Professional Documents

Culture Documents

Chapter GSM Paper16

Uploaded by

Pavan KumarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter GSM Paper16

Uploaded by

Pavan KumarCopyright:

Available Formats

International Journal of Mechanical and Industrial Engineering (IJMIE), ISSN No.

22316477, Volume-1, Issue-2, 2011

87

GSM Based Motor Monitoring and Speed Control

V. Bhaskar & T. Gowri Manohar

Department of E.E.E., S.V. University, Tirupati, A.P., India.

E-mail : velurubhaskar@ymail.com

Abstract - In this paper, the design aspects of an embedded device which can control up to 8 devices by sending a specific SMS

message from a mobile phone are presented. This controller is extremely handy at places where we have to control the ON and OFF

switching of the devices but no wired connection to that place is available. To implement this, a GSM modem is connected to a

programmed microcontroller which would receive the SMS from a reference cell phone. The control signal part of the received SMS

is extracted and is changed to microcontroller-preferred format. A PC which is connected to the microcontroller using a serial

communication through RS232 can be used for monitoring and transmission of the control signals to the modem. The monitoring is

also done by interfacing a LCD to the microcontroller. AT commands were used for controlling the functionality of modems

(Global Systems for Mobile Communication) is vastly used because of its simplicity in both transmitter and receiver design, can

operate at 900 or 1800MHZ band, faster, more reliable and globally network. Here the system is capable of controlling the motor by

receiving control message from an authorized mobile number. Microcontroller is the heart of our system, which controls the overall

operation of our system. System is always alert for receiving SMS from valid number and that message can be displayed on the LCD

(Liquid Crystal Display).

In the project work undertaken, GSM technology based automatic control system is designed to monitor and control speed of an

Induction motor/DC motor and also performs necessary operation like start, stop, reverse the rotation ext.

Key words - Short Message Service (SMS), Global Systems for Mobile Communication (GSM), AT Command, GSM Modem,

monitoring and control, Radio frequency (RF).

I. INTRODUCTION

This Project is a very good example of embedded

system as all its operations are controlled by intelligent

software inside the microcontroller. The aim of this

project is to control i.e. to ON/OFF and speed control of

different motors, the electrical or electronic appliances

connected to this system from anywhere in the world.

For this purpose user can use any type of Mobile. This

way it overcomes the limited range of infrared and radio

remote controls. Using the convenience of SMS, this

project lets you remotely control equipment by sending

plain text messages, such as "abcdn1", "abcdnaf3",

"abcdf57n142" all of which can be pre-programmed

into the controller and easily remembered later. It can

control up to eight external devices Short Message

Service (SMS) is defined as a text-based service.

That enables up to 160 characters to be sent from

one mobile phone to another. In a similar vein to email,

messages are stored and forwarded at an SMS centre,

allowing messages to be retrieved later if you are not

immediately available to receive them. Unlike voice

calls, SMS messages travel over the mobile networks

low-speed control channel.

"Texting", as its also known, is a fast and

convenient way of communicating. In fact, SMS has

taken on a life of its own, spawning a whole new

shorthand language thats rapidly Many industries have

been quick to make use of this technology, with millions

of handsets currently in use. As new models with "must

have" features hit the market, older models become

virtually worthless and if not recycled, end up in

landfill. With this in mind, weve designed the project to

work with sim300 GSM modem with simcom

technology.

II. SYSTEM COMMUNICATION

ARCHITECTURE

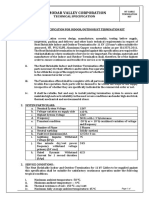

As shown in Figure 1 the wireless transference of

industrial monitoring messages discussed in this paper is

built on the SMS of the GSM network. Data messages

produced at one end of the monitoring system are

encapsulated into a short message by the gateway and

sent to remote monitoring devices at another end. When

a short message is received, it can be restored to its

original industrial form by removing the SMS PDU

head. This is also conducted by the gateway of the

monitoring system. If needed, the message content can

Internation

be put into ot

through other

is a trans-ne

perform protoc

The system m

GSM network

This is not

different types

Pc connected to

the RS232 port

GSM module

M Speed medium

M Speed low

Fig. 1 :

III. WORKIN

In this pro

micro control

C) is a smal

consisting of

support functio

etc. Microco

controlled pro

engine contr

machines, app

will give the

displays the cu

controller is u

upon the softw

to receive the

control of in

breaker in sub

person authori

GSM modem

microcontrolle

chip. As pe

microcontrolle

the SMS is ex

connected to i

nal Journal of M

ther form and

industrial netw

etwork task,

col conversion

makes use of

k to deliver a m

only control

s motors.

SMS

A

GSM&

GPRS

M Speed hi

System Comm

NG

oject we are us

ler (also micr

ll computer on

a relatively s

ons such as a c

ontrollers are

oducts and de

rol systems,

pliances, powe

professional l

urrent operatio

used to control

ware program.

e SMS to spee

nduction moto

station

Initially the

ized to use thi

(SIM300 MOD

er devices kit w

er the AT c

er to the mode

xtracted and is

it. We have to

GSM

Mechanical and In

forwarded by

work. Since th

gateways are

n along with ot

the routing fu

message to ano

ling and also

Microcontroller

Circuit

Relay drivers

And motor

Drivers

Authorized mobile

M Speed an

igh

M Spe

munication Arc

sing the GSM t

ro controller u

n a single inte

imple CPU co

crystal oscillat

e used in

evices such a

remote con

er tools and to

look for the p

on of the syste

the relay driv

Major role of

ed control of

or and contro

SMS is recei

is setup (destin

DEM) & is tran

with the help o

commands gi

em, the contro

used to contro

o convert the 's

Based Motor M

ndustrial Engine

y the gateway

e transference

e required to

ther functions.

unction of the

other gateway.

o monitoring

Motor 1

Motor3

Motor2

ticlockwise

eed clockwise

LCD

hitecture

technology. A

unit, MCU or

egrated circuit

ombined with

tor, timers and

automatically

as automobile

ntrols, office

oys. The LCD

roject. It also

em. The micro

ers depending

this project is

dc motor and

ol for circuit

ived from the

nation) by the

nsferred to the

of a MAX 232

iven by the

ol signal from

ol the devices

septets' of the

Monitoring and S

eering (IJMIE), I

88

phone to

with 8 b

length a

process

A progr

received

kit, and

microco

memory

until the

one sec

part of t

the SMS

control t

message

data is

particula

is AB

implies

remainin

to the p

their stat

OFF. A

format

SPEED

different

IV. CO

Pow

Mic

LC

RS

Fla

Kei

V. SPE

A. Spe

The

From e

controlle

Flux

Res

Con

peed Control

ISSN No. 2231

o 'octets' becau

bits length ( T

and 'octet' is 1

is necessary to

ram (for extrac

d SMS) is loa

then the circui

ntroller now tr

y location of the

e modem rece

ond). Before

the SMS, the m

S and verifies

the device or n

e will be sent

converted to

ar output is ena

the equival

that the output

ng ports are di

orts of microc

tus indicates w

And speed con

like MOTOR

MEDUIM an

t motors.

MPONENTS

wer Supply: 5v

cro controller: P

D: 16x2 charac

232 converter

ash Magic: Visi

il C m-vision:

EED CONTRO

ed Control of a

e speed of a m

equation 1 O

ed by varying

x/pole, (Flu

istance R

a

o

ntrol) and Appl

6477, Volume-

use the micro-c

The 'septet' is

byte with 8 b

o decode the m

cting the contr

aded into micr

it is connected

ries to read the

e modem and i

eives any (pro

implementing

modem extrac

if this numbe

not. For control

in hexa decim

the equivale

abled. For exam

lent binary is

t 1, 3, 5, 7, 8

sabled. We ha

controller to sh

whether the por

ntrol like send

R SPEED LO

nd MOTOR

USED

and 3.6v and 4

Philips P89V5

cters

r: MAX 232

ion 2.4

Vision3 (IDE

OL OF A MO

a DC Motor

motor is give

Obvious that t

ux Control)

of armature

lied voltage V

-1, Issue-2, 2011

controller need

1 byte with 7

bits length). Al

message from

rol signal part

rocontroller de

d to the modem

e SMS from th

it keeps trying

grammed for

the control s

cts the number

er has the acce

lling the device

mal format. Th

ent binary and

mple if the me

s 10101011

are enabled an

ave connected

how the outpu

rts are set to O

the message in

OW and MO

SPEED HIGH

4.6v, 12v DC

1RD2-8bit.

E-Version)

OTOR

en by the Rela

the speed ca

circuit (Rheo

(Voltage Contr

1

bytes

7 bits

ll this

SMS.

from

evices

m. The

he 1st

again

every

signal

r from

ess to

es, the

he hex

d the

essage

this

nd the

LEDs

ut and

ON or

n text

OTOR

H for

ation

(1)

an be

ostatic

rol)

GSM Based Motor Monitoring and Speed Control

International Journal of Mechanical and Industrial Engineering (IJMIE), ISSN No. 22316477, Volume-1, Issue-2, 2011

89

1. Speed Control of Shunt Motors:

(a) Variation of Flux or Flux Control Method: By

decreasing the flux, the speed can be increased and vice

versa. The flux of a dc motor can be changed by

changing I

sh

wi t h help of a shunt field rheostat.

Since I

sh

is relatively small, shunt field rheostat has to

carry only a small current, which means I

2

sh

R loss is

small, so that rheostat is small in size

(b) Armature or Rheostatic Control Method: This

method is used when speeds below the no-load speed

are required. As the supply voltage is normally

constant, the voltage across the armature is varied by

i nserting a variable rheostat in series with the armature

circuit. As controller resistance is increased, voltage

across the armature is decreased, thereby decreasing

the armature speed. For a load constant torque,

speed is approximately proportional to the voltage

across the armature. From the speed/armature current

characteristic, it is seen that greater the resistance in the

armature circuit, greater is the fall in the speed.

(c) Voltage control method: In this method, the shunt

field of the motor is connected permanently to a fixed

exciting voltage, but the armature is supplied with

different voltages by connecting it across one of the

several different voltages by means of suitable

switchgear.

The armature speed will be approximately

proportional to this different voltage. The intermediate

speeds can be obtained by adjusting the shunt field

regulator.

2. Speed Control of Series Motors:

Flux Control Method: Variations in the flux of a

series motor can be brought about in any one of the

following ways:

(a) Field Diverters: The series winding are shunted

by a variable resistance known as field diverter. Any

desired amount of current can be passed through the

diverter by adjusting its resistance. Hence the flux can

be decreased and consequently, the speed of the motor

increased.

(b) Armature Diverter: A diverter across the armature

can be used for giving speeds lower than the normal

speed. For a given constant load torque, if I

a

is

reduced due to armature diverter, the must

increase (T

a

I

a)

This results in an increase in current

taken from the supply which increases the flux and a

fall in speed (N I/ ) The variation in speed can be

controlled by varying the diverter resistance.

3. A Brief Introduction of Induction Motor :

Three-phase induction motors are the most

common and frequently encountered machines in

industry

Simple design, rugged, low-price, easy

maintenance

Wide range of power ratings: fractional

horsepower to 10 MW

Run essentially as constant speed from no-

load to full load

Its speed depends on the frequency of the

power source

Not easy to have variable speed control

Requires a variable-frequency power-

electronic drive for optimal speed control

4. A Brief introduction to Microcontroller

Description: The 89C51RB2/RC2/RD2 device contains

a non-volatile 16kB/32kB/64kB Flash program memory

that is both parallel programmable and serial In-System

and In- Application Programmable. In-System

Programming (ISP) allows the user to download new

code while the microcontroller sits in the application. In-

Application Programming (IAP) means that the

microcontroller fetches new program code and

reprograms itself while in the system. This allows for

remote programming over a modem link. A default

serial loader (boot loader) program in ROM allows

serial In-System programming of the Flash memory via

the UART without the need for a loader in the Flash

code. For In Application Programming, the user

program erases and reprograms the Flash memory by

use of standard routines contained in ROM. This device

executes one machine cycle in 6 clock cycles, hence

providing twice the speed of a conventional 80C51. This

device is a Single-Chip 8-Bit Microcontroller

manufactured in advanced CMOS process and is a

derivative of the 80C51 microcontroller family. The

device also has four 8-bit I/O ports, three 16-bit

timer/event counters, a multi-source, four-priority-level,

nested interrupt structure, an enhanced UART and on-

chip oscillator and timing circuits.

The added feature of the P89C51RB2/RC2/RD2

makes it a powerful microcontroller for applications that

require pulse width modulation, high-speed I/O and

up/down counting capabilities such as motor control.

5. A Brief Introduction of Development Tools

Keil (Vision 2):

The Keil C51 Cross Compiler is an ANSI C

Compiler that is written specifically to generate fast,

GSM Based Motor Monitoring and Speed Control

International Journal of Mechanical and Industrial Engineering (IJMIE), ISSN No. 22316477, Volume-1, Issue-2, 2011

90

compact code for the 8051 microcontroller family. The

C51 Compiler generates object code that matches the

efficiency and speed of assembly programming.

Using a high-level language like C has many

advantages over assembly language programming:

Knowledge of the processor instruction set is

not required. Rudimentary knowledge of the

memory structure of the 8051 CPU is desirable

(but not necessary).

Details like register allocation and addressing

of the various memory types and data types is

managed by the compiler.

Programs get a formal structure (which is

imposed by the C programming language) and

can be divided into separate functions. This

contributes to source code reusability as well as

better overall application structure.

The ability to combine variable selection with

specific operations improves program

readability.

Keywords and operational functions that more

nearly resemble the human thought process

may be used.

Programming and program test time is

drastically reduced.

The C run-time library contains many standard

routines such as: formatted output, numeric

conversions, and floating-point arithmetic.

Existing program parts can be more easily

included into new programs because of

modular program construction techniques.

The language C is a very portable language

(based on the ANSI standard) that enjoys wide

popular support and is easily obtained for most

systems.

VI. A BRIEF INTRODUCTION OF GSM SIM 300

MODEM WITH SIMCOM TECHNOLOGY

GSM modem with RS 232 connector: The Global

System for Mobile Communications (GSM) is the most

popular standard for mobile phones in the world. It is the

European standard for digital cellular service that

includes enhanced features. It is based on TDMA

technology and is used on 900/1900 MHz. We are using

the sim 300, a GSM modem from simcom. This is a

powerful GSM/GPRS Terminal with compact and self-

contained unit. This has standard connector interfaces

and has an integral SIM card reader. The modem has a

RJ9 connector through which a speaker and microphone

can be connected allowing audio calls being established,

but this feature is not utilized in this project as only data

transfer is needed. Following are few technical details of

the modem.

1. Interfaces

TTL Tx,Rx , VCC , GND

Serial port baud rate adjustable 1200 to115200

bps (9600 default)

BRK connector for MIC & SPK, SIM card

holder

LED status of GSM / GPRS module

2. Features

Data: RS232 9way (V.28)

Audio 4-wire Handset Interface (RJ9)

Antenna: 50_ (FME male)

This GSM modem is a highly flexible plug and

play quad band GSM modem

for direct and as integration to TTL

Supports features like Voice, Data/Fax, SMS,

GPRS and integrated TCP/IP stack.

Control via AT commands (GSM 07.07, 07.05

and as enhanced AT commands)

Use DC Power 3.6 - 4.6 Volts Maximum

Current Consumption in normal operation

250mA, can rise up to 1Amp while

transmission.

VII. A BRIEF INTRODUCTION OF AT

COMMAND

Shown in Figure 1, the GSM modem and the PC

are wire-connected through RS232serialports.They

communicate with AT commands. AT commands are a

set of commands that has been standardized to

communicate with terminal equipments such as modem,

mobile phone as well as control them. Most GSM

modems support AT commands. The command set is

quite elaborate. However, only a small part of it is

related to SMS operations. The most frequently used

commands are:

AT+CMGS: To send a short message

AT+CMGR: To read a short message from the GSM

module

AT+CMGL: To list SMS short messages stored in the

GSM module

GSM Based Motor Monitoring and Speed Control

International Journal of Mechanical and Industrial Engineering (IJMIE), ISSN No. 22316477, Volume-1, Issue-2, 2011

91

AT+CMGD: To delete a short message from the GSM

module

AT+CNMI Remind mode Setup when receive a new

SMS

As the low-level function interface to the GSM

modem, these commands play a fundamental role in the

software developing of the gateway program.

VIII. FORMAT AND ANALYSIS OF SMS PDU

AND TEXT FORMAT

This section discusses the SMS traits that are

related with building a monitoring system. Apparently,

SMS PDU employs a point-to-point transference

scheme. In the GSM network, the target node can be

identified by its SIM card number. That is to say, if a

short message is not to be forwarded, the monitoring

system can quit addressing the supervisory computer

and the subordinate computer, as well as other

communication nodes, and simply send the message to

the target point according to the SIM card number. This

method comes handy for most systems. Although this

method is convenient, it has a defect that each time the

SIM card of a machine changes, the gateway software

routine may need to be modified correspondingly. For

most systems, theres no such concern. As shown in

Table I , protocol data unit (PDU) of a short message

consists of multiple fields. This paper will not elaborate

on the meaning of each field. Only the ones close to the

gateway design of monitoring systems are discussed.

Fie id SCA Type MR DA PID DCS VP UDL UD

length 1 1 1

2-

12

1 1 1 1

0-

140

Table 1 : The PDU format of a SMS

The UD (user data) field can contain up to 140

bytes of user data. It has no restriction on how the data

is coded---User data can be transferred as either ASCII

characters or as octet values. In the ASCII mode, a short

message is able to contain 160 ASCII characters, that is,

140 bytes with the 7-bit coding method. The octet value

mode is also known as the 8-bit coding mode.

Comparing to the ASCII mode, a short message in octet

mode can carry more information with the limited 140

bytes. It is the first choice for monitoring systems.

In text format sending a message like abcd1 on and

abcd1 off and abcd2 on and abcd2 off ext.

The VP field specifies the valid period of a short

message. Once a message exceeds its valid period and it

still has not reached the destination, it will be dumped

by SMSC. The SCTS field of a received message stores

its sending time. On one hand, SMSC dumps messages

that have run out the specified time delay; on the other

hand, a received short message can be tagged as

obsolete according to the SCTS field of its PDU by the

gateway.

IX. FLOW CHART AND SOFTWARE

IMPLEMENTATION

Software development: The software for the system

is developed in Embedded C and Visual Basic. The

flowcharts depicting the monitoring and the induction

motor control of speed control of dc motor is shown in

GSM

MODULE

GSM

MOBILE

PC/SCM PC/SCM

Sms

Microcontroller

And switching

Devices 1,2,3,4,5,

AT

Command

Fig. 9 : Software Implementation

Flow chart:

Y

If pass

Decode SMS&

S/W Devices

X

Change pass

Send SMS pass

Changed

X

Send SMS to

Microcontroller

GSM Based Motor Monitoring and Speed Control

International Journal of Mechanical and Industrial Engineering (IJMIE), ISSN No. 22316477, Volume-1, Issue-2, 2011

92

START

Initialize SIM300 GSM modem

OFF all motors

Greeting on LCD AT+

Initialize LCD, Serial port

Send F-Bus initialization command

IF RST PASS

?

Reload default

message

If SMS

Found

Delete SMS

Check message

If match

found

Check for SMS

IR

IF IR

Check for

SW

If sw

Send SW

Msg

X

Send IR

Msg

X

X

Print invalid mesg

X

Y

V. CONCLUSION

In the paper low cost, secure, ubiquitously

accessible, auto-configurable, remotely controlled

solution for automation of different motors has been

introduced. The approach discussed in the paper has

achieved the target to control industrial appliances

remotely using the GSM -based system satisfying user

needs and requirements.

GSM technology capable solution has proved to be

controlled remotely, provide industrial security and has

achieved the target to control different industrial

appliances remotely using the SMS-based system

satisfying user needs and requirements GSM technology

capable solution has proved to be controlled remotely,

provide industrial security and is cost-effective as

compared to the previously existing systems.

Hence we can conclude that the required goals and

objectives of GSM based induction motor monitoring

and speed control of dc motors have been achieved.

The basic level of industrial appliance control and

remote monitoring has been implemented for agriculture

purpose to control and monitor induction motor.

REFERENCES

[1] Lu, Willie w, open wireless architecture and

Enhanced performance, guest Editorial, IEEE

Communication Magazine, June 2003

[2] http://www.google.co.in

[3] http://www.imagesco.com/catalog/index.html

[4] http://nationalsemiconductors.com

[5] http://www.electronicslab.com/projects

/index.html

[6] http://www.electronicsforu.com/electronicsforu/la

b/

[7] http://www.visualgsm.com/wire_sms_index.htm

[8] http://en.wikipedia.org/wiki/Gsm

[9] http://www.camiresearch.com/Data_Com_Basics

/RS232

[10] http//www.beyondlogic.org/serial/serial.htm

[11] http://www.dreamfabric.com/sms/

[12] http://www.nobbi.com/pduspy.htm

[13] http://www.serasidis.gr/circuits/smscontroller/sm

scontroller.htm

[14] http://www.gsm-modem.de/sms-text-mode.html

You might also like

- Artificial Intelligence Substation ControllerDocument3 pagesArtificial Intelligence Substation ControllerJITHINRAJ35100% (1)

- Kishenpur Grid Station CompleteDocument39 pagesKishenpur Grid Station CompletepunitkapoorNo ratings yet

- GSM Based Transformer Fault Monitoring SystemDocument5 pagesGSM Based Transformer Fault Monitoring SystemEditor IJTSRDNo ratings yet

- Improved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationDocument9 pagesImproved Design and Evaluation of Electrical Earthing Systems For Maryland 13233 KV Transmission StationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 64eac6de-94a2-40c3-ab79-e92c08fb7f2aDocument24 pages64eac6de-94a2-40c3-ab79-e92c08fb7f2aemy1188100% (1)

- Seminar Report On PLCCDocument25 pagesSeminar Report On PLCCanon_946814792No ratings yet

- FOX615 2013 Low PDFDocument12 pagesFOX615 2013 Low PDFNeelakandan Masilamani100% (1)

- Report of Seminar On Underground Cable Detection TechnologyDocument34 pagesReport of Seminar On Underground Cable Detection TechnologyAnand Krishnan67% (3)

- Transmission Line Inspection RobotDocument1 pageTransmission Line Inspection Robotbalu2258No ratings yet

- 2.1 History and Development of Facts DevicesDocument22 pages2.1 History and Development of Facts DevicesmianNo ratings yet

- Specifications For Transformer Online Dissolved Gas Analyser (DGA)Document3 pagesSpecifications For Transformer Online Dissolved Gas Analyser (DGA)crazy devilNo ratings yet

- Flying WindmillDocument12 pagesFlying Windmill18-205 Shreyah GurramNo ratings yet

- INDIAN ELECTRICITY RULES AND INDUSTRIAL SAFETY One Point E & C PDFDocument5 pagesINDIAN ELECTRICITY RULES AND INDUSTRIAL SAFETY One Point E & C PDFHarshal VaidyaNo ratings yet

- Small EPABX Systems Configuaration: Schedule 1Document24 pagesSmall EPABX Systems Configuaration: Schedule 1rads2012No ratings yet

- Gas Insulated Substation 11405 IIumEUfDocument10 pagesGas Insulated Substation 11405 IIumEUfSowmyaNo ratings yet

- A Project Report On Scada System: Submitted By:-Sanskar Sagar Electrical 2017/130Document27 pagesA Project Report On Scada System: Submitted By:-Sanskar Sagar Electrical 2017/130Sharma Saab100% (1)

- Surge Current Protection Using Super ConductorsDocument23 pagesSurge Current Protection Using Super ConductorsPratik KumarNo ratings yet

- SafeGrid Reference ManualDocument16 pagesSafeGrid Reference Manualrajarao1234No ratings yet

- 6 RTU Specifications III A 2216Document10 pages6 RTU Specifications III A 2216rasim_m1146No ratings yet

- Inspections and Tests For GISDocument16 pagesInspections and Tests For GISsanjay sharmaNo ratings yet

- Nuisance TrippingDocument6 pagesNuisance TrippingSeindahNyaNo ratings yet

- Internship REPORTDocument30 pagesInternship REPORTVipin KshirasagarNo ratings yet

- Congestion in Power SystemDocument4 pagesCongestion in Power Systemsangeetarai100% (1)

- Technical Specification Joint Kits and TerminationsDocument10 pagesTechnical Specification Joint Kits and TerminationsYörükNo ratings yet

- MobileDocument31 pagesMobileTELECOM INJINIYANo ratings yet

- BBB M, M, KLKLKL JJKDocument16 pagesBBB M, M, KLKLKL JJKEngr Irfan AkhtarNo ratings yet

- RRVPNLDocument51 pagesRRVPNLbhavesh jangidNo ratings yet

- Circuit Breakers Lecture Notes 2Document61 pagesCircuit Breakers Lecture Notes 2bharathNo ratings yet

- GSM Based Fault Monitoring SystemDocument23 pagesGSM Based Fault Monitoring SystemSanjana Singh100% (1)

- Transmission Line Tower Earthing Analysis Using SafeGridDocument5 pagesTransmission Line Tower Earthing Analysis Using SafeGridajrojas1359No ratings yet

- Siemens Power Engineering Guide 7E 138Document1 pageSiemens Power Engineering Guide 7E 138mydearteacherNo ratings yet

- HVM Partial Discharge Testing and Monitoring Cables R06 11Document4 pagesHVM Partial Discharge Testing and Monitoring Cables R06 11Ahmed Mohamed HassanNo ratings yet

- Motor Speed Control System by Using GSM MobileDocument16 pagesMotor Speed Control System by Using GSM MobileAditya TomarNo ratings yet

- Gis 145kv 4Document18 pagesGis 145kv 4tafseerahmedNo ratings yet

- Electric Traction With CollectersDocument33 pagesElectric Traction With Collectersk rajendra100% (1)

- Frequently Asked Questions (FAQ) About TETRA, SCADA, Telemetry and TelecontrolDocument5 pagesFrequently Asked Questions (FAQ) About TETRA, SCADA, Telemetry and TelecontroltrsghstrhsNo ratings yet

- Designing of HV Power Substation and LayoutDocument6 pagesDesigning of HV Power Substation and LayoutRagavanNo ratings yet

- Transmission Line Tower Design ConceptsDocument28 pagesTransmission Line Tower Design ConceptsDiego Cobo del ArcoNo ratings yet

- Construction & Design Features of Gas Insulated System (Gis)Document4 pagesConstruction & Design Features of Gas Insulated System (Gis)NRLDCNo ratings yet

- KP PPTDocument22 pagesKP PPTSaurabh AgarwalNo ratings yet

- 22kV GIS Cable Terminal - Installation ManualDocument11 pages22kV GIS Cable Terminal - Installation ManualNorma RetamozoNo ratings yet

- Guarantee Technical ParametersDocument3 pagesGuarantee Technical ParametersDramebaaz SandeepNo ratings yet

- Transmission Line Multiple Fault Detection and Indication To Electricity BoardDocument74 pagesTransmission Line Multiple Fault Detection and Indication To Electricity BoardCrisp100% (1)

- Aac Spec 543010Document51 pagesAac Spec 543010synergykiranNo ratings yet

- Solar Insect Killer - 20191106Document17 pagesSolar Insect Killer - 20191106Vineet ChauhanNo ratings yet

- Project Title: A Presentation OnDocument23 pagesProject Title: A Presentation OnAnonymous qh5UUGTNo ratings yet

- Polymer InsulatorsDocument34 pagesPolymer InsulatorsAbraiz Khan KhattakNo ratings yet

- Critical Review On Power Oscillation Damping ControllersDocument6 pagesCritical Review On Power Oscillation Damping ControllersSonam Singh ChauhanNo ratings yet

- Underground Cable Fault DetectorDocument21 pagesUnderground Cable Fault DetectorgiriNo ratings yet

- CVT - EMVTS ComparisionDocument1 pageCVT - EMVTS ComparisiondseshireddyNo ratings yet

- HVDC Rihand 500KVDocument6 pagesHVDC Rihand 500KVpremredNo ratings yet

- DC MOTOR GSM REORT FinalDocument28 pagesDC MOTOR GSM REORT FinalUMADEVI K MNo ratings yet

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- STATCOM Review PDFDocument6 pagesSTATCOM Review PDFMoataz JabarNo ratings yet

- SMPS PresentationDocument33 pagesSMPS PresentationGeorge AntonyNo ratings yet

- Preparation of Transformer SpecificationDocument54 pagesPreparation of Transformer SpecificationparvezblogNo ratings yet

- Commissioning of Transformers and Reactors - ArunDocument71 pagesCommissioning of Transformers and Reactors - Arunsumit kumarNo ratings yet

- GSM Based Motor Monitoring and Speed ControlDocument7 pagesGSM Based Motor Monitoring and Speed ControlRavikumar PrajapatiNo ratings yet

- SD 8Document29 pagesSD 8Orsu HarishNo ratings yet

- Notification 2017 FDA & SdaDocument43 pagesNotification 2017 FDA & SdaPinnam MallikarjunaNo ratings yet

- Cgle Notice 22 02 2016Document1 pageCgle Notice 22 02 2016Pinnam MallikarjunaNo ratings yet

- Transformerless H6D2 InverterDocument47 pagesTransformerless H6D2 InverterPinnam MallikarjunaNo ratings yet

- The History of ElectricityDocument2 pagesThe History of ElectricityPinnam MallikarjunaNo ratings yet

- Abstract of Mini ProDocument1 pageAbstract of Mini ProPinnam MallikarjunaNo ratings yet

- Sri Krishna KarnamrutamDocument48 pagesSri Krishna KarnamrutamPinnam MallikarjunaNo ratings yet

- Guru Paduka Stotram MeaningDocument2 pagesGuru Paduka Stotram MeaningPinnam Mallikarjuna100% (1)

- Project On Training & Development in HBLDocument61 pagesProject On Training & Development in HBLPinnam MallikarjunaNo ratings yet