0% found this document useful (0 votes)

491 views26 pagesFunctional Overview: Oracle Warehouse Management System & Oracle Mobile Supply Chain Application

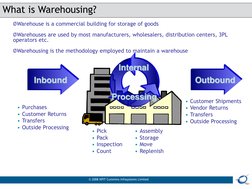

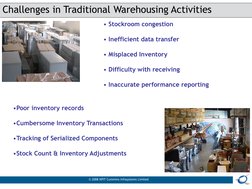

The document provides an overview of Oracle Warehouse Management System and Oracle Mobile Supply Chain Applications. It discusses challenges with traditional warehousing, how a warehouse management system and mobile applications can help address these challenges, and key features of Oracle's solutions like rules-driven processes, barcode support, advanced material management and compliance labeling, cross docking, and integration capabilities.

Uploaded by

maniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

491 views26 pagesFunctional Overview: Oracle Warehouse Management System & Oracle Mobile Supply Chain Application

The document provides an overview of Oracle Warehouse Management System and Oracle Mobile Supply Chain Applications. It discusses challenges with traditional warehousing, how a warehouse management system and mobile applications can help address these challenges, and key features of Oracle's solutions like rules-driven processes, barcode support, advanced material management and compliance labeling, cross docking, and integration capabilities.

Uploaded by

maniCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PPT, PDF, TXT or read online on Scribd