Professional Documents

Culture Documents

Series 60 Service Manual: From Bulletin 5-60-98 13-29d

Series 60 Service Manual: From Bulletin 5-60-98 13-29d

Uploaded by

victover0 ratings0% found this document useful (0 votes)

8 views2 pagesOriginal Title

Guidelines Water Pump 3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views2 pagesSeries 60 Service Manual: From Bulletin 5-60-98 13-29d

Series 60 Service Manual: From Bulletin 5-60-98 13-29d

Uploaded by

victoverCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

SERIES 60 SERVICE MANUAL

All information subject to change without notice.

6SE483 9610 1996 DETROIT DIESEL CORPORATION From Bulletin 5-60-98 13-29d

NOTE:

Water pump which exhibits a chemical build-up in the weep hole do not necessarily

require replacement. See Figure 13-3d. Some weeping is expected as a result of the

coolant lubrication of the seal surface.

Figure 13-3d Water Pump Showing Normal Mineral Deposits Caused By

Weeping

Replace water pump if oil is found coming from the weep hole on gear-driven

water pumps. The engine oil must then be tested for excess debris, and replaced

if not conforming to specifications.

The SCA inhalators and glycol concentration must be checked according to the

recommended maintenance schedule as described in the Detroit Diesel Service

Manual and Operators Guide for that specific engine or DDC Publication

7SE298.

13.8 DESCRIPTION OF MAINTENANCE ITEMS

All information subject to change without notice.

13-30 From Bulletin 5-60-98 6SE483 9610 1996 DETROIT DIESEL CORPORATION

13.8.4.4 Water Pump Leak Test Summary

Test water pump for leaks as follows:

1. Ensure weep hole is clear.

2. Run engine and look for coolant leaking from weep hole.

[a] Do not replace water pump due to chemical streaks.

[b] Replace the water pump if coolant is leaking or dripping.

3. Run engine and check for oil leaks from weep hole.

[a] If oil leak is observed, replace the water pump and conduct an oil analysis

per publication, 7SE390, then replace water pump as needed.

4. Test and reformulate the coolant to proper glycol and SCA concentrations per

the Service Manual Maintenance schedule as indicated in the engine operators

guide or DDC publication, 7SE298.

13.8.4.5 Test Procedure for DDEC Engines Equipped with Low Coolant

Level Sensor (CLS)

The following test procedure is for engine cooling systems that are equipped with a low coolant

sensor mounted in the top tank of the radiator. This sensor must be tested annually or every

100,000 miles (160,000 km), whichever comes first.

Do not remove the pressure control cap from the radiator or

attempt to drain the coolant until the engine has cooled.

Once the engine has cooled, use extreme caution when

removing the cap. The sudden release of pressure from a

heated cooling system can result in a loss of coolant and

possible personal injury (scalding, eye injury, etc.) from the

hot liquid.

1. Allow the engine to cool to ambient temperature.

2. Turn ignition switch on and verify no coolant level sensor codes.(DO NOT START

ENGINE.)

3. Reduce coolant level below CLS level.

4. Check stop engine light". It should illuminate within 10 seconds, indicating low coolant

level.

[a] If light illuminates, system is working properly.

[b] If light does not illuminate, refer to section 13.8.4.2.

5. Fill coolant to proper level. Refer to section 13.8.4.

You might also like

- Cummins n855 Engine Specs PDF FreeDocument6 pagesCummins n855 Engine Specs PDF Freema.powersourceNo ratings yet

- Business Proposal: Ashtang ArogyashalaDocument10 pagesBusiness Proposal: Ashtang ArogyashalaSenarathne Nandadewa100% (1)

- 3406E and C15 Marine Engines-Maintenance IntervalsDocument21 pages3406E and C15 Marine Engines-Maintenance Intervalswoulkan100% (2)

- 1ST Term J1 Agricultural Science-1Document21 pages1ST Term J1 Agricultural Science-1Peter Omovigho Dugbo100% (4)

- Arbol de Levas EspecificacionesDocument73 pagesArbol de Levas Especificacionesariel avalosNo ratings yet

- 5-650kva 60HZ en PDFDocument26 pages5-650kva 60HZ en PDFAndrésRozoNo ratings yet

- Capstone 2020Document11 pagesCapstone 2020ChadZs Arellano MutiaNo ratings yet

- Performance Boat TermsDocument6 pagesPerformance Boat TermsParamaet TamNo ratings yet

- Reliability Engineering - Prob Models and Maintenance Methods PDFDocument395 pagesReliability Engineering - Prob Models and Maintenance Methods PDFamaurybento100% (3)

- Engine JXH6DDocument2 pagesEngine JXH6Dcesar0% (1)

- Clarke Engine HP Curve Jw6h-Ufaa80 U131251Document1 pageClarke Engine HP Curve Jw6h-Ufaa80 U131251zona amrullohNo ratings yet

- Oiling System 101: To Restrict or Not To Restrict?: - From Dart Cylinder HeadsDocument7 pagesOiling System 101: To Restrict or Not To Restrict?: - From Dart Cylinder Headsm_najmanNo ratings yet

- PZH (PZ-8) Pump Parts List AF 19002011Document25 pagesPZH (PZ-8) Pump Parts List AF 19002011mantilla7No ratings yet

- Ed021084 Cummin Repair PDFDocument58 pagesEd021084 Cummin Repair PDFDoDuyBac100% (2)

- 400HP AC Drilling Motor WL250040 2Document2 pages400HP AC Drilling Motor WL250040 2HayLenLeeNo ratings yet

- Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks)Document2 pagesEngine Model Lead Time (Weeks) Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks) Engine Model Lead Time (Weeks)dinduntobzNo ratings yet

- Marine Pump Instruction ManualDocument4 pagesMarine Pump Instruction ManualSvetoslav Stoimenov100% (1)

- Cruisair Seawater PumpsDocument2 pagesCruisair Seawater PumpsorlandoNo ratings yet

- DS PF4-71TDocument2 pagesDS PF4-71TIrwin JoseNo ratings yet

- Clarkedieselengineju46h NL v2Document2 pagesClarkedieselengineju46h NL v2Fedrik GrabcarNo ratings yet

- 2300 Series ManualDocument24 pages2300 Series ManualJuprayNo ratings yet

- 13 - Basic Engine CulataDocument3 pages13 - Basic Engine CulataMARIO DEL PINO MUÑOZNo ratings yet

- J 205 J 604 Workshop ManualDocument38 pagesJ 205 J 604 Workshop ManualSan CayetanoNo ratings yet

- FM600-11-12-13-14 19 Spare Parts List PDFDocument2 pagesFM600-11-12-13-14 19 Spare Parts List PDFMario GallardoNo ratings yet

- Dong-I Datos PDFDocument8 pagesDong-I Datos PDFraulNo ratings yet

- Cumminssec7 PDFDocument28 pagesCumminssec7 PDFjosecarlosvjNo ratings yet

- Bnl20 r0058 750gpm@12bar Haseen Habib DTD 9apr20Document22 pagesBnl20 r0058 750gpm@12bar Haseen Habib DTD 9apr20Faheem MushtaqNo ratings yet

- Wichita PH D e 0616 PDFDocument92 pagesWichita PH D e 0616 PDFsahidNo ratings yet

- 6315 Crankshaft, Pulley, Flywheel, Vibration DamperDocument2 pages6315 Crankshaft, Pulley, Flywheel, Vibration DamperMOHANNo ratings yet

- 4.VGF L36GSI WKI TimingCuvre B PDFDocument1 page4.VGF L36GSI WKI TimingCuvre B PDFfoobar2016No ratings yet

- C Dodge eDocument74 pagesC Dodge eLuis RojasNo ratings yet

- Fire Pump AccessoriesDocument23 pagesFire Pump AccessoriesMuhammad ArslanNo ratings yet

- 3406C GENERATOR SET ENGINE CaterpillarDocument1 page3406C GENERATOR SET ENGINE CaterpillarAmazonas ManutençãoNo ratings yet

- QuickServe Online - (4388870) QSB5.9 CM2880 B139 Service ManualDocument7 pagesQuickServe Online - (4388870) QSB5.9 CM2880 B139 Service Manualnam phạmNo ratings yet

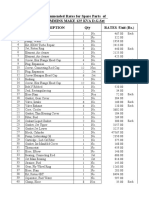

- Description: Recommended Rates For Spare Parts of Cummins Make 125 Kva D.G.Set S.L. Qty RATES /unit (RS.)Document2 pagesDescription: Recommended Rates For Spare Parts of Cummins Make 125 Kva D.G.Set S.L. Qty RATES /unit (RS.)kewalpal singhNo ratings yet

- TP 6981Document194 pagesTP 6981AzizullahNo ratings yet

- Oasis Sykes Pumps WP150-60Document2 pagesOasis Sykes Pumps WP150-60JayNo ratings yet

- AOSS AccumulatorsDocument7 pagesAOSS AccumulatorsPiero Fabrizzio Mendoza FuenteNo ratings yet

- Engine CoolingDocument7 pagesEngine CoolingpradipNo ratings yet

- KCB Gear Oil PumpDocument1 pageKCB Gear Oil PumpRahmad DesmanNo ratings yet

- TF-450 Power EndDocument2 pagesTF-450 Power EndppglNo ratings yet

- Alternator ReferenceDocument57 pagesAlternator ReferenceghazipowerNo ratings yet

- Ficha Tecnica JU6H-UF84 PDFDocument10 pagesFicha Tecnica JU6H-UF84 PDFMark XavierNo ratings yet

- 3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Piston RingDocument4 pages3516B Marine Engine S2S00001-UP (SEBP3921 - 51) - Basic Search Piston RingPhamLeDanNo ratings yet

- Catalogue Cummins 6LTAA8.9 G2Document4 pagesCatalogue Cummins 6LTAA8.9 G2akbar muslim100% (1)

- Mitsubishi Diesel Engine - S12R-PTAA2Document2 pagesMitsubishi Diesel Engine - S12R-PTAA2Anonymous yugocxnNo ratings yet

- Installation GuidelinesDocument19 pagesInstallation GuidelinesBalamurugan ArumugamNo ratings yet

- Manual Book Gold Star 140 MillerDocument24 pagesManual Book Gold Star 140 MillerAndongDalam AnDaNo ratings yet

- Omega 600S ManualDocument36 pagesOmega 600S ManualLeandroNo ratings yet

- Generac EK130 Gas Generator Engine Parts Manual 3Document41 pagesGenerac EK130 Gas Generator Engine Parts Manual 3Planejamento MegaWattNo ratings yet

- Engine Model Alternator Model LL5014J Engine Build: 1606A-E93TAG4 WU5530PDocument2 pagesEngine Model Alternator Model LL5014J Engine Build: 1606A-E93TAG4 WU5530PairtupasNo ratings yet

- Louisville Zoo Train Accident ReportDocument12 pagesLouisville Zoo Train Accident ReportCourier JournalNo ratings yet

- 'Documents - MX - Oil Anlaysis Techn For HHP Diesel Enginescummins 2 PDFDocument5 pages'Documents - MX - Oil Anlaysis Techn For HHP Diesel Enginescummins 2 PDFDavid PomaNo ratings yet

- Industrial Engine ALLDocument2 pagesIndustrial Engine ALLBalasundaramSrinivasaRajkumarNo ratings yet

- Detroit Series 60 DataDocument3 pagesDetroit Series 60 DataHocineAhmedBoumalek100% (1)

- Catalogo de Conectores Hidraulicos PARKER PDFDocument86 pagesCatalogo de Conectores Hidraulicos PARKER PDFgbobadillaNo ratings yet

- Yanmar Industrial Engine: Gaskets/Washers/O-ringsDocument1 pageYanmar Industrial Engine: Gaskets/Washers/O-ringscabdirisaaq shaqaleNo ratings yet

- Baldwin Filters EqvivalentsDocument109 pagesBaldwin Filters EqvivalentsZalvessNo ratings yet

- Silent Type 30kw Diesel Generator 480v 60hz - Buy 30kw Diesel Generator 480v 60hz, Chinese Engine Generators, Engine Generator Product On PDFDocument6 pagesSilent Type 30kw Diesel Generator 480v 60hz - Buy 30kw Diesel Generator 480v 60hz, Chinese Engine Generators, Engine Generator Product On PDFM-Aulan Niam AunimNo ratings yet

- Injectores S 60 PDFDocument18 pagesInjectores S 60 PDFfranciscoNo ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- 13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualDocument2 pages13.8.4.1 Guidelines For Water Pump Replacement: Series 60 Service ManualvictoverNo ratings yet

- SPB 25 Coolant Specification and MaintenanceDocument6 pagesSPB 25 Coolant Specification and Maintenancehuguer1No ratings yet

- Engine Oil Pressure - Test 966H - 01Document7 pagesEngine Oil Pressure - Test 966H - 01Freddy QuispeNo ratings yet

- Test de Presion de Aceite 3126Document8 pagesTest de Presion de Aceite 3126WilsonAntonioGualdrónPachecoNo ratings yet

- Water Pump PDFDocument2 pagesWater Pump PDFvictoverNo ratings yet

- 1.16.1 Repair or Replacement of Flywheel HousingDocument2 pages1.16.1 Repair or Replacement of Flywheel HousingvictoverNo ratings yet

- 8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionDocument2 pages8.2.3.2 Checking 12-Rib Poly-Vee Belt-Driven 50 DN Alternator Belt TensionvictoverNo ratings yet

- Engine Coolant 2 PDFDocument3 pagesEngine Coolant 2 PDFvictoverNo ratings yet

- Connecting Rod PDFDocument9 pagesConnecting Rod PDFvictoverNo ratings yet

- NGR Guide PDFDocument4 pagesNGR Guide PDFajaymannNo ratings yet

- Science, Technology and SocietyDocument67 pagesScience, Technology and SocietyMae-ann P. MarcelinoNo ratings yet

- 2a. D BT 02. Reliability Management. 8JP. OKDocument50 pages2a. D BT 02. Reliability Management. 8JP. OKadmiralengineerNo ratings yet

- Multiplexing and Multiple AccessDocument25 pagesMultiplexing and Multiple AccessAbdou GayeNo ratings yet

- Supply Chain ManagementDocument17 pagesSupply Chain ManagementEkundayo FademiNo ratings yet

- (BS EN 12673 - 1999) - Water Quality. Gas Chromatographic Determination of Some Selected Chlorophenols in Water.Document20 pages(BS EN 12673 - 1999) - Water Quality. Gas Chromatographic Determination of Some Selected Chlorophenols in Water.Hector CardenasNo ratings yet

- Creating Transparency, Expecting Accountability: (RFID Shop Floor Data Tracking System)Document6 pagesCreating Transparency, Expecting Accountability: (RFID Shop Floor Data Tracking System)Jahangir Alam SohagNo ratings yet

- MSDS Desmanol PDFDocument6 pagesMSDS Desmanol PDFARIKANo ratings yet

- Bedside Nursing Handover A Case StudyDocument8 pagesBedside Nursing Handover A Case StudyAisha MagarangNo ratings yet

- PLSQL Cig1Document2 pagesPLSQL Cig1ram5584No ratings yet

- The Structure Proposal/Dissertation (MBA) Research Dissertation (20,000 Words)Document1 pageThe Structure Proposal/Dissertation (MBA) Research Dissertation (20,000 Words)Suleman Khan YousufzaiNo ratings yet

- Latter v. Braddell 1881 EnglandDocument7 pagesLatter v. Braddell 1881 EnglandJulieNo ratings yet

- STLED316S: Serial-Interfaced 6-Digit LED Controller With KeyscanDocument33 pagesSTLED316S: Serial-Interfaced 6-Digit LED Controller With KeyscanDhivya NNo ratings yet

- Cond Serv Data Gravely L EngDocument9 pagesCond Serv Data Gravely L Engda008co50% (2)

- United States v. Jim H. Gay-Lord, D/B/A MacKey Net & Rope Company, Inc., 799 F.2d 124, 4th Cir. (1986)Document4 pagesUnited States v. Jim H. Gay-Lord, D/B/A MacKey Net & Rope Company, Inc., 799 F.2d 124, 4th Cir. (1986)Scribd Government DocsNo ratings yet

- AmulDocument22 pagesAmulanushriNo ratings yet

- Fragrances in The United Arab Emirates - Datagraphics: Country Report - Jun 2019Document4 pagesFragrances in The United Arab Emirates - Datagraphics: Country Report - Jun 2019Avani ShitoleNo ratings yet

- Saudi Aramco Test Report: External Tank Bottom Testing 24-Jul-18 CP-SATR-X-3204Document7 pagesSaudi Aramco Test Report: External Tank Bottom Testing 24-Jul-18 CP-SATR-X-3204nadeem shaikhNo ratings yet

- Beginning Molecular Biology Laboratory Manual-UMBC.2003 (Por Trisquelion)Document52 pagesBeginning Molecular Biology Laboratory Manual-UMBC.2003 (Por Trisquelion)Sivan AndiNo ratings yet

- Setting The Rules Dean BakerDocument11 pagesSetting The Rules Dean BakerOccupyEconomicsNo ratings yet

- Financial Statements - TATA - MotorsDocument6 pagesFinancial Statements - TATA - MotorsSANDHALI JOSHI PGP 2021-23 BatchNo ratings yet

- Chapter 2Document10 pagesChapter 2Abolade OluwaseyiNo ratings yet

- Eng Spec For Fire Fighting System DesignDocument27 pagesEng Spec For Fire Fighting System DesignIndunil WarnasooriyaNo ratings yet

- Learning HangeulDocument102 pagesLearning HangeulwitarinaNo ratings yet

- Qra HPCL Jalandhar Ird-Draft r1Document92 pagesQra HPCL Jalandhar Ird-Draft r1PABNo ratings yet