Professional Documents

Culture Documents

NDT RT Repair

Uploaded by

praveentien0 ratings0% found this document useful (0 votes)

148 views1 pageCSWIP TEST

Original Title

NDT RT REPAIR

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCSWIP TEST

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

148 views1 pageNDT RT Repair

Uploaded by

praveentienCSWIP TEST

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

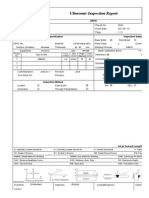

WIS10 MSR/BR/RT2 issue 3 Date: 28/05/03

THE WELDING INSTITUTE

Report on test item:

Shot A: Density 2 - 3 IQI 6 wires visible Re-shoot

Shot B: Density 1.5 1.8 IQI not visible Accept

Shot C: Density 4.3 4.8 IQI 4% Accept

Shot D: Not yet completed.

Operators name:

Signature:

TWI INSPECTION SERVICES

RADIOGRAPHIC TESTING REPORT Bad example 2

Work location:

Radiographic test procedure applicable: AP 126/ 567

Defect acceptance criteria: BS 2910 Radiographic technique: DWSI

Weld identification: SEC 21 W8 Material type: Steel

Weld process: SMAW Wall thickness:12 mm

Radiation Source: X-ray IQI type: BS 3971 type 2 13-18

Joint type: Single V butt; pipe to pipe

10 inch diameter

Weld preparation: Root gap 3.5

Root face 2.5

60

o

included angle

Exposure time: 12 ci mins FFD/SFD: 1200 mm

Source strength: 350 kvs

Kilovoltage: N/ A

Source size: N/ A

Focal spot size: 6 ! 3 mm

Film type: Medium grain factor 25 Screens: Salt

Development:

Time: 5 mins Temp: 40

o

C

Fixing:

Time: 6 mins Temp: 20

o

C

You might also like

- Digital Radiography ReportDocument7 pagesDigital Radiography ReportadityaromasNo ratings yet

- QB 5 - Basic NDT - LT QBDocument5 pagesQB 5 - Basic NDT - LT QBprabhakaran.SNo ratings yet

- Basic NDT - Et QB 2Document4 pagesBasic NDT - Et QB 2prabhakaran.SNo ratings yet

- Radiographic TestingDocument58 pagesRadiographic TestingLeduc HanhNo ratings yet

- Sitco H 101 (J) Rev2 - Jis Z 3104 (RT)Document30 pagesSitco H 101 (J) Rev2 - Jis Z 3104 (RT)G_ARVALIS8470No ratings yet

- RT-Technique Sheet Items Level IIDocument3 pagesRT-Technique Sheet Items Level IISugianto TanNo ratings yet

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- General Level-II QuestionsDocument4 pagesGeneral Level-II QuestionsGomathi SankarNo ratings yet

- Radiograph FormulaDocument2 pagesRadiograph Formulaहेमंत कुमार मीणाNo ratings yet

- RI CW BDocument5 pagesRI CW Bmangalraj900No ratings yet

- NDT Steel CastingsDocument17 pagesNDT Steel CastingsWoodrow FoxNo ratings yet

- RT ProcedureDocument10 pagesRT ProcedureSandeep SundriyalNo ratings yet

- Twi Training & Certification (S.E. Asia) SDN - BHDDocument1 pageTwi Training & Certification (S.E. Asia) SDN - BHDjasminneeNo ratings yet

- Iqi'sDocument6 pagesIqi's24inspector100% (1)

- RT Pratical Exam FormulasDocument2 pagesRT Pratical Exam FormulasKartik SharmaNo ratings yet

- Ut PDFDocument88 pagesUt PDFphillipskincaidNo ratings yet

- Rad Multi ChoiceDocument2 pagesRad Multi Choicesabba_420No ratings yet

- NDT - Magnetic ParticleDocument73 pagesNDT - Magnetic ParticleUmaibalanNo ratings yet

- 24 Practical Visual InspectionDocument5 pages24 Practical Visual InspectionMai Anh TaiNo ratings yet

- Visual Testing of Asme Codes & Iso Standars Differences and SimilaritiesDocument2 pagesVisual Testing of Asme Codes & Iso Standars Differences and SimilaritiesNaik Kiran GopiNo ratings yet

- Introduction To UT Flaw DetectorDocument26 pagesIntroduction To UT Flaw DetectorNail Widya Satya100% (1)

- As Spec Ri 002 AnswerDocument6 pagesAs Spec Ri 002 AnswerKarthikeyan GanesanNo ratings yet

- Phased Array Calculations With AnswersDocument8 pagesPhased Array Calculations With AnswersLương Hồ VũNo ratings yet

- RT Standards NotesDocument4 pagesRT Standards NotesprabhuNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Radiography Testing Level I and II PDFDocument87 pagesRadiography Testing Level I and II PDFIdeal NaradmuniNo ratings yet

- LPT Spe QB 2Document6 pagesLPT Spe QB 2Aruchamy SelvakumarNo ratings yet

- N F: NFT S C: EAR Ield Tandard Alibration TubeDocument1 pageN F: NFT S C: EAR Ield Tandard Alibration TubeMahmood KhanNo ratings yet

- NDT MT nds1Document41 pagesNDT MT nds1sathi11189No ratings yet

- RT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeDocument19 pagesRT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeShanmuga NavaneethanNo ratings yet

- As RI GEN 002 With AnswersDocument6 pagesAs RI GEN 002 With AnswersKarthikeyan GanesanNo ratings yet

- PT - Level 2 - S - 002 - Revised by RVMDocument4 pagesPT - Level 2 - S - 002 - Revised by RVMkingstonNo ratings yet

- Asnt Recer RT QB Level IDocument9 pagesAsnt Recer RT QB Level IkingstonNo ratings yet

- Technology Multiple Choice Exam 1Document8 pagesTechnology Multiple Choice Exam 1saifullah629No ratings yet

- Aries - Saturated Eddycurrent - Tube - ProcedureDocument17 pagesAries - Saturated Eddycurrent - Tube - ProcedureVipin ShettyNo ratings yet

- Doppler: Product ManualDocument30 pagesDoppler: Product ManualJulio SaintDLC100% (1)

- Radiography Part 1 - TWI PDFDocument7 pagesRadiography Part 1 - TWI PDFPahe DriveNo ratings yet

- Radiographic Testing Report: EGB-S-RT-0002Document4 pagesRadiographic Testing Report: EGB-S-RT-0002Tuấn ĐậuNo ratings yet

- Q&A Liquid Penetrant Testing Level 1 y 2 PDFDocument36 pagesQ&A Liquid Penetrant Testing Level 1 y 2 PDFGonzalo TelleríaNo ratings yet

- Radiographic Testing (RT) Level - 2 Specific Exam-2Document7 pagesRadiographic Testing (RT) Level - 2 Specific Exam-2Mohammed Aljawhar100% (1)

- PRR CalculationDocument4 pagesPRR CalculationnavitaNo ratings yet

- Thickness Gauging Level 2 (Questions & Answers)Document3 pagesThickness Gauging Level 2 (Questions & Answers)kingston100% (2)

- Radiograph Interpretation CASTINGSDocument5 pagesRadiograph Interpretation CASTINGSDavid MacatangayNo ratings yet

- Ultrasonic Testing: NDT Training & CertificationDocument21 pagesUltrasonic Testing: NDT Training & CertificationMidhun K ChandraboseNo ratings yet

- SIUI Industrial Ultrasonic Products PDFDocument13 pagesSIUI Industrial Ultrasonic Products PDFShahbaz AhmadNo ratings yet

- Set 1Document5 pagesSet 1mangalraj900No ratings yet

- M2.2.3 Visual InspectionDocument11 pagesM2.2.3 Visual InspectionAldy Bagus PratamaNo ratings yet

- TOFD and PAUT For Weld Root CorrosionDocument38 pagesTOFD and PAUT For Weld Root CorrosionMuthumonickamNo ratings yet

- CWB 2 Module 22 Questions Flashcards - Quizlet - PDF (CWB 2)Document8 pagesCWB 2 Module 22 Questions Flashcards - Quizlet - PDF (CWB 2)HusnainAhmedNo ratings yet

- H L T Level 1Document8 pagesH L T Level 1prabhakaran.SNo ratings yet

- Ultrasonic Report: Probe Details and Position (Fig 1)Document2 pagesUltrasonic Report: Probe Details and Position (Fig 1)BALA GANESH100% (1)

- API UT21 ThicknessProcedure 20190304Document7 pagesAPI UT21 ThicknessProcedure 20190304michaelNo ratings yet

- Procedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesDocument10 pagesProcedimiento IT-ET - UT-014 Rev 02 API 1104 - 2013 InglesJonathan Espinoza MejiaNo ratings yet

- AsuuuuuuuuuuuuDocument22 pagesAsuuuuuuuuuuuuyusuf akbar100% (1)

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989From EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookNo ratings yet

- M Rogers: Radiographic Test Report Bad Example 5Document1 pageM Rogers: Radiographic Test Report Bad Example 5Sundar KumarNo ratings yet

- Kamlesh Kumar Singh Engineers Pvt. LTDDocument24 pagesKamlesh Kumar Singh Engineers Pvt. LTDAADARSHNo ratings yet

- PT Shahib Sejati (Siap Cetak)Document8 pagesPT Shahib Sejati (Siap Cetak)Ade RafikNo ratings yet

- Technology: Answers Drawing BDocument5 pagesTechnology: Answers Drawing BWellington S. França100% (1)

- File No. 6 - API 936Document10 pagesFile No. 6 - API 936praveentienNo ratings yet

- Welding Handbook MILDocument868 pagesWelding Handbook MILpraveentienNo ratings yet

- Piping Inspector's Handbook (Rev 2)Document10 pagesPiping Inspector's Handbook (Rev 2)praveentien100% (1)

- File No. 7 - API 936Document8 pagesFile No. 7 - API 936praveentien100% (1)

- File No. 10 - API 936Document19 pagesFile No. 10 - API 936praveentien100% (6)

- Kaowool Paper 1260Document2 pagesKaowool Paper 1260praveentienNo ratings yet

- API570 Model Qus - 1Document125 pagesAPI570 Model Qus - 1praveentienNo ratings yet

- Cera BoardDocument2 pagesCera BoardpraveentienNo ratings yet

- Mother Teresa's PoemDocument1 pageMother Teresa's Poempraveentien100% (1)

- Welding & Quality Engineering A Prestigious Mou Between PSGCT, Coimbatore and Bhel, TrichyDocument4 pagesWelding & Quality Engineering A Prestigious Mou Between PSGCT, Coimbatore and Bhel, TrichypraveentienNo ratings yet

- RT DwdiDocument1 pageRT DwdipraveentienNo ratings yet

- Petal To Petal Long Seam WeldingDocument11 pagesPetal To Petal Long Seam WeldingpraveentienNo ratings yet

- RT Level I BasicDocument290 pagesRT Level I Basicpraveentien100% (11)

- Approved Brand List ElectrodeDocument7 pagesApproved Brand List Electrodepraveentien0% (1)

- A Beggar: "I Hope You Don't Plan To Educate Them All at My Expense."Document1 pageA Beggar: "I Hope You Don't Plan To Educate Them All at My Expense."praveentienNo ratings yet

- Radiography Calculation SheetDocument2 pagesRadiography Calculation SheetpraveentienNo ratings yet

- Visual INSPECTION OF WELDSDocument49 pagesVisual INSPECTION OF WELDSpraveentienNo ratings yet

- 6A CAP GSKJ KJSHG K Lsks Kouo (TPIAPOIHKJBDocument1 page6A CAP GSKJ KJSHG K Lsks Kouo (TPIAPOIHKJBabidaliabid1No ratings yet

- Is 12843Document5 pagesIs 12843praveentien100% (1)

- MPT NDTDocument60 pagesMPT NDTpraveentienNo ratings yet

- Is 3815Document9 pagesIs 3815praveentienNo ratings yet