Professional Documents

Culture Documents

Bolt Torque Equations

Bolt Torque Equations

Uploaded by

yatin888Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolt Torque Equations

Bolt Torque Equations

Uploaded by

yatin888Copyright:

Available Formats

How much torque is required for proper tensioning of a bolt in a given situation?

How can a given amount

of work in the form of torque application be translated into the desired tension? A simplified screw jack

formula by Farr shows that necessary torque is a function of the tension required, certain dimensions of the

nuts and bolts, and the coefficient of friction existing on he bearing surfaces of the threads and nut faces.

+ + = f R

Cos

f R P F

T

s

t a

2 12

Where

T = Torque in foot - pounds

F

a

= Force in pounds of tension required in bolt

P = Lead of threads, inches

R

t

= Average mean radius from axis of bolt out to point where load is applied to thread surface

R

s

= Mean radius of nut face, or shoulder

Cos = Cos of one half the included thread angle measured on a plane through axis, degrees usually 30,

therefore, Cos - 0.86603

F = Coefficient of friction (See figure 1)

All terms of this equation are fixed for any given nut and bolt size, once the tension, F

a

is established, with

the single exception of F, the coefficient of friction. This parameter can vary with the result that the

required torque will also vary widely. The efficiency of the situation - the percentage of the effort applied

to the nut that is translated into bolt tension-varies widely when the effective coefficient of friction varies.

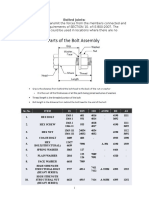

Fig 1 - A bolt (or stud) is called and externally threaded

fastener and a nut is called an internally threaded

fastener. The thread is and example of the inclined

plane, one of the basic mechanical principals. All terms

of this equation are fixed for any given nut and bolt size,

once the tension, F

a

is established, with the single

exception of F, the coefficient of friction. This

parameter can vary with the result that the required

torque will also vary widely. The efficiency of the

situation - the percentage of the effort applied to the nut

that is translated into bolt tension-varies widely when

the effective coefficient of friction varies.

The use of torque has long been associated with methods of tightening and inspecting bolts. The object of

tightening bolts is to achieve a minimum tension, not torque, in the bolts. There is a relationship between

torque and tension, but it is highly variable and must be used with caution.

The variables in the torque-tension relationship include lubrication, thread fit, the use of a washer and the

tension in the bolt. The torque used to tighten a bolt is consumed by overcoming the friction between nut

and washer (about 60%), overcoming the friction between bolt thread and nut threads (about 30%), and

providing energy to elongate the bolt (about 10%). Tests have indicated that torque-tension relationships

for structural bolts easily vary by as much as 40%.

The Specifications do not permit the use of any tabulated torque or calculated torque for either installation

or inspection. Installation and inspection torques must be determined or set using Skidmore-Wilhelm (or

similar) devices to establish actual tension, then determine the torque. A basic equation to estimate the

torque-tension relationship is:

T = 0.0167 x P x D

Where

T = torque (foot-pounds)

P = bolt tension (pounds)

D = bolt diameter (inches)

The value 0.0167, called the nut factor, is a traditional industry average. It can range as low as 0.01 for

well-lubricated assemblies and can exceed 0.025 for dry or rusty fasteners.

For convenience only, the following table may be used to estimate the torque ranges for various A325 bolts

when the minimum required pretension is present. It may be used for the selection of installation and

inspection tools. If bolt tensions are higher than the required minimum, torques can be correspondingly

higher. Table values have been rounded. This table cannot be used for either installation or inspection

purposes.

A325 Approximate Torques (foot-pounds)

Torque

A325

Bolt

Diameter

(inches)

Required

Tension

(kips)

Low

(0.01)

Average

(0.0167)

High

(0.025)

1/2 12 60 100 150

5/8 19 120 200 300

3/4 28 200 350 500

7/8 39 350 550 850

1 51 500 850 1300

1-1/8 56 650 1050 1600

1-1/4 71 900 1500 2200

1-3/8 85 1150 1950 2900

1-1/2 103 1550 2600 3900

For convenience, the following table may be used to estimate the torque ranges for various A490 bolts

when the minimum required pretension is present. It may be used for the selection of installation and

inspection tools. If bolt tensions are higher than the required minimum, torques can be correspondingly

higher. Table values have been rounded. This table cannot be used for either installation or inspection

purposes.

A490 Approximate Torques (foot-pounds)

Torque

A490

Bolt

Diameter

(inches)

Required

Tension

(kips)

Low

(0.01)

Average

(0.0167)

High

(0.025)

1/2 15 70 130 200

5/8 24 150 250 400

3/4 35 250 450 650

7/8 49 450 700 1100

1 64 650 1100 1600

1-1/8 80 900 1500 2300

1-1/4 102 1300 2100 3200

1-3/8 121 1700 2800 4200

1-1/2 148 2200 3700 5500

You might also like

- DSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Document16 pagesDSI Underground Systems Mechanical Rock Bolts Extension Bolts Stelpipe Bolts US 01Tato Del AguilaNo ratings yet

- Bolt CalculateDocument6 pagesBolt CalculateBahtiar YudhistiraNo ratings yet

- Bolt Torquing AnalysisDocument7 pagesBolt Torquing AnalysisEleonor MaderazoNo ratings yet

- Typical Cohesion and Internal Friction ValuesDocument11 pagesTypical Cohesion and Internal Friction ValuesFahim MarwatNo ratings yet

- SPT, Procedure-Method Statement PDFDocument30 pagesSPT, Procedure-Method Statement PDFAsif Khanzada100% (1)

- ASD Vs LRFDDocument5 pagesASD Vs LRFDUsman AfzalNo ratings yet

- Rock AnchorDocument12 pagesRock AnchorpkNo ratings yet

- GR L Weap 2010 Whats New 2010Document6 pagesGR L Weap 2010 Whats New 2010Nguyen Quoc VuNo ratings yet

- Bolted Joints:: Lecture Notes: CRB/CIV/MSECDocument7 pagesBolted Joints:: Lecture Notes: CRB/CIV/MSECrameshbabu_1979No ratings yet

- Great Waters - Business Track Record 2012-16Document16 pagesGreat Waters - Business Track Record 2012-16KK NairNo ratings yet

- Linde forklift-HD12 20T-03-Service-TrainingDocument238 pagesLinde forklift-HD12 20T-03-Service-TrainingchinhNo ratings yet

- "Brgplt9" - Beam Bearing Plate DesignDocument3 pages"Brgplt9" - Beam Bearing Plate DesignPhanikrishnab100% (2)

- A Comparison of Dynamic Pile Driving Formulas With The Wave EquationDocument22 pagesA Comparison of Dynamic Pile Driving Formulas With The Wave Equationmkr1980No ratings yet

- Steep Reinforced SlopesDocument35 pagesSteep Reinforced SlopesOanaNo ratings yet

- 3103 EM35MR Gas Valve - Product ManualDocument50 pages3103 EM35MR Gas Valve - Product ManualJoão Pedro MoreiraNo ratings yet

- QF1500, QF2500 & QF2500S HCQF Sprayer: Parts Lists SERIAL NOS. 75000 - PresentDocument47 pagesQF1500, QF2500 & QF2500S HCQF Sprayer: Parts Lists SERIAL NOS. 75000 - PresentDmytroNo ratings yet

- WeldDocument43 pagesWeldAuggie AranzadoNo ratings yet

- Ingersoll Rand FA10 Popeye Winch Air Tugger ManualDocument85 pagesIngersoll Rand FA10 Popeye Winch Air Tugger ManualAleksei ChernozhukovNo ratings yet

- Design Calc Sheet - Septic Tank Rev1 15-03-09 - 200Document12 pagesDesign Calc Sheet - Septic Tank Rev1 15-03-09 - 200Bok MortegaNo ratings yet

- QTZ6516tower Crane Manual BookDocument48 pagesQTZ6516tower Crane Manual BookMuhammad Iqbal100% (1)

- Automatic Raising BollardsDocument26 pagesAutomatic Raising BollardsK SubramaniNo ratings yet

- Instant Download Calculus I With Precalculus 3rd Edition Larson Solutions Manual PDF Full ChapterDocument32 pagesInstant Download Calculus I With Precalculus 3rd Edition Larson Solutions Manual PDF Full ChapterJosephCraiggmax100% (8)

- Mat FoundationsDocument10 pagesMat FoundationsKamran KhurshidNo ratings yet

- Introduction To Pile FoudDocument103 pagesIntroduction To Pile FoudAjit SinghNo ratings yet

- 325 UniPile Version 5 - User and Examples ManualDocument98 pages325 UniPile Version 5 - User and Examples ManualFernando SmithNo ratings yet

- Seismic Load Calc: Equivalent Lateral Force Analysis: InputDocument5 pagesSeismic Load Calc: Equivalent Lateral Force Analysis: InputMohammed Saleem Syed KhaderNo ratings yet

- Fatigue Study On Structural Supports For Luminaries, Traffic Signals, Highway SignsDocument91 pagesFatigue Study On Structural Supports For Luminaries, Traffic Signals, Highway SignsjeffuangNo ratings yet

- PM - 220E - 225E - MkII - Logger Partes y Piezas PDFDocument317 pagesPM - 220E - 225E - MkII - Logger Partes y Piezas PDFDaniller anabalon100% (2)

- Bolted Joint AnalysisDocument19 pagesBolted Joint AnalysisSyed MajeedNo ratings yet

- Astm d3689 - XYZDocument4 pagesAstm d3689 - XYZCindy LLavoresNo ratings yet

- KDS 41 17 00 건축물 내진설계기준Document131 pagesKDS 41 17 00 건축물 내진설계기준colt0No ratings yet

- Relationship Between Shear Stress and Shear StrainDocument4 pagesRelationship Between Shear Stress and Shear Strainwindgust820% (1)

- Shear Lug Verification Example 2Document1 pageShear Lug Verification Example 2Nasrul AdliNo ratings yet

- Design of Simple WeldDocument1 pageDesign of Simple Weldshantanu chowdhuryNo ratings yet

- Staad ExampleDocument45 pagesStaad ExamplehgorNo ratings yet

- Example 4Document4 pagesExample 4dane05No ratings yet

- Pole Base DRM Design ChartsDocument9 pagesPole Base DRM Design Chartsvananhlt18No ratings yet

- Pile DesignDocument13 pagesPile DesignMohafisto SofistoNo ratings yet

- 1.3 - Tubular Member Design ConsiderationsDocument27 pages1.3 - Tubular Member Design ConsiderationsDanNo ratings yet

- Features of Wrench Project Lifecycle Management SoftwareDocument3 pagesFeatures of Wrench Project Lifecycle Management Softwaremopw100% (1)

- Evolution of Pile Shaft Capacity Over Time in Mari PDFDocument15 pagesEvolution of Pile Shaft Capacity Over Time in Mari PDFRazvan-Ionut SimionNo ratings yet

- 7 - Subgrade CharacterizationDocument18 pages7 - Subgrade CharacterizationOkondu ChieduNo ratings yet

- KDACI New V1 PDFDocument30 pagesKDACI New V1 PDFVasaNo ratings yet

- Fuel Tank Pad DesignDocument32 pagesFuel Tank Pad DesigndjgiumixNo ratings yet

- Up PileDocument273 pagesUp PileJorge PalominoNo ratings yet

- Studies On Correlation Between Flexural Strength and Compressive Strength of ConcreteDocument6 pagesStudies On Correlation Between Flexural Strength and Compressive Strength of ConcreteTim Lin50% (2)

- Design of Tension Member - Gusset Plates Lug Angles and Tension SplicesDocument28 pagesDesign of Tension Member - Gusset Plates Lug Angles and Tension SplicesDarsHan MoHanNo ratings yet

- PCI DH-Loss of PrestressDocument5 pagesPCI DH-Loss of PrestressCarlisle Flores-GarayNo ratings yet

- Shear Force and Bending Moment Diagrams PDFDocument18 pagesShear Force and Bending Moment Diagrams PDFCholan PillaiNo ratings yet

- N1 Seismic JointsDocument37 pagesN1 Seismic JointsmabuhamdNo ratings yet

- Slope Stability ImprovementDocument43 pagesSlope Stability Improvementomar cNo ratings yet

- Install Guide Spunlite Poles 2015Document6 pagesInstall Guide Spunlite Poles 2015Balaji PalaniNo ratings yet

- Updated Stock of General Store December 2014Document184 pagesUpdated Stock of General Store December 2014Muhammad Imran HashmiNo ratings yet

- T.9.1.4 Punching Shear To EUROCODE2: RAPT User ManualDocument16 pagesT.9.1.4 Punching Shear To EUROCODE2: RAPT User Manualtailieuxaydung2019No ratings yet

- Project: Location: By: Date: Chk. By: Date: Clear Data Entry CellsDocument1 pageProject: Location: By: Date: Chk. By: Date: Clear Data Entry Cellsblackk7No ratings yet

- Prensa Digital Triaxial-MATESTDocument42 pagesPrensa Digital Triaxial-MATESTAlvaro G. MCNo ratings yet

- A Review of Pile Set-UpDocument20 pagesA Review of Pile Set-UpFernando SmithNo ratings yet

- Guidelines For The Design of Sediment ContainmentDocument10 pagesGuidelines For The Design of Sediment ContainmentBudi NadatamaNo ratings yet

- Safety Factor Pile AASHTO 1997, CBC 1992Document36 pagesSafety Factor Pile AASHTO 1997, CBC 1992Rahmaddian Nanda PerdanaNo ratings yet

- Bending Moment Capacity of PipesDocument13 pagesBending Moment Capacity of Pipess3201696No ratings yet

- Astm D4718D4718M-15Document3 pagesAstm D4718D4718M-15Jha AcostaNo ratings yet

- Evavluation of The ..... Resilent ModulusDocument9 pagesEvavluation of The ..... Resilent ModulusAna Beatriz Postigo FarfanNo ratings yet

- USD T BeamDocument10 pagesUSD T BeammanowarNo ratings yet

- Xie Liping 200906 PHD ThesisDocument374 pagesXie Liping 200906 PHD ThesisrammirisNo ratings yet

- Loaded Flat PlatesDocument8 pagesLoaded Flat Platessloane01No ratings yet

- Numerical Methods and Implementation in Geotechnical Engineering – Part 1From EverandNumerical Methods and Implementation in Geotechnical Engineering – Part 1No ratings yet

- Distribution of Shear Stresses in Circular ShaftsDocument5 pagesDistribution of Shear Stresses in Circular ShaftsSnehasish IsharNo ratings yet

- MOV Design BasisDocument18 pagesMOV Design Basisrieza_fNo ratings yet

- Technical Product Information: Halfen Huc Universal ConnectionDocument28 pagesTechnical Product Information: Halfen Huc Universal ConnectionJack KenningNo ratings yet

- VG 6.1600, 6.2100 DP - TC Manual de Instructiuni Si Date TehniceDocument36 pagesVG 6.1600, 6.2100 DP - TC Manual de Instructiuni Si Date TehniceClaudiu MacoveiNo ratings yet

- Compressor SafetyDocument56 pagesCompressor SafetyAnonymous v5mGxgXii6No ratings yet

- Thermoelectric Technical ReferenceDocument54 pagesThermoelectric Technical ReferenceVikram BorkhediyaNo ratings yet

- Manual de Abrazaderas VictaulicDocument27 pagesManual de Abrazaderas VictaulicSalvador LopezNo ratings yet

- 966H/972H Wheel Loader Parts Reference GuideDocument7 pages966H/972H Wheel Loader Parts Reference GuideEbenezer Yawson100% (1)

- FK 4161Document8 pagesFK 4161Nguyen KhaNo ratings yet

- Grain Spreader: Models GS-3 and GS-6 Installation and Specifications/Owner-Operator's ManualDocument24 pagesGrain Spreader: Models GS-3 and GS-6 Installation and Specifications/Owner-Operator's ManualNicolás LondoñoNo ratings yet

- Final Certified: Chart Cooler Service Co, IncDocument3 pagesFinal Certified: Chart Cooler Service Co, IncArslanNo ratings yet

- B41a RRH8x20 Installation GuideDocument32 pagesB41a RRH8x20 Installation GuideNicolás RuedaNo ratings yet

- Mauricius 2.5 Hunslet Type Loco Julius de WaalDocument9 pagesMauricius 2.5 Hunslet Type Loco Julius de WaalBán ZoltánNo ratings yet

- Berca Engineering SUBMITTEDDocument20 pagesBerca Engineering SUBMITTEDJohandika FerbiantokoNo ratings yet

- Doka Cooling Tower Formwork SK 175Document32 pagesDoka Cooling Tower Formwork SK 175anilNo ratings yet

- Clestae3 Chair PDFDocument28 pagesClestae3 Chair PDFmohan kNo ratings yet

- Click Wrench RepairDocument31 pagesClick Wrench RepairTu PhamNo ratings yet

- US2394521 Lynn PatentDocument4 pagesUS2394521 Lynn PatentFulcrum386No ratings yet

- Installation Operational and Maintenance Instructions - MS Wheels RLPS CAS 3600Document17 pagesInstallation Operational and Maintenance Instructions - MS Wheels RLPS CAS 3600VitNo ratings yet

- 0910sem1 Me3263Document8 pages0910sem1 Me3263ismu2003_903265473No ratings yet

- Morse Starrett Catalog March 2009Document8 pagesMorse Starrett Catalog March 2009Gallego CarlosNo ratings yet

- Am450-1 S8 Steel Parts Book (Linkbelt 460X2) Rev.1.00Document37 pagesAm450-1 S8 Steel Parts Book (Linkbelt 460X2) Rev.1.00CamiloFigueroaNo ratings yet

- Basic EngineDocument24 pagesBasic EngineAshokNo ratings yet

- Design MabangisDocument156 pagesDesign MabangissedexxNo ratings yet