Professional Documents

Culture Documents

Shell Inputs: Page No Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzle

Shell Inputs: Page No Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzle

Uploaded by

Visas SivaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shell Inputs: Page No Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzle

Shell Inputs: Page No Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzle

Uploaded by

Visas SivaCopyright:

Available Formats

P kgf/cm2 5.

602

D mm 3500

t

r,int

mm 7.0096

t

r,ext

mm 0

S

v

kgf/cm2 1406.14

c.a.

,shell

mm 3.2

t

'

mm 14

d' mm 610

t

n

'

mm 16

L

pr1

mm 400

S

n

kgf/cm2 1406.14

Off mm 0

t

r n,ext

mm 1.34

D

p

mm 0

t

e

mm 0

h mm 25

L' mm 20

X mm 100

leg

1

mm 0

leg

2

mm 16

c.a.

,nozzle

mm 3.2

S

p

kgf/cm2 1406.14

t mm 10.8

t

n

mm 12.8

d mm 584.4

W mm 0

radian 0

t

r n mm 1.213173

t

r

mm 7.0096

inside diameter of nozzle

Reqd. thickness of shell (corresponding to internal pressure)

weld leg between nozzle and pad/shell

allowable stress in nozzle

INTEGRAL NOZZLE INPUTS

weld leg between pad and shell

CERTAIN DERIVED PARAMETERS

Nozzle wall thickness after corrosion

Shell thickness after corrosion

Shell thickness provided

WELD LEGS INPUTS

reqd. nozzle thickness(corresponding to external pressure)

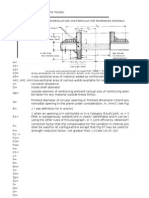

USE ASME CODE SECTION-8 DIVISION I (UG-37)

allowable stress in reinforcing pad at given temp

width of reinforcing pad

layout angle

NOZZLE INPUTS

REINFORCING PAD INPUTS

Reqd. thickness of shell (governing the case)

corrosion allowance of nozzle (internal only)

hub thickness of integral nozzle

reqd. nozzle thk

Reqd. thickness of shell (corresponding to external pressure)

set on nozzle without pad

Allowable stress in shell at given temp

outside diameter of reinforcing pad

Corrosion allowance of shell

NO

Nozzle wall thickness provided

nozzle projection outside the vessel wall

Offset distance

Doc. No. Revision

Page No

DESIGN CALCULATION FOR SET IN, SET ON NOZZLE WITH

AND WITHOUT PAD AND SELF REINFORCED NOZZLE

Internal pressure

Internal diameter of the shell

SHELL INPUTS

hub height of integral nozzle

thickness of reinforcing pad

type of nozzle

is it split type padding

Nozzle O.D.

height of beveled transition

WITHOUT CORROSION ALLOWANCE

WITHOUT CORROSION ALLOWANCE

CONSIDER LIQUID HEAD

SELECT FROM DROP DOWN LIST

FALSE

SELECT FROM DROP DOWN LIST

WARNING:PUT ALL FIELDS AS ZERO

max(t

a

,.min(t

b3

,max(t

b2

,t

b1

)))

t

b2

mm 4.413173

mm 10.2096

mm 4.54

min nozzle thickness(t

ug45

)

fr3

mm 10.2096

MIN NOZZLE THICKNESS (ACCORDING TO UG-45)

t

a

(P(d')/(2(S

n

+(0.4*P)))+c.a.

,nozzle

t

b1

t

int

+c.a.

,nozzle

t

ext

+c.a.

,nozzle

t

b3

from table +c.a.

,nozzle

mm 11.54

fr1,fr2

Sn/Sv

min(Sn,Sp)/Sv

- -

LIMITS OF REINFORCEMENT

limit parallel to vessel wall (D

1

)

D1 mm

-

min(2.5t,2.5t

n

+t

e

)

1

27

-

tlnp mm

1168.8

1

CALCULATIONS BY ASME CODE SECTION-8 DIVISION I (UG-37)

CALCULATION OF CERTAIN FACTORS

PROVIDED NOZZLE WALL THICKNESS IS SUFFICIENT

2*max(d,R

n

+t

n

+t)

limit normal to vessel wall (t

lnp

)

max(t

lnp

-h,0)*((max(t

lnp

-h,0)/L')*(X-t

n

))+(X-t

n

-((max(t

lnp

-h,0)/L'))*(X-tn))*max(t

lnp

-h,0)*2

[if fr<1] dt

r

F + 2t

n

t

r

F(1-f

r1

), else dt

r

F

AREA CALCULATION

A

1

max(d[E

1

t-Ft

r

]-2t

n

(E

1

t-Ft

r

)(1-f

r1

) , 2(t+t

n

)(E

1

t-Ft

r

)-2t

n

(E

1

t-Ft

r

)(1-f

r1

))

total area available

Area available in bevel

Area available in hub plus bevel

mm

2

0

3096.798

mm

2

A

61

-

if integral type(0.75+0.25cos2),else 1

1

1

mm

2

Area available in welds

(min(D

p

,2*d,2*(R

n

+t

n

+t))-d-2t

n

)t

e

f

r4

2*min(h,t

lnp

,L

pr1

)*(X-t

n

')*f

r2

fr4

Sp/Sv

force correlation factor

min(5f

r2

t(t

n

-t

r n

),2f

r2

t

n

(t

n

-t

r n

)(2.5t

n

+t

e

)

(leg

1

)

2

f

r1

Area available in nozzle

0

4096.41

2215.11

625.6886

256

A

2

A

4

A

5

A

1

+A

2

+A

41

+A

42

+A

5

+A

61

+A

62

Area available in pad

Area available in hub

A

T

A

6

Area available in shell

A

61

+A

62

mm

2

mm

2

OPENING IS NOT ADEQUATELY REINFORCED, INCREASE THICKNESS OF

REINFORCING ELEMENTS

mm

2

-

A

r

-

-

Area required

0

mm

2

mm

2

mm

2

0

A

62

MIN NOZZLE THICKNESS (ACCORDING TO UG-45)

t

a

mm 4.413173

(P(d')/(2(S

n

+(0.4*P)))+c.a.

,nozzle

mm

t

int

+c.a.

,nozzle

10.2096

t

b2

mm

mm L

R

86.4

t

b3

mm 11.54

from table +c.a.

,nozzle

min nozzle thickness(t

ug45

)

4.54

mm

max(t

a

,.min(t

b3

,max(t

b2

,t

b1

)))

effective vessel wall length

effective pressure radius

D/2+c.a

,shell

.

8t,10t,8(t+t

e

)(acc to diff condtns.)

LIMITS OF REINFORCEMENT

PROVIDED NOZZLE WALL THICKNESS IS SUFFICIENT

R

eff

1753.2

CERTAIN PARAMETERS

mm

(d'-2t

n

)/2

inside radius of nozzle

t

ext

+c.a.

,nozzle

t

b1

CALCULATION BY APPENDIX 1-10

R

n

mm 292.2

10.2096

for calculating L

H

t+0.78(R

n

t

n

)0.5

L

H1

PR

n

(L

H

-t)

internal pressure force on shell

PR

eff

(L

R

+t

n

)

area contributed by vessel

tL

R

max(1,/4)

mm

2

0.5Leg

1

2

+ 0.5leg

2

2

141.9814

L

pr1

+ t

ALLOWABLE STRESS

kgf/cm

2

mm

2

f

N

A

4

CALCULATION OF AREAS

mm

2

A

2

area contributed by welds

3.495137

933.12

0

1.5*S

n

A

1

mm

2

mm

2

effective nozzel wall length

if(h=0),min(L

H1

,L

H2

,L

H3

) else min(L

H1

,L

H2

,L

H4

)

nozzle radius opening in vessel along long chord

if t

e

>0.5tand w>8(t+t

e

),t+t

e

else t

mm

mm

128

effective thickness used in calc. of pressure stress

8(t+t

e

)

for calculating LH

mm

kgf

10.8

-176.786

292.2

mm

mm

mm

86.4

0

for calculating L

H

for calculating L

H

X(h+t)+0.78(t

n

/(X-c.a.))(R

n

t

n

)

0.5

0

1061.12

2109.21

FORCE CALCULATION

R

n

/cos

internal pressure force on nozzle

area contributed by reinforcing pad

min(A

5a

,A

5b

)

f

S

kgf

17992.85

-

if(L

H

<h+t)t

n

L

H

else(X(h+t)+0.78(t

n

2

/(X-c.a.))(R

n

t

n

)

0.5

)

total area available

A

1

+A

2

+A

41

+A

42

+A

5

allowable local primary membrane stress

for calculating A

1

min(10, (2R

n

+t

n

)/((D+t

eff

)t

eff

)

0.5

area contributed by nozzle

A

5

A

T

S

allow

R

nc

L

H2

410.8

t

eff

L

H3

L

H4

L

H

mm 0

max. local primary membrane stress at nozzle intersection

OPENING IS NOT ADEQUATELY REINFORCED, INCREASE THICKNESS OF

REINFORCING ELEMENTS

max[2

avg

-

circ

,

circ

]

(f

N

+f

S

+f

Y

)/A

T

Pr

eff

/t

eff

S

allow

/(2(A

p

/A

T

)-(R

eff

/t

eff

))

STRESS CALCULATION

general primary membrane stress

S

n

*(t/R

eff

)

P

max2

P

max

avg

circ

909.3913

7857.624

4383.508

MAXIMUM ALLOWABLE PRESSURE CALCULATION

1.503736

8.662053

1.503736

P

max1

830315.5

28698.21 f

Y

kgf/cm

2

kgf/cm

2

kgf/cm

2

kgf/cm

2

R

n

(L

H

-t)+R

eff

(L

R

+t

n

+R

nc

)

kgf/cm

2

kgf/cm

2

A

P mm

2

kgf

P

L

average primary membrane stress

discontinuity force from internal pressure

PR

eff

R

nc

used in calculation of P

max1

used in calculation of P

max

min(P

max1

,P

max2

)

nozzle maximum allowable pressure

used in calculation of P

max

some additional conditions are imposed on ug-37 when we use appendix 1-7 but area

min((d

1

-d-2t

n

)t

e

f

r4

,(D

p

-d-2t

n

)t

e

f

r4

)

mm

2

1107.555

mm 27

A

1

same as in ug-37

d

2

area contributed by nozzle

MIN NOZZLE THICKNESS (ACCORDING TO UG-45)

t

a

mm 4.413173

(P(d')/(2(S

n

+(0.4*P)))+c.a.

,nozzle

(d

1

-2*R

n

)*[E

1

t-Ft

r

]-2t

n

(E

1

t-Ft

r

)(1-f

r1

)

area contributed by shell

AREA CALCULATION

t

b1

mm 10.2096

t

int

+c.a.

,nozzle

t

b3

mm 11.54

from table +c.a.

,nozzle

t

b2

mm 4.54

t

ext

+c.a.

,nozzle

min nozzle thickness(t

ug45

)

mm 10.2096

A

T mm

2

4096.41

A

R mm

2

2730.94

A

2 mm

2

625.6886

A

4

mm

2

0

same as in ug-37

2*max(0.75*d,R

n

+t+t

n)

min(2.5*t,2.5t

n

+t

e

)

limit normal to vessel wall

limit parallel to vessel wall

mm 876.6 d

1

area contributed by welds

area contributed by pad

mm

2

256

A

5

PROVIDED NOZZLE WALL THICKNESS IS SUFFICIENT

from ug-37

CALCULATION BY APPENDIX 1-7

CONDITION ON LIMIT OF REINFORCEMENT

(A

T,l

>A

R

)

LIMITS OF REINFORCEMENT

area required for reinforcement

required for reinforcement remains the same and thus we will directly use it

two third of area required

max(t

a

,.min(t

b3

,max(t

b2

,t

b1

)))

0.6666666*A

T

A

q

+A

2

+A

41

+A

42

+A

5

+A

61

+A

62

same as in ug-37

A

62

same as in ug-37

area contributed by hub

total area within limits

LIMIT OF REINFORCEMENT IS NOT SATISFIED

area contributed by bevel

mm

2

CONDITION ON STRESSES

(S

m

<S

m,allow

and S

m+b

<S

m+b,allow

)

check following condition on stresses only if nozzle I.D. is greater than 1000mm

FOR GIVEN INPUTS IT NEED NOT BE CHECKED

0

A

T,l mm

2

1989.244

0 A

61 mm

2

and 3.4 (Rt)

0.5

and and vessel I.D. is greater than 1500mm

mm

2

A

4

A

5 mm

2

0

distance between neutral axis &shell midwell

area of hub

1303.12

M

S

b kgf/cm

2

589.9798

66.48866

I

kgfcm

0.5*(X-tn')*k

2

e+t/2

P(R(R

n

+t

n

+(R

m

t)

0.5

)+R(t+(R

nm

t

n

)

0.5

))/A

s

kgf/cm

2

S

m

713.1405

198606.9

max. membrane stress

1758.6

CALCULATION OF MOMENT OF INERTIA

area of bevel

A

3 mm

2

a mm

e mm

(X-t

n

')*(k

1

+t)

A

1

t

n

*min(L

pr1

+t,max(t+t

e

+(R

nm

t

n

)

0.5

,t+t

e

+16t

n

))

area of nozzle

mm

2

1866.24

mm

2

0

combined membrane and bending stress

max bending stress

bending moment

P(R

n

3

/6 +RR

n

e)

Ma/I

S

m

+S

b

S

m+b kgf/cm

2

A

2

area of shell

t

e

*min(16t,W,(R

m

t)

0.5

)

area of reinforcing pad

R

n

+ t

n

/2

CALCULATION OF AREAS FOR BENDING STRESS

R

nm

mm 298.6

mean radius of nozzle

distance between neutral axis and shell bottom

STRESS CALCULATION

61.08866

22382297

mm

4

moment of inertia

t*max(16t,(R

m

t)

0.5

)

R

m

mm

R

eff

+ t/2

mean radius of shell

CALCULATION OF SHADED AREAS FOR MEMBRANE STRESS

2759.68

0

shaded area in fig 1-7-1 A

s mm

2

6265.172

S

m,allow kgf/cm

2

1406.14

S

m+b,allow kgf/cm

2

2109.21

1.5*Sn

allowable combined membrane and bending stress

S

n

allowable membrane stress

STRESS CONDITION IS SATISFIED

0.5*(X-t

n

')*min(L',(t+t

n

+(R

nm

t

n

)

0.5

-h))+(X-t

n

')*(t+min(t+t

e

+(R

nm

t

n

)

0.5

,h))+t

n

(t+t

e

+(R

nm

t

n)

0.5

)+ t*(R

m

t)

0.5

+ t

e

(min(16t,W)

0.5*(X-t

n

')*min(L',(t+t

n

+(R

nm

t

n

)

0.5

-h))+(X-t

n

')*(t+min(t+t

e

+(R

nm

t

n

)

0.5

,h))+t

n

(t+t

e

+(R

nm

t

n)

0.5

)+ t*(R

m

t)

0.5

+ t

e

(min(16t,W)

P Kgf/cm2 5.602

E - 1

Di mm 3500

Do mm 610

Rn mm 292.2

D mm 584.4

t mm 70

tn2 mm 16

tn mm 100

Lx3 mm 25

C mm 3.2

S Kgf/cm2 1406.14

SN Kgf/cm2 1406.14

Leg mm 16

Lx4-Lx3 mm 84

Lpr1 mm 133.0171

DO THK.

323.8 8.34

273 8.11

219.1 7.16

168.3 6.22

141.3 5.73

114.3 5.27

101.6 5.02

88.9 4.8

73 4.52

60.3 3.42

48.3 3.22

42.2 3.12

33.4 2.96

26.7 2.51

21.3 2.42

17.1 2.02

13.7 1.96

10.3 1.51

610 8.34

DESIGN CALCULATION FOR VARIBLE THICKNESS NOZZLE TO

HEMI HEAD

Page No

Doc. No. Revision

INTERNAL PRESSURE

JOINT EFFICIENCY

INSIDE DIA OF SHELL

OUTSIDE DIA OF NOZZLE

INSIDE RADIUS OF NOZZLE

INSIDE DIA OF NOZZLE

HEAD THICKNESS

NOZZLE THICKNESS

HUB THICKNESS

HUB HEIGHT

CORROSION ALLOWANCE

SHELL ALLOWBLE

NOZZLEALLOWBLE

OUTSIDE NOZZLE FILLET WELD

BEVEL HEIGHT

GIVEN PERPENDICULAR LIMIT OF REINFORCEMENT

COMPUTED MINIMUM REQUIRED THICKNESS

0.5*D*(EXP(P/(S*E))-1)+C tn2 mm 4.366434

THIS IS MINIMUM REQUIRED THICKNESS OF NOZZLE AS PER TABLE 4.5.2 .

BUT WE HAVE TO CHECK MINIMUM THICKNESS OF NOZZLE BY INTERNAL

PRESSURE & EXTERNAL PRESSURE CALCULATION ALSO

HENCE MIN REQIRED THK OF NOZZLE MAX(tnX,tnY) 11.54

THICKNESS OF NOZZLE IS ADEQUATE

THICKNESS OF NOZZLE IS NOT ADEQUATE

NOZZLE MATERIAL FACTOR

frn - 1

MIN(Sn/S,1)

(DI+2C)/t - 52.49102

Reff mm 1753.2

Fp - 0.878244

LH1 mm 147.7043

LH2 mm 133

- 1.394305

A2 cm

2

193.423

A2a cm

2

24.2

A2b cm

1

16.41785

A2C cm

2

57.67096

A2 cm

2

81.87096

A4 cm

2

1.28

At cm

2

311.7532

EFFECTIVE HUB THICKNESS

tneff mm 96.8

tn-c

EFFECTIVE NOZZLE THICKNESS

tn2eff mm 12.8

tn2-c

SHELL DIA TO THICKNESS RATIO

EFFECTIVE RADIUS OF SHELL

PARALLEL LIMIT OF REINFORCEMENT

EFFECTIVE LENGTH OF VESSEL WALL

LR mm 342

MIN(SQRT(Reff x t),2 x Rn)

PERPENDICULAR LIMIT OF REINFORCEMENT

FEA DERIVED FACTOR TO MODIFY NOZZLE LENGTH

Cn - 0.878244

MIN((t/tn)^0.35,1)

NOZZLE ATTACHMENT FACTOR

LH1 ( Fp x SQRT(Rn,tn) )

LH2 (Equal to Lpr1)

EFFECTIVE NOZZLE WALL LENGTH OUTSIDE THE VESSEL

LH mm 199.8171

MIN(LH1,LH2) + t

NON LINERATITY PARAMETER

AREA CALCULATION

AREA PROVIDED BY VESSEL WALL

A1 cm2 228.6022 t x LR x max(/5^0.85),1)

A2 (IF PERPENDICULAR LIMIT IF LESS THAN HUB HEIGHT)

A2a ( REINFORCEMENT BY HUB)

A2b ( REINFORCEMENT BY BEVEL)

A2c ( REINFORCEMENT BY BEVEL+ NOZZLE WALL)

TOTAL AREA PROVIDED BY NOZZLE

AREA PROVIDE BY NOZZLE-SHELL FILLET WELD

TOTAL AREA

AREA REINFORCEMENT & MAWP CALCULATION

NOZZLE RADIUS FOR FORCE CALCULATION

Rxn mm 338.2848

tn/ In(1+tn/Rn)

PL Kgf/cm2 184.1059

Sallow Kgf/cm2 2109.21

SHELL RADIUS FOR FORCE CALCULATION

Rxs mm 1786.338

teff/ In(1+teff/Reff)

ALLOWABLE LOCAL PRIMARY MEMBRANE STRESS

Sallow Kgf/cm2 2109.21

1.5 x S x E

FORCE ACTING ON THE NOZZLE

fn kgf 3786.677

P x Rxn x LH

FORCE ACTING ON THE SHELL

fs kgf 21966.45

P x Rxs (LR + tn)

DISCONTINUITY FORCE FROM INTERNAL PRESSURE

fy kgf 14620.32

P x Rxs x Rnc/2

AREA RESISTING INTERNAL PRESSURE

Ap cm2 7206.971

( fs + fy + fn )/ P

MAXIMUM ALLOWABLE WORKING PRESSURE CANDIDATE 1

Pmax1 Kgf/cm2 64.17933

Sallow/ ( 2 x Ap/At - Rxs/2 X teff )

MAXIMUM ALLOWABLE WORKING PRESSURE CANDIDATE 1

Pmax1 Kgf/cm2 105.165

2 X S/ (t / Rxs)

MAXIMUM ALLOWABLE WORKING PRESSURE CANDIDATE

Pmax1 Kgf/cm2 64.17933

MIN(Pmax1,Pmax2)

NOZZLE PASS

STRESS CALCULATION

AVERAGE PRIMARY MEMBRANE STRESS

avg Kgf/cm2 129.5045

( fs + fy + fn )/ At

GENERAL PRIMARY MEMBRANE STRESS

circ Kgf/cm2 74.90319

P x Rxs / (2 X teff)

LOCAL PRIMARY MEMBRANE STRESS

PL Kgf/cm2 184.1059

MAX(2 x avg -circ , circ)

SUMMARY OS STRESS RESULT

LOCAL PRIMARY MEMBRANE STRESS

ALLOWED LOCAL PRIMARY MEMBRANE STRESS

STRESSES ARE UNDER PERMISIBLE LIMIT

STRENGTH OF NOZZLE ATTACHMENT WELDS

DICONTINUITY FORCE FACTOR

Ky - 1.33128

(Rn+tn) / Rnc

WELD LENGTH OF NOZZLE

L

- 610.73

- mm 11.3136

L

- 610.73

/2 x (Rn/tn)

Kgf/cm2 0.698533

WELD THROAT DIMENSION

WELD LOAD VALUE

fwelds kgf

DATE

WELD STRENGTH IS OK

PREPARED BY

VERIFIED BY

19463.74

MIN(fy x ky , 1.5 x Sn x A2) , x P x Rn^2 x ky^2)

WELD STRESS VALUE

1.060904 8275.052

0.087287

You might also like

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Sample Design Calculation - Vessel Supported On LugsDocument4 pagesSample Design Calculation - Vessel Supported On LugsAbhay Upadhyay0% (1)

- Jump Start Aspen Custom Modeler V8 PDFDocument26 pagesJump Start Aspen Custom Modeler V8 PDFAlessandro TrigilioNo ratings yet

- Rectangular Tank Design ExelDocument43 pagesRectangular Tank Design ExelNguyễn Quốc PhượngNo ratings yet

- Design of Tooth Locked Quick Open Die Pressure VesselDocument4 pagesDesign of Tooth Locked Quick Open Die Pressure VesselSEP-PublisherNo ratings yet

- Pd5500 Flange CalculationDocument6 pagesPd5500 Flange CalculationMakrand SakpalNo ratings yet

- MD He Tema Asme v0.1Document31 pagesMD He Tema Asme v0.1Sharon Lambert100% (1)

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amar100% (1)

- Pressure Vessel THCK CalcDocument8 pagesPressure Vessel THCK Calcmkchy12100% (1)

- C506 E075SONIALVISION G4 BrochureDocument9 pagesC506 E075SONIALVISION G4 Brochuremikaela05No ratings yet

- Final Year ThesisDocument70 pagesFinal Year ThesisEngr Raja Rashid Ali100% (1)

- New - Reinforcement of NozzleDocument24 pagesNew - Reinforcement of NozzleVaniya GoelNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleNithin ZsNo ratings yet

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaNo ratings yet

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocument25 pagesPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNo ratings yet

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindeNo ratings yet

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- TEMA Shell Bundle Entrance and Exit AreasDocument3 pagesTEMA Shell Bundle Entrance and Exit AreasArunkumar MyakalaNo ratings yet

- Mechanical Design of ColumnDocument12 pagesMechanical Design of ColumnfarahanisiliasNo ratings yet

- Welding Calculation ModulDocument5 pagesWelding Calculation ModulricardoNo ratings yet

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhobleNo ratings yet

- 7-12-0024 Rev 7Document1 page7-12-0024 Rev 7cynideNo ratings yet

- Reinf S1Document2 pagesReinf S1tasingenieriaNo ratings yet

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianNo ratings yet

- Saddle CalculationDocument10 pagesSaddle Calculationpharis_chrisNo ratings yet

- Cone To Shell ReinforcementDocument4 pagesCone To Shell ReinforcementSajal KulshresthaNo ratings yet

- Check 18Document6 pagesCheck 18Anonymous qBwHKusNo ratings yet

- Lug SupportDocument2 pagesLug SupportSachin5586No ratings yet

- PV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Document32 pagesPV Elite 2015 Sp1 Licensee: SPLM Licensed User Filename: Untitled Nozzle Calcs.: N1 Nozl: 3 9:36am Dec 7,2018Priyo Jati WahyonoNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Area Reinforcement CalculatorDocument5 pagesArea Reinforcement CalculatorAnonymous Iev5ggSR100% (1)

- Nozzle Calcs Rev ADocument6 pagesNozzle Calcs Rev AbolivarNo ratings yet

- Ferrofab Fze: Collar Bolt Sizing CalculationDocument2 pagesFerrofab Fze: Collar Bolt Sizing CalculationMohammad Zahid50% (2)

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- Calc Asme Viii Div-1 2007 Ed - Rev1Document32 pagesCalc Asme Viii Div-1 2007 Ed - Rev1AndiWSutomoNo ratings yet

- Nozzle 1Document25 pagesNozzle 1Sasikumar JothiNo ratings yet

- Nozzle & FlangeDocument14 pagesNozzle & FlangeRaghNo ratings yet

- Design Calculation Anchor Flange - ASME VIII Div 1Document6 pagesDesign Calculation Anchor Flange - ASME VIII Div 1Johakim974No ratings yet

- Sample FLG CalcDocument6 pagesSample FLG CalcameyyammaiNo ratings yet

- Rectangular Tank (With Horizontal Stiffner)Document5 pagesRectangular Tank (With Horizontal Stiffner)DURGAIRAJ100% (1)

- Vessel Allowable LoadingsDocument50 pagesVessel Allowable LoadingsfahadfiazNo ratings yet

- Design Calculations For Pressure VesselsDocument54 pagesDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozNo ratings yet

- Wind Seismic Calculation DataDocument8 pagesWind Seismic Calculation Dataaknauriyal2013No ratings yet

- Pressure Vessel Design CalculationsDocument2 pagesPressure Vessel Design CalculationsMohan VarkeyNo ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Nozzle ReinforcementDocument8 pagesNozzle ReinforcementHafizi HZnumismatic0% (1)

- Section VIII CalDocument22 pagesSection VIII CalthodathersNo ratings yet

- Superheated Steam Condensate TankDocument4 pagesSuperheated Steam Condensate TankGanesh BhardwajNo ratings yet

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of Nozzlehardik5818No ratings yet

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Document34 pagesShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNo ratings yet

- 6 Inch NB Nozzle Calculation Appendex 1-7Document11 pages6 Inch NB Nozzle Calculation Appendex 1-7SACHIN PATELNo ratings yet

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Document7 pagesSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNo ratings yet

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadNo ratings yet

- 3 Inch NB Nozzle Calculation Appendex 1-10Document6 pages3 Inch NB Nozzle Calculation Appendex 1-10SACHIN PATELNo ratings yet

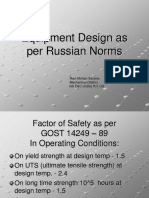

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocument24 pagesPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleAboMuhmadSr.No ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczNo ratings yet

- Retaining Wall DesignDocument168 pagesRetaining Wall DesignSuraj Muley0% (1)

- Thickness Calculation of Pressure Vessel ShellDocument17 pagesThickness Calculation of Pressure Vessel ShellVishnuGK100% (1)

- A Study On The Relationships Between Different Presentation Modes of Graphical Icons and Users' AttentionDocument11 pagesA Study On The Relationships Between Different Presentation Modes of Graphical Icons and Users' AttentionzonenorNo ratings yet

- BioFlex Guide 10Document7 pagesBioFlex Guide 10Riccardo MantelliNo ratings yet

- Terms & Conditions - Redone App: Page 1 of 2Document2 pagesTerms & Conditions - Redone App: Page 1 of 2Ong ZhangNo ratings yet

- Guidelines For Managing ProjectsDocument48 pagesGuidelines For Managing Projectsfifit mirowati100% (1)

- Lwha Sales EngDocument2 pagesLwha Sales EngWanandi HasanNo ratings yet

- Alphatron 161-Gyro AM AlphaMidiCourse InstOper Manual 27-3-2019 PDFDocument82 pagesAlphatron 161-Gyro AM AlphaMidiCourse InstOper Manual 27-3-2019 PDFVishal AnandNo ratings yet

- MS - Cement Plastering R1Document14 pagesMS - Cement Plastering R1Dinesh PriyankaraNo ratings yet

- Meter Reading Application For Android Based Handheld Device-IJAERDV04I0147592Document6 pagesMeter Reading Application For Android Based Handheld Device-IJAERDV04I0147592Editor IJAERDNo ratings yet

- ResortDocument12 pagesResortSheela.omsai GupthaNo ratings yet

- Catalogo U2900 PDFDocument7 pagesCatalogo U2900 PDFdernivaljrNo ratings yet

- Experiment 3 Series Resonance PDFDocument11 pagesExperiment 3 Series Resonance PDFSimon Christopher CerdeñaNo ratings yet

- CNC Turning CenterDocument41 pagesCNC Turning CenterHammad NaeemNo ratings yet

- Demand Management Forecasting ParametersDocument11 pagesDemand Management Forecasting Parametersolu2014No ratings yet

- 345C Specalog APD (AEHQ5622) PDFDocument32 pages345C Specalog APD (AEHQ5622) PDFsuwarjitechnic100% (1)

- Permastic Vinyl Acrylic EmulsionDocument1 pagePermastic Vinyl Acrylic EmulsionCynthia MillerNo ratings yet

- Card UI Architecture Design Deck PDFDocument121 pagesCard UI Architecture Design Deck PDFRezki BangsawanNo ratings yet

- Roles and Authorizations in SAP E-Recruiting: ContentsDocument17 pagesRoles and Authorizations in SAP E-Recruiting: ContentsvanessamacNo ratings yet

- Installation V 24 Ipasolink 400 PDFDocument98 pagesInstallation V 24 Ipasolink 400 PDFAaron HongreiNo ratings yet

- Check List For Power TransformerDocument7 pagesCheck List For Power Transformermatthew_7No ratings yet

- Gas Interference Sucker Rod PumpsDocument9 pagesGas Interference Sucker Rod PumpspohanisirNo ratings yet

- Brochure All New TeriosDocument2 pagesBrochure All New Teriosdonyk1133No ratings yet

- Catalogo AvinetDocument20 pagesCatalogo AvinetJCNo ratings yet

- CCCCCCCCCCCCCCCCCCCCCCCCCCCCC C C C CC C C CDocument13 pagesCCCCCCCCCCCCCCCCCCCCCCCCCCCCC C C C CC C C CHarsha BondNo ratings yet

- Power Distribution and UtilizationDocument2 pagesPower Distribution and UtilizationZoya DurraniNo ratings yet

- Screw Conveyor Drives: Gearmotor Speed ReducerDocument6 pagesScrew Conveyor Drives: Gearmotor Speed ReducerYavuz SolmazNo ratings yet

- Ap001 Motor DatasheetDocument1 pageAp001 Motor DatasheetShubham Kumar VermaNo ratings yet

- Reaction Paper On Mobile DevicesDocument3 pagesReaction Paper On Mobile DevicesUriel Maglines100% (2)