Professional Documents

Culture Documents

Hose Burst Protection Valves Insert-Type: HB-G02-Y-Z

Uploaded by

matiasgtxOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hose Burst Protection Valves Insert-Type: HB-G02-Y-Z

Uploaded by

matiasgtxCopyright:

Available Formats

L1

A

G

F

H

1

m

i

n

G

H

2

m

i

n

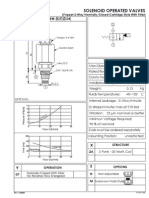

HB-G02-Y-Z

14.0 Hex.

(9/16 inch)

L

L

2

F

TECHNICAL DATA

Max. pressure: 350 bar

Rev.110708 B.340.101

Ordering Code:

UNIT:mm

P

r

e

s

s

u

r

e

-

P

(

b

a

r

)

0 5 10 20 30

2

4

6

Flow-Q(l/min)

8

Weight

0.007

X=

G02

G A B E

G 1/4" 8.5 18 2.4

HOSE BURST PROTECTION VALVES

Standard Type

OPERATION

20

Y

Nm

TIGHTENING TORQUE

Cartridge

Flow

kg

21 4

15 25 35

25 15

Flow-Q(l/min)

30 20 10 5 0

D

I

S

C

G

A

P

"

S

"

S

=

0

.

2

S

=

0

.

5

S

=

1

S

=

1

.

2

Flow: see below graphs ("S"-Q)

Special flow settings are available.

Please contact factory authorized

representative for ordering code.

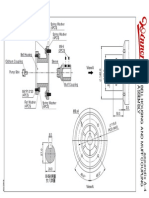

The valve is only supposed to be operated in case of hose

failure. In the case of a hose failure, flow increases across the

valve until the maximum safe limit is reached at which point

the valve will close. The "S" gap must be adjusted to allow a

flow at least 50% over the nominal regulated flow from the

actuator. These valves can be supplied (on reguest) with an

orifice on the disc, allowing an emergency lowering of load.

It is recommended to fit a flow regulator valve downstream

the hose burst valve, at the end of the flexible hose, to

control the lowering speed at the nominal value.

25

min max

0.5

1

1.5

9.5 8

C D F H2 Hex

on request 11 5.5

Flow performance from to depending on S-lenght

FITTING TOOL DIMENSION

F L L1 L2

Tool's ordering

code

11.3 120 110 60 HBG02-T

1

1.2

1.3

1.5

1.9

2.0 20

19

15

13

12

10

0.9 09

0.8 08

0.7 07

0.6 06

05

0.5

no orifice 00

ORIFICE DIAMETER (mm) Z

25

H1

UNIT:mm

Performance curves R/flow (allowance can be 10% from the curve)

After assembling the valves are preadjustated at the following valves

"S"= 0.7 mm

03

0.3

INSERT-TYPE

E

Hex adjustment bolts

C

B

"

S

"

D

2

1

Hose burst

check valve

2

1

Hose burst valve

with orifice

1

2

You might also like

- Relief Valve: RD-08W-X-Y-ZDocument1 pageRelief Valve: RD-08W-X-Y-ZmatiasgtxNo ratings yet

- 041159X85Z Re18318-07 PDFDocument2 pages041159X85Z Re18318-07 PDFHamid CRNo ratings yet

- Piston valve flowmeter designDocument2 pagesPiston valve flowmeter designAstri NgentNo ratings yet

- Ac PDFDocument95 pagesAc PDFCarlos TorresNo ratings yet

- 14564625Document2 pages14564625kisgobeNo ratings yet

- Series Check Valve: Check, Manually Operated 5.5-15 L/Min (1.5-4 Usgpm) - 210 Bar (3000 Psi)Document2 pagesSeries Check Valve: Check, Manually Operated 5.5-15 L/Min (1.5-4 Usgpm) - 210 Bar (3000 Psi)Daniel CringusNo ratings yet

- Throttle (And Check) Valve: FeaturesDocument3 pagesThrottle (And Check) Valve: FeaturessalamrefighNo ratings yet

- DLM142EDocument28 pagesDLM142Eseaqu3stNo ratings yet

- 041118X09Z Re18318-24 PDFDocument2 pages041118X09Z Re18318-24 PDFThalia CRNo ratings yet

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- Valve Sizing CalculationDocument1 pageValve Sizing CalculationGrupoMecatrónicaNo ratings yet

- MPF Filtri en v6Document18 pagesMPF Filtri en v6Ricardo Morán SilvaNo ratings yet

- Client: Asco Steel Plant: SR NO Tag No Detail Unit Locat ION Range HH H L LLDocument1 pageClient: Asco Steel Plant: SR NO Tag No Detail Unit Locat ION Range HH H L LLvhpatel67No ratings yet

- Proportional Pressure Reducing Valve Screw-In Cartridge - Pilot Operated - Q 20 L/min - P 350 Bar - P 315 BarDocument2 pagesProportional Pressure Reducing Valve Screw-In Cartridge - Pilot Operated - Q 20 L/min - P 350 Bar - P 315 BarJason BrinkNo ratings yet

- SD 14 eDocument12 pagesSD 14 eseaqu3stNo ratings yet

- Filter Regulator SMC PDFDocument27 pagesFilter Regulator SMC PDFTuấn Anh NguyễnNo ratings yet

- Pressure Reducing Regulator: PR, PM, PH, PD, PLDocument12 pagesPressure Reducing Regulator: PR, PM, PH, PD, PLadventure11111No ratings yet

- A4VGDocument68 pagesA4VGAgus YulfizarNo ratings yet

- 1-Axial Piston Pumps and Motors-HydromobilDocument8 pages1-Axial Piston Pumps and Motors-HydromobilSocaciu VioricaNo ratings yet

- Rupture DiscDocument1 pageRupture DiscGithu OommenNo ratings yet

- Control Valve Specification and Sizing DetailsDocument34 pagesControl Valve Specification and Sizing DetailsRahulTewari67% (3)

- Relay AP Suat DanfossDocument16 pagesRelay AP Suat DanfossVo Ngoc DucNo ratings yet

- Classic Series F518 (Globe), F1518 (Angle) Specification SheetDocument2 pagesClassic Series F518 (Globe), F1518 (Angle) Specification SheetWattsNo ratings yet

- Valvulas XT PDFDocument4 pagesValvulas XT PDFIsidro Gomez GarciaNo ratings yet

- XOMOXLinedPlugValvesEMEA TechnicalDataDocument20 pagesXOMOXLinedPlugValvesEMEA TechnicalDataperoooNo ratings yet

- OMALDocument6 pagesOMALhachzoliNo ratings yet

- R10/R11 General Purpose RegulatorsDocument1 pageR10/R11 General Purpose RegulatorsDemnyer Asid RaultNo ratings yet

- SDM 080 eDocument28 pagesSDM 080 eseaqu3stNo ratings yet

- Elster G-400 PDFDocument8 pagesElster G-400 PDFalexrm12No ratings yet

- Data Sheet: FH G1/4" Green-BrassDocument12 pagesData Sheet: FH G1/4" Green-BrassRoger RofesNo ratings yet

- Seleccion de Valvulas As de Presion de AnguloDocument9 pagesSeleccion de Valvulas As de Presion de AnguloMildner NietoNo ratings yet

- SD 6 eDocument16 pagesSD 6 eseaqu3stNo ratings yet

- Sistema de Lubricacion Pump HorizontalesDocument16 pagesSistema de Lubricacion Pump HorizontalesRodríguez EdwardNo ratings yet

- Series Constant Flow Speed Controller: Model 4 6 8 JKC 4-01 JKC 6-01 JKC 6-02 JKC 8-01 JKC 8-02 StraightDocument1 pageSeries Constant Flow Speed Controller: Model 4 6 8 JKC 4-01 JKC 6-01 JKC 6-02 JKC 8-01 JKC 8-02 StraightPedro Guerrero PérezNo ratings yet

- PG 511 B 1 B 1: Ordering Code Series PGP/PGM511Document7 pagesPG 511 B 1 B 1: Ordering Code Series PGP/PGM511Four SticksNo ratings yet

- r 930007142Document2 pagesr 930007142Andon XhumbaNo ratings yet

- SD 11 eDocument12 pagesSD 11 eseaqu3stNo ratings yet

- Sds 150 eDocument16 pagesSds 150 ejbsb1No ratings yet

- Bomba Flygt 3080caracteristicasDocument2 pagesBomba Flygt 3080caracteristicasOtoniel Cardenas100% (1)

- 11 042Document2 pages11 042toha82No ratings yet

- SMC Neumatic CatalogDocument98 pagesSMC Neumatic CataloganderssonpcNo ratings yet

- Parker Flow Control Valves PDFDocument4 pagesParker Flow Control Valves PDFMAZM17No ratings yet

- E5907 ws08z01-1Document2 pagesE5907 ws08z01-1raul20132013No ratings yet

- MAXROY Series A, B & D DatasheetDocument4 pagesMAXROY Series A, B & D Datasheetnguyenquoc1988No ratings yet

- Atos Industrial ValvesDocument22 pagesAtos Industrial ValvesM S GokulNo ratings yet

- KITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFDocument16 pagesKITZ DJ Series Ductile Iron Butterfly Valves E-231-06 PDFYulita Ika PawestriNo ratings yet

- Hydraulic Check ValveDocument8 pagesHydraulic Check ValveswainpiyushNo ratings yet

- SD 16 eDocument20 pagesSD 16 eseaqu3stNo ratings yet

- For Air or Water G 1/8 and G 1/4: SpecificationDocument1 pageFor Air or Water G 1/8 and G 1/4: Specificationrahulsingh_1No ratings yet

- Flow Meters, Flow Switches and Flow Transmitters: A Piston Design For Low Flows of LiquidsDocument6 pagesFlow Meters, Flow Switches and Flow Transmitters: A Piston Design For Low Flows of LiquidspamururamuNo ratings yet

- DSG ValvesDocument17 pagesDSG ValvesChris RoederNo ratings yet

- 160S 1Document51 pages160S 1Ahmad Mustaghfiri AsrarNo ratings yet

- 9900 Series DatasheetDocument3 pages9900 Series DatasheetHans HongNo ratings yet

- Vickers Counterbalance Valve CBV 10Document2 pagesVickers Counterbalance Valve CBV 10rafarodrig6No ratings yet

- Low-Weight Wafer Butterfly Valve Technical DataDocument6 pagesLow-Weight Wafer Butterfly Valve Technical DataWellington S. FrançaNo ratings yet

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDocument8 pages4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 87 87 1 PBDocument10 pages87 87 1 PBmatiasgtxNo ratings yet

- Hand Pump: HP-10W-X-Y-ZDocument1 pageHand Pump: HP-10W-X-Y-ZmatiasgtxNo ratings yet

- Toca Race Driver 3 Manual PDFDocument28 pagesToca Race Driver 3 Manual PDFmatiasgtxNo ratings yet

- Auto DeskDocument1 pageAuto DeskmatiasgtxNo ratings yet

- Maxion International High Speed Engineering Performance CurveDocument1 pageMaxion International High Speed Engineering Performance CurvematiasgtxNo ratings yet

- How To Order: 140 & 180 TANKS) Standard Ac Motor Hydraulic Power Packs (W800532 Steel ManifoldDocument1 pageHow To Order: 140 & 180 TANKS) Standard Ac Motor Hydraulic Power Packs (W800532 Steel ManifoldmatiasgtxNo ratings yet

- Rev.090903 B.403.101Document1 pageRev.090903 B.403.101matiasgtxNo ratings yet

- B 301 201Document1 pageB 301 201matiasgtxNo ratings yet

- Hose Burst Protection Valves Insert-Type: HB-G02-Y-ZDocument1 pageHose Burst Protection Valves Insert-Type: HB-G02-Y-ZmatiasgtxNo ratings yet

- Round Steel Reservoirs: 180 MM For 152x152 ManifoldDocument1 pageRound Steel Reservoirs: 180 MM For 152x152 ManifoldmatiasgtxNo ratings yet

- Flow Control Valve: FR-08W-X-Y-ZDocument1 pageFlow Control Valve: FR-08W-X-Y-ZmatiasgtxNo ratings yet

- EC-04W Coil 2-Way Normally Closed CartridgeDocument1 pageEC-04W Coil 2-Way Normally Closed CartridgematiasgtxNo ratings yet

- Rev.090903 B.403.101Document1 pageRev.090903 B.403.101matiasgtxNo ratings yet

- Power Packs Hydraulic: SeriesDocument1 pagePower Packs Hydraulic: SeriesmatiasgtxNo ratings yet

- B14-90 Small Frame KGCB001: Type: Ordering CodeDocument1 pageB14-90 Small Frame KGCB001: Type: Ordering CodematiasgtxNo ratings yet

- Check Valve: CV-08W-X-Y-ZDocument1 pageCheck Valve: CV-08W-X-Y-ZmatiasgtxNo ratings yet

- N Type: Hydraulic Power PacksDocument1 pageN Type: Hydraulic Power PacksmatiasgtxNo ratings yet

- Check Valve: CV-08W-X-Y-ZDocument1 pageCheck Valve: CV-08W-X-Y-ZmatiasgtxNo ratings yet

- How To Order: 140 & 180 TANKS) Standard Ac Motor Hydraulic Power Packs (W800532 Steel ManifoldDocument1 pageHow To Order: 140 & 180 TANKS) Standard Ac Motor Hydraulic Power Packs (W800532 Steel ManifoldmatiasgtxNo ratings yet

- MR & MK Type MK MR: Hydraulic Power PacksDocument1 pageMR & MK Type MK MR: Hydraulic Power PacksmatiasgtxNo ratings yet

- Workbench ModellingDocument26 pagesWorkbench ModellingRohan KarandeNo ratings yet

- Single Plane Balance 091401Document16 pagesSingle Plane Balance 091401ridzim4638No ratings yet

- 5120 7633ot 04Document2 pages5120 7633ot 04matiasgtxNo ratings yet

- Magnetic Field Generation in Electrically Conducting Fluids - MoffattDocument354 pagesMagnetic Field Generation in Electrically Conducting Fluids - Moffattmatiasgtx100% (1)

- S40MY2005 EnginesDocument24 pagesS40MY2005 Enginesmatiasgtx100% (1)

- Catalogo Retenes SAVDocument48 pagesCatalogo Retenes SAVPedro Diehl50% (6)