Professional Documents

Culture Documents

Flow Divertor Ball Valve DN20 - DN32 - DN50: Description

Uploaded by

윤병택Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Divertor Ball Valve DN20 - DN32 - DN50: Description

Uploaded by

윤병택Copyright:

Available Formats

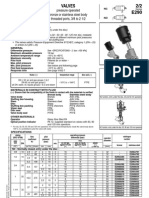

FLOW DIVERTOR BALL VALVE

DN20 DN32 DN50

Bestobell Valves is a world leader in the design and manufacture of

cryogenic valves, recognised globally for product quality and

innovation. Our valves are used with numerous cryogenic liquefied

gases including oxygen, carbon dioxide, nitrogen, liquid natural gas

(LNG) and argon. Bestobell Valves manufactures for a wide range

of applications and in a comprehensive range of materials.

Description

It is essential that a cryogenic liquid storage vessel is always

protected by a relief valve. If only one relief valve was fitted to the

vessel it would be impossible to disconnect for routine maintenance

or checking of lifting pressures without prejudicing the safety of the

vessel.

For this reason, all cryogenic storage tanks require two relief valves to

be connected to the tank via a flow diverter valve. This allows one

relief valve to remain connected to the vessel while the other

undergoes maintenance.

The Bestobell flow diverter is a quarter turn ball valve design allowing

for fats changeover between relief valves. It is available in a very

wide range of configurations to suit the customers requirements. The

valve comprises three main components: the centre body

incorporating the inlet port, ball and operating lever, and the two end

adaptors incorporating the various outlet ports. It is available in three

basic sizes (DN20, DN32, DN50) determined by the diameter of the

flow passages through the ball.

This valve is usually at the hub of a fairly complex piping system and

many variations on the basic design have evolved to suit customers

specific requirements. An outline of the various options is given

below for simplicity; the centre body is described separately from the

end flanges.

All valves are degreased for oxygen duty, assembled in clean room

conditions, and sealed in robust polythene bags prior to despatch

Maximum Working Pressure

(Subject to end connections and material)

50bar

Features and Benefits

T Port

The position of the entry port helps the system designer to fit the

valve into the particular space and position he has available. With the

bottom entry valve, the inlet port is on the opposite side of the centre

body from the opening lever (see drawing). The front entry valve has

the inlet port on the face at 90 to the operating lever (photograph).

The DN20, DN32 and DN50 valves are available with bottom or front

entry configurations.

Bestobell Valves, President Park, President Way, Sheffield, S4 7UR

Tel: + 44 (0) 114 224 0000

Fax: + 44 (0) 114 278 4974

E-mail sales@bestobellvalves.com Website: http://www.bestobellvalves.com

Rev No: 8

23.10.06

FLOW DIVERTOR BALL VALVE

DN20 DN32 DN50

The three position T-port offers significant advantages. The first of

these is that it is possible to have both relief valves connected to the

storage vessel (or mobile tanker) at one time. This enables the

discharge of higher volumes of gas, which in turn allows faster filling

or quicker tank turnaround. The second main advantage is that, even

during movement of the operating lever from one position to another,

the flow capacity of the valve is not reduced below that available from

one fully open port. The integrity of the vessel is not threatened,

therefore, even if the operator inadvertently leaves the operating lever

mid-position.

The vital part that the diverter valve plays in the integrity of a storage

system requires it to be designed with safety in mind. The following

features help to ensure that the valve fulfils its role reliably.

Anti- blow out stem

Porting indications on handle.

Handle designed to prevent attachment to valve in wrong position.

Ball machined to prevent incorrect assembly.

Drilled and tapped mounting bosses to allow rigid mounting.

Spares - All wearing items are available as spares. Please enquire for details.

Materials

Body

End Adaptors

Spindle

Lever

Ball

Seat, Gland

Fasteners

BSEN 1982 CC491K

BSEN 1982 CC491K

BSEN 12164 CW721R

BSEN 1982 CC491K

Brass

Virgin PTFE

BS6105 A4/A2 GR70

Technical Data

ISO 9001 accreditation designed and manufacture to ASTM B31.3

& BSEN1626.

Optional full material traceability backed by BSEN 10204 3.1B / 3.1C

Certification

Designed and engineered for use with O2, N2, Ar, CO2, He, Kr, Ne, H2,

C2H4, N2O service

Marking according to Pressure Equipment Directive 97/23/EC

For other options please contact us.

Specifications

End Flange Configuration

The main function of the end flanges is to duct the flow from the

centre body to the relief valves. In addition to this primary function

however, is the subsidiary one of providing additional ports to allow

connection of pressure test apparatus and/or bursting disc. The

variety of options is laid out in table 1. Note that the end flanges can

be fitted in any one of four positions, each at 90 to the other. The

operating arc of the valve lever may prevent several of these

positions being used because of the 180 lever operation.

Bestobell Valves, President Park, President Way, Sheffield, S4 7UR

Tel: + 44 (0) 114 224 0000

Fax: + 44 (0) 114 278 4974

E-mail sales@bestobellvalves.com Website: http://www.bestobellvalves.com

Rev No: 8

23.10.06

FLOW DIVERTOR BALL VALVE

DN20 DN32 DN50

Table 1: - DN20 Divertor

A

NPT

NPT

NPT Plugged

NPT Plugged

PL Plugged

TR Plugged

NPT

-

PL

PL

1 NPT

NPT

1 PL

NPT

1 TR

3/8 PL Plugged

NPT

NPT Plugged

NPT Plugged

NPT Plugged

PL

PL

PL

1 NPT

NPT

1 PL

NPT

1 TR

PL

TR

NPT

NPT

NPT

PL

170

170

170

170

170

170

170

170

170

170

170

170

170

44

44

44

44

44

44

44

44

44

44

44

44

44

1NB

1NB

1NPT

1 NPT

1 NB

1 NB

1 NB

1PL

1 TR

1 NPT

1 NPT

1 NPT

M40/2

168

168

168

168

168

168

168

168

168

168

168

168

168

Bottom or

Front Entry

B

B

B

F

F

F

F

F

F

F

F

F

F

Part No.

CJB40SS5ABT1T

CJB40TA5AAT1T

CJB40TE5BZT1T

CJF40SS5APT1T

CJF40SS5B2T1T

CJF40555H4E1T

CJF40555H6E1T

CJF40TA5AKE1TVA

CJF40TC5B8E1TVA

CJF40TE5APT1T

CJF40TE5BEE1TVA

CJF40TE5BFE1TVA

CJF40TH5B8E1TVA

Table 2: - DN32 Divertor

A

1 NPT

NPT

NPT

NPT

-

1 TR

NPT

1 TR

1 NPT

1 NPT

1 TR

1 TR

1 NPT

1 TR

1 NPT

1 NPT

1 TR

225

225

225

225

225

225

225

67.5

67.5

67.5

67.5

67.5

67.5

67.5

1 NPT

1 NB

1 NB

1 NB

1 NB

1 NPT

1 TR

223

223

223

223

223

223

223

Bottom or

Front Entry

B

F

F

F

F

F

F

Part No.

CJB60TE6C9E1T

CJF60SS7BEE1T

CJF60SS7CHE1T

CJF60SS7CJEITQ5

CJF60SS7CLE1T

CJF600SS7CLE1T

CJF60TC6BE1T

Table 3: - DN50 Divertor

A

3/8 TR

3/8 TR

TR

TR Plugged

1 TR Plugged

TR

-

1 " PL

1 PL

1 TR

1 TR

NPT Plugged

2 TR

NPT Plugged

NPT

2 PL

1 TR

1 PL

1 PL

1 TR

1 TR

1 TR

2 TR

NPT

TR

2 PL

1 TR

225

225

225

225

225

225

225

225

225

225

95

95

95

95

95

95

95

95

95

95

1 NB

1 NB

2 TR

1 NB

2 TR

2 NB

2 TR

2 TR

2 TR

2 TR

222

222

222

222

222

222

222

222

222

222

Bottom or

Front Entry

B

B

B

F

F

F

F

F

F

F

Part No.

CJB80TA6E4T1T

CJB08TA6EDT1T

CJB80TC7FGE1T

CJF80SS6F4TITQC

CJF80TC7EPEITVA

CJF80SS7F2T1T

CJF807FDEITVA

CJF80TC7F6E1T

CJF80TC7F6E1T

CJF80TC7EDE1T

The information on this data sheet is accurate to the best of Bestobells knowledge, however we reserve the right to alter the product

specification at any time. For any specific updated detail, please contact us.

Bestobell Valves, President Park, President Way, Sheffield, S4 7UR

Tel: + 44 (0) 114 224 0000

Fax: + 44 (0) 114 278 4974

E-mail sales@bestobellvalves.com Website: http://www.bestobellvalves.com

Rev No: 8

23.10.06

You might also like

- Crane - Series.rs Center LineDocument23 pagesCrane - Series.rs Center LinenedwestNo ratings yet

- Oventrop Valve Technical SpecDocument15 pagesOventrop Valve Technical SpecblindjaxxNo ratings yet

- 187 - Robineti Retinere Cu Bila PVC FiletDocument6 pages187 - Robineti Retinere Cu Bila PVC FiletCiprianSarbuNo ratings yet

- Water Control Valve DV-5Document8 pagesWater Control Valve DV-5Christian FherNo ratings yet

- VALVULA DE SOLENOIDE HS7 BulletinDocument4 pagesVALVULA DE SOLENOIDE HS7 BulletinJoséMarcanoNo ratings yet

- FM-200 Alpha Series SystemsDocument6 pagesFM-200 Alpha Series SystemsGurusumiNo ratings yet

- Valves & Controls: Crosby Safety Valves Style HSLDocument12 pagesValves & Controls: Crosby Safety Valves Style HSLeborresonNo ratings yet

- CO2 AnsulDocument17 pagesCO2 AnsulJorge RVNo ratings yet

- Danfoss Non Return ValvesDocument28 pagesDanfoss Non Return Valveskostaviga777No ratings yet

- v101 v102 Butterfly ValvesDocument6 pagesv101 v102 Butterfly Valvesapi-18982376No ratings yet

- Vortex Float ValveDocument3 pagesVortex Float ValveFrancisco Javier Villegas AndersonNo ratings yet

- Neojv 0040 enDocument0 pagesNeojv 0040 enLuis GuevaraNo ratings yet

- Tyco Alarm ValveDocument22 pagesTyco Alarm ValveMohammed BaquarNo ratings yet

- Apollo ValvesDocument44 pagesApollo ValvesDevdatt WaghuleNo ratings yet

- Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500Document8 pagesTechnical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500mohammadazraiNo ratings yet

- Cryogenic Bronze Globe Valve GuideDocument2 pagesCryogenic Bronze Globe Valve GuidesivagulfNo ratings yet

- DAN-EX Brochure WebDocument12 pagesDAN-EX Brochure Webzakkyf6455No ratings yet

- Valvulas de Control FisherDocument16 pagesValvulas de Control FisherAnonymous GKTRypNo ratings yet

- Double Block and Bleed ValveDocument16 pagesDouble Block and Bleed ValveBa Jun Thối100% (1)

- BRH Eplug Rotaryshaftvalves GeDocument28 pagesBRH Eplug Rotaryshaftvalves GeJosh FryNo ratings yet

- Fisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesDocument20 pagesFisherr 8510 and 8510B Eccentric Disc Control Valves (EMA) : FeaturesFabián HerreraNo ratings yet

- Guided Valves Technical BulletinDocument15 pagesGuided Valves Technical BulletinVladimir VuletinNo ratings yet

- Cryogenic Bola Ac. Inox.Document2 pagesCryogenic Bola Ac. Inox.Sergio DjbucaneroNo ratings yet

- Delvalcataloguemay 3006Document4 pagesDelvalcataloguemay 3006Balu VedhachalamNo ratings yet

- 160.75-RP1 (210) - Yk (G)Document92 pages160.75-RP1 (210) - Yk (G)JayashtonNo ratings yet

- Unique Single Seat Valve-Simply UniqueDocument8 pagesUnique Single Seat Valve-Simply UniquelggomezupbNo ratings yet

- Stop and Check ValvesDocument24 pagesStop and Check ValvesRahul PatilNo ratings yet

- Econ Gate ValvesDocument20 pagesEcon Gate ValvesEngr.Mmosaad100% (1)

- MIV product overview valves, fittings and butterfly valvesDocument13 pagesMIV product overview valves, fittings and butterfly valvesAmir_skorpionNo ratings yet

- Deluge ValveDocument10 pagesDeluge ValvevpnrrajaNo ratings yet

- Essential features and installation instructions for Velan valvesDocument9 pagesEssential features and installation instructions for Velan valvesrawatbs2020No ratings yet

- AVK ValveDocument2 pagesAVK Valvemih4iNo ratings yet

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDocument5 pagesSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroNo ratings yet

- Double Eccentric Butterfly Valves R1Document20 pagesDouble Eccentric Butterfly Valves R1Sandi AslanNo ratings yet

- 100 Series 45Â Fill Valve1Document3 pages100 Series 45Â Fill Valve1Ivan OlivaNo ratings yet

- D 101363 X 012Document20 pagesD 101363 X 012AmiroucheBenlakehalNo ratings yet

- Fluid Components Full CatalogDocument464 pagesFluid Components Full Catalognegg 348No ratings yet

- USPVH-0012 M94 4Pg BrochureDocument4 pagesUSPVH-0012 M94 4Pg Brochurebkup2007No ratings yet

- Dwyer - Valvula de Bola Inox Serie BV2M, IOMDocument1 pageDwyer - Valvula de Bola Inox Serie BV2M, IOMGabriel Ortiz MontesNo ratings yet

- Topworx Valvetop D-Series With GO Switches ManualDocument20 pagesTopworx Valvetop D-Series With GO Switches ManualJuan LuisNo ratings yet

- BusDocument34 pagesBusernesto hidalgoNo ratings yet

- Inside Sales For Valves Part 3Document6 pagesInside Sales For Valves Part 3niket honnalliNo ratings yet

- 45Kg Cylinder & Valve AssemblyDocument4 pages45Kg Cylinder & Valve AssemblyRaju Saha100% (1)

- Purga Fondo BBV 980 A PDFDocument2 pagesPurga Fondo BBV 980 A PDFaugusto7777No ratings yet

- VNotchDocument3 pagesVNotchThiruThirunavukkarasuNo ratings yet

- Safety Relief ValvesDocument52 pagesSafety Relief ValvesHamza NoumanNo ratings yet

- Eko4000-4100 WebDocument4 pagesEko4000-4100 WebSubramanian SaravananNo ratings yet

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuNo ratings yet

- Manual Zetkama Fig.215 - 216Document8 pagesManual Zetkama Fig.215 - 216George_Wabag_2014No ratings yet

- Bulletin B150-5 - Ball Valve For H2O2Document0 pagesBulletin B150-5 - Ball Valve For H2O2pdaga19691383No ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- ChemGuide 8677 PDocument32 pagesChemGuide 8677 PPiok Piere TenengNo ratings yet

- Chemical resistant chart for common materialsDocument40 pagesChemical resistant chart for common materials윤병택No ratings yet

- Chemical Resistant Chart (Rubber Cal) PDFDocument8 pagesChemical Resistant Chart (Rubber Cal) PDF윤병택No ratings yet

- STUD BOLT LENGTH (HD-HD, HD-BLD, VS-VS, VS-BLD) - 2000M & 2400 R0 - 15 April 13Document38 pagesSTUD BOLT LENGTH (HD-HD, HD-BLD, VS-VS, VS-BLD) - 2000M & 2400 R0 - 15 April 13윤병택No ratings yet

- Chemical Resistance of Rubbers (AIP)Document7 pagesChemical Resistance of Rubbers (AIP)윤병택No ratings yet

- AutoCAD Shortcuts 11x8.5 MECH-REV PDFDocument11 pagesAutoCAD Shortcuts 11x8.5 MECH-REV PDFKristijan BorasNo ratings yet

- Chem ResistanceDocument18 pagesChem Resistancepeng88apNo ratings yet

- Chemical Resistance Guide: An Overview of Elastomer SuitabilityDocument12 pagesChemical Resistance Guide: An Overview of Elastomer SuitabilitysreeyukthaNo ratings yet

- Chemical Resistance Chart (Trelleborg)Document8 pagesChemical Resistance Chart (Trelleborg)윤병택No ratings yet

- Isa PDFDocument7 pagesIsa PDFairsorNo ratings yet

- ! Chemical Resistance Chart (Burkert) PDFDocument20 pages! Chemical Resistance Chart (Burkert) PDF윤병택No ratings yet

- Estandares de NaamsB 1 1Document1 pageEstandares de NaamsB 1 1EderNo ratings yet

- Emerson Control ValveDocument319 pagesEmerson Control ValveMudabbir Shan AhmedNo ratings yet

- Steel Tube Sizing Chart Quick Reference Guide 4Document10 pagesSteel Tube Sizing Chart Quick Reference Guide 4ChetanNo ratings yet

- Lovett - 2013 PDFDocument151 pagesLovett - 2013 PDF윤병택No ratings yet

- Chilled Water by GilDocument4 pagesChilled Water by Gil윤병택No ratings yet

- Chilled Water by GilDocument4 pagesChilled Water by Gil윤병택No ratings yet

- Ductle Iron Spec2Document18 pagesDuctle Iron Spec2윤병택No ratings yet

- Darcy Weisbach FormulaDocument3 pagesDarcy Weisbach Formulasairam2234No ratings yet

- Mentorpaper 101392Document13 pagesMentorpaper 101392윤병택No ratings yet

- TA-Therm EN LowDocument8 pagesTA-Therm EN Low윤병택No ratings yet

- 2 RBM Tita Fix 2018 en FR Ru Ro Es de WebDocument37 pages2 RBM Tita Fix 2018 en FR Ru Ro Es de Web윤병택No ratings yet

- EMDG Imperial 2014Document110 pagesEMDG Imperial 2014윤병택No ratings yet

- News&Notes Entire MagazineDocument40 pagesNews&Notes Entire Magazine윤병택No ratings yet

- End TypesDocument2 pagesEnd TypesvenkateaNo ratings yet

- Ductle Iron Spec1Document8 pagesDuctle Iron Spec1윤병택No ratings yet

- Evopicv EngDocument1 pageEvopicv Eng윤병택No ratings yet

- Bulletin A6Document4 pagesBulletin A6Sabino LaraNo ratings yet

- Flange BS10 AS2129 ANSIBS4504Document12 pagesFlange BS10 AS2129 ANSIBS4504윤병택No ratings yet

- ISA Submits New Control Valve StandardsDocument1 pageISA Submits New Control Valve Standards윤병택No ratings yet

- Medical ImagingDocument412 pagesMedical Imagingalexandraiuliana0% (1)

- Vocational Training at PGCIL SubstationDocument22 pagesVocational Training at PGCIL SubstationSanitha Michail100% (1)

- 49 - 56 CatalogDocument122 pages49 - 56 CatalogJose Alejandro Arias MNo ratings yet

- Mitsubishi Electric MXZ-2D-6D VA Service Manual EngDocument542 pagesMitsubishi Electric MXZ-2D-6D VA Service Manual EngAnonymous wsOiKPMNo ratings yet

- SMC Imu Data Sheet Motion SensorDocument2 pagesSMC Imu Data Sheet Motion SensorErwin ArdiasNo ratings yet

- Clutch Cylinder With PWM Valves and Sensor PDFDocument2 pagesClutch Cylinder With PWM Valves and Sensor PDFSherzad Chem100% (5)

- Ot Ce101p 1 Ce151Document6 pagesOt Ce101p 1 Ce151Nikko San QuimioNo ratings yet

- Boyles Law and Charles LawDocument23 pagesBoyles Law and Charles LawSharmaine C. TABADANo ratings yet

- حلول لوكDocument2 pagesحلول لوكاحمدعطيهNo ratings yet

- NEF Tier 3 Electronic EngineDocument120 pagesNEF Tier 3 Electronic EngineJuan Guzmán100% (12)

- Tahir Iqbal CVDocument4 pagesTahir Iqbal CVAnonymous bCFC8fjLVNo ratings yet

- Viz Artist 3 ScriptDocument123 pagesViz Artist 3 ScriptFabian Ledesma0% (1)

- Facial BoneDocument34 pagesFacial BoneIrfanHadiWijayaNo ratings yet

- DENSO A/C ComponentsDocument478 pagesDENSO A/C ComponentsPapp Ilona100% (1)

- Horary astrology chart interpretationDocument3 pagesHorary astrology chart interpretationSanjeev AgarwalNo ratings yet

- Adjustment Computation Notes by UotilaDocument59 pagesAdjustment Computation Notes by Uotilatangdc99No ratings yet

- Hydraulic Jump ExperimentDocument16 pagesHydraulic Jump ExperimentDaniel MabengoNo ratings yet

- Admin, Journal Manager, PROSIDING 8Document3 pagesAdmin, Journal Manager, PROSIDING 8Aziz Nur FathoniNo ratings yet

- MODUS FLY8000 pendant luminaire tech sheetDocument2 pagesMODUS FLY8000 pendant luminaire tech sheetvikiNo ratings yet

- Delhi Public School, Ranchi: Coordination CompoundsDocument1 pageDelhi Public School, Ranchi: Coordination CompoundsScience SpiritNo ratings yet

- Afm E308-16 Afm E308h-16Document13 pagesAfm E308-16 Afm E308h-16Julio Cesar Lazcano PintoNo ratings yet

- Bioluminescence PDFDocument34 pagesBioluminescence PDFArup DasNo ratings yet

- COUPLINGS, ADAPTERS AND FITTINGS GUIDEDocument1 pageCOUPLINGS, ADAPTERS AND FITTINGS GUIDEMonica CarrenoNo ratings yet

- Freyssinet Webinar Introduction To Passive Control System For Seismic Damage Mitigation - Tri SuryadiDocument62 pagesFreyssinet Webinar Introduction To Passive Control System For Seismic Damage Mitigation - Tri SuryadiAnto Destianto100% (1)

- Casio AT 1 Service ManualDocument28 pagesCasio AT 1 Service ManualMario Gabriel MoralliNo ratings yet

- Hb2637l-Evk-301 DPT HSDocument10 pagesHb2637l-Evk-301 DPT HSAlec NanetteNo ratings yet

- 73 Magazine 1961 06 June PDFDocument76 pages73 Magazine 1961 06 June PDFCatalin ZestranNo ratings yet

- CVA DVA Werkstuk Bekele - tcm39 91310Document40 pagesCVA DVA Werkstuk Bekele - tcm39 91310s_75No ratings yet

- Reservoir Engineering-1 Unit 1Document21 pagesReservoir Engineering-1 Unit 1PE9001 AarthiNo ratings yet

- Alia AUF790 Ultrasonic Open Channel FlowmeterDocument4 pagesAlia AUF790 Ultrasonic Open Channel FlowmeterRexCrazyMindNo ratings yet