Professional Documents

Culture Documents

Titrimetric Analysis of Biofuels: Acid Number in Biodiesel (EN 14104) Sulfate Content in Bioethanol (ASTM D 7318)

Uploaded by

terepzkdoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Titrimetric Analysis of Biofuels: Acid Number in Biodiesel (EN 14104) Sulfate Content in Bioethanol (ASTM D 7318)

Uploaded by

terepzkdoCopyright:

Available Formats

Titrimetric analysis of biofuels

Summary

Acid number in biodiesel (EN 14104)

Sulfate content in bioethanol (ASTM D 7318)

The DIN EN 14214 biodiesel standard stipulates a non-aqueous potentiometric

acid-base titration for determining the acid number and a redox titration with

sodium thiosulfate solution for the determination of the iodine number. While in

the first case the equivalence point is detected by the Solvotrode, the iodine

number is determined using a Pt Titrode. Both methods are very user-friendly and

characterized by high accuracy and precision. With an acid number of

0.202 mg/g and a iodine number of 114.4 g I2/100 g, the investigated biodiesel

sample complies with the limits of 0.5 mg/g and 120 g I2/100g stipulated in DIN

EN 14214.

Between 14 and 15 g of the biodiesel sample are dissolved in 50 mL of a

bioethanol/diethyl ether mixture (1:1). The titrant is an alcoholic solution

of potassium hydroxide (0.1 mol/L). After each titration the Solvotrode is

thoroughly rinsed with isopropyl alcohol. The regeneration of the membrane is

achieved by immersing the electrode in water for at least three minutes.

ASTM D 7318 in ASTM D 4806 prescribes a potentiometric titration procedure for

the determination of sulfate.

100 g of the bioethanol sample is spiked with known amounts of a sulfate

standard. After the addition of 1 mL of 0.1 mol/L perchloric acid the sulfate is

precipitated with a lead nitrate solution. The Pb-selective electrode detects the first

excess of lead ions at the equivalence point. A double-junction Ag/AgCl or a

glassy-carbon-rod electrode are used as the reference electrode.

According to ASTM D 4806, potentiometric titration of total sulfate in bioethanol

with lead nitrate can be performed using a Pb-selective working electrode and a

double-junction Ag/AgCl or a glassy-carbon-rod reference electrode. Although

both reference electrodes show comparable recovery rates, the latter needs lower

maintenance. For both electrodes the ideal operating range is between 1 and 20

ppm sulfate. Corresponding recovery rates are 98109%. Increasing the sulfate

standard and the perchloric acid content in commercial bioethanol blends (E85)

allows to monitor sulfate contents in the sub-ppm range.

Introduction

The interest in biofuels obtained from renewable vegetable sources has greatly

increased in recent years. The reasons are the increasing demand for mineral oil as

well as the environmental problems linked with burning fossil fuels. In order to

avoid disturbances in the injection system and in the engine itself, vehicle and

biofuel manufacturers have developed quality standards that define testing

methods and specifications for biofuels. While there are two major biodiesel

standards, the European EN 14214 and the American ASTM D 6751, there

currently exists only one major bioethanol standard, the ASTM D 4806. Its

European equivalent, the EN 15376, is currently under development.

The determination of the water content of biogenic engine fuels is beyond the

scope of this work and is presented under http://products.metrohm.com (search

for 8.000.6030EN).

Acid number in biodiesel according to EN 14104

The acid number is a sum parameter comprising all acidic components; it serves as

a measure for the long-term stability and corrosiveness of the biofuel. The smaller

the value, the higher the quality. Standard EN 14104 in DIN EN 14214 stipulates a

non-aqueous potentiometric acid-base titration for determining the acid number.

Iodine number in biodiesel according to EN 14111

The iodine number is a measure for the number of double bonds in a sample. It

specifies the amount of iodine in g that are consumed by 100 g of the biodiesel

sample under the given conditions. The determination of the iodine number by

redox titration with a solution of sodium thiosulfate is described by the European

standard EN 14111.

Titer

Acid number

Mean value

0.987

0.202 mg/g

Standard deviation

0.003

0.002 mg/g

Relative standard deviation

0.34%

0.94%

Number of determinations n

The acid number determined in the biodiesel sample, in terms of mg KOH per g

biodiesel, is 0.202 mg/g. This value complies with the requirements of ASTM D

6751 and EN 14214, which both stipulate a maximal acid number of

0.50 mg/g.

Iodine number in biodiesel (EN 14111)

For the titer determination 50 mg potassium iodate, oven-dried overnight, is

dissolved in 80 mL distilled water. After

the addition of approximately 1 g of

228.545

potassium iodide and 10 mL of sulfuric acid, the released elemental iodine is

titrated with 0.1 mol/L sodium thiosulfate solution. Potentiometric endpoint

detection occurs with a Pt Titrode.

Conc.

[ppm]

0.998

Determinations n

Titer

1.0155

1.0188

1.0210

Mean value

1.0184

Standard deviation

0.0027

Relative standard deviation

0.27%

Blank

Biodiesel

47.71

33.79

Iodine number [g iodine/100 g sample]

114.40

Standard deviation

0.50

Relative standard deviation [%]

0.44

Mean value thiosulfate consumption [mL]

0.978

0.81

98.0

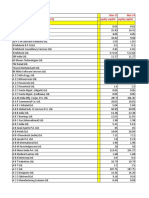

Glassy-Carbon-Rod Electrode

Sulfate conc.a RSDb nc

Recovery rate

[%]

[%]

[ppm]

1.063

1.46

106.5

4.989

5.229

0.41

104.8

5.268

0.23

105.6

9.978

10.047

0.52

100.7

10.063

0.24

100.9

19.965

21.627

1.08

108.3

21.735

0.75

108.9

sulfate concentrations determined by potentiometric titration, brelative standard deviation, cnumber of determinations

While sulfate concentrations between 5 and 10 ppm result in recovery rates of

100.7...105.6%, sulfate contents of 1 and 20 ppm provide recovery rates of

98.0...106.5% and 108.3...108.9%, respectively.

0.15 g of the biodiesel sample is dissolved in 20 mL glacial acetic acid and treated

with 25 mL Wijs reagent. After 5 minutes, 15 mL potassium iodide is added. The

released elemental iodine is then titrated with 0.1 mol/L sodium thiosulfate

solution up to the first end point.

Number of determinations n

Double-Junction Ag/AgCl Reference Electrode

Sulfate conc.a RSDb nc

Recovery rate

[%]

[%]

[ppm]

Sulfate content of an E85 bioethanol sample

The low sulfate content in commercial bioethanol fuel blends results in a marginal

consumption of lead nitrate, thus impairing the standard deviation. Moreover, a

possible lead carbonate formation and weighing errors from evaporation losses

falsify the results. In the following, we evaluate the influence of increased sulfate

standard and perchloric acid addition on the method precision.

Bioethanol sample E 85

na

Concentration

[mg sulfate/kg sample]

RSDb

[%]

0.348

4.81

2.087

0.27

+ 0.2 mL sulfate standard (blank)

+ 1.0 mL perchloric acid (0.1 mol/L)

+ 0.4 mL sulfate standard (blank)

+ 2.0 mL perchloric acid (0.1 mol/L)

a

number of titrimetric analyses, brelative standard deviation

Sulfate content in bioethanol according to ASTM D 7318

Potentiometric titration with lead nitrate is a proven method for sulfate

determination, a Pb ISE serving as the indicator electrode. The latter detects the

first excess of lead ions at the equivalence point.

Download a copy of this poster from http://products.metrohm.com (search for 8.000.6020EN).

The investigated biodiesel sample has a iodine value of 114.4 and thus meets the

requirements of EN 14111, which allows a maximal value of 120 g iodine per

100 g sample.

The precision of the determinations is significantly improved by dublicating the

content of perchloric acid and sulfate standard.

The observed sulfate concentration of 2.087 ppm is below the limit of 4 pm

stipulated by ASTM D 4806.

Metrohm AG, CH-9101 Herisau/Switzerland, hc@metrohm.com, phone +41 71 353 86 52

Titration

C. Haider and G. Spinnler

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Edwin EmulsificationDocument3 pagesEdwin EmulsificationDaniel LieNo ratings yet

- PSV Calculation Report - 2-Phase - Direct Method Sizing CaseDocument1 pagePSV Calculation Report - 2-Phase - Direct Method Sizing CaseDaniel LieNo ratings yet

- PRD Calculation Report - Fire Load CaseDocument1 pagePRD Calculation Report - Fire Load CaseDaniel LieNo ratings yet

- Imr Chart Example: Viscosity of Initial 20 Batches of Aircraft Primer PaintDocument2 pagesImr Chart Example: Viscosity of Initial 20 Batches of Aircraft Primer PaintDaniel LieNo ratings yet

- 2 ChlorobutaneDocument5 pages2 ChlorobutaneDaniel LieNo ratings yet

- Material Safety Data Sheet U.S. Department of Labor: Section IDocument2 pagesMaterial Safety Data Sheet U.S. Department of Labor: Section IDaniel LieNo ratings yet

- Ekstraksi Senyawa Organik Asam, Basa, NetralDocument6 pagesEkstraksi Senyawa Organik Asam, Basa, NetralDaniel LieNo ratings yet

- LucasDocument1 pageLucasDaniel LieNo ratings yet

- How Clothing Evolves: Daniel-XII IPA 3-7Document4 pagesHow Clothing Evolves: Daniel-XII IPA 3-7Daniel LieNo ratings yet

- 2.c.5.a Copper Production GB2009Document20 pages2.c.5.a Copper Production GB2009Daniel LieNo ratings yet

- Mechanism of Cannizzaro ReactionDocument8 pagesMechanism of Cannizzaro ReactionDaniel LieNo ratings yet

- Brown Stock WashingDocument5 pagesBrown Stock WashingDaniel LieNo ratings yet

- Basic Troubleshooting (Disc Saveall)Document7 pagesBasic Troubleshooting (Disc Saveall)Daniel Lie100% (1)

- Aluminum Alkyl HalidesDocument6 pagesAluminum Alkyl HalidesDaniel LieNo ratings yet

- Blanco 1989 JoCEDocument3 pagesBlanco 1989 JoCEDaniel LieNo ratings yet

- Vertical Termosyphon Reboiler: Light Naphtha (XDocument1 pageVertical Termosyphon Reboiler: Light Naphtha (XDaniel LieNo ratings yet

- M.S - C P I E F: Name First Name Student Number SignatureDocument6 pagesM.S - C P I E F: Name First Name Student Number SignatureDaniel LieNo ratings yet

- Postgraduate Prospectus For 2014 EntryDocument296 pagesPostgraduate Prospectus For 2014 EntryDaniel LieNo ratings yet

- Enthalpy of Vaporization LabDocument5 pagesEnthalpy of Vaporization LabDaniel LieNo ratings yet

- Nutrition FactsDocument1 pageNutrition FactsDaniel LieNo ratings yet

- Likes and DislikesDocument4 pagesLikes and DislikesgabysoteloNo ratings yet

- Zool 322 Lecture 2 2019-2020Document24 pagesZool 322 Lecture 2 2019-2020Timothy MutaiNo ratings yet

- Hockey Stick 1Document1,617 pagesHockey Stick 1sabyasachi sarkarNo ratings yet

- Nutrition Through-Out Lifespan (Infancy)Document37 pagesNutrition Through-Out Lifespan (Infancy)Vincent Maralit MaterialNo ratings yet

- COVID-19 Vaccine and Guillain-Barré Syndrome: Let's Not Leap To AssociationsDocument10 pagesCOVID-19 Vaccine and Guillain-Barré Syndrome: Let's Not Leap To AssociationsAsok DattaNo ratings yet

- 3rd - Sem-Ct-23-Chemical EngineeringDocument3 pages3rd - Sem-Ct-23-Chemical EngineeringJay RanjanNo ratings yet

- Short Tricks To Remember GK EasilyDocument3 pagesShort Tricks To Remember GK EasilyManoj KiningeNo ratings yet

- Waxman Et Al., 2004: AnalysisDocument2 pagesWaxman Et Al., 2004: AnalysisAmanodin E. TambakNo ratings yet

- MankindDocument23 pagesMankindanandkas2005100% (1)

- ĐỀ 9Document4 pagesĐỀ 9Hau NgoNo ratings yet

- Adjust Risks, Threats, and Vulnerabilities With COBIT PO9 Risk Management ControlsDocument2 pagesAdjust Risks, Threats, and Vulnerabilities With COBIT PO9 Risk Management ControlsHenry WiliamNo ratings yet

- Individual TAXDocument6 pagesIndividual TAXPushpa ValliNo ratings yet

- Bài tập thì Quá khứ đơn-Quá khứ tiếp diễnDocument8 pagesBài tập thì Quá khứ đơn-Quá khứ tiếp diễnÁnh Hồng100% (1)

- Solar Direct-Drive Vaccine Refrigerators and Freezers: The Need For Off-Grid Cooling OptionsDocument10 pagesSolar Direct-Drive Vaccine Refrigerators and Freezers: The Need For Off-Grid Cooling OptionsRolando mendozaNo ratings yet

- Anabolic PDFDocument21 pagesAnabolic PDFNe MiNo ratings yet

- Motor Disturbance in ChildrenDocument84 pagesMotor Disturbance in ChildrenYuri BrosgolNo ratings yet

- History of Co-Operative Credit Society in IndiaDocument14 pagesHistory of Co-Operative Credit Society in IndiaTerry YanamNo ratings yet

- Star Bazaar Koramangala - Google SearchDocument1 pageStar Bazaar Koramangala - Google SearchChris AlphonsoNo ratings yet

- Latsol Pat Ing - 11 Ipa Mei 2023Document3 pagesLatsol Pat Ing - 11 Ipa Mei 2023primagama sragenNo ratings yet

- Advanced Structural Design - Lecture Note 03Document29 pagesAdvanced Structural Design - Lecture Note 03cdmcgc100% (1)

- Brunei 2Document16 pagesBrunei 2Eva PurnamasariNo ratings yet

- 3 - Life History TraitsDocument16 pages3 - Life History TraitsJorge Botia BecerraNo ratings yet

- Lymph Node - Any of The Small, Oval or Round Bodies, Located Along The Lymphatic VesselsDocument2 pagesLymph Node - Any of The Small, Oval or Round Bodies, Located Along The Lymphatic VesselsKaren ParraNo ratings yet

- Immortality of Eating MeatDocument7 pagesImmortality of Eating MeatSumit KapoorNo ratings yet

- G3520 Lehe2832 02 PDFDocument6 pagesG3520 Lehe2832 02 PDFCostas Aggelidis100% (1)

- (PDF) Concrete Cracks Repair Using Epoxy ResinDocument18 pages(PDF) Concrete Cracks Repair Using Epoxy ResinAakanksha SaxenaNo ratings yet

- Journal of Drug Delivery Science and TechnologyDocument11 pagesJournal of Drug Delivery Science and TechnologyNguyen PhuongNo ratings yet

- Iron Deficiency AnemiaDocument16 pagesIron Deficiency AnemiaSaboorMalikNo ratings yet

- Introduction To Chemical BondingDocument5 pagesIntroduction To Chemical BondingMini PGNo ratings yet

- Psychiatric Nurse's Role As Member of The Research TeamDocument3 pagesPsychiatric Nurse's Role As Member of The Research TeamKim Tango100% (1)