Professional Documents

Culture Documents

03 Boiler Shut Down SOP

Uploaded by

amzad06Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

03 Boiler Shut Down SOP

Uploaded by

amzad06Copyright:

Available Formats

PRAN DAIRY LTD

PRAN Beverage Laboratory

Bagpara, Palash, Narshingdi

DOC NO: SOP-PDL-boiler shut3.1.3

ISSUE NO: 01

ISSUE DATE: 01.10.2012

AUTHOR: ...............................................

REVISION NO: 00

REVISION DATE: 00

APPROVED BY: ................................

SOP# 03: Boiler Shutdown Procedure

A. CHANGE HISTORY:

Date

Revision

Description

B. DISTRIBUTION:

DEPUTY MANAGING DIRECTOR (DMD)

DIRECTOR-PRAN

HEAD OF QC

GM-FACTORY

MANAGER QC

MANAGER PRODUCTION

Page 1 of 3

PRAN DAIRY LTD

PRAN Beverage Laboratory

Bagpara, Palash, Narshingdi

DOC NO: SOP-PDL-boiler shut3.1.3

ISSUE NO: 01

ISSUE DATE: 01.10.2012

AUTHOR: ...............................................

REVISION NO: 00

REVISION DATE: 00

APPROVED BY: ................................

SOP# 03: Boiler Shutdown Procedure

1.0 PURPOSE:

To ensure standard shutdown procedures of Boiler are followed.

2.0 SCOPE:

Area: Boiler.

Personnel: Boiler Operator

3.0 RESPONSIBILITIES:

Boiler operator:

1) Safe & efficient operation, cleaning of the Boiler.

2) To be followed SOP of shutdown procedure of Boiler.

Maintenance In charge:

1) Responsible for carry out routine breakdown & preventive maintenance for safe & efficient

operation of machine.

2) Check machine on regular basis as per maintenance checklist & responsible for overall

condition of the machine.

4.0 DEFINITIONS:

Shutdown: The activities carried out at the time of shutdown of the Boiler.

Data: Information which are used as the basis for decision, conclusion.

Defects: The non-fulfillment of intended usage or performance requirements.

Page 2 of 3

PRAN DAIRY LTD

PRAN Beverage Laboratory

Bagpara, Palash, Narshingdi

DOC NO: SOP-PDL-boiler shut3.1.3

ISSUE NO: 01

ISSUE DATE: 01.10.2012

AUTHOR: ...............................................

REVISION NO: 00

REVISION DATE: 00

APPROVED BY: ................................

SOP# 03: Boiler Shutdown Procedure

Root cause: The originating source of non-conforming effect.

Records: Official copies of documents & activities that are maintained & stored under

appropriate condition

5.0 PROCEDURE:

6.1 First of all, Damper must have to be remaining Off.

6.2 Check the Steam Supply because; Steam Supply must have to be remaining Off

6.3 By manual operation, excess pressure must have to be released from the header by the

pressure out line.

6.4 The pressure must have to be kept constant after when the pressure reduce to 02kg.

6.5 Check the water level in Boiler by using the gauge glass.

6.6 After that, Switch Off the Feed Pump.

6.7 Then the Circulation pump must have to be remain Off.

6.8 At last the panel board must have to be remain Off by isolating it from the power line.

Page 3 of 3

You might also like

- Coal Switching Program, PT PJB Paiton Coal Fired Power PlantDocument15 pagesCoal Switching Program, PT PJB Paiton Coal Fired Power PlantRiza RifaldyNo ratings yet

- Power PlantDocument24 pagesPower PlantARUNGREESMANo ratings yet

- CMMS NR 2 2013 PDFDocument180 pagesCMMS NR 2 2013 PDFnacachimbandiNo ratings yet

- IntroductionEnergyModeling (Yamaguchi)Document24 pagesIntroductionEnergyModeling (Yamaguchi)Disyon DxNo ratings yet

- Skema Pltu SuralayaDocument10 pagesSkema Pltu SuralayaAnnisa AnugraNo ratings yet

- Proses Konstruksi, Proteksi Turbin Dan CommisioningDocument11 pagesProses Konstruksi, Proteksi Turbin Dan CommisioningAji PrastiaNo ratings yet

- 02 Logsheet Turbin DeskDocument7 pages02 Logsheet Turbin DeskKeniBataraNo ratings yet

- Tata Cara Start - Up Auxiliary BoilerDocument2 pagesTata Cara Start - Up Auxiliary BoilerMuhammad Fauzan0% (1)

- BTG Ets MFT Alarm ListDocument20 pagesBTG Ets MFT Alarm ListriyantoNo ratings yet

- Syllabus 0f Maintenance and Protection SubstationDocument4 pagesSyllabus 0f Maintenance and Protection Substationdeepu kumarNo ratings yet

- APCDocument25 pagesAPCTawanda Precious SingiziNo ratings yet

- Steam Power PlantDocument33 pagesSteam Power Plantajeet kumarNo ratings yet

- Installation, Operation and Maintenance InstructionsDocument72 pagesInstallation, Operation and Maintenance InstructionsSamuel Duruibe100% (1)

- NACA 4314 Airfoil ProfileDocument3 pagesNACA 4314 Airfoil ProfileRohit GuptaNo ratings yet

- Ba Test Com Panel TMDocument7 pagesBa Test Com Panel TMAhmad Gofur100% (1)

- Lesson 2 Rev Introduction To Power PlantDocument53 pagesLesson 2 Rev Introduction To Power Plantfelix asadeNo ratings yet

- Panduan Pengoperasian TurbineDocument60 pagesPanduan Pengoperasian TurbineIfdal SalmaNo ratings yet

- Flow Proses Plant#2 CFK #3 1 X 50 MWDocument2 pagesFlow Proses Plant#2 CFK #3 1 X 50 MWNur Ali SaidNo ratings yet

- Kerusakan Komponen Turbin UAPDocument21 pagesKerusakan Komponen Turbin UAPDoli MotorNo ratings yet

- Input, Output Module FDCIO221 Technical Manual PDFDocument50 pagesInput, Output Module FDCIO221 Technical Manual PDFBilbureanu Robert FlorinNo ratings yet

- Heat Rate Pembangkit Thermal Rev.01Document67 pagesHeat Rate Pembangkit Thermal Rev.01Mizan Akbar Isnaini PNo ratings yet

- PaperDocument1 pagePaperFajar Adi PrabowoNo ratings yet

- Manual GM-100 (852c) PDFDocument12 pagesManual GM-100 (852c) PDFGuilhermeNo ratings yet

- Shell Thermia BDocument2 pagesShell Thermia Bsegunoyes100% (1)

- DLT 852-2016 enDocument75 pagesDLT 852-2016 enWinnjone YinNo ratings yet

- 3 Boiler PAF and System Commissioning Procedure-TöàtéëS+Ç íTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+Document34 pages3 Boiler PAF and System Commissioning Procedure-TöàtéëS+Ç íTúÄ Såèsà T +T+ƑF Âf Ò Ä Û+kvsagarNo ratings yet

- 1-SMR-RAB Civil Work NDC Storage Tank 400m3Document2 pages1-SMR-RAB Civil Work NDC Storage Tank 400m3Ossa SetiawanNo ratings yet

- Sop Coal MillDocument7 pagesSop Coal MillrobbyNo ratings yet

- Executive Summary - Sintang 12 MW BTG Biomass Power PlantDocument11 pagesExecutive Summary - Sintang 12 MW BTG Biomass Power PlantKomang SuantikaNo ratings yet

- IIGCE 2022 - Full Paper - Calcite Scaling in Vapor Dominated Well, Patuha Geothermal FieldDocument9 pagesIIGCE 2022 - Full Paper - Calcite Scaling in Vapor Dominated Well, Patuha Geothermal FieldLucky HeliosNo ratings yet

- Mike Crosetti - Policy, Financing and Institutional Innovations For Geothermal Energy Generation in IndonesiaDocument10 pagesMike Crosetti - Policy, Financing and Institutional Innovations For Geothermal Energy Generation in IndonesiaAsia Clean Energy ForumNo ratings yet

- DDA Book 01 IntroductionDocument18 pagesDDA Book 01 IntroductionOpik SariefNo ratings yet

- Manual Dci DX LPRDocument24 pagesManual Dci DX LPRsaiful anwarNo ratings yet

- License Key - AOMEI FoneTool ProfessionalDocument1 pageLicense Key - AOMEI FoneTool ProfessionalBaby CryNo ratings yet

- Maintenance Prevention On Coal Fired Power Plant BoilerDocument5 pagesMaintenance Prevention On Coal Fired Power Plant BoilerInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- K3 Listrik Untuk PLTSDocument134 pagesK3 Listrik Untuk PLTSAinun PWNo ratings yet

- Harga Pekerjaan Repair Valve Rev1Document21 pagesHarga Pekerjaan Repair Valve Rev1sandrositohangNo ratings yet

- Data Pengukuran BFPT ADocument3 pagesData Pengukuran BFPT AazisyuswandiNo ratings yet

- Training TransformerDocument23 pagesTraining TransformerDidi Nurtadi LibraNo ratings yet

- WELCOME To Unit 7&8 Coal Fire Power PlantDocument21 pagesWELCOME To Unit 7&8 Coal Fire Power PlantIwan RuhiyanaNo ratings yet

- List Equipment Pltu Pangkalan Susu 2x200mwDocument7 pagesList Equipment Pltu Pangkalan Susu 2x200mwDanny SurbaktiNo ratings yet

- Presented by - Sandeep Agrawal (Am-Mech) Siddhartha Raizada (Am-Elec)Document24 pagesPresented by - Sandeep Agrawal (Am-Mech) Siddhartha Raizada (Am-Elec)sidraiz26No ratings yet

- Presentation Energi Entelemi Indonesia - 2021 Rev.0Document9 pagesPresentation Energi Entelemi Indonesia - 2021 Rev.0Bram AzaryaNo ratings yet

- Hxe320 User Mannual V2Document57 pagesHxe320 User Mannual V2IBMANNo ratings yet

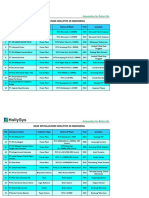

- Indonesia HollySys Base-Installation. 11.03.2019Document3 pagesIndonesia HollySys Base-Installation. 11.03.2019Aerox neoNo ratings yet

- Bab 3Document18 pagesBab 3trisnadewiNo ratings yet

- Plasma Ignition Combustion StabilizingDocument21 pagesPlasma Ignition Combustion StabilizingK R Kumar RanjanNo ratings yet

- (Pertamina) Geoth Sistem Ebtke Unpad 09032017Document57 pages(Pertamina) Geoth Sistem Ebtke Unpad 09032017sugiantoNo ratings yet

- Data GRS PLTP Gunung Salak #3 PDFDocument28 pagesData GRS PLTP Gunung Salak #3 PDFfirmantuakiaNo ratings yet

- Daily Report Day 53 (Senin, 29 April 2019)Document4 pagesDaily Report Day 53 (Senin, 29 April 2019)Richard SinagaNo ratings yet

- Kurva S Pembangunan PLTSDocument1 pageKurva S Pembangunan PLTSEris Osman RifkiNo ratings yet

- Contoh SubstationDocument27 pagesContoh SubstationFahrulNo ratings yet

- Proprietary & Confidential: PM AuthorisationDocument55 pagesProprietary & Confidential: PM AuthorisationMuhammad Najam AbbasNo ratings yet

- H2 Leakage Identification and Arresting SOPDocument12 pagesH2 Leakage Identification and Arresting SOPSanjay SharmaNo ratings yet

- NGP 001 PCS 15.03 2001-15-00 Specification For Fired HeaterDocument22 pagesNGP 001 PCS 15.03 2001-15-00 Specification For Fired Heaterm.shehreyar.khanNo ratings yet

- Procedure Pek. Mooring Dolphin Rev01Document9 pagesProcedure Pek. Mooring Dolphin Rev01Damar WardhanaNo ratings yet

- Protocol Jacketed MFG Tank LV02Document7 pagesProtocol Jacketed MFG Tank LV02pooja aswal100% (3)

- 01 Air Compressure Operation SOP ME.2.1Document2 pages01 Air Compressure Operation SOP ME.2.1amzad06100% (1)

- PFG SOP For Documents Sub-Station Operating (Gas)Document6 pagesPFG SOP For Documents Sub-Station Operating (Gas)Sharif 087No ratings yet

- FHP011 03Document10 pagesFHP011 03Omonigho SapeleNo ratings yet

- 01 Air Compressure Operation SOP ME.2.1Document2 pages01 Air Compressure Operation SOP ME.2.1amzad06100% (1)

- Sidel DrawingDocument169 pagesSidel Drawingamzad0681% (26)

- Parts of SpeechDocument1 pageParts of SpeechyangkaraNo ratings yet

- The 50 Most Common Phrasal Verbs B T Stoakley PDFDocument6 pagesThe 50 Most Common Phrasal Verbs B T Stoakley PDFJaime AntonioNo ratings yet

- ManualDocument7 pagesManualamzad06100% (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksFrom EverandArizona, Utah & New Mexico: A Guide to the State & National ParksRating: 4 out of 5 stars4/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensFrom EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNo ratings yet

- The Bahamas a Taste of the Islands ExcerptFrom EverandThe Bahamas a Taste of the Islands ExcerptRating: 4 out of 5 stars4/5 (1)

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoFrom EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoRating: 5 out of 5 stars5/5 (1)

- New York & New Jersey: A Guide to the State & National ParksFrom EverandNew York & New Jersey: A Guide to the State & National ParksNo ratings yet

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptFrom EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptRating: 5 out of 5 stars5/5 (1)