Professional Documents

Culture Documents

The Technology Behind Glucose Meters

The Technology Behind Glucose Meters

Uploaded by

wahyuthp43Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Technology Behind Glucose Meters

The Technology Behind Glucose Meters

Uploaded by

wahyuthp43Copyright:

Available Formats

S-10

DIABETES TECHNOLOGY & THERAPEUTICS

Volume 10, Supplement 1, 2008

Mary Ann Liebert, Inc.

DOI: 10.1089/dia.2008.0005

The Technology Behind Glucose Meters: Test Strips

JOACHIM HNES, Dr. rer. nat.,

1

PETER MLLER, Dr. rer. nat.,

1

and NIGEL SURRIDGE, Ph.D.

2

ABSTRACT

Blood glucose meters are the basis for people with diabetes to live a near-normal life avoid-

ing acute and late complications. The main part of the technology behind blood glucose meters

is formed by test strips. This paper tries to give an overview and some insight into the princi-

ples of test strips. They contain enzymes, coenzymes, mediators, and indicators in the form of

a dry layer and convert blood glucose concentration into a signal that is readable by the meter.

Measurement speed, specificity, accuracy, and precision are dominated by test strip chemistry

and design. During the last decades, they have been developed to do the job in 5 s, with less

than 1 L of blood. It is our firm belief that they will be developed further and stay important

for decades to come.

INTRODUCTION

I

NABILITY TO CONTROL their blood sugar levels

is a major challenge for many patients with

diabetes. After decades of development and

use of self-measurement of blood glucose, com-

bined with intensified insulin therapy, the Di-

abetes Control and Complications Trial study

1

has proven that frequent control and proper

regulation of blood glucose are essential for

those with diabetes to live a near normal life

and to avoid late complications. Today, people

with diabetes can choose from a multitude of

blood glucose meters. Every time a measure-

ment is required, a finger (or other site) is

lanced with a small lancing device, and a tiny

blood drop is obtained and then placed onto a

small, single-use test strip. After a few seconds,

the meter displays the result, and the patient

can act accordingly.

Everyone is familiar with blood glucose me-

ters, but what is the technology behind them?

The meter is an electronic device converting

a signal to a digital value, which then is shown

on the display. Electronic memory, communi-

cation with a personal computer, and many

other features are packed into a nicely designed

housing. Handling is generally easy, and me-

ters have become more like nice examples of

consumer electronics. But in a nutshell, the ba-

sic function is that of an ampere meter in the

case of electrochemical measurement or a pho-

tometer for color-forming strips.

The key for accurate measurement of blood

glucose is conversion of the glucose concentra-

tion to a specific signal. This has to be done

from a small drop (typically around 1 L) of

the highly complex blood sample. Continuous

improvements of technology have enabled test

strips to do this difficult job in just 5 s. (For the

1

Roche Diagnostics GmbH, Mannheim, Germany.

2

Roche Diagnostics Operations Inc., Indianapolis, Indiana.

role of meters, see the section Measurement

Methods: Electrochemistry and Photometry.)

Lets have a closer look inside these little

pieces of plastic, and behind such well-de-

signed blood glucose meters.

HISTORY

Self-measurement of blood glucose started

around 1970 with test strips designed for visual

evaluation by the patient. HGT 20-800 or Chem-

strip bG

from Boehringer Mannheim

(Mannheim, Germany) and Ames (Elkhart, IN)

Dextrostix

were typical products in 1975. With

Chemstrip bG, the customer had to place a large

drop of blood (25 L) on top of the chemistry

coating. After a precisely measured time interval

of 1 min, the blood was manually wiped off, and

after a further minute, the color of the chemistry

pad had to be compared with a printed color

scale. Well-trained patients were able to read

blood glucose with sufficient accuracy to man-

age their diabetes successfully. Blood glucose

meters came into use around 1975.

The next revolution came in 1987, when

LifeScan (Milpitas, CA) introduced the One

Touch

system. The test strip was a flat piece

of plastic with a hole covered by a membrane.

The blood drop was placed on the top side of

the membrane. Since the membrane layer did

not separate erythrocytes, the resulting color

was a mixture of red from hemoglobin plus

blue dye from the glucose reaction. Therefore,

visual evaluation was not possible. After 45 s,

the meter measured from the bottom side of the

strip, with two wavelengths being used to com-

pensate for the color of blood.

2

In 19871988,

the first test strip employing an electrochemi-

cal measurement was introduced with the Ex-

acTech

Pen meter (Medisense, Waltham, MA;

now Abbott Diabetes Care, Alameda, CA).

Wiping was unnecessary, and visual evalua-

tion was not applicable, of course. All other

companies reacted and developed non-wipe

systems as well, and wipe strips and visual

evaluation are completely outdated now.

Since the late 1980s, test strip measurements

became faster and faster, and nowadays, 5 s is

state of the art. In parallel, the sample volume

required has decreased (Fig. 1), and the test sys-

tem with the lowest volume currently is

Therasenses [now Abbott Diabetes Cares]

FreeStyle with 0.3 L, introduced in 1999.

The motivation for this development to low

volume was to enable a successful test every

BLOOD GLUCOSE TEST STRIPS S-11

0,01

0,1

1

10

100

1965 1970 1975 1980 1985 1990 1995 2000 2005 2010 2015

Year of Product Launch

B

l

o

o

d

V

o

l

u

m

e

(

L

)

Roche electrochemical

Roche photometric

LifeScan

Abbott

Bayer

New Competitors

Four major players have

lined up between 0.3-1 l

FIG. 1. Overview of sample volume need versus time of product introduction. Test strips have been developed dur-

ing the last decades to work with samples as small as 0.3 L.

time. Furthermore, it enabled shallower lanc-

ing depth to avoid pain. Our feeling is that

this goal has been achieved by all major prod-

ucts at a volume around or below 1 L. Cus-

tomers cannot control lancing to precisely

produce smaller amounts. After lancing, they

either get nothing because lancing depth was

insufficient, or they are easily able to produce

a drop of 1 L or even greater. Such a drop

is necessary to allow easy targeting, espe-

cially when the capillary entrance of a test

strip has to be hit. The lower the volume

gained, the more difficult is the application.

A further reduction of net volume required

would not be advantageous for the customer.

If accompanied by a further miniaturization

of strips and capillaries, it would even make

handling more difficult.

A further development needs to be men-

tioned. In the beginning, visual or photometric

test strips were dosed from the top, and a large

blood drop was placed on the surface. Electro-

chemical strips, in contrast, are filled by con-

tacting the drop with the entrance of a capil-

lary, mostly from an edge of the strip. Even

some current photometric strips like Accu-

Chek

(Roche Diagnostics, Mannheim) Com-

pact use capillary fill. The market has moved

to a certain extent from photometry and top

dosing towards electrochemistry and capillary

fill. This is certainly due to the fact that in cer-

tain circumstances such as professional health-

care environments, it is important to keep

blood away from the main meter housing for

hygienic/safety reasons. Electrochemical test

strips, up to this point, have been better able to

deliver this feature because of the length of con-

ducting leads that can be placed between the

meter and the blood application site of the test

strips. No such severe limitation exists for the

application of photometry in systems to be

used by single individuals, and photometry

may also provide this benefit without the need

to fill a lengthy capillary in novel future itera-

tions of the technology.

In general, 30 years of continuous develop-

ment by many competing companies have led

self-monitoring of blood glucose to an ease of

use that makes it applicable for nearly every-

one.

THE TECHNOLOGY INSIDE STRIPS

Enzymes

All current strips use enzymes as specifiers

for glucose. The enzymes are oxidoreductases,

and oxidize glucose to gluconolactone. Elec-

trons from the glucose are generally then trans-

ferred to the oxidized form of a mediator mol-

ecule, thereby converting it to the reduced

form. (A mediator is usually a small organic or

inorganic chemical capable of existing in both

an oxidized and a reduced form, and generally

reacts quickly to donate or receive electrons.)

This mediator in turn delivers the electrons to

an electrode for electrochemical measurement

or to an indicator molecule, which in turn

forms color. All enzymes use coenzymes (or co-

factors), and additional enzymes may even be

necessary where the overall reaction involves

intermediate steps. Table 1 shows an overview.

The three types of glucose dehydrogenases

(GDHs) are completely different enzymes.

Pyrrolo quinoline quinone (PQQ)-dependent

GDH is also known as glucose dye oxidore-

ductase (GlucDOR). The combination of hexo-

kinase with glucose-6-phosphate dehydroge-

nase, which is the standard reference method

in many laboratories, is not used in current test

strips. The enzyme is responsible for the test

strips sugar specificity, but none of the en-

zymes is completely specific for glucose. Glu-

cose oxidase (GOD) has been described as be-

ing highly specific,

3

but, e.g., mannose is an

interferent although in the low percentage

range. Both 2- and 6-deoxyglucoses react even

at higher rates.

4

PQQ-dependent GDH con-

verts maltose and glucose with similar catalytic

efficiency.

5

Nicotinamide adenine dinucleotide

(NAD)-dependent GDH reacts with xylose,

6

and flavin adenine dinucleotide (FAD)-depen-

dent GDH reacts with maltose, mannose, galac-

tose, and lactose but (like GOD) in the single

digit percentage range only.

7

A high specificity

in enzyme activity tests is a good prerequisite

for using the enzyme in a test strip. However,

high concentrations of enzyme in the formula-

tions can make low side activities a real inter-

ference.

In general, these sugars are not present in the

blood of healthy people or people with dia-

HNES ET AL. S-12

betes. But in the case of some medications or

rare diseases, maltose, xylose, or galactose may

be found, leading to false-positive glucose

readings. It is essential for patients and physi-

cians to carefully read the package insert of test

strips and to avoid using products with the

wrong enzyme system for that special treat-

ment case. On the other hand, it is essential for

the companies to improve specificity even if

sugar nonspecificity is an issue for only a few

patients. Intensive work has been dedicated to

improvement in the specificity of PQQ-depen-

dent GDH. Mutations have been used to reduce

maltose reaction to below 2% of the wild-type

or nonmutated value,

8,9

and product imple-

mentation is in progress. Bayer Healthcare

(Tarrytown, NY) has already changed the en-

zyme of their Ascensia

Microfill

strip prod-

uct from PQQ-dependent GDH to FAD-de-

pendent GDH. GOD also seems to be

advantageous in terms of sugar specificity

since mannose is not used in medications to-

day and deoxy sugars are of academic interest

only, but the natural second substrate of this

enzyme is oxygen. The reduced form of this

substrate is the active oxidant hydrogen per-

oxide. Consequently, nonspecific oxidation of

metabolites and drugs by this hydrogen per-

oxide leads to interferences, e.g., from uric acid

and bilirubin. The alternative for GOD is to use

a non-natural mediator instead of oxygen, but

such a mediator needs to compete with oxygen

for the electrons from glucose. Variations in

oxygen content of the sample, e.g., among ve-

nous, capillary, and arterial blood, then lead to

apparent differences in measured glucose. Al-

titude dependency is a frequent interference

with GOD-based strips, too.

Mediators

The enzyme transfers electrons from glucose

to the oxidized mediator. The reduced media-

tor formed transfers the electrons to a working

electrode, producing a current, or to an indica-

tor, forming color. Ferrocene derivatives and

BLOOD GLUCOSE TEST STRIPS S-13

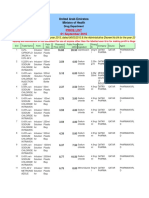

TABLE 1. ENZYME/MEDIATOR SYSTEMS

Additional

Enzyme Coenzyme enzyme Mediator system Indicator Product examples

GOD FAD POD Air oxygen/hydrogen Leuco dye Chemstrip bG,

peroxide One Touch

GOD FAD None Hexacyanoferrate Palladium Accu-Chek

III/hexacyanoferrate II electrode Advantage

GOD FAD None Hexacyanoferrate Carbon electrode One Touch Ultra

III/Hexacyanoferrate II

GDH (GlucDOR) PQQ None Hexacyanoferrate Palladium Accu-Chek

III/hexacyanoferrate II electrode Advantage

(Comfort Curve

strip)

GDH (GlucDOR) PQQ None Quinoneimine/ Phosphomolybdic Accu-Chek

phenylendiamine acid Active, Accu-

Chek Compact,

Accu-Chek Go

GDH (GlucDOR) PQQ None Quinoneimine/ Gold electrode Accu-Chek Aviva

phenylendiamine

GDH (GlucDOR) PQQ None Osmium Electrode FreeStyle

GDH NAD None Phenanthroline quinone Electrode Precision Xtra

GDH FAD None Hexacyanoferrate Palladium Ascensia

III/hexacyanoferrate II electrode Microfill

This is not a complete overview. Other combinations have been used and will be used in the future. Glucose oxi-

dase (GOD) was used first. Glucose dehydrogenase (GDH)/flavin adenine dinucleotide (FAD) is the enzyme most

recently introduced. GlucDOR, glucose dye oxidoreductase; NAD, nicotinamide adenine dinucleotide; POD, peroxi-

dase/ PQQ, pyrrolo quinoline quinone.

Accu-Chek is a trademark of Roche Diagnostics, Ascensia Microfill of Bayer Healthcare, Chemstrip bG of Boehringer

Mannheim, Freestyle and Precision Xtra of Abbott Diabetes Care, and One Touch of LifeScan.

hexacyanoferrate are examples of one-electron

mediators working in this relatively simple

manner. Two-electron mediators, e.g., quinones

are used as well. Phenanthroline quinone is the

mediator in Abbott Diabetes Cares Precision

Xtra

. The same enzyme/mediator system

may sometimes be used for photometric and

electrochemical measurement as is the case for

hexacyanoferrate, which was used as an elec-

trochemical mediator in many products and as

part of the now discontinued Accu-Chek Easy

(Boehringer Mannheim, Indianapolis, IN) pho-

tometric system.

Some mediator systems are more complex

than the simple scheme of Figure 2. The scheme

for GOD/peroxidase (POD) systems working

with atmospheric oxygen is shown in Figure 3.

This is a very atypical mediator system since

oxygen and hydrogen peroxide are not recy-

cled. Instead, the oxidative power of oxygen is

used in two steps: the first is dependent on glu-

cose, and the second uses the intermediate

formed to oxidize a leuco dye. A clear propor-

tionality of dye formation to glucose should be

the consequence. However, many dyes are also

substrates of GOD,

4

including the one formed

from tetramethyl benzidine. Using glucose,

they can be reduced again to the leuco dye.

With an excess of glucose over oxygen, nearly

no dye is formed. This is the explanation why

an early optical test strip, Chemstrip bG, did

not form significant amounts of color in the first

minute when the test pads were covered by the

sample. This could easily be observed using

aqueous glucose solutions instead of blood.

Only a faint blue borderline at the edge of the

sample drop indicated the reaction in this first

phase. Color formation was only visible after

wiping when oxygen freely diffused into the

layer and competed effectively with the dye for

the electrons from glucose. A further observa-

tion in Chemstrip bG was that hydrogen per-

oxide formed much more color than an equiv-

alent amount of glucose. Taking into account

that GOD uses only -D-glucose, which is two-

thirds of the full glucose concentration, we cal-

culated that the relative yield of dye from glu-

cose (normalized to the dye from hydrogen

peroxide) was between 60% at 1 mM and be-

low 10% at 30 mM. This deviation from clear

stoichiometry of the chemical reaction was em-

pirically built into the test strip formulation

during development. With high and constant

yield, the color at high glucose would have

been much too intensive for precise measure-

ment.

Apart from competition by oxygen, there are

also other reasons that drive the search for new

mediators. These include the basic require-

ments of stability and the ability to react

quickly with typical coenzyme sites (thus al-

lowing fast measurements and high signals), as

well as having low redox potentials that reduce

the cross-reactivity of mediators with other bi-

ological molecules, which can contribute to in-

accuracy. In the case of electrochemical sensors,

a lower redox potential of the mediator also al-

lows the measurement electrode to operate at

lower applied potential, also reducing interfer-

ing reactions and inaccuracy.

Nitrosoanilines are a further example of an

atypical test strip constituent in that they are

not mediators themselves, although they do

address many of the advantages listed

above.

10,11

Rather, they react in situ on the test

strip with glucose, and the enzyme to form a

HNES ET AL. S-14

Glucose Mediator

ox

2 Electrons Electrode

r o t a c i d n I e m y z n E

Glucono-

lactone Mediator

red

Glucose Oxygen

GOD

Glucono-

lactone

Hydrogen

peroxide

Leuco

dye

Glucono-

lactone

POD GOD

Water Dye Glucose

FIG. 2. Scheme of mediator action. The mediator is a

catalyst transferring reduction equivalents from the re-

duced enzyme/coenzyme system to an electrode or to a

color-forming indicator substance.

FIG. 3. Reactions in strips with athmosperic oxygen

mediator and GOD/POD enzymes. This is a very atypi-

cal mediator system since oxygen/hydrogen peroxide is

not recycled. Instead, the oxidative power of oxygen is

used in two steps. Because of the lack of specificity of

GOD, many dyes just formed can be reduced again using

a second molecule of glucose.

species that can act as a mediator. Figure 4

shows the mediator cycle derived from N,N-

bis-(2-hydroxyethyl)-4-hydroximino-cyclo-

hexa-2,5-dienylidene ammonium chloride. The

compound might be called a quinone diimine

oxide. It is in mesomeric equilibrium with the

corresponding C-nitrosoaniline (see Eq. 145 in

Boyer

12

). Unlike N-nitrosoanilines, which are

known to be potent carcinogens, it passed all

tests for mutagenesis and carcinogenesis with-

out positive results. Electrons eventually are

transferred either to an electrode in an electro-

chemical strip or to the indicator in a photo-

metric strip.

Many oxidoreductases accept nitrosoani-

lines for electron transfer, including the GDHs

with FAD and PQQ cofactors and GOD. The

enzymes catalyze a very similar reduction

twice. First they work with a quinone diimine

oxide, then with a quinone diimine. The first

intermediate, a hydroxylamine, is unstable be-

cause of the electron donating power of the p-

amino group and decays to the quinone di-

imine (see the reaction with NAD-dependent

dehydrogenases described below). Thus the

nitrosoaniline is a stable precursor for the

catalytically active and less stable mediator

pair quinone diimine/phenylenediamine. Af-

ter the second enzymatic reduction step, trans-

fer of electrons to a working electrode or to an

indicator like phosphomolybdic acid is a rapid,

nonenzymatic process.

Nitrosoanilines can be reduced by aldehyde

reductases or NAD-dependent alcohol dehy-

drogenases as well since the nitroso group is

isoelectronic with an aldehyde. Reduction

equivalents for this reaction come from NADH,

which in turn is oxidized to NAD. But the

mechanism is a hydride transfer to the nitroso

group, and the product is the quinone diimine

formed by nonenzymatic decay of the primary

reduction product, the aromatic hydroxyl-

amine.

13

This reaction does not produce reduc-

tive equivalents but a new oxidizing species,

and it is not used in glucose test strips.

Electrochemical reactions need a reaction at

the counter electrode to close the current cycle.

In this case we simply use the electrochemical

BLOOD GLUCOSE TEST STRIPS S-15

FIG. 4. The mediator system in Roche photometric strips (R HOCH

2

CH

2

). Many oxidoreductases accept ni-

trosoanilines for electron transfer including the GDHs with FAD and PQQ cofactors and GOD. The resulting re-

duction equivalents can be transferred to a working electrode or to a color-forming indicator substance. In the case

of electrochemical measurement, the current cycle is closed by a reduction at the counter electrode, which is com-

pletely equivalent to the enzymatic reduction.

reduction of nitrosoanilines, which proceeds

in the same way as the enzymatic route. It is

well known that aromatic nitroso compounds

with electron donating substituents are elec-

trochemically reduced in a four-electron reac-

tion to the corresponding anilines.

14

Thus ni-

trosoanilines are used successfully in both

photometric and electrochemical test strips

from Roche.

What is the reason for all those difficult

chemical reactions? Why not select the most

simple mediator reaction of hexacyanoferrate

III/hexacyanoferrate II, which is widely used

in todays products? The mediator reaction is

a potential source of interferences by reducing

agents. Uric acid and bilirubin are endogenous

sources; acetaminophen, dopamine, ascorbic

acid, and many other medications introduce

exogenous reduction equivalents. A simple in-

organic complex like ferricyanide is a redox

mediator without kinetic barriers and reacts

rapidly with all those compounds. We found

that the chemical interferences can be very

much improved using more complex chem-

istry. A mediator of high chemical selectivity is

an advantageous choice like the selection of a

specific enzyme. However, quantitative effects

of interferents are influenced by the properties

of dry chemistry layers and by design of the

measurement chamber and the measurement

method. Appropriate information on remain-

ing interferences can be found in the package

insert of test strips.

Enzyme kinetics

The interaction of enzymes with the sub-

strate glucose and the mediator is not a simple

saturation curve like the well-known

Michaelis-Menten kinetics. GOD and the PQQ-

and FAD-dependent GDH enzymes have only

a single active center. An ordered sequence of

reactions is necessary to transfer the electrons

from glucose to the mediator (Fig. 5).

At high concentrations of glucose, this sub-

strate may enter the active center even when

the coenzyme PQQ is in the reduced form of

PQQH

2

(formed by previous reaction with an-

other glucose molecule). The active center can-

not then accept oxidized mediator until glucose

dissociates again. Thus high concentrations of

substrate lead to inhibition of the desired reac-

tion. The same is true for high concentrations

of mediator binding to the oxidized form of the

enzyme. A detailed study of the interaction of

PQQ-dependent GDH with mediators derived

from nitrosoaniline and several sugars has

been published.

15

The other enzymes have the

same general mechanism. Mediator inhibition

phenomena have been detected with FAD-de-

pendent GDH as well (authors unpublished

data).

NAD-dependent GDH is different. Like in

other NAD-dependent dehydrogenases, both

the coenzyme and the substrate glucose are

bound at the same time near to each other but

in distinct parts of the active center. The mech-

anism does not show substrate or coenzyme in-

hibition. The interaction with the mediator is a

nonenzymatic one. Reductive equivalents are

transferred to mediators by nonenzymatic in-

teraction with the reduced form NADH in the

dissociated state. An inhibition of the enzy-

matic reaction by mediator is not to be expected

and has not been observed.

Dry chemistry layers

Test strips contain enzyme, mediator (or pre-

cursor), indicator, and many additional ingre-

dients in the form of dry layers. A very simple

approach for production is impregnation of a

HNES ET AL. S-16

FIG. 5. Catalytic mechanism of GlucDOR PQQ-dependent GDH. GlucD

OR

ox means that the oxidized coenzyme

PQQ; GlucDOR

red

means that the reduced form of the coenzyme PQQH

2

is bound to the protein scaffold of the en-

zyme.

preformed membrane with a buffered solution

of enzyme and indicator.

2

Screen printing has

been widely used as well.

16

Blade coating is the

method employed by Roche for photometric

strips, and the application is followed by dry-

ing. Usually this is done in continuous run-

through dryers. Short intensive drying is ad-

vantageous to avoid denaturation of enzyme

protein and/or unwanted prereactions of me-

diator and indicator. Many enzymes survive

surprisingly well even if dryer temperatures

reach 70C or 80C, a temperature well above

their melting point. Drying starts with evap-

oration of water from the wet layer holding

temperature far below the temperature of dry-

ing air. Drying ends with the dry hot layer

where the enzyme survives well for a few min-

utes since the liquid environment for denatu-

ration is absent. The critical phase is the time

when temperature rises towards the end of

drying when a little water is present. This

phase can be made as short as a few seconds.

The product of this process is a dry layer, which

then is processed into individual test strips.

Another process called slot-die coating is em-

ployed at Roche for their latest electrochemical

test strip. Here only a selected portion of a pre-

formed test strip base is coated with a thin

stripe of chemistry through a special slot open-

ing in a coating head.

17

Otherwise, the drying

considerations are very similar. A full overview

of the processes used for strip production is

outside the scope of this article.

Dry chemistry uses reactive ingredients that

are able to work in classical wet analytics as well.

However, important differences are obvious

when comparing to laboratory analytical test run-

ning in solution in a cuvette or the like (Table 2).

Mixing is absent in dry chemistry strips,

leading to inhomogeneous distribution of

product through the depth of the layer and in

the sample. The chemical system is open, i.e.,

the layer continuously admits water and glu-

cose from the sample and allows out-diffusion

of soluble ingredients like oxidized and re-

duced mediator, products, and possibly even

enzyme. Conversion of sample glucose is usu-

ally incomplete. An exception to this is the

coulometric method of Therasense FreeStyle.

18

Coulometry measures the total charge in the

capillary volume. This requires good control of

the volume to be analyzed. This means that the

height of the sample layer above the chemistry

layer needs to be held within narrow toler-

ances. Furthermore, a thin capillary space (50

m in the product above) is needed to speed

up the diffusion.

Incomplete conversion seems dangerous to

classic analytic thinking. For instance, how can

conversion speed of enzymes be controlled,

e.g., over cold and hot conditions? The key is

to transfer rate control to diffusion processes

instead of the enzyme/mediator reaction. This

is accomplished by overdosing of enzyme in

the chemistry layer. Once diffusion of glucose

is slower than its enzymatic conversion, even

at low temperature, the high dependency of

enzyme speed on temperature is eliminated.

However, even diffusion is sensitive to tem-

perature with approximately 2% change in

speed for a 1K change in temperature. Most

electrochemical strips show this dependency of

current on temperature. Usually the meter con-

tains a temperature sensor and calculates a glu-

cose value correction based on the estimate of

the temperature outside the meter where the

BLOOD GLUCOSE TEST STRIPS S-17

TABLE 2. A COMPARISON OF DRY CHEMISTRY WITH CONVENTIONAL LAB ANALYTICS

Dry chemistry Lab chemistry

Reagents Dry Wet

Chemistry format Layer Cuvette

Sample application On top of layer Mixing

Chemical system Open (continuous exchange of Closed (no exchange

ingredients with sample after mixing)

during reaction)

Conversion of analyte Partial

a

Full

a

Distribution of product Inhomogeneous Homogeneous

a

Exceptions dependent on analyte and measurement method.

reaction is actually taking place. This correction

falls short in the case of differences between

meter temperature and strip temperature, e.g.,

shortly after a temperature change such as re-

moving a meter from a hot car and testing out-

side (or vice versa). Therefore recommenda-

tions for appropriate waiting times before

testing under dynamic temperature conditions

are given in many meter manuals.

To overcome this inconvenience, Roche re-

cently introduced a novel dual-mode measure-

ment method using electrochemical impedance

in their Accu-Chek Aviva product line.

19

The

impedance measurement is used to determine

the actual temperature of the reaction zone and

correct the standard glucose estimate made by

the more conventional DC amperometric de-

termination.

Roche photometric layers employ a further

method for reduction of temperature influ-

ences. The dye heteropoly blue formed from

the mediator 2,18-phosphomolybdic acid is sol-

uble and diffuses out. This can easily be seen

when a drop of aqueous glucose solution, e.g.,

a control solution, is placed on an Accu-Chek

Active strip. The sample drop becomes green.

This means that yellow mediator-precursor

plus blue dye diffuse into the sample. After a

few seconds, the photometric signal from the

layer is stable, but coloration of the sample in-

creases. Our interpretation is that continued in-

diffusion of glucose (and conversion to dye) is

now compensated by out-diffusion of the dye.

Thus after a short time, a flow equilibrium with

constant dye concentration in the layer is es-

tablished. The temperature dependency of this

flow equilibrium and thus of the photometric

signal is low and needs only a small correction

by the temperature sensor in the meter. As ex-

pected from theory, in-diffusion of glucose and

out-diffusion of blue dye exhibit the same de-

pendency on temperature. Hematocrit depen-

dency is low as well since both diffusion paths

are influenced the same way by the diffusion

blocking effect of erythrocytes.

The compensation of in- and out-diffusion is

an effect that necessarily is present in any layer

when the product of glucose conversion is solu-

ble. This is not a special effect of photometric lay-

ers but applies to the electrochemical world as

well to some extent (Fig. 6). The relevant prod-

uct here is reduced mediator, which needs to be

soluble for diffusing to the electrode. The relation

between reduced mediator lost by diffusion into

the sample and reduced mediator used for oxi-

dation at the electrode is not known, however. A

complete exception is the use of polymer-bound

osmium mediator (TheraSense Freestyle),

18

which cannot diffuse out.

Most test strips today exclude erythrocytes

from entering the reaction layer, with the layer

surface acting as a filter. This is true even for

layers made exclusively from soluble ingredi-

ents. In the few seconds until a typical mea-

HNES ET AL. S-18

Diffusion of Glucose into layer

Diffusion of product(s) into sample

Sample

Chemistry layer

Sample

Chemistry layer

Carrier layer

Transparent

carrier layer

Electrodes

FIG. 6. Schematic cross section through the reactive area of test strips. Amperometric strips and photometric strips

are quite similar. Color formed from the reaction of glucose is observed visually or by means of reflection photome-

try from the side opposite to the sample through the transparent carrier layer in photometric strips (left). Electrode

reactions in amperometric strips (right) occur at the bottom of the chemistry layer opposite to the sample application

side. In either case, the chemistry layers exchange glucose, products, and all soluble ingredients with the sample by

means of diffusion.

surement is finished, complete dissolution and

homogeneous mixing with the sample do not

occur. Clogging by a filter cake of erythrocytes

is avoided by using very thin layers of a few

micrometers. The membrane in the LifeScan

One Touch only partially excluded blood cells.

This caused the necessity of two-wavelength

measurement.

2

Accutrend strips (Roche)

worked with a thick open film. Erythrocytes

were filtered above the chemistry layer using a

glass fiber fleece, which was an extremely rapid

filter. The chemistry layer filled in 0.5 s. How-

ever, the fleece was a volume filter needing

roughly half a millimeter in thickness. Thus

more than 10 L of sample volume was

needed, and this type of product is no longer

state of the art.

MEASUREMENT METHODS:

ELECTROCHEMISTRY AND

PHOTOMETRY

Both methods use similar designs of the de-

tection zone. In both cases, the sample is placed

on top of the layer even if a capillary transports

the sample to the layer from the side. The prod-

uct is observed from the side opposite to the

application of sample (Fig. 6), but the mea-

surement methods are different.

A photometric strip, the Accu-Chek Active,

is shown in Figure 7. Photometric measure-

ment is done by illumination with light. Usu-

ally a narrow wavelength bundle, e.g., from a

light-emitting diode, is used. A part of the dif-

fuse reflection arrives at a photodetector and is

converted to a current. The measurement can

be done with a very fast flash of light. The re-

action product is not changed at all by the mea-

surement, which is purely physical. Accuracy

and precision are clearly dominated by the

strip design in this case. Meter errors contrib-

ute to the system error, but nowadays meters

can be factory calibrated to make this contri-

bution low.

The area of chemistry layer times the neces-

sary thickness of sample over the layer defines

the volume needed since the volume uptake

into the layer is negligible with current thin

layer strips. The formation of color versus

thickness of sample follows a saturation curve,

i.e., only above a certain threshold, color be-

comes independent of sample thickness. The

measurement area is defined by the illumina-

tion area of the optics since the application spot

is usually made larger than the illumination

spot. The theoretical limit to lowering the area

and thus decreasing the necessary volume is

given by granularity of the layer leading to in-

creased variation. This limit is currently at a

sample volume of a few nanoliters (Fig. 8). This

ability is not used currently in any product

since the customer is not able to hit such a small

target area with such a tiny non-visible drop.

Amperometric or colorimetric measure-

ments, in contrast, convert the reaction prod-

uct, i.e., the reduced mediator, to the oxidized

form again. This reaction occurs at the surface

of the electrodes, and diffusion is needed to

transport reduced species to the surface and ox-

idized mediator away from it. The primary

product of the glucose reaction is changed in

this way. In principle, this is a slower process

than the instantaneous observation in photom-

etry; however, the reaction can be finished in a

few seconds or even below a second. Thus the

measurement time is not prolonged signifi-

cantly by comparison. Both electrochemical

and photometric strips have reached 5 s. But

even in the few seconds of applying voltage

and measuring current, the diffusion gradients

of reduced and oxidized mediator are not con-

fined to the few micrometers of the chemistry

layer, but reach out into the sample for those

systems with diffusing reagent components.

Diffusion is limiting the current, thus re-intro-

ducing temperature dependency. Diffusion

through the sample reintroduces hematocrit

dependency, which might have been mitigated

by the layer as described above.

Temperature dependency can be corrected

by the meter as described. Hematocrit depen-

dency can be mitigated by evaluating the pro-

file of current versus time in amperometric

measurements (for example, Accu-Chek Ad-

vantage [Roche, Indianapolis]). Significantly

better compensation of sample hematocrit (as

well as the strip temperature as described

above) is achieved with the addition of AC im-

pedance measurements used in the Accu-Chek

Aviva.

19

Electrochemical measurement quality

is a result of a close cooperation between dry

BLOOD GLUCOSE TEST STRIPS S-19

chemistry and measurement method including

the evaluation algorithm. Sophisticated correc-

tions by the meter are able to improve quality

far beyond the level of simple current mea-

surement. The allowed range (in terms of

hematocrit and temperature) for accurate mea-

surement can be wider than with the built-in

correction of photometric layers. But a word of

HNES ET AL. S-20

FIG. 7. Accu-Chek Active photometric test strip. Measurement is done from the bottom of the strip on the color

comparison field. Three light spots are used to detect for potential underdosing.

Homogeneity Accu-Chek Active film

0

1

2

3

4

5

6

7

0 0,2 0,4 0,6 0,8 1 1,2

detection area [mm]

CV [%]

CV% Sample 100

CV% Sample 250

sample volume [nl] 50 40 30 20 10 0

100 mg/dl

250 mg/dl

FIG. 8. Precision of photometric measurement versus evaluation area with the Accu-Chek Active chemistry layer.

The photometric film was evaluated with a CCD camera. Coefficient of variation (CV) values were calculated from

n 5. The chemistry film enables a precise measurement with 0.1 mm

2

or 316 m316 m area 50 m sample

thickness. This is equivalent to a 5 nl sample requirement.

caution may be allowed: the tolerance for de-

viations caused by temperature and hematocrit

seems to be company-specific. A wide allowed

range may be due to a good correction or to ac-

ceptance of large deviations.

20

The design of electrochemical test strips can

vary significantly, especially in the number of

electrodes used to contact the reagent and

blood sample and in the way in which they are

employed. One of the simplest designs such as

Accu-Chek Advantage

21

uses just two chemi-

cally identical electrodes in a biamperometric

measurement, where the actual potential ap-

plied to the strip is not referenced.

22

A refer-

ence electrode made from silver/silver chlo-

ride can be substituted for one of these two

electrodes to control and stabilize the absolute

potential applied at the measurement (or work-

ing) electrode. Another working electrode can

be added to make a three-electrode strip, as in

the case of LifeScans One Touch Ultra system,

to help safeguard against or compensate for ef-

fects unrelated to glucose concentration (e.g.,

partial filling of the strip or electrochemical re-

actions not derived from glucose). Further elec-

trodes can be added for better ensuring strips

are adequately filled before starting a mea-

surement sequence

23

(Fig. 9).

In any case, for amperometric measurements

(as opposed to coulometric), the measured cur-

rent and hence glucose estimation are propor-

tional to the working electrode area in the test

strip. Thus normal production tolerance and

accuracy issues define a lower limit to the prac-

tical size of the electrode, and hence to the sam-

ple size. However, recent advances in electrode

forming by laser ablation techniques

24

have

been employed in several systems, including

Accu-Chek Aviva and Bayer Contour. These

advanced techniques are able to produce elec-

trodes of highly precise dimensions, which

promises overall reduction of size and thus

sample volume. The sample volume is also

practically limited in the third dimension by

the ability to reproducibly control sample

chamber heights above the working elec-

trode(s), and hence avoid imprecision. As pre-

viously mentioned, the TheraSense FreeStyle

product currently uses the smallest sample

layer thickness above the electrodes of ap-

proximately 50 m.

In a nutshell, the differences between the two

measurement methods are the following:

Photometric layers are building blocks.

They can be cut and mounted as required by

the product design. In contact with sample,

they produce a signal needing only little pro-

cessing. Dependent on the optics, volumes

down to a few nanoliters can be measured

with state of the art layers. However, the

sample has to be placed just on top of the op-

tics, or a capillary is necessary for hygienic

sample transport.

Electrochemical measurement cells are sys-

tems where electrode area and capillary

thickness have a profound influence on the

signal in addition to the chemistry layer.

Measurement method and evaluation algo-

rithm strongly add to measurement quality.

Downsizing of volume to the nanoliter range

would likely require the construction of new

measurement cells and may need a revolu-

tion? in production methods. An advantage

to this point has been hygiene, specifically in

environments where a meter is used by more

than one individual.

ACCURACY AND PRECISION

State of the art systems nowadays achieve a

precision of 23% coefficient of variation (23

mg/dL SD below 100 mg/dL) and a deviation

within 5% (5 mg/dL below 100 mg/dL) of

the lab reference. More than 95% of all data

usually are within 15% as compared to the

reference. The medical need for accuracy was

described for many years by the Clarke error

grid.

25

A system error of 15% (15 mg/dL

below 100 mg/dL) completely fulfills this need.

In the hypoglycemic region, the tolerance for

positive bias is narrow, but above 60 mg/dL,

dry chemistry systems perform better than

needed. A newer error grid was proposed in

2000.

26

The tolerances in the hypoglycemic re-

gion are wider here. Generally, self-monitoring

systems perform fully within these require-

ments (Fig. 10).

With this in mind, improvements in accuracy

and precision may seem to be unnecessary. In

fact, most customers assume that accuracy ful-

BLOOD GLUCOSE TEST STRIPS S-21

HNES ET AL. S-22

0

50

100

150

200

250

300

350

400

450

500

0 50 100 150 200 250 300 350 400 450 500

Reference (Glucose, Hexokinase, mg/dL)

M

e

a

s

u

r

e

m

e

n

t

s

(

G

l

u

c

o

s

e

,

A

C

C

P

c

o

r

r

e

c

t

e

d

C

o

d

e

s

,

m

g

/

d

L

)

A

A

B

B

C

C

D D

E

E

FIG. 9.

FIG. 10.

fills the medical needs for managing their dis-

ease, and the Diabetes Control and Complica-

tions Trial study

1

supports that view. However,

there is much scientific debate around accu-

racy, including errors made by customers as

opposed to well-trained lab personal (see, for

example, Nichols

27

). The American Diabetes

Association

28

asks for improved systems with

a system error within 5%. Are new technol-

ogy and improved product development able

to fulfill this extreme or at least a more mod-

erate improvement? Lets have a closer look to

a less well-known source of errors, the lab ref-

erence. In 1999, we did an evaluation of the

Roche Glucotrend system versus the definitive

method using isotope dilution

29

(Fig. 11).

Glucotrend showed a system error (the

range for 95% of values) of just below 10%

versus the gas chromatography/isotope di-

lution mass spectrometry definitive method.

Usually, method comparisons versus the con-

ventional hexokinase reference method show

higher values with a mean of 13%. Appar-

ently there is a significant error contribution of

the conventional reference. The use of a perfect

reference system would improve accuracy to

10% without changes in the self-monitoring

system. Improving to 5% versus the conven-

tional reference would be hopeless, however,

since the error of the hexokinase method ver-

sus the definitive method was found to be

above 5% (data not shown). Improvements

clearly are completely excluded if the system

would have to match arbitrarily selected refer-

ences where ease of use and cost of the refer-

ence system are important and reference sys-

tems change from time to time.

27

The

experiment above is a snapshot only where

both the reference and customer systems were

well controlled. Handling errors in sample

preparation for the lab and in the use of self-

monitoring seem to be a much larger error con-

tribution than the apparent errors in this com-

parison. Our learning from many years of

in-house and external method comparisons is

that a reference needs to be controlled with

the same care as the self-monitoring system.

The situation is further exacerbated by the

fact that clinically obtained reference values are

sometimes derived from venous plasma sam-

ples as opposed to reference values derived

from capillary fingerstick sources. The known

physiological differences between these two

sample types for individuals not at glucose ho-

meostasis render more accurate strips even less

worthwhile if results are compared only to ve-

nous samples. Finally, the use of alternate sites

(arm, etc.) to glucose testing might be men-

tioned here. Again, equivalent glucose concen-

trations are observed only at glucose homeo-

stasis plus rapid capillary circulation. A perfect

glucose test strip certainly cannot compensate

for the potential errors in sample acquisition.

Our feeling is that accuracy improvements

should be worked on in the field of sample ac-

quisition and handling both in the reference

method and in the test strip system. Automa-

tized highly integrated spot monitoring sys-

tems are expected to show a high value here

because of error avoidance, although they are

originally intended for maximizing ease of use.

THE FUTURE

What does the future hold for self-monitor-

ing of blood glucose, and for test strips in par-

ticular? The rate of type 1 diabetes incidence,

which represents the majority of those that

need to monitor their blood glucose, is in-

creasing worldwide, although not nearly as fast

as type 2 diabetes, where monitoring is more

controversial. Nevertheless, there is some med-

ical consensus that those individuals with

noninsulin-dependent, type 2 diabetes should

still be testing at higher rates than currently

practiced even in the United States,

30

especially

those needing insulin therapy. A cure for dia-

BLOOD GLUCOSE TEST STRIPS S-23

FIG. 9. Accu-Chek Aviva electrochemical test strip. Two electrodes are used for the measurement. Further elec-

trodes are used for safety features.

FIG. 10. Method comparison of a test strip system with the hexokinase reference showing the Clarke error grid

25

zones AE. Data points represent pairs of glucose values using the Accu-Chek Compact Plus system and the hexo-

kinase reference method. Samples for both were obtained from the same fingerstick.

betes that would eliminate all need for moni-

toring is hoped for, but practically seems far

off. The closest we have come to a cure so far

is pancreas transplantation and islet cell trans-

plantation, which suffer from a lack of organ

availability and also bring with them the side

effects of continuous immune suppression. Ad-

ditionally, despite much initial optimism,

transplanted islet cells offer only transient mit-

igation of the disease.

Assuming the need for testing blood glucose

will exist for the next few decades, what might

be the alternatives to test strips or their equiv-

alents? Noninvasive measurement of blood

glucose has been the focus of intensive efforts

for the last 20 years or so. A wide variety of ap-

proaches have been assessed, but none has

overcome the fundamental issues. These are

that the observation would need to focus on a

volume where glucose is comparable to the

blood value and the general absence of specific

signals from glucose. When glucose levels are

measured from outside the body, there is no

property of glucose that has a unique interac-

tion with any part of the electromagnetic spec-

trum, making an accurate determination of this

molecule extraordinarily difficult.

Continuous monitoring, while still invasive,

has been proposed as an alternative to spot

monitoring. Improvements in accuracy clearly

would be needed to make the method accept-

able as a basis for insulin dosing. The devices

are still rather cumbersome, and even if re-

duced in size, all require an indwelling sensor

HNES ET AL. S-24

FIG. 11. Method comparison of Glucotrend versus the definitive isotope dilution method. Samples for data pairs

were taken from fingersticks (like in Fig. 10). The data demonstrate that the Glucotrend system is capable of a sys-

tem error (the range for 95% of values) of just below 10% versus the gas chromatography/isotope dilution mass

spectrometry (GC-IDMS) definitive method.

of some type that must be changed periodi-

cally. There are, indeed, medically valid use

cases where such high data density will yield

valuable metabolic insights and enable better

therapy optimization. We have no doubt that

these devices will take their appropriate place

in the arsenal available to patients and health-

care professionals, but we believe that higher

cost and more difficult handling will limit their

broad acceptance. However, potential benefits

are arguably not so much on the lines of inva-

siveness as they are on data density. We main-

tain that there are perhaps an equal number of

medical use cases where less dense and less in-

convenient, spot monitoring data will be suffi-

cient for the task at hand. In fact, Roche has re-

cently launched an episodic testing aid in the

form of the Accu-Chek 360 View data visual-

ization tool, which allows patients to chart a

special spot testing regimen of seven tests per

day for 3 days so that with their doctor they

can gain very useful information about their

disease and behavior.

31

The convenience and cost-effectiveness of in-

dividual blood glucose tests seem to justify their

continued existence for many years to come, and

this is particularly likely in the light of devel-

oping nations with less sophisticated infrastruc-

ture for healthcare delivery. Cost pressure on

developed healthcare systems acts in the same

direction. How will test strips and blood glucose

meters evolve? In the past, ease of use was im-

proved by the race for speed and low sample

volume. These parameters have reached mean-

ingful lower limits. However, ease of use and

the concurrent avoidance of handling errors re-

main important. As we continue to see the in-

troduction of the more convenient integrated

systems that incorporate the test elements in

drums, spools, or cartridges, even ease waste

disposal, and eventually might work in a fully

automated mode, it seems likely that the role of

strip technology in the market place will only be

extended. However, they will be even more hid-

den inside the system than today.

REFERENCES

1. The effect of intensive treatment of diabetes on the

development and progression of long-term compli-

cations in insulin-dependent diabetes mellitus. The

Diabetes Control and Complications Trial Research

Group. N Engl J Med 1993;329:977986.

2. Phillips R, McGarraugh G, Jurik F, Underwood R:

Minimum procedure system for the determination of

analytes. US Patent 4,935,346. June 19, 1990.

3. Keilin B, Hartree EF: Specificity of glucose oxidase.

Biochem J 1952;50:331341.

4. Leskovac V, Trivic S, Wohlfahrt G, Kandrac J, Pericin

D: Glucose oxidase from Aspergillus niger: the mech-

anism of action with molecular oxygen, quinones, and

one-electron acceptors. Int J Biochem Cell Biol 2005;

37:731750.

5. Olsthoorn AJJ, Duine JA: On the mechanism and

specificity of soluble, quinoprotein glucose dehydro-

genase in the oxidation of aldose sugars. Biochemistry

1998;37:1385413861.

6. Pauly HE, Pfleiderer G: D-Glucose dehydrogenase

from Bacillus megaterium. Hoppe Seylers Z Physiol

Chem 1976;356:16131623.

7. Tsujimura S, Kojima S, Kano K, Ikeda T, Sato M, Sanada

H, Omura H: Novel FAD-dependent glucose dehydro-

genase for a dioxygen-insensitive glucose biosensor.

Biosci Biotechnol Biochem 2006;70:654659.

8. Kratzsch P, Schmuck R, Bunk D, Shao Z, Thym D,

Knappe W: Variants of soluble pyrroloquinoline qui-

none-dependent glucose dehydrogenase. WO Patent

Application 2002/34919 A1. May 2, 2002.

9. Boenitz-Dulat M, Laggerbauer J, Schmuck R, Kratzsch

P, Knappe W: Genetically engineered pyrroloquino-

line quinone-dependent glucose dehydrogenase com-

prising an amino acid insertion. WO Patent Applica-

tion 2006/008132 A1. January 26, 2006.

10. Hoenes J: Colorimetric assay by enzymatic oxidation

in the presence of an aromatic nitroso or oxime com-

pound. US Patent 5,206,147. April 27, 1993.

11. Hoenes J, Schaeffler J: Method and sensor electrode sys-

tem for the electrochemical determination of an analyte

or an oxidoreductase as well as the use of suitable com-

pounds therefor. US Patent 5,122,244. June 16, 1992.

12. Boyer JH: Formation of the nitroso group and its re-

actions. In: Feuer H, ed. The Chemistry of the Nitro

and Nitroso Group. New York: Interscience Publish-

ers, 1969:258.

13. Kovar J, Plocek J: Investigation of the arylnitroso re-

ductase activity of pig liver aldehyde reductase.

Biochem J 1986;235:537543.

14. Fry AJ: The electrochemistry of nitro, nitroso, and re-

lated compounds. In: Patay S, ed. The Chemistry of

Amino, Nitroso, Nitro and Related Groups, Supple-

ment F2. New York: Wiley, 1996:846847.

15. Becker O: Die Glucose-Dye-Oxidoreduktase in der

klinischen Diagnostik: Kinetische Charakterisierung

und Thermostabilitt des Wildtyps sowie zweier

Mutanten des Enzyms aus Acinetobacter Calcoaceti-

cus [Ph.D. thesis]. Kaiserslautern, Germany: Univer-

sity of Kaiserslautern, 2005.

16. Hill HAO, Higgins IJ, McCann JM, Davis G, Treidl

BL, Birket NN, Plotkin EV, Zwanziger R: Printed elec-

trodes. European Patent 0351891B1. January 24, 1990.

BLOOD GLUCOSE TEST STRIPS S-25

17. Burke DW, Marquant M, Zapf U, Fritz M, Mosoiu D,

Wilsey C: Reagent stripe for test strip. US Patent Ap-

plication 20050016844A1. January 27, 2005.

18. Feldman BJ, Heller A, Heller E, Mao F, Vivolo JA, Fun-

derburk JV, Colman FC, Krishnan R: Small volume in

vitro analyte sensor with diffusible or non-leachable

redox mediator. US Patent 6,299,757. October 9, 2001.

19. Beaty TA, Kuhn LS, Svetnik V, Burke DW: Meter and

method of using the meter for determining the con-

centration of a component of a fluid. US Patent

6,645,368. November 11, 2003.

20. Kuhn LS, Burke DW, Henning Groll H, Celentano M,

Surridge N: Impedance techniques in blood glucose

biosensors: Accu-Chek Aviva. Poster presented at the

Biocrossroads Indiana Biosensor Symposium, Indi-

anapolis, IN, April 6, 2005.

21. Hill B: Accu-Chek

Advantage: electrochemistry for di-

abetes management. Curr Separations 2005;21(2):4548.

22. Kuhn L: Biosensors: blockbuster or bomb? Elec-

trochem Soc Interface 1998;7(4):2631.

23. Ikeda S, Yoshioka T, Nankai S, Tsutsumi H, Baba H,

Tokuno Y, Miyazaki S: Biosensor, and a method and a

device for quantifying a substrate in a sample liquid us-

ing the same. US Patent 5,582,697. December 10, 1996.

24. Bhullar RS, Diebold ER, Hill BS, Surridge NA,

Walling DP: Method of making a biosensor. US Patent

7,073,246. July 11, 2006.

25. Clarke WL, Cox D, Gonder-Frederick LA, Carter W,

Pohl SL: Evaluating clinical accuracy of systems for

self-monitoring of blood glucose. Diabetes Care

1987;10:622628.

26. Parkes JL, Slatin SL, Pardo S, Ginsberg BH: A new

consensus error grid to evaluate the clinical signifi-

cance of inaccuracies in the measurement of blood

glucose. Diabetes Care 2000;23:11431148.

27. Nichols JH: What is accuracy and how close must the

agreement be? Diabetes Technol Ther 2005;7:558562.

28. American Diabetes Association: Self-monitoring of

blood glucose. Diabetes Care 1994;17:8186.

29. Schumann G, Bttner J: Determination of glucose in

reference materials by isotope dilution-mass spec-

trometry. Fresenius J Anal Chem 1988;330:424425.

30. Bergenstal J, Gavin JR 3

rd

; Global Consensus Confer-

ence on Glucose Monitoring Panel: The role of self-

monitoring of blood glucose in the care of people with

diabetes: report of a global consensus conference. Am

J Med 2005;118(Suppl 9A):1S6S.

31. Childs B, Laan R: Development of a novel bG analy-

sis system for episodic bG monitoring in persons with

Type 2 diabetes. Poster 0427-P presented at the Amer-

ican Diabetes Association 67

th

Scientific Session,

Chicago, IL, 2007.

Address reprint requests to:

Dr. Joachim Hnes

Roche Diagnostics GmbH

Sandhofer Strae 116

68305 Mannheim, Germany

E-mail: joachim.hoenes@roche.com

HNES ET AL. S-26

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- NUTRITION EXPERT SCREENING ANSWERS-updatedDocument13 pagesNUTRITION EXPERT SCREENING ANSWERS-updatedatonymutembeiNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Past Papers:BiochemistryDocument5 pagesPast Papers:BiochemistryMalavikaNNo ratings yet

- Assignment 1 - Food ChemistryDocument44 pagesAssignment 1 - Food ChemistryQuoc Khanh100% (2)

- Physioex Lab Report: Pre-Lab Quiz ResultsDocument3 pagesPhysioex Lab Report: Pre-Lab Quiz ResultsNicole de Leon0% (1)

- Handy Health Guide To DiabetesDocument49 pagesHandy Health Guide To DiabetesDiabetes Care100% (1)

- Breathing and Gas ExchangeDocument21 pagesBreathing and Gas ExchangeAnna DixonNo ratings yet

- Solution Manual For Human Biology 16th Edition Sylvia Mader Michael WindelspechtDocument36 pagesSolution Manual For Human Biology 16th Edition Sylvia Mader Michael Windelspechtoverspinmeetklac40100% (48)

- 03 Chemistry (25-Shift1)Document7 pages03 Chemistry (25-Shift1)abhiNo ratings yet

- Understanding Feed Analysis TerminologyDocument5 pagesUnderstanding Feed Analysis Terminologyamamùra maamarNo ratings yet

- Chapter I: Food Components: CarbohydrateDocument14 pagesChapter I: Food Components: CarbohydrateJaylina MabulayNo ratings yet

- Hydrolysis of StarchDocument5 pagesHydrolysis of StarchJann Russ EsmeraldaNo ratings yet

- UNIT4 Expt1Document6 pagesUNIT4 Expt1Christian Franco RuizNo ratings yet

- Sharad Pratap Singh's Answer To Is It Necessary To Memorise The Name of The Organic Reactions For JEE or Is The Mechanism and Reagents Enough - QuoraDocument7 pagesSharad Pratap Singh's Answer To Is It Necessary To Memorise The Name of The Organic Reactions For JEE or Is The Mechanism and Reagents Enough - QuorasumitNo ratings yet

- Midterm NutriDocument66 pagesMidterm NutriMaye ArugayNo ratings yet

- Review Article: Pullulanase: Role in Starch Hydrolysis and Potential Industrial ApplicationsDocument15 pagesReview Article: Pullulanase: Role in Starch Hydrolysis and Potential Industrial Applicationsbogdan marianNo ratings yet

- Experiment 3Document6 pagesExperiment 3lechupajarilloNo ratings yet

- Ig ScienceSingleAward TRPDocument71 pagesIg ScienceSingleAward TRPzunairaNo ratings yet

- पञ्चकर्म Part ADocument100 pagesपञ्चकर्म Part AAnil DasNo ratings yet

- K-YBGL Validation ReportDocument5 pagesK-YBGL Validation ReportThu HuyềnNo ratings yet

- Unit 2 - PFD - NumericalsDocument3 pagesUnit 2 - PFD - Numericalssannu986No ratings yet

- Ebook Eliminate Cancers Favorite Building Block Ty Bollinger TTAC PDFDocument32 pagesEbook Eliminate Cancers Favorite Building Block Ty Bollinger TTAC PDFmilanmanijakNo ratings yet

- Whole 4th Year SyllabusDocument161 pagesWhole 4th Year SyllabusPravesh NiraulaNo ratings yet

- Healthy Living Event Proposal 2013 Group 3Document7 pagesHealthy Living Event Proposal 2013 Group 3api-235001675No ratings yet

- What Is Organic Compound?Document3 pagesWhat Is Organic Compound?Mark Joseph LatadeNo ratings yet

- Bulking For MesomorphsDocument41 pagesBulking For MesomorphsSixp8ck100% (2)

- MOH Medicines Price List For Official Use As On 1st of Sep 2016Document579 pagesMOH Medicines Price List For Official Use As On 1st of Sep 2016Sajitha SujeeshNo ratings yet

- In Plant 2Document76 pagesIn Plant 2Nirban SahaNo ratings yet

- Chapter 10-Integration of MetabolismDocument4 pagesChapter 10-Integration of MetabolismJenelyn Lanang DiariosNo ratings yet

- Cmcchapter23 100613135130 Phpapp02 PDFDocument104 pagesCmcchapter23 100613135130 Phpapp02 PDFRicki HanNo ratings yet

- (DD13 14) Bio PhysioDocument587 pages(DD13 14) Bio PhysiominiarNo ratings yet