Professional Documents

Culture Documents

Oil Seal Designs

Uploaded by

Gayashan KulathungaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Oil Seal Designs

Uploaded by

Gayashan KulathungaCopyright:

Available Formats

Oil Seal Design

Rubber cover O.D. for

improved O.D. sealing

ability.

Metal O.D. with ground

surface and front chamfer.

Metal O.D. with

an inner case.

SC

SB

SA

TC

TB

TA

VC

VB

VA

KC

KB

KA

Single lip

with a garter

spring.

Dual lip with

a garter

spring.

Single lip

without a

garter spring.

Dual lip

without a

garter spring.

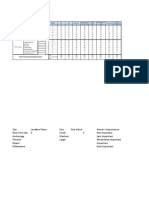

Lip Material:

It is very important to take

into account the environment

in which the seal will operate

when you are selecting the

sealing element material. The

most important factors are

temperature, medium being

sealed, pressure, and shaft

speed.

The table and figures to the

right provide general

information to help select the

compound according to

physical property.

Compound

Nitriles

(Code N)

Poly Acrylates

(Code P)

Silicone

(Code S)

Temperature Range

Abrasion Resistance

Compression Set

Cracking Resistance

Cut Growth Resistance

Flex Cracking Resistance

Impact Strength

Low Temperature Resistance

Oxidation Resistance

Sun Light Resistance

Tear Resistance

Weathering resistance

-40 to 248F

2

2

3

2

3

2

2

2

3

2

2

-22 to 302F

3

3

3

2

3

4

4

1

1

4

1

-58 to 356F

4

2

1

4

2

3

1

1

1

4

1

Fluoro Rubber

Viton

(Code V)

-22 to 392F

2

2

2

4

2

3

2

1

1

3

1

1 = Excellent

2 = Good

3 = Fair

4 = Poor

Note:

125 Parker Court I Chardon, Ohio 44024 I P: 440-285-9594 I F: 440-285-3845 I www.gbsa.com

You might also like

- 03 Cutterbit PDFDocument6 pages03 Cutterbit PDFsanty222No ratings yet

- QC SkillDocument31 pagesQC SkillJagdish100% (1)

- ALLOY-20 - FI - US - EN Very Good All AboutDocument55 pagesALLOY-20 - FI - US - EN Very Good All Aboutmahmoud_allam3No ratings yet

- Section 18 Design of Plastic Gears PDFDocument15 pagesSection 18 Design of Plastic Gears PDFSergio CandiottiNo ratings yet

- API 934 Minutes Fluor ATT CDocument28 pagesAPI 934 Minutes Fluor ATT CAnonymous rUs4PjYo5No ratings yet

- Sany HBT80C-1818DIIIDocument1 pageSany HBT80C-1818DIIIGayashan KulathungaNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- AGS Gaskets TrainingDocument31 pagesAGS Gaskets TrainingMee WinNo ratings yet

- Project Report On Aluminium ExtrusionDocument8 pagesProject Report On Aluminium ExtrusionEIRI Board of Consultants and PublishersNo ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Presentation For Mathura Site RCC - WorkDocument143 pagesPresentation For Mathura Site RCC - WorkAnbu100% (1)

- EngineeringWithCladSteel2ndEd PDFDocument24 pagesEngineeringWithCladSteel2ndEd PDFUNIISCRIBDNo ratings yet

- Corrosion Control of Marine StructuresDocument35 pagesCorrosion Control of Marine StructuresCong-OanhNguyenNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Catalogo JuntasDocument49 pagesCatalogo Juntasdavidmn19100% (1)

- CK404Document8 pagesCK404Manoj KumarNo ratings yet

- 10 - Cutting Tool MaterialsDocument5 pages10 - Cutting Tool MaterialsEko Feri BudiNo ratings yet

- Bit Technology: Bit Technology Additional Reading Available at The Spe ElibraryDocument9 pagesBit Technology: Bit Technology Additional Reading Available at The Spe ElibrarymvkellyNo ratings yet

- Code Code 120 120 15 15: Construction and Materials Hot Side Cold SideDocument1 pageCode Code 120 120 15 15: Construction and Materials Hot Side Cold SideAnonymous a4Jwz14WNo ratings yet

- Resistência 1Document11 pagesResistência 1ricobimNo ratings yet

- DataDocument39 pagesDataJunghoon LeeNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Production Technology Ch21Document16 pagesProduction Technology Ch21Nimmagadda BharathNo ratings yet

- Sikabond® at Metal: Product Data SheetDocument3 pagesSikabond® at Metal: Product Data SheetHarjasa AdhiNo ratings yet

- Desempeño Sismico de Una Columna Rectangular Formado en Frio Conectado Al DiafragmaDocument9 pagesDesempeño Sismico de Una Columna Rectangular Formado en Frio Conectado Al DiafragmaSebastian Contreras ContrerasNo ratings yet

- Devcon Plastic Steel Putty (A) - TDSDocument3 pagesDevcon Plastic Steel Putty (A) - TDSsibi_s_raj100% (2)

- Dycote : ManualDocument30 pagesDycote : ManualG Alex QSNo ratings yet

- RTV Silicone SealantDocument2 pagesRTV Silicone SealantDaniel Salazar CruzNo ratings yet

- Pressure Vessels AsmeDocument45 pagesPressure Vessels AsmeetayhailuNo ratings yet

- Wear of Flame-Sprayed Ni-Cr-B-Si Powder Coating On Journal For Seal ContactDocument6 pagesWear of Flame-Sprayed Ni-Cr-B-Si Powder Coating On Journal For Seal Contactmuhammad abduhNo ratings yet

- En 24Document1 pageEn 24V. A. TripathiNo ratings yet

- Sikadur 42 MP NormalDocument7 pagesSikadur 42 MP NormalcharlessimoNo ratings yet

- Performance Test of Cryogenically Treated and Coated Tungsten Carbide Cutting InsertsDocument5 pagesPerformance Test of Cryogenically Treated and Coated Tungsten Carbide Cutting InsertsfacebookdeepuNo ratings yet

- HASTELLOY® C-22HS™alloyDocument16 pagesHASTELLOY® C-22HS™alloyYudha SatriaNo ratings yet

- Sika Anchorfix - 1: Fast Curing Anchoring AdhesiveDocument6 pagesSika Anchorfix - 1: Fast Curing Anchoring Adhesiveeye4aneye1989No ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Alloy Solution To Marine Fastener ProblemsDocument10 pagesAlloy Solution To Marine Fastener ProblemsBackia LakshmiNo ratings yet

- Orifice PlatesDocument12 pagesOrifice PlatesPhaitoon PudsriNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Primary Met Final SpreadsDocument5 pagesPrimary Met Final SpreadsPablo GarciaNo ratings yet

- Es805-001 Rev 4 Decorative Chrome PlatingDocument7 pagesEs805-001 Rev 4 Decorative Chrome PlatingFrancisco BocanegraNo ratings yet

- Super 00Cr Stainless Steel Sucker Rod IntroductionDocument15 pagesSuper 00Cr Stainless Steel Sucker Rod IntroductionKevin XuNo ratings yet

- 2 - Sikadur-42 PC - PDS - GCC - (05-2018) - 2 PDFDocument5 pages2 - Sikadur-42 PC - PDS - GCC - (05-2018) - 2 PDFAkhil VelayudhanNo ratings yet

- 110 00 Training Guide Rev 1Document30 pages110 00 Training Guide Rev 1vilegual1No ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- PVD Coating-ADocument12 pagesPVD Coating-Arijoy p pNo ratings yet

- Corrosion Resistant OCTG and Bar For Sour Gas Service PDFDocument14 pagesCorrosion Resistant OCTG and Bar For Sour Gas Service PDFallouche_abdNo ratings yet

- Impact: Wear Resistant SteelDocument6 pagesImpact: Wear Resistant SteelmazuckNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Design With 316 SS For SCC in Sodium Chloride SolutionsDocument33 pagesDesign With 316 SS For SCC in Sodium Chloride Solutionsanon_410770000No ratings yet

- Corrosion in Sodium Hydroxide - Assignment-1Document5 pagesCorrosion in Sodium Hydroxide - Assignment-1NITIN KUMARNo ratings yet

- Pressure Vessel Inspection ReportDocument33 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- MSF 618-619 591Document4 pagesMSF 618-619 591Barak VinklerNo ratings yet

- 198 Faf2500 Flanged y Type StrainerDocument4 pages198 Faf2500 Flanged y Type Strainerinfo8176No ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Advances in Ceramic Armor XIFrom EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNo ratings yet

- Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IIFrom EverandAdvanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials IITatsuki OhjiNo ratings yet

- Advances in Solid Oxide Fuel Cells and Electronic CeramicsFrom EverandAdvances in Solid Oxide Fuel Cells and Electronic CeramicsNo ratings yet

- Exploring corrective conjunctionsDocument14 pagesExploring corrective conjunctionsGayashan KulathungaNo ratings yet

- The Design Squad: Project Information Sheet The ClientDocument2 pagesThe Design Squad: Project Information Sheet The ClientGayashan KulathungaNo ratings yet

- RatesDocument1 pageRatesGayashan KulathungaNo ratings yet

- 10 Descriptive Writing TipsDocument11 pages10 Descriptive Writing TipsGayashan KulathungaNo ratings yet

- CircularDocument6 pagesCircularGayashan KulathungaNo ratings yet

- Whole Foods Demonstration KitchenDocument17 pagesWhole Foods Demonstration KitchenGayashan KulathungaNo ratings yet

- MSD 2016 02SDocument86 pagesMSD 2016 02SGayashan KulathungaNo ratings yet

- Technical Papers Format - 2017Document3 pagesTechnical Papers Format - 2017Gayashan KulathungaNo ratings yet

- World Food Day & Boss'S Day: Good Morning Wayners, Happy WednesdayDocument1 pageWorld Food Day & Boss'S Day: Good Morning Wayners, Happy WednesdayGayashan KulathungaNo ratings yet

- 8350 FCM2041-U3 Cerberus PRO Modular Operator InterfaceDocument4 pages8350 FCM2041-U3 Cerberus PRO Modular Operator InterfaceGayashan KulathungaNo ratings yet

- Study About Energy Saving Control Strategies For Variable Air Volume SystemsDocument2 pagesStudy About Energy Saving Control Strategies For Variable Air Volume SystemsGayashan KulathungaNo ratings yet

- View Factor TablesDocument2 pagesView Factor TablesGayashan KulathungaNo ratings yet

- Burn Stomach Fat Fast by Drinking This Before Going To Bed - Wishma LokayaDocument2 pagesBurn Stomach Fat Fast by Drinking This Before Going To Bed - Wishma LokayaGayashan KulathungaNo ratings yet

- Vesak PPT - Implementation Details 7.02.2017Document19 pagesVesak PPT - Implementation Details 7.02.2017Gayashan KulathungaNo ratings yet

- Lighting CalculationsDocument8 pagesLighting CalculationsGayashan KulathungaNo ratings yet

- MATLABDocument1 pageMATLABGayashan KulathungaNo ratings yet

- Ezv 440Document2 pagesEzv 440Gayashan KulathungaNo ratings yet

- Fan Coil Filters: AdvantagesDocument1 pageFan Coil Filters: AdvantagesGayashan KulathungaNo ratings yet

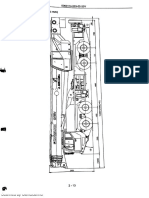

- Zoomlion QY55V - Overall DimensionDocument2 pagesZoomlion QY55V - Overall DimensionGayashan KulathungaNo ratings yet

- DS-2B - Rain / Snow Sensor ControllerDocument2 pagesDS-2B - Rain / Snow Sensor ControllerGayashan KulathungaNo ratings yet