Professional Documents

Culture Documents

Wms Vs Mobile

Wms Vs Mobile

Uploaded by

JuNAiDSuAlEh0 ratings0% found this document useful (0 votes)

25 views19 pagesOriginal Title

Wms vs Mobile

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views19 pagesWms Vs Mobile

Wms Vs Mobile

Uploaded by

JuNAiDSuAlEhCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 19

WMS mobile device functions vs

WSH form functions

An Oracle Topical Essay

Updated March 2003

Product Design and Architecture

CONTENTS

Overview...................................................................................................................................................................................... 3

Introduction ................................................................................................................................................................................ 4

WMS Extends the Supply Chain Functionality....................................................................................................................... 5

Warehousing in WMS................................................................................................................................................................ 6

Pack .......................................................................................................................................................................................... 6

Unpack...................................................................................................................................................................................... 6

Consolidate ............................................................................................................................................................................... 7

Split........................................................................................................................................................................................... 7

Bulk Pack.................................................................................................................................................................................. 7

Update....................................................................................................................................................................................... 8

Material Workbench ................................................................................................................................................................. 8

Shipping With Pick Release in WMS........................................................................................................................................ 9

Picking...................................................................................................................................................................................... 9

Shipping.................................................................................................................................................................................. 10

Shipping Without Pick Release in WMS................................................................................................................................ 12

Direct Ship.............................................................................................................................................................................. 12

WSH Features Disabled in WMS Environment .................................................................................................................... 13

Packing ................................................................................................................................................................................... 13

Shipped Quantity Field Closed............................................................................................................................................... 14

Packed Quantity Becomes Shipped Quantity ......................................................................................................................... 14

Substitution of Container Items Allowed ............................................................................................................................... 14

No Planning of LPNs.............................................................................................................................................................. 15

All Delivery Lines Assigned to LPN...................................................................................................................................... 15

Serial Number Entry in STF Disabled.................................................................................................................................... 15

Load Planning Disallowed...................................................................................................................................................... 16

Transact Move Orders ............................................................................................................................................................ 16

Container Management Conditions ........................................................................................................................................ 16

WSH Features that Impact WMS Environment.................................................................................................................... 17

Delivery Grouping Rule ......................................................................................................................................................... 17

Auto Allocate.......................................................................................................................................................................... 17

Pick Slip Grouping Rule......................................................................................................................................................... 17

Maximum Lines per Pick Slip ................................................................................................................................................ 17

WMS vs WSH functionalities Table........................................................................................................................................ 18

Overview

This document highlights features in Oracle Warehouse Management System (WMS), available

through mobile device outbound, that are not supported by Oracle Shipping Executions (WSH)

Shipping Transactions form in Oracle e-Business Suite.

This analysis document is based upon the Oracle Warehouse Management System Users Guide

and Oracle Shipping Execution Users Guide.

The purpose of this document is to:

- Provide a comprehensive list of the Oracle Warehouse Management System shipping

functionalities through mobile device.

- Describe features in Oracle Shipping Execution that are disabled or changed in a WMS-

enabled environment to prevent conflicting functionality.

Introduction

Oracles Shipping Execution (WSH) application operates in conjunction with Oracle Order

Management (OM) to process orders from order capture through ship confirm. Oracle

Warehouse Management System application extends the supply chain functionality to encompass

warehouse storage and inventory control operations. It is possible to run Shipping Execution

without WMS, but it is not possible to run WMS without Shipping Execution.

In a WMS-enabled environment certain functions and features are disabled in Shipping Execution.

This disabling of the Shipping Execution application is necessary because some features exist in

both applications. For example, each application allows the user to perform data entry for

tracking numbers, quantities, and container names. Likewise, each application allows the user to

perform functions related to packing containers and planning. However, when a user chooses a

WMS-enabled instance, it is necessary to disable like operations within Shipping Execution and

allow the information (data captured) to flow from WMS to Shipping Execution. In the

warehouse operation, mobile devices and their capabilities replace desktop computers and the

functions usually entered through the Shipping Transactions form in Oracle Shipping Execution.

WMS Extends the Supply Chain Functionality

Oracle Warehouse Management System provides additional shipping management capabilities

that automate picking tasks, including:

o WMS Rules Engine allocates inventory for sales orders based on advanced rules and

strategies that model customer inventory preferences, warehouse stock rotation policies

or other factors driving the selection of subinventories, locators, lots and serials used to

fulfill the sales order request. The rules engine can also be used to select the appropriate

staging locator based on the carrier, ship method or other shipping attributes.

o WMS manages the work required to pick material for sales orders by dispatching the

work as tasks to appropriate warehouse users based on their skill set and the equipment

available for material picking. These sales order pick tasks can be interleaved with other

warehouse tasks such as replenishments and inventory accuracy counts.

o WMS helps container and License Plate Number (LPN) management by packing and

consolidating materials into LPNs, tracking the contents of containers in receiving,

inventory, shipping, and in-transit inventories.

o WMS generates labels according to customer or carrier preferred format through an

interface with compliance labeling systems.

o WMS can create dock appointments for outbound trips and direct pickers to the

appropriate corresponding staging lanes for those appointments.

By contrast, Oracle Shipping Execution does not support these functions: suggestion and task

management which are supported in WMS. As a side note, suggestions do occur as part of core

Inventory but it is not advanced rules based. Inventory picking rules only support ordering

material for allocation by stock rotation policies such as FIFO, FEFO, or ordering by a preferred

subinventory/locator.

Warehousing in WMS

The Warehousing menu is used to perform tasks inside of the warehouse. Warehousing

transactions, such as cycle and physical counting, miscellaneous issuing and receiving material,

moving inventory from one location to another (move orders), moving within your organization,

kanban replenishment.

The Oracle WMS LPN features enable you to:

o Pack

o Unpack

o Consolidate

o Split

o Update LPNs

In general, these functions are more closely linked to Oracle Inventory function than Shipping

Execution function. Since Shipping Execution only packs delivery lines and WMS packs on hand

inventory, packed configurations will not be reflected in the Shipping Transactions form until

after pick confirmation (task completion).

Both WMS and Shipping Execution allow infinite levels of nesting of LPNs (packing LPNs

within LPNs), however, WMS only passes to Shipping Execution the innermost LPN pack

information. Thus, if material for a delivery line is packed into an LPN during picking, then that

LPN will be visible in the Shipping Transaction form. However, if that LPN is further packed

into another LPN, the outermost LPN will not be visible.

Pack

WMS allows you to pack items into a newly generated LPN or into an existing LPN that resides in

inventory.

The Shipping Execution application allows you to perform this type of warehousing process from

the Shipping Transactions form Action menu, however, this feature is disabled in a WMS-enabled

organization.

Unpack

WMS allows you to unpack items from an existing LPN or you can unpack an LPN within

another LPN.

The Shipping Execution application allows you to manually unpack delivery line items if you

want to modify the delivery lines assigned to a packed delivery. Unpacking returns the delivery to

the status it held prior to packing, and allows for changes. The unpacking Action in the Shipping

Transactions form is disabled in a WMS-enabled organization.

Consolidate

WMS allows you to consolidate an existing LPN (residing within inventory) with another

existing LPN (residing within inventory) or you can consolidate an existing LPN (residing

within inventory) with a newly generated LPN.

The Shipping Execution application allows you to perform packing of a container into a

container through multiple levels. This type of warehousing process is performed in the

Shipping Transactions form Action menu by using Pack, Auto Pack, and/or Auto Pack

Master. However, this feature is disabled in a WMS-enabled organization.

Split

WMS allows you to split the contents of an existing LPN into multiple LPNs.

The Shipping Execution application requires that you first unpack the container, split the

delivery line, create the containers, and then pack the items again. However, the unpack and

pack Actions are disabled in a WMS-enabled organization.

Bulk Pack

In WMS, mobile bulk packing is used to suggest containers into which you can pack material in a

particular locator in the warehouse. Mobile bulk packing also automatically generates the

appropriate LPN labels. With bulk packing, you enter an item and quantity to be packed. You can

enter a container item if you want the system to suggest the appropriate quantity of that container

only, or you can let the system suggest both the type and quantity of containers. This system

directed packing option is available both for on hand inventory and for material allocations so that

the system can direct the picker to consolidate delivery lines into the same container based on

packing constraints and delivery grouping rules.

Any material for which there is a positive on-hand balance can be packed using this method.

It is equivalent to WSH Pack function for a delivery, however, the pack Action is disabled

in a WMS-enabled organization.

Update

WMS allows you to update the attributes of an LPN including:

o Weight UOM

o Volume UOM

o Volume content

o Container item

The Shipping Execution application does not allow performing this type of warehousing process.

Material Workbench

The Material Workbench in WMS allows you to view the contents of an LPN, the attributes of a

particular LPN, and/or the details of your warehouse, by any of the following criteria: Location,

Item, Cost Group, Status, LPN, Serial, Lot.

Shipping With Pick Release in WMS

The current shipping process consists of several steps, including: Trip Plan, Stop Plan, Delivery

Creation, Delivery Plan, Pick Release, Pick Confirm, Pack, and Ship Confirm. Some steps are

mandatory and some are optional.

Order

Management

Enter Sales

Order

WMS User

Processes

System Directed

Shipping w/Dock

Door

Appointments

OR

User Driven

Shipping

WMS System

Processes

WMS Outbound Logistic Processes Picking and Shipping

Pick Release

Create

Allocations

Assign Task

Type

Cartonization

Split/Merge

Tasks

Dispatch Task

Accept Next

Task

Load Material

Drop Material

in Staging Area

User Reports

Task Error

Corrective

Action

Workflow

Started

Yes

Task Error

Corrected

No

Scan Dock

Door to Load

System directs

User to LPNs

Scan Dock to

Close

Missing LPNs

on Trip

Ship Confirm No

Yes

Scan Dock

Door to Load

Scan LPNs to

Load

Missing LPNs

on Delivery

System directs

User to LPNs

Yes Ship Confirm

No

Missing items

on Trip

No

Yes

Picking

WMS: Pick Release Process

Warehouse Management System (WMS) uses the pick release process to select orders for release

to the warehouse for picking and shipping. After the orders are released, Oracle WMS uses the

Rules Engine to determine the appropriate material allocations. When the system completes the

allocations, the Task Type Assignment engine assigns the appropriate task types, and the system

then suggests packing configurations. At this time, order lines are also split or merged, based on

equipment capacity and pick methodology.

In non-WMS environments, the WMS Rules Engine is not used to determine appropriate material

allocations. However, shipping by License Plates Numbers (LPN) is supported.

In pre-Patchset H environments, if WMS is enabled for an existing inventory organization, users

need to set up picking and put away rules and strategies before running pick release or the orders

will backorder.

This changed in Patchset H. The user should run the compile all rules concurrent request after

installing the patchset so that the users do not need to set up picking and put away rules and

strategies.

In a WMS-enabled environment, you will not be able to use the Transact Move Order form to

transact pick wave move orders. Picks must be performed through the mobile task dispatching

infrastructure.

WMS: Picking Process

The WMS system dispatches tasks through the mobile device user interface. Through this user

interface, the picker can view the item, quantity, subinventory, and locator from which the load

can be picked. If the items are revision or lot controlled, the system also displays those details.

The picking tasks assigned by the system to a user may include any of the following:

o Pick loose items into an LPN

o Pick whole LPNs

o Pick multiple LPNs, for example, pick 5 boxes of 10 each to fulfill a task to pick 50

o Pick from LPNs, for example, pick 5 items out of a box of 10

o Pick multiple partial LPNs, full LPNs, and loose picks for a single task

o Build larger LPNs

o View cartonization suggestion

The user can confirm a pick by scanning one or more LPNs to load. If the material in the storage

locator is not identified with an LPN, then the user must confirm the item, quantity, storage

subinventory, and locator to confirm the pick.

The user can also unpack an LPN to fulfill the pick, however, if the pick units of measure are

appropriately established during system setup, then unpacking an LPN to fulfill a pick should not

be necessary. The user can also pick the items or the whole LPN into another larger LPN (like a

pallet or carton), thus building a package that can be shipped. If Cartonization is enabled, the user

will also see the container suggestion in his or her task queue.

In a non-WMS enabled environment, Oracle Inventory allows performing this type of picking

process through Transact Move Order transactions.

Shipping

Oracle WMS allows the user to perform the following three types of shipment confirmation using

Mobile User Interface:

o Quick Ship

o LPN Ship

o Dock Door Ship

Alternatively, users can ship confirm using the Shipping Transactions form on their desktop.

Quick Ship

In WMS, Quick Ship is used to ship an entire delivery without confirming individual LPNs

associated with the delivery. Because the deliver number triggers it, quick ship requires that

deliveries be manually or auto created. Furthermore, prior to performing a Quick Ship, all of the

order lines on the delivery must be staged. The material status of the staging subinventory, as well

as inventory controls is included in the Delivery Details at the time of shipment confirmation.

Also, the delivery cannot include items that are serial controlled at sales order issue. Ship sets

must be completely contained within the single delivery to ship using the Quick Ship method.

The Shipping Execution application allows you to perform this type of shipment confirmation

process through the Shipping Transaction form on the desktop; with or without WMS installed.

You can enter weight, waybill, and ship method for the delivery prior to ship confirmation.

LPN Ship

In WMS, LPN Ship is used to confirm the shipment of individual LPNs on a delivery, or to create

new deliveries and confirm the shipment of LPNs that do not yet have a delivery. You begin the

LPN Ship transaction by scanning the dock door from which the LPNs will be shipped. Next, you

scan each LPN. If the LPN cannot be ship confirmed because of a material status assigned to a lot

or serialized item contained in the LPN, or the staging subinventory and locator, then the system

displays a message with this information on the mobile device.

After all validation is successfully performed, the system uses delivery grouping rules to create the

deliveries and trips for LPNs that do not already have deliveries created. For each delivery that is

at the dock, you can optionally enter the shipment weight, shipment method, waybill number, and

other delivery-specific information.

The Shipping Execution application does not allow you to perform this type of shipping process.

A delivery is the only entity that may be ship confirmed in the WSH Shipping Transaction form.

You can pick release trips, stops, deliveries, containers (LPNs), and lines. You can associate

desired LPNs to delivery and enter details. But to complete the process, you must ship confirm

the delivery.

Dock Door Ship

Dock Door Ship is used to load and ship entire trips based on previously created dock door

appointments for the trip. Dock Door Ship uses a dock schedule and dock door appointments to

intelligently suggest the best staging lane for the material. In order to take advantage of these

features, the trip and a dock door appointment must be set up prior to pick release. The mobile

user interface form for Dock Door Ship is similar to the LPN Ship form with the exception that

since a dock appointment has been created for the trip, the system can direct the user to the

appropriate staging lane where the LPNs for the trip have been dropped.

The Shipping Execution application does not perform this type of shipping process. In WSH, you

can ship confirm Deliveries that may include LPNs. Trip and dock appointments are not

supported in WSH, however, planned pick up at origin and drop off at destination can be entered

as attributes of a Stop.

Shipping Without Pick Release in WMS

The current shipping process consists of several steps including Trip Plan, Stop Plan, Delivery

Creation, Delivery Plan, Pick Release, Pick Confirmation, Packing, and Ship Confirm. At a

minimum, users are required to create deliveries, pick release, pick confirm, and ship confirm.

Some of these steps can be automated to minimize user intervention but there must be a point at

which pick release is initiated where the system can allocate inventory that must already be on

hand in order to proceed to the ship confirm step. In just-in-time assemble to order environments

where material moves directly from the end of the manufacturing line to the delivery truck, the

function of pick release may be an unnecessary overhead.

Direct Ship

The WMS feature Direct Ship allows shipping of material directly after sales order is booked,

bypassing the pick-release/ pick-confirm process. This functionality was added to WMS to allow

users to perform ship confirmation through mobile user interface without requiring the picking

processes.

All shipped product must be packed in LPNs. Loose material cannot be shipped.

Order

Management

Enter Sales

Order

User Driven

Shipping

WMS System

Processes

(OPTIONAL)

WMS Outbound Logistic Processes Direct Ship

Scheduled

Shipment

Report

Scan Dock

Door to Load

Scan Sales

Order & Order

Line

Missing LPNs

on Delivery

System directs

User to LPNs

Yes Ship Confirm

No

Scan LPNs to

Load

.

WSH Features Disabled in WMS Environment

Several Shipping Execution features are disabled in a WMS-enabled environment. This means

that the Shipping Transaction form cannot be used to complete specific Actions.

Packing

In a WMS-enabled environment, packing operations in Shipping Transactions form are

disallowed or disabled completely for delivery details and containers. The disabled Actions

associated with packing operations, include:

Pack

Unpack

Auto-pack

Auto-pack Master

Packing Workbench

The screen shot below shows in bold the Actions related to packing that are disabled.

Additionally, when the packing operations are disabled, load planning in WSH is not possible.

Instead, these transactions are performed through the WMS mobile user interface.

Actions:

Auto-pack

Auto-pack Master

Pack

Unpack

Packing Workbench

Shipped Quantity Field Closed

In a WMS-enabled environment, Shipped Quantity is set at packing time. Since the shipped

quantity is entered at pick confirm by a RF device within a WMS-enabled organization, it is no

longer possible to enter the Shipped Quantity within the Shipping Transactions form. The

Shipped Quantity field (shown as an open field in this example) is closed, or grayed out when

this form is accessed in a WMS-enabled organization.

Packed Quantity Becomes Shipped Quantity

In a WMS-enabled environment, you cannot ship less than nor more than the packed quantity

per LPN/container (Requested Qty = Shipped Qty). When a container is packed, then that

packed quantity becomes the shipped quantity.

Substitution of Container Items Allowed

In a WMS-enabled environment, the container item (pallet, box, etc) can be changed when

confirming a picking operation. For example, if a shipper runs out of a box type, and needs to

substitute a different box type prior to pick confirming.

No Planning of LPNs

In a WMS-enabled environment, no LPNs or LPN contents will be created until pick confirm.

Because this functionality exists in a WMS-enabled organization, it is not possible to create LPNs

in the Shipping Transactions form and the Action Create LPN is disabled in the Lines/LPN

tab. The following window shows the Create LPN Action that is disabled.

All Delivery Lines Assigned to LPN

In a WMS-enabled environment, all picks need to pass to a pack container/LPN at pick confirm.

Every staged delivery must be assigned to an LPN. When you pick confirm the delivery line, you

must provide the LPN in which it is packed. The WMS mobile users do the packing and pick

confirm.

Only the innermost picked LPN is visible on the Shipping Transaction form (STF). Subsequent

packs that further nest that LPN, however, will not be visible on the STF. If the user needs to

see the levels of nesting, they must use the Material Workbench form in Inventory.

Serial Number Entry in STF Disabled

In a WMS-enabled environment, details and LPNs under serial control will always have serial

numbers entered at pick confirm through a mobile device. It is not possible to enter the serial

number(s) within the Shipping Transactions form.

Load Planning Disallowed

In a WMS-enabled environment, load planning is not possible because the packing functionality

is disabled within the Shipping Transactions form.

Transact Move Orders

In a WMS-enabled environment, the Transact button is disabled in the Transact Move Order form

because this function is carried out through the mobile user interface.

Container Management Conditions

The following container management conditions apply only in a WMS-enabled environment.

Packing Required Before or During Pick Confirm

The user must be in WMS to pack the contents before or during pick confirming or staging

them. WMS does the packing and passes the updated shipping information to Shipping

Execution.

Assigning/Unassigning Lines and Containers

In a WMS-enabled environment, if you are removing (unassigning) a delivery line from a delivery,

you must first remove (unassign) it from its container and vice versa when assigning. The

material and the LPN physically reside together on the warehouse floor. You cannot manipulate

only the LPN delivery line or only the content/material delivery line. For example, if you have

detail LPNs packed into a master container, you can only assign/unassign the master container

not the detail container.

WSH Features that Impact WMS Environment

All Shipping setup is honored in a WMS enabled organizations, including: Shipping Parameters,

container item relationships, release sequence rules, and release rules. However, in WMS enabled

organizations, the functionality is extended to coordinate tasks.

Delivery Grouping Rule

In WMS-enabled organizations, the Delivery Grouping rule impacts cartonization. Picking tasks

are grouped by the Delivery Grouping rule criteria for cartonization suggestions, regardless of

whether deliveries are auto created at or before pick release. This functionality is used to ensure

that the system never allows a user to pack material for different shipments into the same

container.

Auto Allocate

In WMS-enabled organizations, if the Auto Allocate box is unchecked in the following three

areas: Shipping Parameters form, Release Rules form, Release Sales Order form, then the pick

wave move order created at Pick Release is not allocated and picking tasks are not released to

warehouse users. This feature is useful if you wish to use the pick wave move order in the WMS

rules simulation form to diagnose problems in the picking rules setup that might ordinarily cause

the delivery line to automatically backorder at allocation time.

Pick Slip Grouping Rule

WMS uses the pick slip grouping rule that is set up in WSH to determine the pick methodology in

the warehouse. Tasks are dispatched to users in groups divided by the grouping rule.

Maximum Lines per Pick Slip

In WMS-enabled organizations, the Shipping Parameter for Number of Pick Slip Lines is used by

WMS to determine the maximum number of tasks that can be dispatched to a user at a time,

regardless of the pick methodology.

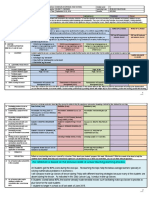

WMS vs WSH functionalities Table

The following table summarizes the WMS mobile device functions vs. Shipping Transactions form functions.

WMS: Function WSH: Equivalent Action on Shipping Transactions form

1. Outbound > Picking Release Sales Orders > Release Sales Orders for Picking > select Auto

Allocate Yes and Move Orders > Transact Move Orders

1.1 Next or Current Task Task is a WMS notion only. No equivalent function.

1.2 Manual Pick

1.3 Pick by LPN

1.4 Express Pick Task is a WMS notion only. No equivalent function.

2. Outbound > Shipping

2.1 Quick Ship Transactions > on query manager window, select search for

deliveries > enter criteria > find button

2.2 LPN ship Transactions > on query manager window, select search for

deliveries or trips > enter criteria > find button

2.3 Dock Door Ship (Load Dock) Task is a WMS notion only. No equivalent function.

2.4 Direct ship In R11i.8, it is not possible to ship through WSH without pick release.

3. Warehousing > LPN

transactions

or Outbound > Packing

Transactions > on query manager window, select search for lines >

enter criteria > find button

3.1 Pack On shipping transactions > select pack action > select Go button

3.2 Unpack On shipping transactions > select unpack action > select Go button

3.3 Consolidate Transactions > on query manager window, select search for LPNs >

enter criteria > find button > select pack action > select Go button

3.4 Split On shipping transactions > select unpack action > select Go button

> select split line & Go > select create LPNs & Go > select pack &

Go

3.5 Bulk Pack Equivalent to Pack function for a delivery. On shipping transactions >

select pack action > select Go button

3.6 LPN update

weight, volume, container

It is impossible to do that through Shipping Execution function.

WMS mobile device functions vs WSH form functions

Created: October 2002

Author: Timothy Conroy

Copyright Oracle Corporation 2001

All Rights Reserved Printed in the U.S.A.

This document is provided for informational purposes

only and the information herein is subject to change

without notice. Please report any errors herein to

Oracle Corporation. Oracle Corporation does not

provide any warranties covering and specifically

disclaims any liability in connection with this document.

O

racle is a registered trademark.

Oracle Corporation

World Headquarters

500 Oracle Parkway

Redwood Shores, CA 94065

U.S.A.

Worldwide Inquiries:

650.506.7000

Fax 650.506.7200

Copyright Oracle Corporation 2000

All Rights Reserved

You might also like

- STP 21-1-SMCTDocument468 pagesSTP 21-1-SMCTNicole Parisio100% (1)

- April 2023Document12 pagesApril 2023Vladyslav VolkovNo ratings yet

- Using OTM GTM To Report Accurate AES Filing To Customs & Border Protection (CBP) For Canada Rail BDocument19 pagesUsing OTM GTM To Report Accurate AES Filing To Customs & Border Protection (CBP) For Canada Rail BNithiyananth DNo ratings yet

- Document 469339.1Document16 pagesDocument 469339.1Venkatesh PR100% (1)

- C15U-22A Getting The Most Out of OTM Planning Gilberto Kuzuhara Oracle ConsultingDocument27 pagesC15U-22A Getting The Most Out of OTM Planning Gilberto Kuzuhara Oracle ConsultingCarlosNo ratings yet

- CMT Tool TechnDocument15 pagesCMT Tool TechnAhmed MoustafaNo ratings yet

- Strategic Audit - People's BankDocument5 pagesStrategic Audit - People's BankDumidu Chathurange Dassanayake100% (4)

- Oraclewmsandoraclemscaoverview 170202051623Document62 pagesOraclewmsandoraclemscaoverview 170202051623manitenkasiNo ratings yet

- WMS FeaturesDocument28 pagesWMS Featuresnmkumar198No ratings yet

- Oracle SOA BPEL Process Manager 11gR1 A Hands-on TutorialFrom EverandOracle SOA BPEL Process Manager 11gR1 A Hands-on TutorialRating: 5 out of 5 stars5/5 (1)

- 10151-Fully Automated Distribution Centre With Oracle Warehouse Management System-Presentation - 76Document31 pages10151-Fully Automated Distribution Centre With Oracle Warehouse Management System-Presentation - 76Venkata jagadish kumarNo ratings yet

- Oracle WMS DirectionsDocument27 pagesOracle WMS DirectionsPoshala_Ramesh100% (1)

- Manh Scale enDocument2 pagesManh Scale enSarit MukherjeeNo ratings yet

- Oracle Transportation Management - HighlevelsolutionDocument12 pagesOracle Transportation Management - HighlevelsolutionAbhinav M.S.No ratings yet

- Oracle Warehouse Management CloudDocument2 pagesOracle Warehouse Management CloudDhanaraaj DevelopersNo ratings yet

- 3PL-Billing Functionality-Oracle WMS Cloud PDFDocument16 pages3PL-Billing Functionality-Oracle WMS Cloud PDFAnthonyStraussNo ratings yet

- How To Pick-Release SO For Reserved.Document7 pagesHow To Pick-Release SO For Reserved.sagarbolisettiNo ratings yet

- Owmsu PDFDocument297 pagesOwmsu PDFbaluanneNo ratings yet

- Oracle Shipping ExecutionDocument57 pagesOracle Shipping Executionsatya221No ratings yet

- Integration XMLDocument10 pagesIntegration XMLHarisha GowdaNo ratings yet

- Functional Overview: Oracle Warehouse Management System & Oracle Mobile Supply Chain ApplicationDocument26 pagesFunctional Overview: Oracle Warehouse Management System & Oracle Mobile Supply Chain ApplicationmaniNo ratings yet

- OTM Settlement Implementation Challenges For 3Pl and Others Anand Madhira Srujan TechnologiesDocument44 pagesOTM Settlement Implementation Challenges For 3Pl and Others Anand Madhira Srujan TechnologiesSambit TripathyNo ratings yet

- Dock Door Shipment Without OTMDocument13 pagesDock Door Shipment Without OTMArun BalajiNo ratings yet

- Oracle E-Business Suite Supply Chain ManagementDocument2 pagesOracle E-Business Suite Supply Chain Managementthetanja100% (1)

- Otm Integration Wms PoDocument17 pagesOtm Integration Wms Pokkathiresan4998No ratings yet

- Oracle OTM 19C DetailsDocument14 pagesOracle OTM 19C DetailsSJ SJNo ratings yet

- Operational Keys For A Successful WMS Go-LiveDocument7 pagesOperational Keys For A Successful WMS Go-Livearun.chuvuk4421No ratings yet

- OAUG Oracle WMS ManagementDocument42 pagesOAUG Oracle WMS ManagementmobakNo ratings yet

- Oracle WMS BAR Code (White Paper)Document5 pagesOracle WMS BAR Code (White Paper)floatingbrain100% (2)

- R12 OPM QltyDocument17 pagesR12 OPM Qltysand_reddyNo ratings yet

- Bulk Picking WMSDocument7 pagesBulk Picking WMSVenkata jagadish kumarNo ratings yet

- Cartonization Contained Container RelationsshipDocument13 pagesCartonization Contained Container RelationsshipameetdeyNo ratings yet

- Oracle Warehouse Management Cloud: Web Reports Gen2 Report CreationDocument50 pagesOracle Warehouse Management Cloud: Web Reports Gen2 Report Creationkirubakar.l3015100% (1)

- 3PL WMS IntegrationORACLE01Document33 pages3PL WMS IntegrationORACLE01Jorge DeaThrider VazquezNo ratings yet

- Integration With Oracle's WMS and MSCA: White PaperDocument7 pagesIntegration With Oracle's WMS and MSCA: White Papergopalkhandelwal1234No ratings yet

- Managing ContainersDocument25 pagesManaging ContainersMuhammad ImtiazNo ratings yet

- 642 Otm NfsDocument37 pages642 Otm Nfsdhruvgoel1No ratings yet

- Setup To Achieve Skip Lot Inspection FunctionalityDocument7 pagesSetup To Achieve Skip Lot Inspection FunctionalityspondugulaNo ratings yet

- © 2008 Oracle Corporation - Proprietary and Confidential 1Document33 pages© 2008 Oracle Corporation - Proprietary and Confidential 1Manikumar KollaNo ratings yet

- Inspirage Planning Central Solution: The ChallengeDocument3 pagesInspirage Planning Central Solution: The ChallengeManu K BhagavathNo ratings yet

- Ports & Shipping Solutions: Presenter's Name: Presenter's TitleDocument30 pagesPorts & Shipping Solutions: Presenter's Name: Presenter's TitleeepabaluNo ratings yet

- Oracle SCM Cloud Shipping With ShipConsoleDocument2 pagesOracle SCM Cloud Shipping With ShipConsoleshipconsoleNo ratings yet

- D61584Document442 pagesD61584Andrea GriffithNo ratings yet

- Defaulting Rules Setup PDFDocument24 pagesDefaulting Rules Setup PDFSandyNo ratings yet

- Oracle WMS PICK White PaperDocument97 pagesOracle WMS PICK White PaperjavierNo ratings yet

- WMS FundamentalsDocument35 pagesWMS FundamentalsKapil KarwalNo ratings yet

- Manage Inventory AccuracyDocument16 pagesManage Inventory Accuracyhimavicky100% (1)

- Understanding and Using WMS CartonizationDocument37 pagesUnderstanding and Using WMS CartonizationameetdeyNo ratings yet

- Test Result JDA ImplementationDocument18 pagesTest Result JDA ImplementationNaek OmpusungguNo ratings yet

- Direct ShippingDocument19 pagesDirect Shippingscribd_mohan100% (1)

- Otm GTM Cloud 642 Recorded Training 3715159 PDFDocument1 pageOtm GTM Cloud 642 Recorded Training 3715159 PDFKhushboo RaniNo ratings yet

- Oracle Implementations Integrations Between Modules: Order Management ShippingDocument9 pagesOracle Implementations Integrations Between Modules: Order Management ShippingSonindhraNo ratings yet

- MRP Supply Chain Planning GlossaryDocument9 pagesMRP Supply Chain Planning Glossarymohun123No ratings yet

- Modified 01-JUL-2010 Type BULLETIN Status PUBLISHED: TOP 20 FAQ's On ATO Process (ID 108774.1)Document9 pagesModified 01-JUL-2010 Type BULLETIN Status PUBLISHED: TOP 20 FAQ's On ATO Process (ID 108774.1)Jonga LnameNo ratings yet

- ICS-based WMS Cloud and INV Cloud Integrations V6Document58 pagesICS-based WMS Cloud and INV Cloud Integrations V6Rady KotbNo ratings yet

- Oracle WMS Rules Engine - Capabilities and Rule TypesDocument1 pageOracle WMS Rules Engine - Capabilities and Rule TypesRajesh LaddhaNo ratings yet

- OM DefRule Proc ConsDocument24 pagesOM DefRule Proc ConsavishekrcNo ratings yet

- OTM Custom FillingDocument50 pagesOTM Custom Fillingaditya udupaNo ratings yet

- WMS Task AssignmentsDocument2 pagesWMS Task AssignmentsNestor BoscanNo ratings yet

- Mobile Supply Chain-Unplugged - Ashok Kowdle, ASTDocument24 pagesMobile Supply Chain-Unplugged - Ashok Kowdle, ASTsdgeigerNo ratings yet

- Consigned Orders in PurchasingDocument28 pagesConsigned Orders in PurchasingOmer ShahzadNo ratings yet

- R12-1Mobile Personalization White Paper NewDocument83 pagesR12-1Mobile Personalization White Paper NewASINGAM100% (3)

- Dissertation Histoire Du Droit ExempleDocument6 pagesDissertation Histoire Du Droit ExempleCollegePaperWriterLittleRock100% (1)

- Ar 14 15Document371 pagesAr 14 15aum sivaNo ratings yet

- Part Catalog Ninja 150 SS 2015Document79 pagesPart Catalog Ninja 150 SS 2015Muhammad Haryorekso KusumoNo ratings yet

- Bhrighu Saral Paddathi-34 BW Final PDFDocument14 pagesBhrighu Saral Paddathi-34 BW Final PDFGarga100% (1)

- Free and Forced ConvectionDocument7 pagesFree and Forced ConvectionBunty Perera83% (6)

- C Astral Mar 2016Document15 pagesC Astral Mar 2016stalin13100% (1)

- MD101Document1 pageMD101mloga86No ratings yet

- DLL - Araling Panlipunan-9 (Sept 26-30)Document3 pagesDLL - Araling Panlipunan-9 (Sept 26-30)G-one Paisones100% (4)

- Important Concepts For General Science UPSC IAS PrelimsDocument4 pagesImportant Concepts For General Science UPSC IAS Prelimshim123verNo ratings yet

- Lapford Lookout - February 2016Document16 pagesLapford Lookout - February 2016StephenWensleyNo ratings yet

- Cylinder Balancing, Fault TracingDocument8 pagesCylinder Balancing, Fault TracingIzz BaharNo ratings yet

- Ncm113 Oxygenation Viral RhinitisDocument11 pagesNcm113 Oxygenation Viral RhinitisJaka Carina CalicaNo ratings yet

- PM RBI Grade B CA Compilation PDFDocument47 pagesPM RBI Grade B CA Compilation PDFRavi KiranNo ratings yet

- HWDocument2 pagesHWSeth0% (1)

- Material AnalysisDocument7 pagesMaterial AnalysisNiña Grace Rita MangleNo ratings yet

- Capital Budget TemplateDocument1 pageCapital Budget TemplaterajvakNo ratings yet

- Property Cases Batch 1Document22 pagesProperty Cases Batch 1JBNo ratings yet

- General Chemistry III: Core InstructorsDocument7 pagesGeneral Chemistry III: Core InstructorsSimon SituNo ratings yet

- Steval Isc003v1Document4 pagesSteval Isc003v1James SpadavecchiaNo ratings yet

- High Performance Concrete Literature ReviewDocument7 pagesHigh Performance Concrete Literature Reviewea3f29j7100% (1)

- Grasas ShellDocument42 pagesGrasas ShellheflodNo ratings yet

- Property Final Exams - ADocument2 pagesProperty Final Exams - ADANICA FLORES100% (1)

- AMPS8105 Jargon Buster Issue 4 A5 04 WebDocument64 pagesAMPS8105 Jargon Buster Issue 4 A5 04 WebdaneNo ratings yet

- Mixed Crop-Livestock Systems: An Economic and Environmental-Friendly Way of Farming?Document9 pagesMixed Crop-Livestock Systems: An Economic and Environmental-Friendly Way of Farming?Wahyu Trimurti HandayaniNo ratings yet

- Intro Units 9-16 Practice Quiz: Unit 9-10 1. Complete The Sentences With A, An, Any, or SomeDocument6 pagesIntro Units 9-16 Practice Quiz: Unit 9-10 1. Complete The Sentences With A, An, Any, or SomeEsther GiannamoreNo ratings yet

- Astm F438Document7 pagesAstm F438Hernando Andrés Ramírez GilNo ratings yet