Professional Documents

Culture Documents

347MVNb Basic

Uploaded by

Kevin WilliamsOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

347MVNb Basic

Uploaded by

Kevin WilliamsCopyright:

Available Formats

September 2010

Avesta

Welding

Covered electrodes

347/ MVNb basic

For welding steels such as

Outokumpu EN ASTM BS NF SS

4541 1.4541 321 321S31 Z6 CNT 18-10 2337

1.4550 347 347S31 Z6 CNNb 18-10 2338

Standard designations

EN 1600 E 19 9 Nb B

AWS A5.4 E347-15

Characteristics

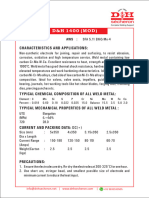

AVESTA347/MVNb basic is a Nb-stabilised

Cr-Ni electrode for welding Ti-stabilised

steels such as ASTM 321 and 347 exposed to

service temperatures exceeding 400C.

347/MVNb basic provides better impact

strength than the AC/DC type electrodes.

Also used for the second layer (first layer 309

type) when cladding mild steel.

Weld deposit data

Metal recovery approx. 100%.

Typical analysis % (All weld metal)

C Si Mn Cr Ni Nb

0.06 0.4 1.0 19.5 10.0 10xC

Ferrite 8 FN WRC-92

Mechanical Typical Min. values

properties values (IIW) EN 1600

Yield strength R

p0.2

520 N/mm

2

350 N/mm

2

Tensile strength R

m

680 N/mm

2

550 N/mm

2

Elongation A

5

30 % 25 %

Impact strength KV

+20C 90 J

40C 65 J

Hardness approx. 255 Brinell

Interpass temperature: Max. 100C.

Heat input: Max. 1.5 kJ/mm.

Heat treatment: Generally none. 347/MVNb

can be used for cladding, which normally

requires stress relieving at around 590C. Such

a heat treatment will lower the ductility at

room temperature. Always consult expertise

before performing post-weld heat treatment.

Structure: Approx. 90% austenite and 10%

ferrite.

Scaling temperature: Approx. 850C (air).

Corrosion resistance: 347/MVNb is

primarily intended for high temperature

service or applications that should be heat

treated. However, the corrossion resistance

corresponds to that of 308H, i.e. good

resistance to general corrosion.

Approvals

CE TV

Welding data

DC+ Diam. mm Current, A

2.5 50 70

3.25 70 100

4.0 100 140

2.53.25 4.0

Welding positions

You might also like

- Acero para BarcosDocument39 pagesAcero para BarcosviyfNo ratings yet

- GMAW Welding ParametersDocument32 pagesGMAW Welding Parametersnarutothunderjet216No ratings yet

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Mock Up, WPS & PQRDocument12 pagesMock Up, WPS & PQRVaibhav100% (1)

- Durehete 950Document5 pagesDurehete 950ellisforheroes100% (1)

- Alloy SteelDocument7 pagesAlloy SteelRavinJohnNo ratings yet

- HR Manual PDFDocument67 pagesHR Manual PDFKevin WilliamsNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Esab DublexDocument8 pagesEsab DublexSuphi YükselNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- 253 MA-NF AC/DC: Covered ElectrodesDocument1 page253 MA-NF AC/DC: Covered ElectrodesElMacheteDelHuesoNo ratings yet

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456No ratings yet

- DH 1232NSDocument1 pageDH 1232NSGopiNathNo ratings yet

- Supranox Rs 347: MMA Electrodes Stainless and Heat Resistant SteelsDocument1 pageSupranox Rs 347: MMA Electrodes Stainless and Heat Resistant SteelsGogo PNo ratings yet

- Avesta 2205 - MIGDocument1 pageAvesta 2205 - MIGgonzomapsNo ratings yet

- AISI 1040: Typical AnalysisDocument2 pagesAISI 1040: Typical Analysisho_chauhanNo ratings yet

- Böhler Nibas 625 PW-FD: DescriptionDocument1 pageBöhler Nibas 625 PW-FD: DescriptionBBalopesabbNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- High Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®Document2 pagesHigh Temperature Stainless Steel EN 1.4835 - UNS S 30815 - 253 MA®ivanoliveira3261No ratings yet

- Thermanit Nicro 82: TIG Rods, Nickel-AlloyDocument2 pagesThermanit Nicro 82: TIG Rods, Nickel-AlloyMaximiliano Ezequiel LopezNo ratings yet

- Böhler Foxa7 Fox A 7Cn: DescriptionDocument1 pageBöhler Foxa7 Fox A 7Cn: Description2003vinayNo ratings yet

- UTP 641 KBDocument1 pageUTP 641 KBVIRPOPNo ratings yet

- Avesta 2205 VDX Ac DCDocument1 pageAvesta 2205 VDX Ac DCpipedown456No ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- Martensitic Stainless Steel EN 1.4057, QT 800Document2 pagesMartensitic Stainless Steel EN 1.4057, QT 800LebasNo ratings yet

- DT-1.4462 WP 380: Stainless Steel Subarc Wire Fused Welding FluxDocument1 pageDT-1.4462 WP 380: Stainless Steel Subarc Wire Fused Welding Fluxmarketing.automatizatNo ratings yet

- Utp 63Document1 pageUtp 63Eileen TylerNo ratings yet

- En40b PDFDocument3 pagesEn40b PDFjeyakumarNo ratings yet

- Avesta 310Document1 pageAvesta 310ulasNo ratings yet

- K48-50 Carbon Film ResistorsDocument3 pagesK48-50 Carbon Film ResistorseminuscloudNo ratings yet

- SS 1.4122Document2 pagesSS 1.4122Bipin Sadasivan100% (2)

- Bohler Fox DMV 83 KB - SmawDocument1 pageBohler Fox DMV 83 KB - Smawsoft4gsmNo ratings yet

- Stainless Steel Grade 310 (UNS S31000)Document3 pagesStainless Steel Grade 310 (UNS S31000)V BNo ratings yet

- T Thermanit Nicro 82 Gtaw 01 01 enDocument2 pagesT Thermanit Nicro 82 Gtaw 01 01 enKathir VelNo ratings yet

- 110 Filarc 76SDocument1 page110 Filarc 76SAzriNo ratings yet

- Duplex Stainless Steel EN 1.4460 PDFDocument2 pagesDuplex Stainless Steel EN 1.4460 PDFtienNo ratings yet

- CSWIP Module Re-ExamDocument2 pagesCSWIP Module Re-ExamAhmad Khalimi Ilmawan100% (1)

- T - Thermanit ATS 4 - Ss - en - 5Document1 pageT - Thermanit ATS 4 - Ss - en - 5rusf123No ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Properties of Ss410Document5 pagesProperties of Ss410gregkilatonNo ratings yet

- CR Om Ot He Rme-9 (M Od) Cromotherme-9 (SPL)Document1 pageCR Om Ot He Rme-9 (M Od) Cromotherme-9 (SPL)Parmasamy SubramaniNo ratings yet

- Metal Plates Property Table Metal Plate MaterialsDocument1 pageMetal Plates Property Table Metal Plate MaterialsaAa1234aAabNo ratings yet

- DH 1200TNS MO6VndCDocument1 pageDH 1200TNS MO6VndCGopiNathNo ratings yet

- SD40ADocument2 pagesSD40AaquilesreinaNo ratings yet

- L1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Document2 pagesL1 - 14983 - en - T - Thermanit Nicro 82 - Se - en - 5Απόστολος ΣτεργιάδηςNo ratings yet

- Conventional Casting WeldingDocument190 pagesConventional Casting WeldingprabhjotbhangalNo ratings yet

- P91 - Modified 9crmo: Data SheetDocument7 pagesP91 - Modified 9crmo: Data SheetpbanerjeeNo ratings yet

- EN26Document3 pagesEN26Moldoveanu TeodorNo ratings yet

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocument1 pageThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNo ratings yet

- Sandvik 2re10Document7 pagesSandvik 2re10himan_chongiNo ratings yet

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgNo ratings yet

- Special Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresDocument10 pagesSpecial Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresCarlos PadillaNo ratings yet

- PK2SPDocument3 pagesPK2SPEmanuelValenciaHenaoNo ratings yet

- UTP A 2535 NBDocument1 pageUTP A 2535 NBRafiqKuNo ratings yet

- DH 1400modDocument1 pageDH 1400modGopiNathNo ratings yet

- XAR 450 (WB 710) EnglischDocument3 pagesXAR 450 (WB 710) EnglischMario MoranNo ratings yet

- Sdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVDocument1 pageSdfs Dfsfs v4t Eg Gyt4fdg e Erert34 GG Efr DFGDGDFG DFG G Sfsfs Gsdfgsdfsdfsdgds FSF STGVsadiqNo ratings yet

- QijeefewkjbfcDocument1 pageQijeefewkjbfcKevin WilliamsNo ratings yet

- SDFVB MDocument1 pageSDFVB MKevin WilliamsNo ratings yet

- LKJBJHKDocument1 pageLKJBJHKKevin WilliamsNo ratings yet

- QijeefewkjbfcDocument1 pageQijeefewkjbfcKevin WilliamsNo ratings yet

- LKUHGYTGYUHIJOKIDocument1 pageLKUHGYTGYUHIJOKIKevin WilliamsNo ratings yet

- SDGDFHBGDSFBGDNFFNDocument1 pageSDGDFHBGDSFBGDNFFNKevin WilliamsNo ratings yet

- Advb N GFN FM PDFDocument1 pageAdvb N GFN FM PDFKevin WilliamsNo ratings yet

- Guide To Public Health Goals (PHGS) For Chemicals in Drinking WaterDocument2 pagesGuide To Public Health Goals (PHGS) For Chemicals in Drinking WaterKevin WilliamsNo ratings yet

- Red & Purple Lines Red & Purple Lines: Monday Through Friday Monday Through FridayDocument7 pagesRed & Purple Lines Red & Purple Lines: Monday Through Friday Monday Through FridayKevin WilliamsNo ratings yet

- DVDSBVFBG NG FN GFNM HG MGHDocument1 pageDVDSBVFBG NG FN GFNM HG MGHKevin WilliamsNo ratings yet

- MVSODS3Document18 pagesMVSODS3Kevin WilliamsNo ratings yet

- Vfdsoft User Manual: English VersionDocument35 pagesVfdsoft User Manual: English Versionmich1206No ratings yet

- Red & Purple Lines Red & Purple Lines: Monday Through Friday Monday Through FridayDocument7 pagesRed & Purple Lines Red & Purple Lines: Monday Through Friday Monday Through FridayKevin WilliamsNo ratings yet

- Hexavalent Chromium (CR VI) : Public Health Goals For Chemicals in Drinking WaterDocument162 pagesHexavalent Chromium (CR VI) : Public Health Goals For Chemicals in Drinking WaterKevin WilliamsNo ratings yet

- Hexavalent Chromium (CR VI) : Public Health Goals For Chemicals in Drinking WaterDocument162 pagesHexavalent Chromium (CR VI) : Public Health Goals For Chemicals in Drinking WaterKevin WilliamsNo ratings yet

- A055 PDFDocument3 pagesA055 PDFKevin WilliamsNo ratings yet

- Red Hat Enterprise Linux-6-Logical Volume Manager Administration-En-USDocument183 pagesRed Hat Enterprise Linux-6-Logical Volume Manager Administration-En-USKevin WilliamsNo ratings yet

- The Knowledge Grid: Towards An Architecture For Knowledge Discovery On The GridDocument1 pageThe Knowledge Grid: Towards An Architecture For Knowledge Discovery On The GridKevin WilliamsNo ratings yet

- BNC Products SpecDocument11 pagesBNC Products SpecKevin WilliamsNo ratings yet

- FGSyndrome FRenPro1053Document3 pagesFGSyndrome FRenPro1053Kevin WilliamsNo ratings yet

- FGK PV FlyerDocument2 pagesFGK PV FlyerKevin WilliamsNo ratings yet

- Intel® Math Kernel Library For Linux OS: User's GuideDocument123 pagesIntel® Math Kernel Library For Linux OS: User's GuideKevin WilliamsNo ratings yet

- 3 - Extract MNFSOP - HADR Handbook, Ver 2.6 (21oct2010) - 0 PDFDocument84 pages3 - Extract MNFSOP - HADR Handbook, Ver 2.6 (21oct2010) - 0 PDFKevin WilliamsNo ratings yet

- Ulrich KJdiagrams PDFDocument10 pagesUlrich KJdiagrams PDFKevin WilliamsNo ratings yet

- Di - Octyl Phthalate (Dop) y y Primar Plasticizer For PVC and PVC Copol MersDocument2 pagesDi - Octyl Phthalate (Dop) y y Primar Plasticizer For PVC and PVC Copol MersalguzduxtanNo ratings yet

- Brand: Ranger Model: RFJ 3TP Description: 3 Ton Professional Series Floor JackDocument1 pageBrand: Ranger Model: RFJ 3TP Description: 3 Ton Professional Series Floor JackKevin WilliamsNo ratings yet

- GX - GF-K Instruction ManualDocument104 pagesGX - GF-K Instruction ManualKevin WilliamsNo ratings yet

- 4 Motivic Dev PDFDocument6 pages4 Motivic Dev PDFKevin WilliamsNo ratings yet

- ASDFLDocument7 pagesASDFLKevin WilliamsNo ratings yet