Professional Documents

Culture Documents

UCK361E: İ.T.Ü Faculty of Aeronautics & Astronautics Department of Aeronautical Engineering

Uploaded by

Mahir HamdiyevOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

UCK361E: İ.T.Ü Faculty of Aeronautics & Astronautics Department of Aeronautical Engineering

Uploaded by

Mahir HamdiyevCopyright:

Available Formats

.T.

FACULTY OF AERONAUTICS & ASTRONAUTICS

DEPARTMENT OF AERONAUTICAL ENGINEERING

UCK361E

Course Name

DESIGN OF

MACHINE

ELEMENTS

Department

Lecturer and office

hours

Teaching assistant and

office hours

Language

Compulsory/Elective

Classroom and

meeting time

Contents

Objectives

Course Educational

Outcomes

Topics - Course

Outline

Code

UCK361

E

Course Regular Credit ECTS Lecture Recitation

Type semester

3

ED

Laboratory

(hour/week)

0

Aeronautical Engineering

Assoc.Prof.Dr. Halit Sleyman TRKMEN, UUBF_228, Tuesday 14:30-16:30

URL: http://www3.itu.edu.tr/~halit

Sedat Ssler

Wednesday 14:30-16:30

English

Compulsory

UUBF_Z09, Wednesday 08:30-11:30

Machine design and phases. Factor of safety. Static strength and design. Variable loading (Fatigue

failure). Tolerances. Design of screws, fasteners and connections. Welded, brazed and bonded joints.

Mechanical springs. Rolling contact bearings. Lubrication and journal bearings. Gearing, spur and

helical gears, Bevel and worm gears, Clutches, brakes, couplings and flywheels, Flexible mechanical

elements, Shafts, axles and spindles.

1.To learn the design of machine elements.

2.To follow technological developments.

3.To design a machine.

After completion of this course, the students should be able to:

1. Understand the mechanical design process (a2,c3,e3,f2,g3,h1,i1,k2)

2. Be able to use standards and design criteria in the process of mechanical design.

(a3,c3,e3,f2,g3,h1,i1,k2)

3. Identify or define the yield stress and the ultimate stress of a material. (a3,c3,e1,f2,g3,h1,i1,k2)

4. Be able to calculate the endurance limit of a material with appropriate corrections.

(a3,c3,e3,f2,g3,h1,i1,k2)

5. Be able to calculate the fatigue safety factor. (a3,c3,e3,f2,g3,h1,i1,k2)

6. Determine the speeds of gears in spur gear systems including planetary systems.

(a3,c3,e3,f2,g3,h1,i1,k2)

7. Be able to analyse mechanical machine elements, permanent joints, detachable joints, rolling

contact bearing, mechanical spring, clutch, break, flexible mechanical elements under static

loading. (a3,c3,e3,f2,g3,h1,i1,k2)

8. Be able to analyse and design gear mechanism. (a3,c3,e3,f2,g3,h1,i1,k2)

9. Be able to determine the size of shafts used in gear mechanisms. (a3,c3,e3,f2,g3,h1,i1,k2)

Note: The letters within the brackets indicate the general program outcomes of Aeronautical

Engineering and Astronautical Engineering.

Duration Date

C.E.O.

Mechanical engineering design, Design considerations, Factor of

1 week

1, 2

Safety, Stress and strain

Deflection and stiffness, Statistical considerations, Mechanical

1 week

3

Properties of Engineering Materials

Steady loading and Static failure theories, Variable loading and

fatigue

1 week

4, 5

Screws, fasteners and connections

Gearing-general, Design of gears

Gearing-general, Design of gears

Rolling-contact bearings

Lubrication and journal bearings

Welded, brazed and bonded joints

Mechanical springs

Clutches, Brakes

Couplings, and Flywheels

Flexible mechanical elements

1 week

1 week

1 week

1 week

1 week

1 week

1 week

1 week

1 week

1 week

1 week

7

6, 8

6, 8

7

7

7

7

7

7

7

Shafts, axles and spindles

.T. FACULTY OF AERONAUTICS & ASTRONAUTICS

DEPARTMENT OF AERONAUTICAL ENGINEERING

UCK361E

Prerequisite(s)

Textbook

Other References

Laboratory Work

Computer Usage

Others

Course Evaluation

Method

Strength of Materials (MUK 204 MIN FF)

1. Shigley, J.E. and Mischke, C.R., 2008, Mechanical Engineering Design, McGraw-Hill.

1. Esposito, A. and Thrower, J.R., Machine Design, Thomson Inc./Publishing Group, 1991.

None

Homework, Excel during design, drawing programs.

Midterm exams

Quizzes

Homework

Projects

Term projects

Laboratory

Others

Final Exam

Number

Min 1

Min 4

Ratio %

15

20

25

1

40

a

b

c

d

e

f

g

h

i

j

Contribution To

Program

3

0

3

0

3

2

3

1

1

0

Outcomes*

Prepared by

Date

Assoc.Prof.Dr. Halit Sleyman TRKMEN

26.03.2010

*Parantez iindeki harfler aadaki a-ky; saylar ise Ders retim ktsnn a-kya katksn gstermektedir.

( 0: katk yok, 1: ok az katk var, 2: Orta derecede katk var. 3: Yksek katk )

PROGRAM OUTCOMES (Program ktlar)

a)

b)

c)

d)

e)

f)

g)

h)

An ability to apply knowledge of mathematics, science, and engineering

An ability to design and conduct experiments, as well as to analyze and interpret data

An ability to design a system, component, or process to meet desired needs

An ability to function on multi-disciplinary teams

An ability to identify, formulate, and solve engineering problems

An understanding of professional and ethical responsibility

An ability to communicate effectively

The broad education necessary to understand the impact of engineering solutions in a global and socieal

context

i)

j)

k)

A recognition of the need for, and an ability to engage in life-long learning

A knowledge of contemporary issues

An ability to use the techniques, skills, and modern engineering tools necessary for engineering practice.

You might also like

- Metallurgical Failure Analysis: Techniques and Case StudiesFrom EverandMetallurgical Failure Analysis: Techniques and Case StudiesRating: 3 out of 5 stars3/5 (1)

- Lennon A. - RC Model Aircraft Design PDFDocument136 pagesLennon A. - RC Model Aircraft Design PDFsanderribeiroNo ratings yet

- 1202 Lecture 1Document51 pages1202 Lecture 1Thomas AbrahamNo ratings yet

- Welding of Metallic Materials: Methods, Metallurgy, and PerformanceFrom EverandWelding of Metallic Materials: Methods, Metallurgy, and PerformanceFuad KhoshnawNo ratings yet

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- The Pre-Columbian Discovery of The American Continent by Muslim SeafarersDocument39 pagesThe Pre-Columbian Discovery of The American Continent by Muslim SeafarersXeyeXofXlynxX100% (12)

- GH13 Heavy Duty Body Installation Manual PDFDocument132 pagesGH13 Heavy Duty Body Installation Manual PDFRobinson Guaneme50% (2)

- B.Tech Automobile Engineering Revised SyllabusDocument38 pagesB.Tech Automobile Engineering Revised SyllabusAlicia CarterNo ratings yet

- Original PDFDocument7 pagesOriginal PDFPriyaKumarNo ratings yet

- Design and Fabrication of Fatigue Test Rig For Composite Leaf SpringDocument12 pagesDesign and Fabrication of Fatigue Test Rig For Composite Leaf SpringIJRASETPublicationsNo ratings yet

- AU 3-8 Sem 090710 (BOS 2010)Document53 pagesAU 3-8 Sem 090710 (BOS 2010)Praveen Singh RathoreNo ratings yet

- 593 Mechanical Engineering 2003Document43 pages593 Mechanical Engineering 2003IntelshkNo ratings yet

- Devi Ahilya Vishwavidyalaya, I Dore I Stitute of E Gi Eeri G & Tech OlogyDocument20 pagesDevi Ahilya Vishwavidyalaya, I Dore I Stitute of E Gi Eeri G & Tech OlogySonal MahajanNo ratings yet

- Dr. Khurshid Alam: "Experimental and Numerical Analysis of Conventional and Ultrasonically-Assisted Cutting of Bone"Document4 pagesDr. Khurshid Alam: "Experimental and Numerical Analysis of Conventional and Ultrasonically-Assisted Cutting of Bone"Pir Aamir Ali ShahNo ratings yet

- JEE135 Statics 2014 PDFDocument10 pagesJEE135 Statics 2014 PDFChristopher LottNo ratings yet

- Basic Mechanical Course - PlanDocument2 pagesBasic Mechanical Course - PlanSachi DhanandamNo ratings yet

- Introduction Fracture Mechanics PDFDocument82 pagesIntroduction Fracture Mechanics PDFpachieduNo ratings yet

- MECE 3270-Course Outline-2013 Rev01Document6 pagesMECE 3270-Course Outline-2013 Rev01colaarawrNo ratings yet

- Engineering Science Courses for B.Tech. 3rd YearDocument14 pagesEngineering Science Courses for B.Tech. 3rd Yearanwar_fgietaero100% (1)

- BDA 30803 Notes (Student Version - Printable) Sem 2 2012 - 2013 PDFDocument203 pagesBDA 30803 Notes (Student Version - Printable) Sem 2 2012 - 2013 PDFIlenggeswaran Murugesu100% (1)

- Rajasthan Technical University (RTU) Mechanical Engineering YEAR II / SEMESTER III THEORY AND PRACTICALSDocument52 pagesRajasthan Technical University (RTU) Mechanical Engineering YEAR II / SEMESTER III THEORY AND PRACTICALSappannusaNo ratings yet

- Universiti Tenaga Nasional: College of EngineeringDocument7 pagesUniversiti Tenaga Nasional: College of EngineeringSaragadam Naga Shivanath RauNo ratings yet

- Performance Prediction of Nozzleless Solid Rocket Motors Using Numerical SimulationDocument108 pagesPerformance Prediction of Nozzleless Solid Rocket Motors Using Numerical SimulationAlperen BozdemirNo ratings yet

- Mechanical Engineering SyllabusDocument3 pagesMechanical Engineering SyllabusVikram BorkhediyaNo ratings yet

- MEC531 Mechanical Engineering Design Course OverviewDocument7 pagesMEC531 Mechanical Engineering Design Course Overviewarina azharyNo ratings yet

- Chapter 5 - Shaft DesignDocument0 pagesChapter 5 - Shaft DesignwanpudinNo ratings yet

- Behaviour of Spliced Beam TestDocument79 pagesBehaviour of Spliced Beam TestAntonio BarónNo ratings yet

- M.S. in Aerospace Engineering/Master of Aerospace EngineeringDocument2 pagesM.S. in Aerospace Engineering/Master of Aerospace EngineeringShafiq Ahmed ShahbazNo ratings yet

- Prognosis BasicsDocument13 pagesPrognosis BasicsElladaNo ratings yet

- Chasalevris2 CV En2018Document9 pagesChasalevris2 CV En2018Jim ErmeidisNo ratings yet

- Strength1,2 Cource OutlineDocument2 pagesStrength1,2 Cource OutlineBehar AbdurahemanNo ratings yet

- MACHINEDESIGNDocument35 pagesMACHINEDESIGNBrandon AllenNo ratings yet

- Modeling, Analyzing and Safety Aspects of Torsion and Noise Effects On Round Mild Steel Shafts by Response Surface MethodologyDocument10 pagesModeling, Analyzing and Safety Aspects of Torsion and Noise Effects On Round Mild Steel Shafts by Response Surface MethodologymsejjournalNo ratings yet

- B (1) .E Mts I-Viii SemDocument93 pagesB (1) .E Mts I-Viii SemKsav MarinerNo ratings yet

- LP Iii I Mech 55019 (2012-2013)Document22 pagesLP Iii I Mech 55019 (2012-2013)Rahul Kumar KNo ratings yet

- Shivaji University, Kolhapur Syllabus Structure of Second Year (S.E. Auto.) Automobile Engineering Course SchemeDocument45 pagesShivaji University, Kolhapur Syllabus Structure of Second Year (S.E. Auto.) Automobile Engineering Course SchemeAmol KharatNo ratings yet

- Investigation On The Dynamic Properties of PropellDocument11 pagesInvestigation On The Dynamic Properties of PropellAli Osman BayirNo ratings yet

- Construction Science and Management Degree FlowchartDocument1 pageConstruction Science and Management Degree FlowchartAnonymous j6i4n9eduNo ratings yet

- S Y B Tech (Mechanical Engg) SyllabusDocument30 pagesS Y B Tech (Mechanical Engg) SyllabusBhavesh JainNo ratings yet

- Fatigue, Damage Tolerance, and Risk Assessment of Aircraft StructuresDocument4 pagesFatigue, Damage Tolerance, and Risk Assessment of Aircraft Structuresvenkat_venkatNo ratings yet

- S.E. Civil EngineeringDocument36 pagesS.E. Civil Engineering94738183No ratings yet

- Engineering Science CoursesDocument14 pagesEngineering Science Courseschutiya collegeNo ratings yet

- Engineering Design 1 (UTHM)Document203 pagesEngineering Design 1 (UTHM)Azim Isha Mudin100% (2)

- Ptu Syllabus of Mechanical 5TH&6TH SemDocument95 pagesPtu Syllabus of Mechanical 5TH&6TH SemNavdeep Sahrawat100% (1)

- 1st To 4th Semester StructureDocument11 pages1st To 4th Semester StructureMascot DtpNo ratings yet

- Mechanical Engineering Course Structure and Subject DetailsDocument6 pagesMechanical Engineering Course Structure and Subject DetailsMathew JohnNo ratings yet

- 1 Mech 260 PresentationDocument22 pages1 Mech 260 Presentation777894292No ratings yet

- Aero3240 PDFDocument118 pagesAero3240 PDFNaga VineetNo ratings yet

- Comparative Study of Wave Spring and Coil Spring using FEMDocument7 pagesComparative Study of Wave Spring and Coil Spring using FEMKetan JadhavNo ratings yet

- 2-11 Course FileDocument74 pages2-11 Course FilepragatinareshNo ratings yet

- Syllabus DFM 2014Document29 pagesSyllabus DFM 2014sudheer920% (1)

- Major Programme Compulsory) enDocument11 pagesMajor Programme Compulsory) ensilensaNo ratings yet

- The Design of Fatigue Strength Machine Being One of The Methods For Determining The Mechanical Properties of The Materials Used in The IndustryDocument10 pagesThe Design of Fatigue Strength Machine Being One of The Methods For Determining The Mechanical Properties of The Materials Used in The Industryluisbmwm6No ratings yet

- Various Techniques Used For Shaft FailureDocument13 pagesVarious Techniques Used For Shaft Failurelaukik_rautNo ratings yet

- Morphing Aerospace Vehicles and StructuresFrom EverandMorphing Aerospace Vehicles and StructuresJohn ValasekNo ratings yet

- Stress, Vibration, and Wave Analysis in Aerospace Composites: SHM and NDE ApplicationsFrom EverandStress, Vibration, and Wave Analysis in Aerospace Composites: SHM and NDE ApplicationsNo ratings yet

- Book 1 - MtreportDocument44 pagesBook 1 - Mtreportgeorge_vinnNo ratings yet

- Bigsecret (PIANO)Document37 pagesBigsecret (PIANO)kvalex5No ratings yet

- Piano NumbersDocument28 pagesPiano NumbersJimmy MaldonadoNo ratings yet

- Flash Cards 3 - PatternsDocument12 pagesFlash Cards 3 - PatternsKyran LucienNo ratings yet

- Music Transformation Chart PDFDocument1 pageMusic Transformation Chart PDFDocStevensNo ratings yet

- Synonyms for Words A-VDocument6 pagesSynonyms for Words A-VMahir HamdiyevNo ratings yet

- YDS KELİME LİSTESİ 1 – ADJECTIVESDocument9 pagesYDS KELİME LİSTESİ 1 – ADJECTIVESMahir HamdiyevNo ratings yet

- 1700 Toefl WordsDocument262 pages1700 Toefl WordsHanh PhamNo ratings yet

- Piano LessonsDocument29 pagesPiano LessonsJalaludin SikanderNo ratings yet

- Music Transformation Chart PDFDocument1 pageMusic Transformation Chart PDFDocStevensNo ratings yet

- YDS KELİME LİSTESİ 1 – ADJECTIVESDocument9 pagesYDS KELİME LİSTESİ 1 – ADJECTIVESMahir HamdiyevNo ratings yet

- Flash Cards 3 - PatternsDocument12 pagesFlash Cards 3 - PatternsKyran LucienNo ratings yet

- Flow Through Wind Tunnels: 1 Basic EquationsDocument3 pagesFlow Through Wind Tunnels: 1 Basic EquationsMahir HamdiyevNo ratings yet

- Study 4 SolDocument2 pagesStudy 4 SolMahir HamdiyevNo ratings yet

- UCK361E: İ.T.Ü Faculty of Aeronautics & Astronautics Department of Aeronautical EngineeringDocument2 pagesUCK361E: İ.T.Ü Faculty of Aeronautics & Astronautics Department of Aeronautical EngineeringMahir HamdiyevNo ratings yet

- Theoretical Information For The Supersonic Flow ExperimentDocument12 pagesTheoretical Information For The Supersonic Flow ExperimentMahir HamdiyevNo ratings yet

- Modeling The Fluid Flow Around Airfoils UsingDocument30 pagesModeling The Fluid Flow Around Airfoils UsingMahir HamdiyevNo ratings yet

- CHAPTER 9 Flow Over Immersed Bodies (4 Edition)Document4 pagesCHAPTER 9 Flow Over Immersed Bodies (4 Edition)Mahir HamdiyevNo ratings yet

- CHAPTER 9 Flow Over Immersed Bodies (4 Edition)Document4 pagesCHAPTER 9 Flow Over Immersed Bodies (4 Edition)Mahir HamdiyevNo ratings yet

- Jet Akis Deneyi - Teorik BilgiDocument4 pagesJet Akis Deneyi - Teorik BilgiMahir HamdiyevNo ratings yet

- Flow Through Wind Tunnels: 1 Basic EquationsDocument3 pagesFlow Through Wind Tunnels: 1 Basic EquationsMahir HamdiyevNo ratings yet

- Pre-Columbian Islamic Presence in the AmericasDocument9 pagesPre-Columbian Islamic Presence in the AmericasMahir HamdiyevNo ratings yet

- CHAPTER 9 Flow Over Immersed Bodies (4 Edition)Document4 pagesCHAPTER 9 Flow Over Immersed Bodies (4 Edition)Mahir HamdiyevNo ratings yet

- Modeling The Fluid Flow Around Airfoils UsingDocument30 pagesModeling The Fluid Flow Around Airfoils UsingMahir HamdiyevNo ratings yet

- RC Build FlyDocument46 pagesRC Build FlyBlashko GjorgjievNo ratings yet

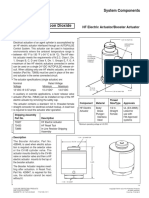

- System Components: HF Electric Actuator/Booster ActuatorDocument1 pageSystem Components: HF Electric Actuator/Booster ActuatorBryan ShanahanNo ratings yet

- Selection of Fans For Thermal PDFDocument188 pagesSelection of Fans For Thermal PDFhardik033No ratings yet

- Catalog 63 English MetricDocument186 pagesCatalog 63 English MetricWilfredo Suarez TorresNo ratings yet

- CoverDocument3 pagesCoverBaxter LoachNo ratings yet

- 12,000 LBS. (5 443 KG) : - Wheel Hubs-Requires No Maintenance-Permanently Sealed With GreaseDocument2 pages12,000 LBS. (5 443 KG) : - Wheel Hubs-Requires No Maintenance-Permanently Sealed With GreaseGustavo MosqueraNo ratings yet

- 4HH High Head Pump: Highly Efficient Clear Liquid Pump Max. 350 M /hour, Max. 120 MWCDocument2 pages4HH High Head Pump: Highly Efficient Clear Liquid Pump Max. 350 M /hour, Max. 120 MWCGonzalez NicolasNo ratings yet

- Report On Stress Concentration FactorsDocument10 pagesReport On Stress Concentration Factorsrahulsinha592100% (1)

- Mechanics of Materials SyllabusDocument3 pagesMechanics of Materials SyllabusgundulpNo ratings yet

- MEBS6006 Environmental Services I Psychrometric AnalysisDocument52 pagesMEBS6006 Environmental Services I Psychrometric Analysisahtin618100% (2)

- OS ABB Comem BR EN 16-05-2018Document12 pagesOS ABB Comem BR EN 16-05-2018RosaFNo ratings yet

- U of A ANSYS Tutorials - Effect of Self WeightDocument5 pagesU of A ANSYS Tutorials - Effect of Self WeightJean David ChanNo ratings yet

- Ceco Brochure PDFDocument8 pagesCeco Brochure PDFNguyễn Thanh Bình50% (2)

- Dynamic Vibration Absorbers and Its Applications: Nils Wagner & Reinhard Helfrich Intes GMBHDocument20 pagesDynamic Vibration Absorbers and Its Applications: Nils Wagner & Reinhard Helfrich Intes GMBHصبا رياض فتاح الرفاعيNo ratings yet

- Water Rocket InstructionsDocument4 pagesWater Rocket InstructionsbadmintNo ratings yet

- Excavator Hydraulic Pump From Bailyn 20210616Document1 pageExcavator Hydraulic Pump From Bailyn 20210616luisNo ratings yet

- Unit 1 Fundamentals of RobotisDocument24 pagesUnit 1 Fundamentals of RobotisdeepakNo ratings yet

- MotorDocument2 pagesMotorKeLvinLazyBoyNo ratings yet

- Submersible Semi-Vortex Sewage Pumps: Applications FeaturesDocument7 pagesSubmersible Semi-Vortex Sewage Pumps: Applications FeaturesSukmo AbadiNo ratings yet

- Microsoft PowerPoint - PACS 350 Lansering 350 - 46Document57 pagesMicrosoft PowerPoint - PACS 350 Lansering 350 - 46Danem HalasNo ratings yet

- Credits: 112 Out of 133 CGPA: 6.21: Regd. NO: 18NH1A0316 Student Name: Nagidi Hijkiya RajuDocument1 pageCredits: 112 Out of 133 CGPA: 6.21: Regd. NO: 18NH1A0316 Student Name: Nagidi Hijkiya RajuKattula Anil kumarNo ratings yet

- 2.3-Circular MotionDocument2 pages2.3-Circular MotionSaina BhatiaNo ratings yet

- Economizer welding mapDocument22 pagesEconomizer welding mapMuhammad Fitransyah Syamsuar Putra100% (2)

- Omni-Directional Mobile Robot With Mecanum WheelDocument6 pagesOmni-Directional Mobile Robot With Mecanum WheelTRUNG QUOC LENo ratings yet

- ZX380LC 5Document4 pagesZX380LC 5ferdyak1No ratings yet

- TR Cat Ramob STD Eng R03 0Document44 pagesTR Cat Ramob STD Eng R03 0pham duongNo ratings yet

- DNCSDocument20 pagesDNCSksankar_2005No ratings yet

- Repair Case Wheel Loader Hydraulic Bypass SystemDocument3 pagesRepair Case Wheel Loader Hydraulic Bypass SystemLeandro SalNo ratings yet

- Solution Machine DesignDocument9 pagesSolution Machine DesignRaDaCa CabsNo ratings yet

- Ae708 Question Bank 2Document5 pagesAe708 Question Bank 2pRoBoTRoGe OPNo ratings yet