Professional Documents

Culture Documents

Suzuki ss80v Manual pt01 General

Suzuki ss80v Manual pt01 General

Uploaded by

shiyoushiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suzuki ss80v Manual pt01 General

Suzuki ss80v Manual pt01 General

Uploaded by

shiyoushiCopyright:

Available Formats

TABLE OF CONTENTS -

- -

1 SERVICE DATA - - - -

[Wtuar SHOO

FUEL PUMP AND FILTER

I ENGINE COD^^ SYSTEM -

1 CAR HEATER

IGNITION SYSTEM

- -

STARTER MOTOR

-- - - -

I CHARGING - SYSTEM

I GEAR SHIFTING CONTROL

1

SUSPENSION

-

--

I STEERING SYSTEM

1 . GENERAL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1 . Exterior View 1-2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. 2 . Specifications 1- 3

. . . . . . . . . . . . . . . . . . . . . .

1. 3 . Locations of Engine Numbel and Body Number 1-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. 4 . Standard Shop Practices 1-8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. 5 . Special Tools 1-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1 . 6 . Required Materials 1-13

1-1. Exterior View

( The photo shows standard specification. I

1-2. Specifications

HATCH

DIMENSION

Standard spark plug

NGK BP5ES

1-3. Locations of Engine Number and Body Number

The engine number i s punched on the skirt part

The body number is punched on the body in the

of the cylinder block under the carburetor.

engine room as shown below.

~ i g . I - 1 . Location of Engine No.

Fig. 1-2 Location of Body No.

1-4. Standard Shop Practices

1. Protect the painted surfaces of the body, and

avoid staining or tearing the seats. When

working on the fenders and seats, be sure

to cover them up with sheets.

2. Disconnect the negative terminal connection

of the battery when working on any electri-

cal part or component. This is necessary for

avoiding electrical shocks and short-circuit-

ing, and i s very simple t o accomplish: merely

loosen the wing nut on the negative terminal

and separate the cable from the terminal post.

3. I n raising the front or rear end off the floor

by jacking, be sure to put the jack up against

the center portion of the rear axle housing

or front suspension frame.

Fig. 1-3

Fig. 1-4

4. To work on the front or rear end raised by

jacking, be sure to place the safety stand

under the front suspension frame or rear axle

to support it in stable condition.

Fig. 1-5

Fig. 1-6

5. Have wheel chocks for ready use i n the shop.

Chock the wheels securely when raising one

end of the m'achine.

6. Orderliness i s a key to successful overhauling.

Trays, pans and shelves are needed t o set aside

the disassembled parts in groups or sets i n

order to avoid confusion and misplacement.

This i s particularly important for engine over-

hauling.

7. Have on hand the liquid packing - SUZUKl

BOND No. 4 (99000-31030) - for ready use.

This packing dope i s an essential item assures

leak-free (water and oil) workmanship.

8. Each bolt must be put back to where it was

taken from or for which it i s intended. Do not

depend on your hunch i n tightening the bolts

for which tightening torque values are speci-

fied: be sure t o use torque wrenches on those

bolts.

9. I t i s advisable t o discard and scrap gaskets and

"0" rings removed i n disassembly. Use new

ones i n reassembly, and t ry not to economize

gaskets and "0" rings.

10. Use of Genuine SUZUKl parts is imperative.

Use of imitation parts i s a big gamble on

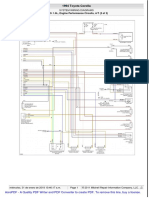

safety and performance. Use Genuine Fig. 1-7 Engine cylinder numbers

SUZUKl parts and live up to the trust your

customer places on you.

11. Special tools save time and ensure good work-

manship: They are available from SUZUKI.

Use them where their use i s specified.

Moreover, your own safety i s assured by the

use of special tools in many of the disassem-

bly and reassembly steps.

12. Refer t o the contents of this MANUAL as

often as practical, and do each job right as

prescribed.

NOTE:

The engine cylinders are identified by

numbers. See Fig. 1-7. Counting from the

crankshaft pulley side, the cylinders are

referred to as No. 1, No. 2 and No. 3

cylinders.

1-5. Special Tools

Special tools assure three things: 1) improved workmanship; 2) speedy execution of jobs for which they

are meant; and 3) protection of parts and components against damage. Here are the special tools pre-

scribed for this Model:

09916-14510

Valve lifter

Valve guide reamer

( A) 7 mm dia

( B) 12.0 rnm dia

(C) Handle

7.

0991 5-47310

Oil filter wrench

10.

099 15-6451 0

Compression gauge

( A) Valve guide & valve stem seal

handle

(6) Valve stem seal installer attach-

ment

(Cl Valve guide installer attachment

0991 6-77310 09915-77310

Piston ring compressor

Oil pressure gauge

11. 12.

099 16-445 10

Valve guide remover

0991 6-8451 0

Forceps

0991 6-97820

Flywheel stopper

0991 5-67310

Vacuum gauge

09930-401 13

Camshaft lock holder

09900-09002

Shock driver set

16.

09900-25002

Pocket tester

17.

09900-281 06

Electro tester

19.

09900-27003

1 Ionition tirninq tester

09915-2781 0

Hexagon socket (10 mm)

20.

09900-061 08

Snap ring pliers (closing type)

22.

09913-61 110

Bearing puller

09900-061 07

Snap ring pliers (opening typc

23.

Tie-rod end puller

09913-75820

Steering pinion bearing installer

09913-801 12

Bearing installer

25.

09913-7581 0

Bearing installer

26.

09922-8581 1

Spring pin remover

09913-75830

Steering pinion bush installer

09922-551 21

Drive shaft installer

09923-378 10

Clutch center guide

09900-27301

Ti mi ng light

31.

09913-17310

Carburetor adjuster

09942-4581 0

Steering plug setting tool

09943-25810

Coil spring setting t ool

32

09943-1791 0

Front wheel hub remover

33. ~,

'"9

G,,

\, -Y'

09942-1551 0

Sliding hammer

1-6. Required Materials

The materials listed below are needed for maintenance work on thisvehicle, and should be kept on hand

for ready use. In addition, such standard materials as cleaning fluids, lubricants, etc., should also be

available. Methods and time of use are discussed i n the text of this manual on later pages.

Ref.

No.

-

Material

GOLDEN CRUISER 1200

"Anti-freeze and Summer Coolant"

(99000-241 20)

<ye--

SUZUKl GREASE SUPER H

v-.. 223

Additive to engine cooling for im-

proving cooling efficiency and for

protection of wet walls against

rusting.

0 For locations indicated i n the sec-

tion dealing with the starter motor.

e Clutch release bearing retainer.

0 Clutch release shaft bushing.

0 Transmission oil seal.

0 Differential oil seal.

0 Steering column.

0 Gear shifting control lever bushing

& seat.

e Door window regulator.

Special grease intended for use on

constant velocity joint.

(Drive shaft joint)

4.

SUZUKl BOND (No. 4)

(99000-31030)

.,,*-.*fit eorJD

S U ~ ~ , - -

For top and bottom mating faces

of transmission case.

e For other locations specifically

indicated in the text of this

manual.

5.

6.

0 Rear axle spindle cap

e Front wheel bearing

e Rear wheel bearing

7.

1 GEAR OI L SAE#90

THREAD-LOCK CEMENT

(99000-32040)

SUZUKl SUPER GREASE E

(99000-25050)

--

WHEEL BEARING GREASE

4-STROKE ENGINE OIL

e Timing belt inside cover bol t

0 Back window hinge screws

e Steering gear case

Steering rack

0 Steering pinion bush

Steering rack boot

Proper oil viscosity chart

SAE

I

2OW-40,2OW-50

Temperature

e Transmission case

2.0 ltr. (4.213.5 USIlrnp. pt.)

Transmission gear and bearing,

For engine oil pan: 2.5 litres

(5.314.4 USIlmp. pt.) for peri-

odical oil change but 3.0 litres

(6.315.3 USIlmp. pt.) for re-

filling a t the time of engine over-

hauling.

e Crank journal bearings and thrust

plate.

e Connecting-rod big-end and small-

end bearings.

@ Camshaft journals and thrust plate.

0 Rocker shafts.

Oil pump gears.

a Pistons and piston rings.

0 Engine oil seals.

Valve stems.

0 Accelerator, choke and clutch

cables.

Parking brake cable.

@ Accelerator, brake and clutch

pedals.

e Door locks and hinges.

Distributor gear.

I

e Brake backing plate

e Timing belt tensioner bol t

o Brake fluid reservoir tank

lo'

11.

12.

SEALING COMPOUND 366E A?

(99000-31090)

&p?

THREAD LOCK CEMENT SUPER 1342

(99000-32050)

BRAKE FLUID "DOT 3, DOT 4" or SAE J1703

You might also like

- Z Force 1000 Service Manual 2018-19 PDFDocument357 pagesZ Force 1000 Service Manual 2018-19 PDFJohn100% (10)

- Isuzu D-Max 2011 Transfer Case Service ManualDocument92 pagesIsuzu D-Max 2011 Transfer Case Service ManualWilmer Huanga92% (13)

- Cf625 3, Cf500 6, Cf625 6 Service Manual v1Document266 pagesCf625 3, Cf500 6, Cf625 6 Service Manual v1NAUTI SUR100% (1)

- C Force 520 Service Manual V1Document294 pagesC Force 520 Service Manual V1ApK100% (2)

- Isuzu Trooper Workshop ManualDocument3,573 pagesIsuzu Trooper Workshop Manualvit otio89% (19)

- Case Skid Steer Loader Service Manual Pgs 988-1192Document204 pagesCase Skid Steer Loader Service Manual Pgs 988-1192gregfortkamp70% (10)

- Nissan Td42 EngineDocument100 pagesNissan Td42 Enginearjun c75% (4)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (3)

- RS150 (K56J) PartsCatalogue2016Document116 pagesRS150 (K56J) PartsCatalogue2016gdon88% (8)

- Gasgas Enduro 200-250-300 2T 2018 Workshop ManualDocument72 pagesGasgas Enduro 200-250-300 2T 2018 Workshop ManualAleš ZaverlaNo ratings yet

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003From EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Rating: 5 out of 5 stars5/5 (1)

- Volvo F9Q EngineDocument42 pagesVolvo F9Q EngineAoife Fitzgerald100% (2)

- Enticer ManualDocument122 pagesEnticer Manualdhaze14No ratings yet

- Foote-Jones 8000 Series Gear Reducer ManualDocument20 pagesFoote-Jones 8000 Series Gear Reducer ManualbwelzNo ratings yet

- Pulper Rotor ManualDocument10 pagesPulper Rotor ManualhenryhariyadiNo ratings yet

- SG Operation ManualDocument51 pagesSG Operation ManualEdin Raul Yalle Rafael100% (1)

- PAINELDocument140 pagesPAINELFelipe SilvaNo ratings yet

- S01 Hydraulic Cylinders - TMKDocument8 pagesS01 Hydraulic Cylinders - TMKAnonymous iu95trpxNNo ratings yet

- D65EX-15 Parts Manual - BD-HDocument273 pagesD65EX-15 Parts Manual - BD-HViktor Rada80% (5)

- Zx200-5g Engine ManualDocument234 pagesZx200-5g Engine ManualPrudz95% (44)

- Mechanical Power Take Off Rubber Block Drive Power Take Off Installation and Maintenance ManualDocument34 pagesMechanical Power Take Off Rubber Block Drive Power Take Off Installation and Maintenance ManualVituwNo ratings yet

- XS650 PDFDocument215 pagesXS650 PDFphilNo ratings yet

- S06 Drilling Pump Rexroth-A10VODocument20 pagesS06 Drilling Pump Rexroth-A10VOdeliaabreguNo ratings yet

- Yamaha Jog 87-90Document249 pagesYamaha Jog 87-90劉擎鎮67% (3)

- Disassembly/Assembly Manual Model SR2100 (DRAX) : RJ-DA-16 05/10Document35 pagesDisassembly/Assembly Manual Model SR2100 (DRAX) : RJ-DA-16 05/10Erica HenryNo ratings yet

- Manual de Operaciones (ZKV-ZKP)Document20 pagesManual de Operaciones (ZKV-ZKP)danielNo ratings yet

- SM Pw170es-6k-962Document625 pagesSM Pw170es-6k-962Эрнест Бекиров100% (1)

- LANCER Workshop ManualDocument21 pagesLANCER Workshop ManualHameed0% (1)

- Cforce 1000 2018Document365 pagesCforce 1000 2018Aigars Mulis100% (1)

- Tyre Machine Instruction ManualDocument20 pagesTyre Machine Instruction ManualRocky SarafNo ratings yet

- Pistons and Connecting Rods - Install: Desmontagem e MontagemDocument3 pagesPistons and Connecting Rods - Install: Desmontagem e MontagemJefferson SilvaNo ratings yet

- Installation, Operation and Maintenance of Airflex@ CM Marine ClutchDocument12 pagesInstallation, Operation and Maintenance of Airflex@ CM Marine Clutchaiyubi2No ratings yet

- S07 311 Range TrammingDocument24 pagesS07 311 Range TrammingLuis JosueNo ratings yet

- Daihatsu CB23 CB60 61 CB70 80 Engine ManualDocument294 pagesDaihatsu CB23 CB60 61 CB70 80 Engine ManualKuvita GarcíaNo ratings yet

- Actyon 200603Document1,103 pagesActyon 200603Ederson BJJNo ratings yet

- Auxiliary Equipment: Service DataDocument5 pagesAuxiliary Equipment: Service DataEko SunaryoNo ratings yet

- Dezurik Mastergear Manual Actuators: Instruction August 2012Document9 pagesDezurik Mastergear Manual Actuators: Instruction August 2012Charles MutetwaNo ratings yet

- Transfer: Workshop ManualDocument92 pagesTransfer: Workshop ManualmailforspamNo ratings yet

- راهنمای موتور ماتو درایوDocument31 pagesراهنمای موتور ماتو درایوbobindra71No ratings yet

- Caterpillar Cat 232D SKID STEER LOADER (Prefix DPR) Service Repair Manual (DPR00001 and Up)Document25 pagesCaterpillar Cat 232D SKID STEER LOADER (Prefix DPR) Service Repair Manual (DPR00001 and Up)rpoy9396615No ratings yet

- CN Manu Sg303745557590a41 e 1000164105-03Document60 pagesCN Manu Sg303745557590a41 e 1000164105-03heruono sitorusNo ratings yet

- Type DSM (Thru Bore) : Instructions On Installation Operation and Maintenance For Kirloskar PumpDocument43 pagesType DSM (Thru Bore) : Instructions On Installation Operation and Maintenance For Kirloskar Pumpkprasad_56900No ratings yet

- Linked PDFDocument244 pagesLinked PDFroparts clujNo ratings yet

- Blackhawk Pump Manual 2018Document75 pagesBlackhawk Pump Manual 2018Ivan MaltsevNo ratings yet

- Manitou Tower ServiceDocument35 pagesManitou Tower ServiceKélio Wolfrane Santos MachadoNo ratings yet

- 2006 Radium - Metal Shock Service ManualDocument16 pages2006 Radium - Metal Shock Service ManualJesus Francisco MorenoNo ratings yet

- 73 Johnson 35HP-SMDocument111 pages73 Johnson 35HP-SMJim PiperNo ratings yet

- Beta RR 250 400 450 525 Service Repair Manual 2005-2007 PDFDocument215 pagesBeta RR 250 400 450 525 Service Repair Manual 2005-2007 PDFvadim vadimNo ratings yet

- Viscossus Fan DriveDocument16 pagesViscossus Fan DriveaaronNo ratings yet

- SRX6 WorkshopManualDocument240 pagesSRX6 WorkshopManualRolando Antonio Troncoso100% (1)

- Caterpillar Cat 235C FRONT SHOVEL (Prefix 4DG) Service Repair Manual (4DG00001 and Up)Document23 pagesCaterpillar Cat 235C FRONT SHOVEL (Prefix 4DG) Service Repair Manual (4DG00001 and Up)rpoy9396615No ratings yet

- 12 V Engine Starter ManualDocument15 pages12 V Engine Starter ManualramonalbertoguzmanNo ratings yet

- Hyundai HX225S-L 8-1. Armado y DesarmadoDocument168 pagesHyundai HX225S-L 8-1. Armado y DesarmadoCristiam QuispeNo ratings yet

- 2017-08-17-Orbit-D-Range-emailing ManualDocument32 pages2017-08-17-Orbit-D-Range-emailing ManualLorenzoNo ratings yet

- Volvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.7Document33 pagesVolvo Penta 3.0 GS, 4.3 GL-GS-Gi, 5.0 GL-Gi, 5.7 GS-GSi, 7.4 Gi-GSi, 8.2 GSi Sez.7Luciano LiuzziNo ratings yet

- Caterpillar Cat M322D Wheeled Excavator (Prefix W2S) Service Repair Manual (W2S00001 and Up) PDFDocument22 pagesCaterpillar Cat M322D Wheeled Excavator (Prefix W2S) Service Repair Manual (W2S00001 and Up) PDFfkdmma100% (1)

- Drive ShaftDocument9 pagesDrive ShaftSteven AmadorNo ratings yet

- 2005 Radium Shock Service ManualDocument16 pages2005 Radium Shock Service ManualvoxborNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Nissan Pathfider 2005 ManualDocument84 pagesNissan Pathfider 2005 ManualDragos StefanNo ratings yet

- Cat Electronic Technician 2015A v1.0 Product Status ReportDocument29 pagesCat Electronic Technician 2015A v1.0 Product Status ReportX'mix DreamerNo ratings yet

- Catalog of RBS HYUNDAI & KIA ListDocument26 pagesCatalog of RBS HYUNDAI & KIA Listcbaautoparts197No ratings yet

- GM 5L40E Automatic Diagrams and ListDocument9 pagesGM 5L40E Automatic Diagrams and ListBrayan Aragon diego100% (1)

- The T-Roc Cabriolet: Price and Specification GuideDocument30 pagesThe T-Roc Cabriolet: Price and Specification GuideKornelija PadleckyteNo ratings yet

- Actia Multidiag Truck PC enDocument4 pagesActia Multidiag Truck PC enArhimed DokoniNo ratings yet

- Daihatsu: Engine Cyl Set Number Line Application Model Bore CC Years Chrome Plain NoDocument2 pagesDaihatsu: Engine Cyl Set Number Line Application Model Bore CC Years Chrome Plain Nomarran almarranyNo ratings yet

- Spare Parts Catalog: 6 AS 1000 TO Material Number: 1346.062.315 Current Date: 30.03.2021Document64 pagesSpare Parts Catalog: 6 AS 1000 TO Material Number: 1346.062.315 Current Date: 30.03.2021Michael KofmanNo ratings yet

- Classic American December 2014 UKDocument124 pagesClassic American December 2014 UKcremamelo23No ratings yet

- Control System, Fuel Supply For Volvo XC60 XC60Document3 pagesControl System, Fuel Supply For Volvo XC60 XC6047ASSONo ratings yet

- Suzuki Electric SystemDocument124 pagesSuzuki Electric SystemVisual DepressantNo ratings yet

- B-Lift 201 Pro ADocument2 pagesB-Lift 201 Pro AALINo ratings yet

- 2003 Nissan Altima 2.5 Serivce Manual GWDocument62 pages2003 Nissan Altima 2.5 Serivce Manual GWAndy Dellinger100% (1)

- 1994 Toyota Corolla 1994 Toyota CorollaDocument1 page1994 Toyota Corolla 1994 Toyota CorollaAngie CamargoNo ratings yet

- Kia Seltos Car DetailsDocument1 pageKia Seltos Car Detailspulkit aggarwalNo ratings yet

- Vigorous PLC: Assessable Benefits - 2021/22 Andrea LeanDocument4 pagesVigorous PLC: Assessable Benefits - 2021/22 Andrea LeanMuhammad AbbasNo ratings yet

- All Trouble CodesDocument79 pagesAll Trouble CodesJustin Cruz100% (1)

- Clutch Control - Test: Shutdown SIS Previous ScreenDocument6 pagesClutch Control - Test: Shutdown SIS Previous Screengalvis1020No ratings yet

- Location of Chassis and Engine NumbersDocument9 pagesLocation of Chassis and Engine NumbersPrashantNo ratings yet

- LAMPIRAN I (Lanjutan)Document8 pagesLAMPIRAN I (Lanjutan)GalNo ratings yet

- Body Builders Layout Book: Electrical Wiring IndexDocument30 pagesBody Builders Layout Book: Electrical Wiring IndexАндрейNo ratings yet

- Boxer BM 125 X PDFDocument65 pagesBoxer BM 125 X PDFhamidhesaraki100% (1)

- V2009 Eng 01 1091Document2 pagesV2009 Eng 01 1091Shane LinNo ratings yet

- Chrysler-Fiat Strategic AllianceDocument37 pagesChrysler-Fiat Strategic AllianceMey Sandrasigaran50% (2)

- SOWA - NIPA - BOSAVI - 23 - AugDocument2 pagesSOWA - NIPA - BOSAVI - 23 - AugIsraelNo ratings yet

- Lexus Case - Emotional PriceDocument2 pagesLexus Case - Emotional PriceAnonymous dUZFpCzLNo ratings yet