Professional Documents

Culture Documents

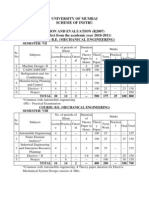

CAD CAM - Chapter 4 Geometric Modelling

CAD CAM - Chapter 4 Geometric Modelling

Uploaded by

JorgeCanoRamirezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CAD CAM - Chapter 4 Geometric Modelling

CAD CAM - Chapter 4 Geometric Modelling

Uploaded by

JorgeCanoRamirezCopyright:

Available Formats

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

1

CAD/CAM Principles and

Applications

Ch 4 Geometric Modelling

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

2

Objectives

Understand the various requirements for the information that is

generated during the geometric modeling stage.

Study various types of geometric models possible and their

applications

Develop various methodologies used for geometric construction

such as sweep, surface models, solid models, etc.

Recognize the various types of surfaces and their application as

used in geometric modelling

Appreciate the concept of parametric modeling which is the

current mainstay of most of the 3D modeling systems

Develop the various mathematical representations of the curves

used in the geometric construction

Discuss the various CAD system requirements that need to be

considered while selecting a system for a given application

Understand the concept of rapid prototyping and the various

methods available for the purpose.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

3

4.1 Requirements of

Geometric Modelling

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

4

Fig. 4.1 Total product cycle in a

manufacturing environment

Ideas

Design

Analysis

Production

Geometric

Modelling

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

5

Functions of Geometric

Modelling

Design analysis:

Evaluation of areas and volumes.

Evaluation of mass and inertia properties.

Interference checking in assemblies.

Analysis of tolerance build-up in assemblies.

Analysis of kinematics mechanics, robotics.

Automatic mesh generation for finite element

analysis.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

6

Functions of Geometric

Modelling

Drafting

Automatic planar cross sectioning.

Automatic hidden line and surface removal.

Automatic production of shaded images.

Automatic dimensioning.

Automatic creation of exploded views for

technical illustrations.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

7

Functions of Geometric

Modelling

Manufacturing

Parts classification.

Process planning.

Numerical control data generation and

verification.

Robot program generation.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

8

Functions of Geometric

Modelling

Production Engineering

Bill of materials.

Material requirement.

Manufacturing resource requirement.

Scheduling.

Inspection and Quality Control:

Program generation for inspection machines.

Comparison of produced part with design.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

9

Requicha and Voelker [1981] specified the following

properties to be desired of in any geometric modelling

(solids) system.

The configuration of solid (geometric model) must stay invariant

with regard to its location and orientation.

The solid must have an interior and must not have isolated

parts.

The solid must be finite and occupy only a finite shape.

The application of a transformation or other operation that adds

or removes parts must produce another solid.

The model of the solid in E3 (Euler space) may contain infinite

number of points. However, it must have a finite number of

surfaces, which can be described.

The boundary of the solid must uniquely identify which part of

the solid is exterior and which is interior.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

10

4.2 Geometric Models

Two-dimensional, and

Three-dimensional.

The three principal classifications can

be

The line model,

The surface model, and

The solid or volume model

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

11

Fig. 4.2 3D geometric representation

techniques

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

S6

S5

S1

S4

S3

S2 S7

S8

V1

V2

(a) LINE MODEL

(b) SURFACE MODEL

(c) VOLUME MODEL

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

12

Fig. 4.3 A geometric model represented in

wire-frame model

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

13

Fig. 4.4 Ambiguities present in the wire-frame

model

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

14

Fig. 4.5 Impossible objects that can be

modelled using a wire-frame model

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

15

Fig. 4.6 Generation of 3D geometry using

planar surfaces

S8

S6

S3

S6

S5

S1

S4

S3

S2 S7

S8

(b) SURFACE MODEL

S1

S5

S4

S2

S7

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

16

4.3 Geometric Construction

Methods

The three-dimensional geometric

construction methods which extend

from the 2D that is normally used are:

Linear extrusion or translational sweep,

and

Rotational sweep.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

17

Fig. 4.8 Component model produced using

translational (linear) sweep (extrusion)

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

18

Fig. 4.9 Component model produced using

translational (linear) sweep with taper in sweep direction

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

19

Fig. 4.10 Component model produced using linear

sweep with the sweep direction along a 3D curve

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

20

Fig. 4.11 Component model produced using

translational (linear) sweep with an overhanging edge

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

21

Fig. 4.12 Component produced by the

rotational sweep technique

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

22

Fig. 4.13 Various solid modelling primitives

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

23

Fig. 4.14 The Boolean operators and their

effect on model construction

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

24

Fig. 4.15 The Boolean operators and their

effect on model construction

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

25

Fig. 4.16 Creating a solid with the 3D primitives in solid modelling

and the model shown in the form of Constructive Solid Geometry

(CSG)

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

26

Fig. 4.17 Model generated using the sculptured surfaces (Image

appears with the permission of IBM World Trade Corporation/Dassault

Systems - Model generated using CATIA)

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

27

Fig. 4.18 The various types of surfaces used

in geometric modelling

Classification of Surfaces

Planar surfaces

Curved surfaces

Free form surfaces

Plane

Single curved

Double curved

Coons surface

Polygon

Polyhedra

Cylinders

Cones

Spheres

Ellipsoids

Paraboloid

Torus

Ruled surfaces Lofted surfaces

B-spline

Bezier surface

NURBS

Fractals

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

28

Fig. 4.19 Ruled surface on the left is shown the curves

from which the ruled surface on the right is formed.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

29

Fig. 4.20 Coons surface generation

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

30

Fig. 4.21 The Bzier curve and the associated

control polygon

X

Y

O

Control

Polygon

Curve

Control points

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

31

Fig. 4.22 The various examples of Bzier curves

depending on the associated control polygons

p0

p0

p0

p1

p1

p1

p2

p3

p2

p3

p3

p2

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

32

Fig. 4.23 The modification of Bezier curve by

tweaking the control points

X

Y

O

Control

Polygon

Curve

Control points

Curve

O

Control points

Y

X

Polygon

Control

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

33

Fig. 4.24 The spline curve

X

Y

O

Control

Polygon

Curve

Control points

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

34

Fig. 4.25 The lofted surface

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

35

Fig. 4.26 Example of filleting or blend method

for model generation

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

36

Fig. 4.27 Example of tweaking method for surface

modification ((Image appears with the permission of IBM World Trade

Corporation/Dassault Systems - Model generated using CATIA))

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

37

4.4 Constraint Based

Modelling

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

38

Fig. 4.28 Example of initial sketch without any

dimensions

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

39

Fig. 4.29 The sketch shown above which is

fully constrained and dimensioned

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

40

Fig. 4.30 The sketch in Fig. 4.29 when swept

along a linear path produces the solid

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

41

Fig. 4.31 The sketch for the new feature (a

cut)

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

42

Fig. 4.32 The solid after executing an

extruded cut of the geometry in Fig. 4.31

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

43

Fig. 4.33 The final solid

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

44

Fig. 4.34 The model tree of the part showing

the modelling process

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

45

Fig. 4.35 A geometric model created following

the sequence of features as

Box Hole Shell

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

46

Fig. 4.36 A geometric model created following

the sequence of features as

Box Shell Hole

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

47

Fig. 4.37 Feature based model and its

modified form

Base feature

Slots - 2

Base feature

Slots - 2

Holes - 5

(A) Original model

Holes - 3

(B) Modified model

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

48

Fig. 4.38 Typical drawing for the variant

method of modelling

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

49

Fig. 4.39 Part model produced using the

symbolic programming

T

C

R

G

N

G C C

SYMBOL KEYS

COMPOSED PART

KEY SEQUENCE

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

50

Fig. 4.40 Examples of form elements used for

model generation in the case of axi-symmetric

components

Knurl

Groove

Taper

Fillet

Arc

Chamfer

Turn

Thread

Face

Blank

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

51

Fig. 4.41 Examples of form features for modelling axi-symmetric

components with milled features

Step

Keyway

Concentric slot

Axial hole

Radial hole

Axial slot

Radial slot

Splines

Turn Taper Face Fillet

Chamfer Groove Thread

Knurl

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

52

Fig. 4.42 Example component modelled using

the features shown in Fig. 4.41

R1.5

1.6

Straight Knurl

Pitch 1mm

All chamfers 1x45

0

-0.015

-0.040

32

75 76

42

187

90

42

M36x1

60

45

3.2

A

0.01 A

+

-

0.50

0.75

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

53

Fig. 4.43 Example component modelled using

the features shown in Fig. 4.41

50

Chamfer 2X2 @45

10 dia 4 holes

12.5

25 80

Chamfer angle 45

25

4 holes on pcd 37.5

2

2X2 Groove

12.5

M8X1 LHT

75

Sectional Elevation

End view

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

54

4.6 Curve representation

Implicit form, and

Parametric form.

In parametric form, the curve is

represented as

X = x(t)

Y = y(t)

Z = z(t)

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

55

Fig. 4.44 Circle

X

Y

O

(X, Y)

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

56

Fig. 4.45 Ellipse

X

Y

O

(X, Y)

a

b

1

2

2

2

2

= +

b

y

a

x

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

57

Fig. 4.46 Parametric curve representation in

Cartesian space

x

y

z

p0

p1

p2

p3

u

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

58

Fig. 4.47 Two cubic Bzier curves joined at p3

x

y

z

p0

p1

p2

p3

u

p4

p5

p6

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

59

4.7 Surface Representation

Methods

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

60

Fig. 4.48 Typical surface display with the

parametric variables u and v

x

y

z

v

u

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

61

Fig. 4.49 A bi-cubic Bzier surface patch

x

y

z

p(u,0), v=0 curve

p11=p(0,0)

p21

p31

p42

p41=p(1,0)

p(0,v), u=0 curve

p12

p22

p32

p43

p33

p21

p24

p13

p23

p44=p(1,1)

p(1,v), u=1 curve

p(u,1), v=1 curve

p14=p(0,1)

u

v

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

62

4.8 Modelling Facilities

Desired

The geometric modelling features.

The editing or manipulation features.

The display control facilities.

The drafting features.

The programming facility.

The analysis features.

The connecting features.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

63

Fig. 4.50 Elimination of hidden lines in display

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

64

Fig. 4.51 Shaded image of a CAD geometric model ((Image

appears with the permission of IBM World Trade Corporation/Dassault Systems -

Model generated using CATIA))

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

65

Fig. 4.52 Orthographic views from a geometric model (Image

appears with the permission of IBM World Trade Corporation/Dassault Systems -

Model generated using CATIA)

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

66

Fig. 4.53 Section view generation from a

geometric model

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

67

Fig. 4.54 Exploded view and bill of materials

of an assembly modelled

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

68

4.9 Rapid Prototyping (RP)

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

69

Figure 4.55 Schematic of Stereolithography

device

Scanning mirror

Laser

Recoating bar

Liquid resin

(to form model)

Cured resin

Platform

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

70

Figure 4.56 Schematic of selective laser

sintering device

Laser

Scanning mirror

Build

powder

Sintered

powder

(to form parts)

Powder feed roller

Platform

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

71

Figure 4.57 Schematic of Three-dimensional

printing device

Powder feed roller

(to form parts)

powder

Glued

powder

Build

Binder solution

Printing head

Nozzle

Platform

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

72

Fig. 4.58 Schematic of Fused deposition

modelling device

Filament from a coil

Feeder

Melter

Extrusion nozzle

Solidified plaster

(to form model)

Platform

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

73

Fig. 4.59 Schematic of Laminated Object

Manufacturing device

material

Take-up roll

Material supply roll

Top view

Laminating roller Contour of actual

cross section of the model

Band of

build material

Splits in excess

material

(for ease of removal)

Platform

Laser

Scanning mirror

Laminating roller

Laminate model

Band of

build material

Excess

laminate

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

74

Summary

Information entered through geometric modeling is utilized in a

number of downstream applications such as drafting,

manufacturing, inspection and planning.

Geometric models are three types, viz line model, surface model

and solid model. Line model though simple is rarely used

because of the ambiguity present. Surface and solid models are

extensively used in industrial applications.

Among the geometric construction methods sweep or extrusion

is most widely used, because of its simplicity and elegance in

developing 3D models.

Solid modeling provides the most unambiguous representation

of the solid model, but is more computing intensive. However to

get the correct geometric model, it is essential to utilize solid

modeling approach.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

75

Summary

Surfaces are more widely used and it is necessary to use

different types of surfaces such as b-splines, Bezier, NURB,

lofted, to get the user requirements fulfilled.

Constraint or parametric based modeling is the main

methodology used by most of the 3D CAD systems. This system

helps in grasping the designers intent and would greatly

facilitate the modification and reuse of the existing designs.

Some variant modeling systems are used based on tabular data

for specific applications.

Form features is another form of modeling system that helps in

designing CAD systems with more intelligence built into the

geometric entities that is possible by purely geometric systems

discussed thus far.

CAD/CAM Principles and

Applications by P N Rao, 2

nd

Ed

76

Summary

The mathematical representation of the geometric entities can

be in implicit or parametric form, the latter being the preferred

method used in CAD systems because of its easier adaptation

in software development.

The curve representation methods can be extended for surface

representations such as used in free form surfaces.

A number of modeling facilities need to be considered while

selecting a CAD/CAM system for any given application.

Rapid prototyping is used to generate the product directly from

the 3D CAD model data. A number of different processes such

as stereo lithography, selective laser sintering, 3D printing,

fused deposition modeling, laminated object manufacturing, are

used for this purpose.

You might also like

- Question Bank - Cad Cam CaeDocument12 pagesQuestion Bank - Cad Cam CaePravin DahalkeNo ratings yet

- Skywalk ReportDocument105 pagesSkywalk Reportchetanchinta100% (5)

- Geometric Modelling: CAD/CAM Principles and Applications 4. Geometric Modelling 4-1/4-23 by P.N.RaoDocument23 pagesGeometric Modelling: CAD/CAM Principles and Applications 4. Geometric Modelling 4-1/4-23 by P.N.RaoDilip BhatNo ratings yet

- CAD CAM Syllabus CoverageDocument7 pagesCAD CAM Syllabus CoverageSubbu SuniNo ratings yet

- Chapter 13 CNC ProgrammingDocument40 pagesChapter 13 CNC ProgrammingSMODI20121994100% (1)

- Cad/Cam Syllabus: B.Tech IV Year I Semester Examination (Mechanical Engineering)Document23 pagesCad/Cam Syllabus: B.Tech IV Year I Semester Examination (Mechanical Engineering)Mohammed SameerNo ratings yet

- Department of Mechanical Engineering Me6501Computer Aided Designquestion Bank Unit - II Part ADocument2 pagesDepartment of Mechanical Engineering Me6501Computer Aided Designquestion Bank Unit - II Part AChennai RajaNo ratings yet

- Course Outcomes by Cad CamDocument2 pagesCourse Outcomes by Cad CamSubhash K0% (1)

- Samarth College of Engineering and Techanology Chap: - 1: Fundamentals of Cad Subject:-CadDocument2 pagesSamarth College of Engineering and Techanology Chap: - 1: Fundamentals of Cad Subject:-CadNilesh Mistry (Nilesh Sharma)No ratings yet

- Introduction To A Modelling SystemDocument12 pagesIntroduction To A Modelling Systemjokerbuddy01No ratings yet

- CAD and Its ApplicationsDocument51 pagesCAD and Its ApplicationsDennis Padec BwochengoNo ratings yet

- CAD Question Bank - MechatronicsDocument3 pagesCAD Question Bank - MechatronicsRohan BhatiaNo ratings yet

- ME6501-Computer Aided Design PDFDocument8 pagesME6501-Computer Aided Design PDFVijay ShankarNo ratings yet

- PED and PipingDocument8 pagesPED and PipingcaveshgmailcomNo ratings yet

- I M.Tech. (Automobile Engg.,), I Semester: ME-5404 ADVANCED CAD L-T-P (4-0-0) 4Document5 pagesI M.Tech. (Automobile Engg.,), I Semester: ME-5404 ADVANCED CAD L-T-P (4-0-0) 4V Phanindra BoguNo ratings yet

- Cadlab Manual For r15Document54 pagesCadlab Manual For r15Guru MaheshNo ratings yet

- CADCAM Course OutlineDocument9 pagesCADCAM Course OutlineJibril JundiNo ratings yet

- BE Mechanical-Mumbai UniversityDocument82 pagesBE Mechanical-Mumbai UniversityJayesh NavareNo ratings yet

- Updated Cad Cam Lab ManualDocument16 pagesUpdated Cad Cam Lab ManualGautam KumarNo ratings yet

- Report CadcamDocument14 pagesReport CadcamAmirun AminNo ratings yet

- CADCAM MinDocument91 pagesCADCAM MinBandi KumarreddyNo ratings yet

- Mec339 - Rapid Prototyping and Reverse Engineering LaboratoryDocument3 pagesMec339 - Rapid Prototyping and Reverse Engineering Laboratorysunilsharma853380100% (1)

- Cad SyllabusDocument5 pagesCad SyllabusSachi DhanandamNo ratings yet

- A Simplified 3d Model Approach in Constructing The Plain Vane Profile of A Radial Type Submersible Pump ImpellerDocument5 pagesA Simplified 3d Model Approach in Constructing The Plain Vane Profile of A Radial Type Submersible Pump ImpellerVignesh KumaranNo ratings yet

- Development of An Integrated Laser-Based Reverse Engineering and Machining SystemDocument6 pagesDevelopment of An Integrated Laser-Based Reverse Engineering and Machining SystemAmrik SinghNo ratings yet

- Manufacturability of Parts With 3D-Annotated Model Generated by 3D-CADDocument10 pagesManufacturability of Parts With 3D-Annotated Model Generated by 3D-CADCADTDDNo ratings yet

- Chapter 18 Group Technologyand CADPlanningDocument25 pagesChapter 18 Group Technologyand CADPlanningmohanmech2006886No ratings yet

- Computer Aided Manufacturing Laboratory: Lab ManualDocument29 pagesComputer Aided Manufacturing Laboratory: Lab ManualdeepakNo ratings yet

- Introduction To CAD/CAM: Pankaj Chhabra Cad/Ca MDocument22 pagesIntroduction To CAD/CAM: Pankaj Chhabra Cad/Ca MPankaj ChhabraNo ratings yet

- Cad CamDocument3 pagesCad CamKannan SreenivasanNo ratings yet

- CS6504-SCAD-MSM-by WWW - LearnEngineering.in PDFDocument158 pagesCS6504-SCAD-MSM-by WWW - LearnEngineering.in PDFAlecNo ratings yet

- BE AUTO2010 SyllabusDocument73 pagesBE AUTO2010 Syllabussss0987654321No ratings yet

- Ansys Lab ManualDocument84 pagesAnsys Lab ManualSharma KripaNo ratings yet

- SurveyDocument41 pagesSurveySushanta Kumar Roy50% (2)

- Zero Lecture MEC 135Document20 pagesZero Lecture MEC 135Vivek SharmaNo ratings yet

- CAD CAM AutomationDocument4 pagesCAD CAM AutomationTiago LopesNo ratings yet

- Course Title Computer GraphicsDocument4 pagesCourse Title Computer GraphicsSami BoyNo ratings yet

- V. S. B Engineering College, Karur - 639 111: Department of Mechanical EngineeringDocument121 pagesV. S. B Engineering College, Karur - 639 111: Department of Mechanical EngineeringvinodkumarNo ratings yet

- Final Year Project ThesisDocument92 pagesFinal Year Project ThesisNazreen Zulkarnain100% (2)

- Subject Code Lecturer Room No Ext No E-Mail Add Web Pre-Requisite: Grafik I (SCG3023), Grafik II (SCG4103) & Programming Skill Course ObjectiveDocument2 pagesSubject Code Lecturer Room No Ext No E-Mail Add Web Pre-Requisite: Grafik I (SCG3023), Grafik II (SCG4103) & Programming Skill Course ObjectivemaherkamelNo ratings yet

- Ansys Lab ManualDocument83 pagesAnsys Lab ManualsouravNo ratings yet

- Unit 2Document34 pagesUnit 2sai venkatsharmaNo ratings yet

- List of Exercises and LAB MANUAL - MEP 106Document19 pagesList of Exercises and LAB MANUAL - MEP 106Arnob RayNo ratings yet

- Bae Kiji 2003 DigitalDocument8 pagesBae Kiji 2003 DigitalJaime Rodriguez UrbinaNo ratings yet

- Cad Cam3 Unit NeelimaDocument96 pagesCad Cam3 Unit Neelimasatish86No ratings yet

- 0 Productlifecycle PDFDocument40 pages0 Productlifecycle PDFCharith ReddyNo ratings yet

- Road-Map For Cae Programmes: Techzilon Training SolutionsDocument8 pagesRoad-Map For Cae Programmes: Techzilon Training SolutionsHemal BarotNo ratings yet

- Development of Canned Cycle For CNC Milling Machine: AbstractDocument9 pagesDevelopment of Canned Cycle For CNC Milling Machine: AbstractandreNo ratings yet

- Investigating The Limitations of Some of The Most Popular Lines and Points Based Camera Calibration Techniques in Photogrammetry and Computer VisionDocument9 pagesInvestigating The Limitations of Some of The Most Popular Lines and Points Based Camera Calibration Techniques in Photogrammetry and Computer VisionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- CAD CAM SyllabusDocument2 pagesCAD CAM SyllabusDeepak AwasthiNo ratings yet

- Applications of Rapid PrototypingDocument13 pagesApplications of Rapid PrototypingM.Saravana Kumar..M.ENo ratings yet

- Cad 12 (4) 2015 383-392Document10 pagesCad 12 (4) 2015 383-392karolina.wrzesniowskaNo ratings yet

- Up and Running with AutoCAD 2014: 2D and 3D Drawing and ModelingFrom EverandUp and Running with AutoCAD 2014: 2D and 3D Drawing and ModelingRating: 5 out of 5 stars5/5 (1)

- A Simplified Benchmarking Model For The Assessment of Dimensional Accuracy in FDM ProcessesDocument12 pagesA Simplified Benchmarking Model For The Assessment of Dimensional Accuracy in FDM Processesantony1993No ratings yet

- Benchmarking For Comparative Evaluation of RP Systems and ProcessesDocument13 pagesBenchmarking For Comparative Evaluation of RP Systems and Processesantony1993No ratings yet

- Benchmarking of FDM Machines Through Part Quality Using IT GradesDocument7 pagesBenchmarking of FDM Machines Through Part Quality Using IT Gradesantony1993No ratings yet

- Niagara TrainingDocument100 pagesNiagara Trainingantony1993No ratings yet

- Characterization and Evaluation of 3D Printed Microfluidic Chip For Cell ProcessingDocument15 pagesCharacterization and Evaluation of 3D Printed Microfluidic Chip For Cell Processingantony1993No ratings yet

- WeeklyReport QualityofPrintsDocument7 pagesWeeklyReport QualityofPrintsantony1993No ratings yet

- Additive Manufacturing - Design - Requirements, Guidelines and RecommendationsDocument15 pagesAdditive Manufacturing - Design - Requirements, Guidelines and Recommendationsantony1993100% (2)

- Additive Manufacturing-Coordinate Systems and Test MethodologiesDocument13 pagesAdditive Manufacturing-Coordinate Systems and Test Methodologiesantony1993No ratings yet

- Surface Roughness Quality and Dimensional AccuracyDocument30 pagesSurface Roughness Quality and Dimensional Accuracyantony1993No ratings yet

- About The Authors: Chua Chee Kai Is The Executive DirectorDocument3 pagesAbout The Authors: Chua Chee Kai Is The Executive Directorantony1993No ratings yet

- Yung Boon Chong PWEDocument352 pagesYung Boon Chong PWEantony1993No ratings yet

- Fundamentals of Engineering (FE) MECHANICAL CBT Exam SpecificationsDocument4 pagesFundamentals of Engineering (FE) MECHANICAL CBT Exam Specificationsantony1993No ratings yet

- BoilerDocument14 pagesBoilerantony1993No ratings yet

- FDMPrinterComparison PDFDocument1 pageFDMPrinterComparison PDFantony1993No ratings yet

- Notes On Genetic AlgorithmDocument6 pagesNotes On Genetic Algorithmantony1993No ratings yet

- DYNAMIC ANALYSIS OF LAMINATED CROSS-PLY PANEL UNDER LOCALIZED MOMENT by Ali Be IglooDocument6 pagesDYNAMIC ANALYSIS OF LAMINATED CROSS-PLY PANEL UNDER LOCALIZED MOMENT by Ali Be Iglooantony1993No ratings yet

- BoilerDocument14 pagesBoilerantony1993No ratings yet

- Course Plan MSTDocument1 pageCourse Plan MSTantony1993No ratings yet

- Calculating Spring Force On Upper and Lower Solenoids Case 1: For Lower TransducerDocument3 pagesCalculating Spring Force On Upper and Lower Solenoids Case 1: For Lower Transducerantony1993No ratings yet

- Finite Element Modelling On GRP by SeibiDocument6 pagesFinite Element Modelling On GRP by Seibiantony1993No ratings yet