Professional Documents

Culture Documents

Full Auto Glock Conversion Manual

Full Auto Glock Conversion Manual

Uploaded by

elvergonzalez10 ratings0% found this document useful (0 votes)

368 views12 pagesFull Auto Glock Conversion Manual

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFull Auto Glock Conversion Manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

368 views12 pagesFull Auto Glock Conversion Manual

Full Auto Glock Conversion Manual

Uploaded by

elvergonzalez1Full Auto Glock Conversion Manual

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

FullAutoGlock

CONVERT YOUR GLOCK TO FULL-AUTO

CHOOSE YOUR FIREPOWER: SEMI OR FULL-AUTO

Please visit the bureau of Alcohol Tobacco and Firearms website at wwwatf.treas.gov

and read the laws regarding the conversion of firearms to fully automatic fire:

Translated loosely, the legal jargon says that unless the finished device is registered

with the ATF, or you possess special exempting qualifications, it is illegal to possess the

finished device or pieces whether or not it is installed on a Glock handgun.

Glock is a registered trademark of Glock Ges.m.b.H. and has no affiliation with this

device.

FullAutoGlock

Material to be C-1015 or C-1020 (standard mild steel) or equivalent. No special steel or

exotic composite materials are required in the production of this device.

A finish of 150 microinches rms is standard.

The individual parts do not need to be Rockwell "C" scale heat treated.

Break all sharp edges to R. 1/16 MAX with 1/32 ok.

All fillets to R. 1/16 MAX with 1/32 ok.

Painting of the end cap and selector switch may be desired to give the device an

Original Equipment Manufacturer (OEM) look. It is not recommended to paint the sear.

Once you have ATF approval to own this device, please familiarize yourself with the

names and functions of the three following pieces:

Disconnector

Selector Rod

ee

and Conversion Back Plate or End Cap. These three parts will replace the existing black

plastic end cap located on the rear of your Glock slide. The following pictures show the

Your full-auto modification device consists of three parts: Selector Rod, Disconnector,

assembled device and the two positions for the selector rod,

Selection:

(1) Small post extended equals

Full auto function

. {2) Small post hidden equals

Semi Auto Full Auto Semi auto function

When the selector rod is positioned for full auto firepower, you contro! how long your

Glock fires through trigger action. A quick trigger pull will release a short burst and a

trigger pull and hold will empty all the rounds in your Glock magazine.

INSTALLATION PROCEDURE (providing you have ATF approval)

1) No one has ever been accidently shot while servicing an unloaded firearm. Now,

knowing and agreeing with this truth, please remove your Glock magazine AND the

CHAMBER ROUND before beginning the assembly steps.

2) Pull back the slide of your Glock handgun and lock it open by applying upward

‘pressure on the slide release. While you may prefer to, it is not necessary to remove

the slide to install your full-auto modification device. A small screwdriver or pointed

key is all that is needed to remove the black plastic end cap on the rear of your Glock

slide.

3) Position the small screwdriver between the metal firing pin notch and the plastic

firing pin jacket. Use the small screwdriver to lever the plastic firing pin jacket away

from the metal firing pin notch. While your are holding back the firing pin jacket,

remove the black plastic end cap by lifting it out or prying it out. Note the small spring

loaded extractor plunger that is now exposed.

4) Assemble the full-auto device and set aside. Now use the small screwdriver to

again lever the plastic firing pin jacket away from the metal firing pin notch. Siip the

assembled device into the empty end cap slots. Now use the screwdriver to push back

the small spring loaded extractor plunger to allow the fully assembled device to fully

seat into the end cap slots.

5) The last step before test firing is to pull and release the slide ten to twenty times to

create a small channel for the disconnector in the frame, Refer to the previous photos

for setting the selector switch to semi or full-auto fire. Once the positions have been

committed to memory, it is time to test fire your new Glock handgun!

TROUBLESHOOTING

If your Glock slide does not close fully: First check to make sure you do not have extra

parts left over! Only the black plastic end cap should be extra. Then check to see that

the device is FULLY seated in the end cap slots. If the device is unseated even a

fraction of an inch, it will cause your slide to not close all the way. If this is still not the

cause, please repeat step 5. The disconnector must create a small channel in the

frame to allow the slide to operate freely.

If your Glock handgun fires full auto in BOTH selector rod positions, disassemble the

device and follow the instructions on the modification page. Due to the fact that all

Glock handguns have slightly different tolerances, the disconnector measurements

compensate for this fact. You will need to shorten the disconnector by following the

instructions on the following page. Remove extremely small amounts and test after

each small modification until the problem no longer persists. It is vitally important that.

you remove only small portions between testings because if your Glock fires semi-auto

in both selector rod positions after filing, you have removed too much and will need to

get 2 new disconnector machined.

Disconnector Modification:

Method (1)

Disconnector Dremel = Sut ort Wheel

Area to pe

Retouche

>

. =a Vice / Support

Instructions:

(1) Use a Dremel™ tool and a # 409 cut off wheel for

use in disconnector modification

(2) Carefully secure the disconnector in a vice

(3) Modify ONLY the area specified

(4) Remove extremely small amounts each time

Disconnector Modification:

Method (2) ve

Di t Back and forth -

isconnector motion _ Zo

Area to be

ms Sharpening Stone

Instructions:

(1) Move the disconnector back and forth on the

sharpening stone

(2). Modify ONLY the area specified

(3) Remove extremely SMALL amounts each time

(4) Test device after each SMALL modification

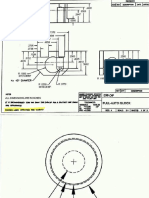

0787 DEEP

4x 45° CHAMFER

NOTES

ALL DIMENSIONS ARE IN INCHES

ITIS RECOMMENDED THAT Yeu Panrr Thar ENDcAD FoR A FACTORY Livi FINISH

AND APPEARANCE:

0010 DEEP

[ev[arr[ bescrTion

[ARE INCHES AND ARE PER

FULL-AUTO GLOCK

SCALE: si | SHEET: 1 OF 3

aoe [aoe Lea

ond rev

R 1800,

0787 DEEP

4x 45* CHAMFER

R 0236, ROS

0010 DEEP

[ary] oesenrnon

we eee | END cP

ALL DIMENSIONS ARE IN INCHES SI Y14.SN— 1994

IT'S RECOMMENDED ‘THAT Yod PAwr THE ENDCAP For A FACTORY LIKE Finis TOLERANCES: .

pews aneies | PULL-AUTO GLOCK

=+.030 +2"

E88

‘SIZE: A SCALE: 31 | SHEET#: 1 OF 3

(AND APPEARANCE

“HIDDEN Lines OnrTHED FoR CLARITY ee

NOTES

ALL DIMENSIONS ARE IN INCHES

(TAS Nor RECOMMENDED TO PUT TH PART

key [ary

SEAR

: FULL-AUTO GLOCK

ae

ye ar

NOTES:

ALL CHAMFERS ARE .0197 @45°

PANTING OF THE SELECTOR SWITCH 1S OPTIONAL. A PAINTED Fis Wut | 2

“BLEND” IN THE SELECTOR SwirtcH WET THE ENOCAP FOR A FACTORY Luxe APPEARMICE: 5

R .1047 «

R .0885 5

R .0850 o

R .0413 ¢

You might also like

- Full Auto GlockDocument11 pagesFull Auto Glockckamel1469992% (25)

- Glock 17 Pistol Full Auto ConversionDocument5 pagesGlock 17 Pistol Full Auto ConversionBrent Divine100% (12)

- Full Auto Glock Conversion ManualDocument13 pagesFull Auto Glock Conversion Manualdustyboner93% (28)

- Dremeling A GLOCKDocument18 pagesDremeling A GLOCKBillyGlock100% (1)

- Glock Full Auto PartsDocument5 pagesGlock Full Auto PartsHarley Hunter Sites82% (11)

- Glock Select Fire - SilencerTalk Review - Multiple VarietiesDocument86 pagesGlock Select Fire - SilencerTalk Review - Multiple Varietiesgsdbonjon367% (3)

- AR15 Lightning Link PlansDocument8 pagesAR15 Lightning Link Planscomservice100% (22)

- Gunsmithing the AR-15, Vol. 3: The Bench ManualFrom EverandGunsmithing the AR-15, Vol. 3: The Bench ManualRating: 2.5 out of 5 stars2.5/5 (4)

- AK-47 Select Fire Full-Auto ConversionDocument16 pagesAK-47 Select Fire Full-Auto Conversion(Administrator)100% (10)

- Selective Fire Kit For Lightning Link Using ARDocument3 pagesSelective Fire Kit For Lightning Link Using ARSpector_27567% (12)

- AR15 AutoDocument28 pagesAR15 AutoChris Fox100% (10)

- M 16 RedactedDocument9 pagesM 16 Redactednotarealaccount92% (13)

- Fabricating The AR-15 Rifle Lightning LinkDocument5 pagesFabricating The AR-15 Rifle Lightning Link(Administrator)93% (15)

- Lightning Link Printable Template V1.0Document4 pagesLightning Link Printable Template V1.0Gilberto Hill83% (23)

- Ruger 10-22 Full Auto ConversionDocument22 pagesRuger 10-22 Full Auto ConversionAdam Steidl85% (20)

- WWW Quarterbore Com 1Document6 pagesWWW Quarterbore Com 1Matt Pineiro100% (1)

- Gun Digest Book of Tactical Weapons Assembly/Disassembly, 3rd Ed.From EverandGun Digest Book of Tactical Weapons Assembly/Disassembly, 3rd Ed.Rating: 4.5 out of 5 stars4.5/5 (2)

- Gunsmithing the AR-15, Vol. 1: How to Maintain, Repair, and AccessorizeFrom EverandGunsmithing the AR-15, Vol. 1: How to Maintain, Repair, and AccessorizeRating: 4.5 out of 5 stars4.5/5 (2)

- Switch 123 Full Auto GlockDocument9 pagesSwitch 123 Full Auto GlockHebert SegreraNo ratings yet

- Full Auto - TabDocument5 pagesFull Auto - Tabbkausshen67% (6)

- Silencer From MagliteDocument5 pagesSilencer From MagliteFlavio Marçal93% (14)

- SKS Variants Full Auto ConversionDocument13 pagesSKS Variants Full Auto ConversionFranke Schein100% (1)

- Gunsmithing Modern Firearms: A Gun Guy's Guide to Making Good Guns Even BetterFrom EverandGunsmithing Modern Firearms: A Gun Guy's Guide to Making Good Guns Even BetterRating: 5 out of 5 stars5/5 (1)

- AR 15 Lower Receiver Step by StepDocument81 pagesAR 15 Lower Receiver Step by StepNorm96% (27)

- Full Auto Colt 1911 HlebooksDocument19 pagesFull Auto Colt 1911 Hlebookstor100% (13)

- Building A Complete AR-15 Lower RecieverDocument27 pagesBuilding A Complete AR-15 Lower RecieverDelta Exrae100% (11)

- Ar15 A3 Style Upper Receiver BlueprintsDocument8 pagesAr15 A3 Style Upper Receiver Blueprintsjbrownrg94% (16)

- The Silencer CookbookDocument47 pagesThe Silencer Cookbookstephan_f87% (15)

- AR15 Full Auto Conversions ATF FOIADocument17 pagesAR15 Full Auto Conversions ATF FOIAD.G.100% (2)

- The $0.25 Glock Trigger Job PDFDocument12 pagesThe $0.25 Glock Trigger Job PDFGerry100% (1)

- Lightning Link Plans (For The AR-15 Rifle)Document8 pagesLightning Link Plans (For The AR-15 Rifle)anthony100% (1)

- Building a Home Defense Remington 870 ShotgunFrom EverandBuilding a Home Defense Remington 870 ShotgunRating: 3.5 out of 5 stars3.5/5 (5)

- Gunsmithing the AR-15, Vol. 4: Building the Performance ARFrom EverandGunsmithing the AR-15, Vol. 4: Building the Performance ARRating: 3 out of 5 stars3/5 (2)

- DIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!From EverandDIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Rating: 4 out of 5 stars4/5 (4)

- Professional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopFrom EverandProfessional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopRating: 5 out of 5 stars5/5 (3)

- Practical Guide to the Operational Use of the UZI Submachine GunFrom EverandPractical Guide to the Operational Use of the UZI Submachine GunNo ratings yet

- Come and Take It: The Gun Printer's Guide to Thinking FreeFrom EverandCome and Take It: The Gun Printer's Guide to Thinking FreeRating: 3.5 out of 5 stars3.5/5 (6)

- Gun Digest Book of Automatic Pistols Assembly/DisassemblyFrom EverandGun Digest Book of Automatic Pistols Assembly/DisassemblyRating: 3 out of 5 stars3/5 (3)

- Cartridges of the AR-15: A Complete Reference Guide to AR -15 and AR-10 AmmoFrom EverandCartridges of the AR-15: A Complete Reference Guide to AR -15 and AR-10 AmmoNo ratings yet

- Custom Gunsmithing for Self-Defense FirearmsFrom EverandCustom Gunsmithing for Self-Defense FirearmsRating: 5 out of 5 stars5/5 (3)

- Advanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)From EverandAdvanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)Rating: 3.5 out of 5 stars3.5/5 (2)

- The Complete Guide to Gunsmithing: Gun Care and RepairFrom EverandThe Complete Guide to Gunsmithing: Gun Care and RepairRating: 3 out of 5 stars3/5 (6)

- Shooter's Bible Guide to AR-15s, 2nd Edition: A Comprehensive Guide to Modern Sporting Rifles and Their VariantsFrom EverandShooter's Bible Guide to AR-15s, 2nd Edition: A Comprehensive Guide to Modern Sporting Rifles and Their VariantsNo ratings yet

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsFrom EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsRating: 5 out of 5 stars5/5 (3)