Professional Documents

Culture Documents

AISC 13.0 Properties Viewer

AISC 13.0 Properties Viewer

Uploaded by

Luis ChipanaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISC 13.0 Properties Viewer

AISC 13.0 Properties Viewer

Uploaded by

Luis ChipanaCopyright:

Available Formats

AISC 13th EDITION MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single Angles Double Angles Rectangular HSS

Y Y Y Y Y Y

k1=0.625

k tf=0.36 tf=0.413 b=3.5 t(des)=0.349

bf=8.28 t=0.375

y(bar)=0.936 x(bar)=0.854

x(bar)=0.586 tf=0.935 d=5 t=0.375 X

d=10.2 T X d=9 X X d=5 h=8 X

d=4.5 X y(bar)=1.6

tw=0.24 tw=0.285 tw=0.57 b=3.5 y(bar)=1.6

(0, 3/8, or 3/4

bf=5.75 bf=2.49 gap) b=6

W10X22 C9X15 WT4X33.5 L5X3-1/2X3/8 2L5X3-1/2X3/8LLBB HSS8X6X3/8

A = 6.49 in.^2 A = 4.41 in.^2 A = 9.84 in.^2 A = 3.05 in.^2 A = 6.1 in.^2 A = 8.97 in.^2

d = 10.2 in. d = 9 in. d = 4.500 in. d = 5 in. d = 5 in. h = 8 in.

tw = 0.24 in. tw = 0.285 in. tw = 0.570 in. b = 3.5 in. b = 3.5 in. b = 6 in.

bf = 5.75 in. bf = 2.49 in. bf = 8.280 in. t = 0.375 in. t = 0.375 in. t(des) = 0.349 in.

tf = 0.36 in. tf = 0.413 in. tf = 0.935 in. k = 0.8125 in. wt./ft. = 20.8 plf. wt./ft. = 32.51 plf.

k(des) = 0.66 in. k = 1 in. k(des) = 1.3300 in. wt./ft. = 10.40 plf. Ix = 15.5 in.^4 Ix = 79.1 in.^4

k(det) = 0.9375 in. T = 7 in. k(det) = 1.6250 in. eo = 0.31 in. Sx = 4.56 in.^3 Sx = 19.8 in.^3

k1 = 0.625 in. gage = 1.375 in. gage = 5.5 in. Ix = 7.75 in.^4 rx = 1.59 in. rx = 2.97 in.

T = 8.25 in. rts = 0.824 in. wt./ft. 33.50 plf. Sx = 2.28 in.^3 y(bar) = 1.6 in. Zx = 24.1 in.^3

gage = 2.75 in. ho = 8.59 in. bf/(2*tf) 4.430 rx = 1.590 in. Zx = 8.18 in.^3 Iy = 50.6 in.^4

wt./ft. = 22 plf. wt./ft. = 15 plf. d/tw 7.890 y(bar) = 1.600 in. yp = 0.93 in. Sy = 16.9 in.^3

bf/(2*tf) 7.99 eo = 0.681 in. Ix = 10.90 in.^4 Zx = 4.090 in.^3 ry(0) = 1.33 in. ry = 2.38 in.

h/tw = 36.9 Ix = 51 in.^4 Sx = 3.05 in.^3 yp = 0.933 in. ry(3/8) = 1.46 in. Zy = 19.8 in.^3

Ix = 118 in.^4 Sx = 11.3 in.^3 rx = 1.05 in. Iy = 3.15 in.^4 ry(3/4) = 1.59 in. h(flat) = 6.3125 in.

Sx = 23.2 in.^3 rx = 3.4 in. y(bar) = 0.936 in. Sy = 1.19 in.^3 Qs(0) = 2.51 b(flat) = 4.3125 in.

rx = 4.27 in. Zx = 13.6 in.^3 Zx = 6.29 in.^3 ry = 1.020 in. Qs = 2.58 J = 100 in.^4

Zx = 26 in.^3 Iy = 1.91 in.^4 yp = 0.594 in. x(bar) = 0.854 in. ro(bar)(0) = 2.66 in. C = 30 in.^3

Iy = 11.4 in.^4 Sy = 1.01 in.^3 Iy = 44.30 in.^4 Zy = 2.120 in.^3 H(0) = 0.683 A(surf) = 2.23 ft^2/ft

Sy = 3.97 in.^3 ry = 0.659 in. Sy = 10.70 in.^3 xp = 0.305 in. ro(bar)(3/8) = 0.7 in.

ry = 1.33 in. x(bar) = 0.586 in. ry = 2.12 in. Iz = 1.74 in.^4 H(3/8) = 0.718 Round HSS & Pipes

Zy = 6.1 in.^3 Zy = 2.04 in.^3 Zy = 16.30 in.^3 Sz = 0.67 in.^3 ro(3/4) = 1 in. Y

rts = 1.55 in. xp = 0.245 in. Qs(50) = 1.000 rz = 0.755 in. H(3/4) = 0.983 t(nom)=0.322

ho = 9.81 in. J = 0.208 in.^4 J = 2.51 in.^4 TAN(a) = 0.485

J = 0.239 in.^4 Cw = 31 in.^6 Cw = 3.56 in.^6 Qs(36) = 0.983

Cw = 275 in.^6 a = 19.64 in. a = 1.92 in. J = 0.15 in.^4 Plates O.D.=8.625 X

a = 54.58 in. ro(bar) = 3.69 in. ro(bar) = 2.41 in. Cw = 0.217 in.^6 Y

Wno = 14.1 in.^2 H = 0.882 H = 0.962 a = 1.94 in. t=0.375 I.D.=7.981

Sw = 7.32 in.^4 ro(bar) = 2.45 in. X

Qf = 4.88 in.^3 H = 0.000 b=12 Pipe8STD

Qw = 12.9 in.^3 A = 7.85 in.^2

t = 0.375 in. O.D. = 8.625 in.

b = 12 in. I.D. = 7.981 in.

wt./ft. = 15.31 plf. t(nom) = 0.322 in.

A = 4.500 in.^2 t(des) = 0.3 in.

Ix = 0.053 in.^4 wt./ft. = 28.60 plf.

Sx = 0.281 in.^3 Ix = Iy = 68.1 in.^4

rx = 0.108 in. Sx = Sy = 15.8 in.^3

Iy = 54.000 in.^4 rx = ry = 2.95 in.

Sy = 9.000 in.^3 Zx = Zy = 20.8 in.^3

ry = 3.464 in. J = 136 in.^4

J = 54.053 in.^4 C = --- in.^3

Reference:

The shapes contained in this database are taken from the AISC Version 13.0

"Shapes Database" CD-ROM Version (12/2005), as well as those listed in the

AISC 13th Edition Manual of Steel Construction (12/2005).

NOMENCLATURE FOR AISC VERSION 13.0 MEMBER PROPERTIES AND DIMENSIONS:

A = Cross-sectional area of member (in.^2)

d = Depth of member, parallel to Y-axis (in.)

h = Depth of member, parallel to Y-axis (in.)

tw = Thickness of web of member (in.)

bf = Width of flange of member, parallel to X-axis (in.)

b = Width of member, parallel to X-axis (in.)

tf = Thickness of flange of member (in.)

k = Distance from outer face of flange to web toe of fillet (in.)

k1 = Distance from web centerline to flange toe of fillet (in.)

T = Distance between fillets for wide-flange or channel shape = d(nom)-2*k(det) (in.)

gage = Standard gage (bolt spacing) for member (in.) (Note: gages for angles are available by viewing comment box at cell K18.)

Ix = Moment of inertia of member taken about X-axis (in.^4)

Sx = Elastic section modulus of member taken about X-axis (in.^3)

rx = Radius of gyration of member taken about X-axis (in.) = SQRT(Ix/A)

Iy = Moment of inertia of member taken about Y-axis (in.^4)

Sy = Elastic section modulus of member taken about Y-axis (in.^3)

ry = Radius of gyration of member taken about Y-axis (in.) = SQRT(Iy/A)

Zx = Plastic section modulus of member taken about X-axis (in.^3)

Zy = Plastic section modulus of member taken about Y-axis (in.^3)

rts = SQRT(SQRT(Iy*Cw)/Sx) (in.)

xp = horizontal distance from designated member edge to plastic neutral axis (in.)

yp = vertical distance from designated member edge to plastic neutral axis (in.)

ho = Distance between centroid of flanges, d-tf (in.)

J = Torsional moment of inertia of member (in.^4)

Cw = Warping constant (in.^6)

C = Torsional constant for HSS shapes (in.^3)

a = Torsional property, a = SQRT(E*Cw/G*J) (in.)

E = Modulus of elasticity of steel = 29,000 ksi

G = Shear modulus of elasticity of steel = 11,200 ksi

Wno = Normalized warping function at a point at the flange edge (in.^2)

Sw = Warping statical moment at a point on the cross section (in.^4)

Qf = Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Qw = Statical moment at the mid-depth of the section (in.^3)

x(bar) = Distance from outside face of web of channel shape or outside face of angle leg to Y-axis (in.)

y(bar) = Distance from outside face of outside face of flange of WT or angle leg to Y-axis (in.)

eo = Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) tf*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

xo = x-coordinate of shear center with respect to the centroid of the section (in.)

yo = y-coordinate of shear center with respect to the centroid of the section (in.)

ro(bar) = Polar radius of gyration about the shear center = SQRT(xo^2+yo^2+(Ix+Iy)/A) (in.)

H = Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

LLBB = Long legs back-to-back for double angles

SLBB = Short legs back-to-back for double angles

h(flat) = The workable flat (straight) dimension along the height, h (in.)

b(flat) = The workable flat (straight) dimension along the width, b (in.)

A(surf) = The total surface area of a rectangular or square HSS section (ft.^2/ft.)

STD = Standard weight (Schedule 40) pipe section

XS = Extra strong (Schedule 80) pipe section

XXS = Double-extra strong pipe section

W24X94

W24X84

W24X76

W24X68

W24X62

W24X55

W21X201

W21X182

You might also like

- VLF Radio Engineering: International Series of Monographs in Electromagnetic WavesFrom EverandVLF Radio Engineering: International Series of Monographs in Electromagnetic WavesNo ratings yet

- AISC 13th Edition Member Dimensions and Properties Viewer (2005) .Document2 pagesAISC 13th Edition Member Dimensions and Properties Viewer (2005) .Jalal Naser FaqiryarNo ratings yet

- Pressure Vessel and Stacks Field Repair ManualFrom EverandPressure Vessel and Stacks Field Repair ManualRating: 4 out of 5 stars4/5 (4)

- Timber and Steel DesignDocument24 pagesTimber and Steel DesignAtt SakdaNo ratings yet

- Analytic Geometry: Graphic Solutions Using Matlab LanguageFrom EverandAnalytic Geometry: Graphic Solutions Using Matlab LanguageNo ratings yet

- Differential Forms on Electromagnetic NetworksFrom EverandDifferential Forms on Electromagnetic NetworksRating: 4 out of 5 stars4/5 (1)

- Aisc Member Dimensions and Properties ViewerDocument3 pagesAisc Member Dimensions and Properties Viewer3ces0% (1)

- Aisc Tabla PerfilesDocument2 pagesAisc Tabla PerfilesRiky Ayala63% (8)

- Circ BaseDocument8 pagesCirc BaseMario Sajulga Dela Cuadra100% (1)

- CALCULOSDocument227 pagesCALCULOSLuisHuamanQuilicheNo ratings yet

- AISC Properties ViewerDocument6 pagesAISC Properties ViewerEriksson GillmarNo ratings yet

- Lite-Deck Book WebDocument23 pagesLite-Deck Book WebFlorencio SandovalNo ratings yet

- Workbook to Accompany Physics for Students of Science and EngineeringFrom EverandWorkbook to Accompany Physics for Students of Science and EngineeringNo ratings yet

- AISC Properties MMDocument31 pagesAISC Properties MMManuel JuanNo ratings yet

- Aisc 13-0 Properties ViewerDocument4 pagesAisc 13-0 Properties ViewerErnesto RQNo ratings yet

- AISC 13.0 Properties ViewerDocument18 pagesAISC 13.0 Properties ViewerramilianNo ratings yet

- Propiedades de Perfiles de Acero EstructuralDocument5 pagesPropiedades de Perfiles de Acero EstructuralmandomendoNo ratings yet

- AISC 13.0 Properties ViewerDocument2 pagesAISC 13.0 Properties ViewerHenri Johonel Mejia VilchezNo ratings yet

- Aceros - AISCDocument4 pagesAceros - AISCFreddy Gallo SanchezNo ratings yet

- Aisc 13.0 Properties RodrigoDocument21 pagesAisc 13.0 Properties RodrigoJavier Alejandro AñazgoNo ratings yet

- Aisc 13.0 Properties RodrigoDocument25 pagesAisc 13.0 Properties RodrigoJosé Carlos TorrezNo ratings yet

- AISC Properties ViewerDocument2 pagesAISC Properties ViewerHaris LeeNo ratings yet

- AISC 14.1 Properties ViewerDocument2 pagesAISC 14.1 Properties ViewerJay GalvanNo ratings yet

- AISC 14.1 Properties ViewerDocument2 pagesAISC 14.1 Properties ViewerDivina Teja Rebanal-Glino0% (1)

- AISC 13.0 Properties ViewerDocument12 pagesAISC 13.0 Properties ViewerRam ValNo ratings yet

- PERFILES Programa para Flexion y CorteDocument16 pagesPERFILES Programa para Flexion y CortePaolo Ordoñez SangaNo ratings yet

- Borrador A MomentoDocument16 pagesBorrador A MomentoDaniel Peña FarfanNo ratings yet

- Diseño de Vigas A FlexionDocument12 pagesDiseño de Vigas A FlexionDaniel Peña FarfanNo ratings yet

- Aisc Member Dimensions and Properties ViewerDocument4 pagesAisc Member Dimensions and Properties ViewercoolkaisyNo ratings yet

- AISC Properties ViewerDocument4 pagesAISC Properties ViewerJorge Luis Borghes CepedaNo ratings yet

- AISC SectionsDocument3 pagesAISC SectionsraymondNo ratings yet

- Aisc Edition Member Dimensions and Properties ViewerDocument2 pagesAisc Edition Member Dimensions and Properties ViewerRoberto CatalaniNo ratings yet

- AISC Properties ViewerDocument4 pagesAISC Properties ViewerMáryuri CriadoNo ratings yet

- AISC Properties ViewerDocument2 pagesAISC Properties ViewerLivian TeddyNo ratings yet

- AISC (MM) PropertiesDocument7 pagesAISC (MM) PropertiesasrhaelNo ratings yet

- Aisc Properties Viewer Perfiles Estruct UsaDocument30 pagesAisc Properties Viewer Perfiles Estruct Usacristhian mayoNo ratings yet

- AISC 13.0 Properties ViewerDocument3 pagesAISC 13.0 Properties ViewerMilton ItaloNo ratings yet

- AISC (MM) PropertiesDocument3 pagesAISC (MM) PropertiesEbert Joel Paico AmayaNo ratings yet

- AISC Propiedades y Pesos TOTALDocument41 pagesAISC Propiedades y Pesos TOTALRicardo BermudezNo ratings yet

- AISC Propiedades y Pesos v14 - TOTALDocument77 pagesAISC Propiedades y Pesos v14 - TOTALAlex RiosNo ratings yet

- Aisc Shape W M S and HP Metric SeriesDocument26 pagesAisc Shape W M S and HP Metric SeriesJustine MagnayeNo ratings yet

- "Endplmc9" - End Plate Moment Connections: Program DescriptionDocument21 pages"Endplmc9" - End Plate Moment Connections: Program DescriptionMartin Cristobal CupitayNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationFrom EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNo ratings yet

- Ten-Decimal Tables of the Logarithms of Complex Numbers and for the Transformation from Cartesian to Polar Coordinates: Volume 33 in Mathematical Tables SeriesFrom EverandTen-Decimal Tables of the Logarithms of Complex Numbers and for the Transformation from Cartesian to Polar Coordinates: Volume 33 in Mathematical Tables SeriesNo ratings yet

- The Plasma Dispersion Function: The Hilbert Transform of the GaussianFrom EverandThe Plasma Dispersion Function: The Hilbert Transform of the GaussianRating: 5 out of 5 stars5/5 (1)

- Electricity in Fish Research and Management: Theory and PracticeFrom EverandElectricity in Fish Research and Management: Theory and PracticeNo ratings yet

- GAD PA-22063 (REV2) NS1# (2022.12.19) 1350-Model HOSPITAL DE CHEPO FOSODocument4 pagesGAD PA-22063 (REV2) NS1# (2022.12.19) 1350-Model HOSPITAL DE CHEPO FOSOFlorencio SandovalNo ratings yet

- ProtaStructure Release Notes - v2022 - 6.0.431Document19 pagesProtaStructure Release Notes - v2022 - 6.0.431Florencio SandovalNo ratings yet

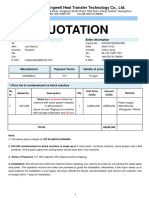

- Quotation: Guangzhou Kingwell Heat Transfer Technology Co., LTDDocument11 pagesQuotation: Guangzhou Kingwell Heat Transfer Technology Co., LTDFlorencio SandovalNo ratings yet

- Key Plan: Model 'B' SupplementDocument4 pagesKey Plan: Model 'B' SupplementFlorencio SandovalNo ratings yet

![Mathematical Tables: Tables of in G [z] for Complex Argument](https://imgv2-2-f.scribdassets.com/img/word_document/282615796/149x198/febb728e8d/1714993295?v=1)