubleshootingFrom EverandOp Amps: Design, Application, and TroubleshootingRating: 5 out of 5 stars5/5 (2)

- Easy(er) Electrical Principles for General Class Ham License (2015-2019)From EverandEasy(er) Electrical Principles for General Class Ham License (2015-2019)Rating: 5 out of 5 stars5/5 (1)