Professional Documents

Culture Documents

Gas Turbine History and Cycle Tutorial

Uploaded by

Hariharan HariOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Turbine History and Cycle Tutorial

Uploaded by

Hariharan HariCopyright:

Available Formats

GAS TURBINE

HISTORY

The earliest example of jet propulsion can be

traced as far back as 150 B.C.to an Egyptian

named Hero. Hero invented a toy that

rotated on top of a boiling pot due to the

reaction effect of hot air or steam exiting

several nozzles arranged radially around a

wheel. He called his invention anaeolipil.

General Turbine Characteristics

Useful work or propulsive thrust can

be obtained from a gas turbine engine.

It may drive a generator, pump, or

propeller or, in the case of a pure jet

aircraft engine, develop thrust by

accelerating the turbine exhaust flow

through a nozzle.

PRO & CONS

Large amounts of power can be produced by such an engine that, for

the same output, is much smaller and lighter than a reciprocating

internal combustion engine. Reciprocating engines depend on the up

and-down motion of a piston, which must then be converted to

rotary motion by a crankshaft arrangement, whereas a gas turbine

delivers rotary shaft power directly.

Although conceptually the gas turbine engine is a simple device, the

components for an efficient unit must be carefully designed and

manufactured from costly materials because of the high

temperatures and stresses encountered during operation. Thus, gas

turbine engine installations are usually limited to large units where

they become cost effectiv

Basic Gas Turbine Cycle

gas turbine operates by doing the

following:

1. Continuously drawing in fresh air.

2. Compressing the air to a higher pressure.

3. Adding and burning fuel in the

compressed air to increase its energy.

4. Directing the high-pressure, high-

temperature air to an expansion turbine

that converts the gas energy to mechanical

energy of a rotating shaft. The resulting

low-pressure, lower temperature gases are

discharged to atmosphere.

BRAYTON CYCLE

The Joule-Brayton (JB) constant pressure closed cycle is the basis

of the cyclic gas turbine power plant

with steady flow of air (or gas) through a compressor, heater, turbine,

cooler within a closed circuit.

Cont.

The turbine drives the

compressor and a generator

delivering the electrical power,

heat is supplied at a constant

pressure and is also rejected at

constant pressure.

CONTI.

Major Turbine Components

Air inlet system

Compressor

Combustion section

Turbine

Exhaust system

Support systems

Base and supports

METHOD FOR IMPROVE EFFICIENCY

REHEAT

REGENERATOR

INTERCOOLING

EFFICIENY & PRESSURE RATION RELATION

Gas Turbine Cycle with Reheat

A common method of increasing the

mean temperature of heat reception is to

reheat the gas after it has expanded in a

part of the gas turbine. By doing so the

mean temperature of heat rejection is

also increased, resulting in a decrease in

the thermal efficiency of the plant.

However , the specific output of the plant

increases due to reheat

Gas Turbine Cycle with Inter-cooling

The cooling of air between two

stages of compression is known

as intercooling. This reduces the

work of compression and

increases the specific output of

the plant with a decrease in the

thermal efficiency. The loss in

efficiency due to intercooling can

be remedied by employing

exhaust heat exchange as in the

reheat cycle.

Simple Cycle with Exhaust Heat

Exchange(Regenerative cycle)

TUTORIAL

TUTORIAL

The earliest example of jet propulsion can be

traced as far back as 150 B.C.to an Egyptian

named Hero. Hero invented a toy that

rotated on top of a boiling pot due to the

reaction effect of hot air or steam exiting

several nozzles arranged radially around a

wheel. He called his invention anaeolipil.

PROBLEM

A gas turbine is supplied with gas at 5 bar

and 1000 K and expands it adiabatically to 1

bar. The mean specific heat at constant

pressure and constant volume are1.0425

kJ/kg K and 0.7662 kJ/kg K respectively.

(i) Draw the temperature-entropy diagram to

represent the processes of the simple gas

turbine system.

(ii) Calculate the power developed in kW per

kg of gas per second and the exhaust gas

temperature.

Q.2

Find the required air-fuel ratio in a gas turbine whose turbine and

compressor efficiencies are 85% and 80%, respectively. Maximum cycle

temperature is 875C. The working fluid can be taken as air (cp = 1.0

kJ/kg K, = 1.4) which enters the compressor at 1 bar and 27C. The

pressure ratio is 4. The fuel used has calorific value of 42000 kJ/kg. There

is a loss of 10% of calorific value in the combustion chamber.

Q.3

In a simple gas turbine plant air enters the compressor at 1 bar and

27c and leaves at 6 bar.it is then heated in the combustion chamber

to 700c and then enters the turbine and expands to 1 bar.

c

and

T

are 0.80 and 0.85 res. And the combustion efficiency is 0.98. the fall

in pressure through c.c. is 0.1 bar.

(i) thermal efficiency

(ii) work ratio

(iii) air rate

(iv) specific fuel consumption

(v) air fuel ratio

You might also like

- GAS TURBINE ENGINES6/115oC1200oCDocument7 pagesGAS TURBINE ENGINES6/115oC1200oCVishal ReddyNo ratings yet

- Thermal Power StationsDocument83 pagesThermal Power StationschdiNo ratings yet

- Chapter 8B - Gas Power Plant Brayton CycleDocument17 pagesChapter 8B - Gas Power Plant Brayton CycleBF3nobel100% (1)

- Chapter 8 Van NessDocument76 pagesChapter 8 Van NessConrad MonterolaNo ratings yet

- CHAPTER 1 STEAM GENERATION (Complete Slide)Document25 pagesCHAPTER 1 STEAM GENERATION (Complete Slide)nisasoberiNo ratings yet

- Ch2 - Gas TurbinesDocument37 pagesCh2 - Gas TurbinesShaktivell Letchumanan100% (1)

- UNIT 8 ThermodynamicsDocument9 pagesUNIT 8 ThermodynamicsHimadhar SaduNo ratings yet

- Chapter Five Gas Turbine Power PlantDocument23 pagesChapter Five Gas Turbine Power PlantBese Mat100% (1)

- Power Plant Engineering 1Document15 pagesPower Plant Engineering 1Anushree GhoshNo ratings yet

- Gas TurbineDocument43 pagesGas TurbineMuhammad Qusyairi50% (2)

- Gas Turbine Power PlantDocument20 pagesGas Turbine Power Plantumar100% (1)

- Thermodynamics Lecture 6Document32 pagesThermodynamics Lecture 6MarkJude Morla100% (1)

- Gas Turbine Power Cycles ExplainedDocument57 pagesGas Turbine Power Cycles ExplainedAdib Nawawi100% (1)

- 02gas tURBINES - A PDFDocument38 pages02gas tURBINES - A PDFAdib ShaidanNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Classification of Gas Turbine Power PlantDocument7 pagesClassification of Gas Turbine Power PlantPK100% (1)

- Gas Turbine BraytonDocument14 pagesGas Turbine BraytonAnonymous 8kVClDX9gNo ratings yet

- 06 Gas Turbine Power PlantDocument31 pages06 Gas Turbine Power PlantRishav niroulaNo ratings yet

- Gas Turbine Power PlantDocument11 pagesGas Turbine Power PlantCK Godinez100% (1)

- Natural Gas EquipmentDocument26 pagesNatural Gas Equipmenthanisshi100% (1)

- Chapter 1 Steam GenerationDocument18 pagesChapter 1 Steam GenerationfaranimohamedNo ratings yet

- Thermal Engineering: Gas Turbine FundamentalsDocument22 pagesThermal Engineering: Gas Turbine FundamentalsRizuanul Arefin EmonNo ratings yet

- Gas Turbine Cycles - LectureDocument18 pagesGas Turbine Cycles - LectureSrinu Reddy100% (1)

- A Gas Turbine UnitDocument9 pagesA Gas Turbine UnitTITU NATHNo ratings yet

- Jet PropulsionDocument45 pagesJet PropulsionPranay SahuNo ratings yet

- Basic Principles of Steam Turbine1Document141 pagesBasic Principles of Steam Turbine1Durga Prasad PadhyNo ratings yet

- Gas Turbine System & PropulsionDocument35 pagesGas Turbine System & PropulsionnaveedsidhuNo ratings yet

- Open Gas Turbine Brayton Cycle SchematicDocument12 pagesOpen Gas Turbine Brayton Cycle SchematicVinoth KumarNo ratings yet

- Automotive Turbocharged Gas Turbine.Document48 pagesAutomotive Turbocharged Gas Turbine.Santanu ChakrabortyNo ratings yet

- Closed Cycle Operation:: 1. A) Sketch Proper T-S Diagram For A Two Stage Gas Turbine Power Plant With Inter CoolerDocument5 pagesClosed Cycle Operation:: 1. A) Sketch Proper T-S Diagram For A Two Stage Gas Turbine Power Plant With Inter CoolerFazil KhanNo ratings yet

- Previous Class: - Chapter 3 - Combustion Air Requirement - Combustion Triangle - Boiler Room - Ultimate AnalysisDocument40 pagesPrevious Class: - Chapter 3 - Combustion Air Requirement - Combustion Triangle - Boiler Room - Ultimate AnalysisJanaki RamanNo ratings yet

- Steam Power PlantsDocument65 pagesSteam Power PlantsVictoria CantiladoNo ratings yet

- THE BRAYTON CYCLE: THE IDEAL GAS TURBINE ENGINE CYCLEDocument15 pagesTHE BRAYTON CYCLE: THE IDEAL GAS TURBINE ENGINE CYCLEAanand Rishabh Daga100% (2)

- Brayton Cycle Reheat Regen RecollingDocument14 pagesBrayton Cycle Reheat Regen RecollingDaxit LodaliyaNo ratings yet

- Adv Therm Week 10Document16 pagesAdv Therm Week 10Tegin Berkay BudakNo ratings yet

- 6.2 Gas Turbine Power Plant: Engr. Jonathan S. RodolfoDocument23 pages6.2 Gas Turbine Power Plant: Engr. Jonathan S. RodolfoIvy Joy UbinaNo ratings yet

- Unit-I Power PlantsDocument22 pagesUnit-I Power Plantsamsk24_24No ratings yet

- GAS _TURBINE_CYCLEDocument41 pagesGAS _TURBINE_CYCLEKalpaniNo ratings yet

- Brayton CycleDocument18 pagesBrayton CycleHassan SheikhNo ratings yet

- Gas TurbineDocument23 pagesGas TurbineNur Achmad Busairi100% (1)

- Jet Propulsion Lecture Gas Turbine Cycle Components EfficiencyDocument32 pagesJet Propulsion Lecture Gas Turbine Cycle Components Efficiencyswai singhNo ratings yet

- Gas Turbine Engine Back Work RatiosDocument7 pagesGas Turbine Engine Back Work RatiosSai Bala100% (1)

- Lec - 8 PP - Combined Cycle PPDocument19 pagesLec - 8 PP - Combined Cycle PPLog XNo ratings yet

- Vapor Power Cycle Lecture2Document32 pagesVapor Power Cycle Lecture2Abdur RehmanNo ratings yet

- Vapor and Combined Power Cycles: Mehmet KanogluDocument22 pagesVapor and Combined Power Cycles: Mehmet Kanogluichig0_89No ratings yet

- Open Cycle Powe PlantDocument31 pagesOpen Cycle Powe PlantherdanandiNo ratings yet

- Chapter 10 LectureDocument22 pagesChapter 10 LectureBala MuruganNo ratings yet

- A Natural Gas Fired Duplex Stirling For Domestic RefrigeratiDocument11 pagesA Natural Gas Fired Duplex Stirling For Domestic RefrigeratiditoNo ratings yet

- Gas Power CycleDocument49 pagesGas Power CycleNafisa AnikaNo ratings yet

- ME 188 - Combined Brayton & Rankine CyclesDocument44 pagesME 188 - Combined Brayton & Rankine CyclesAzherRoiFerrer100% (1)

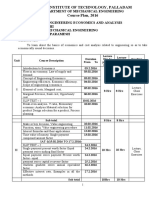

- MECHANICAL ENGINEERING DEPARTMENT DATE: 15/7/2013 COURSE CODE: MBB 42223Document11 pagesMECHANICAL ENGINEERING DEPARTMENT DATE: 15/7/2013 COURSE CODE: MBB 42223Muhammad Khuzairi33% (3)

- Producing Power from Heat: The Rankine CycleDocument55 pagesProducing Power from Heat: The Rankine CyclemjunaidNo ratings yet

- Electric CarsDocument48 pagesElectric Carsabdokhamis000No ratings yet

- Heat Engines ME111Document43 pagesHeat Engines ME111Arct John Alfante ZamoraNo ratings yet

- Introduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesDocument9 pagesIntroduction To Gas Turbine:: Land Based Gas Turbines Are of Two TypesTahir MuneebNo ratings yet

- null-3Document54 pagesnull-3mukhtarnefo97No ratings yet

- SCAD Gas Dynamics and Jet Propulsion Course PlanDocument3 pagesSCAD Gas Dynamics and Jet Propulsion Course PlanHariharan HariNo ratings yet

- Scad Institute of Technology, Palladam Course Plan, 2016: Department of Mechanical EngineeringDocument3 pagesScad Institute of Technology, Palladam Course Plan, 2016: Department of Mechanical EngineeringHariharan HariNo ratings yet

- Principal's Message from MECHXIMA '15 Symposium SouvenirDocument3 pagesPrincipal's Message from MECHXIMA '15 Symposium SouvenirHariharan HariNo ratings yet

- Messages from leaders kick off MechXima '15Document5 pagesMessages from leaders kick off MechXima '15Hariharan HariNo ratings yet

- Scad Institute of Technology, Palladam Course Plan, 2016: Department of Mechanical EngineeringDocument3 pagesScad Institute of Technology, Palladam Course Plan, 2016: Department of Mechanical EngineeringHariharan HariNo ratings yet

- 3.scad Institute of Technology, Palladam Course Plan, 2016: Department of Mechanical EngineeringDocument3 pages3.scad Institute of Technology, Palladam Course Plan, 2016: Department of Mechanical EngineeringHariharan HariNo ratings yet

- SCAD Gas Dynamics and Jet Propulsion Course PlanDocument3 pagesSCAD Gas Dynamics and Jet Propulsion Course PlanHariharan HariNo ratings yet

- Scad Institute of Technology, Palladam Course Plan, 2016: Department of Mechanical EngineeringDocument3 pagesScad Institute of Technology, Palladam Course Plan, 2016: Department of Mechanical EngineeringHariharan HariNo ratings yet

- Messages from leaders kick off MechXima '15Document5 pagesMessages from leaders kick off MechXima '15Hariharan HariNo ratings yet

- Scad Institute of Technology: Department of Mechanical EngineeringDocument2 pagesScad Institute of Technology: Department of Mechanical EngineeringHariharan HariNo ratings yet

- Principal's Message from MECHXIMA '15 Symposium SouvenirDocument3 pagesPrincipal's Message from MECHXIMA '15 Symposium SouvenirHariharan HariNo ratings yet

- Advanced I.C Engines: G.PraneshDocument168 pagesAdvanced I.C Engines: G.PraneshHariharan HariNo ratings yet

- Principal's Message from MECHXIMA '15 Symposium SouvenirDocument3 pagesPrincipal's Message from MECHXIMA '15 Symposium SouvenirHariharan HariNo ratings yet

- Scad Institute of Technology: Association Inauguration Function On 19.07.2016Document2 pagesScad Institute of Technology: Association Inauguration Function On 19.07.2016Hariharan HariNo ratings yet

- Scadinstitute of Technology: Department of Mechanical EngineeringDocument1 pageScadinstitute of Technology: Department of Mechanical EngineeringHariharan HariNo ratings yet

- Scad Institute of Technology, PalladamDocument1 pageScad Institute of Technology, PalladamHariharan HariNo ratings yet

- Img 0001Document1 pageImg 0001Hariharan HariNo ratings yet

- 9Z, R 5-H,-Q : Pts Ar'Rs Srensy HR+/,"R - ODocument1 page9Z, R 5-H,-Q : Pts Ar'Rs Srensy HR+/,"R - OHariharan HariNo ratings yet

- Carnot CyclesDocument5 pagesCarnot CyclesHariharan HariNo ratings yet

- Advanced I.C Engines: G.PraneshDocument168 pagesAdvanced I.C Engines: G.PraneshHariharan HariNo ratings yet

- Saraswathi Velu College of Engineering Department of Mechanical EngineeringDocument11 pagesSaraswathi Velu College of Engineering Department of Mechanical EngineeringHariharan HariNo ratings yet

- Img 0001Document1 pageImg 0001Hariharan HariNo ratings yet

- Gprtci: - R@ I 1. KR, 2. 3. I +Document1 pageGprtci: - R@ I 1. KR, 2. 3. I +Hariharan HariNo ratings yet

- A Collection of Mature Technologies CalledDocument1 pageA Collection of Mature Technologies CalledHariharan HariNo ratings yet

- Solar Thermal Energy (STE) Is A Form of Energy and ADocument1 pageSolar Thermal Energy (STE) Is A Form of Energy and AHariharan HariNo ratings yet

- Solar HeatingDocument1 pageSolar HeatingHariharan HariNo ratings yet

- Clausius Inequality and EntropyDocument18 pagesClausius Inequality and EntropyShoaib MughalNo ratings yet

- C - Attend ModifiedDocument2 pagesC - Attend ModifiedHariharan HariNo ratings yet

- NounDocument2 pagesNounHariharan HariNo ratings yet

- Low-Temperature Heating and Cooling: Augustin Mouchot 1878 Universal Exhibition in Paris Sahara Frank ShumanDocument2 pagesLow-Temperature Heating and Cooling: Augustin Mouchot 1878 Universal Exhibition in Paris Sahara Frank ShumanHariharan HariNo ratings yet