Professional Documents

Culture Documents

0012ua3120-E-De 1001.001 (En)

0012ua3120-E-De 1001.001 (En)

Uploaded by

salamrefighOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

0012ua3120-E-De 1001.001 (En)

0012ua3120-E-De 1001.001 (En)

Uploaded by

salamrefighCopyright:

Available Formats

Innovative Power Transmission

HIGH SPEED

GEARBOXES

Innovative Gear in Power Plants Systems

First-Class Gearboxes

1 General

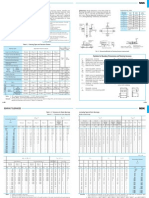

3 Type Designation

For many decades, RENK

has been a leading manufacturer of highspeed gearboxes

and enjoys an excellent reputation with their series TS,

TB, TL, TNA and TNB.

Supported by up-to-date

CAD-systems and computercontrolled production, products of superior quality are

built and delivered worldwide.

Construction series and centre distances are identified by

the gearbox designation. The

overview shown below

explains the meaning of the

alphanumerical designation.

The numerical part refers to

the centre distance. TNA and

TL types are gear units with

wide gear teeth which allow

to realize low transmission

ratios. TNB and TS have narrow gear teeth for high transmission ratios. For centre

distances up to 400 mm, the

gear casings are manufactures with high-quality cast iron;

Casings with welded steel

construction are used for

centre distances up to

450 mm.

2 Gearboxes

Depending on the specification, the gearboxes are built

according to DIN 3990,

AGMA 421.06 or API 613

standard. In order to achieve

optimum efficiency and excellent running characteristics

regarding vibration and noise,

the gear teeth, bearings,

natural frequencies and rotor

dynamics are calculated

according to the latest state

of the art.

Series

Type Code

TNA,TNB gearboxes

- centre distance [mm]

- centre distance [mm]

- = standard

Q = quill shaft

- = standard

Q = quill shaft

- = double helical teeth

E = single helical teeth

S = narrow gearing

B = mean tooth width.

L = wide gearing

B = narrow gearing

A = wide gearing

N = double helical teeth

E = single helical teeth

D = trust collar + single helical teeth

- = without thrust collar

D = thrust collar

T = high-speed gearbox

T

T

T

S

B

S

E

E

- 560

- 900

- 630

T = high-speed gearbox

written:

TDSEQ-560

TB-900

TSE-630

Transmission ratio i

Series

The following type code indicates the designations of the standard

gearbox series:

Type Code

TS,TB,TL gearboxes

Gearbox

T

T

T

D

N

E

A

A

B

- 355

- 315

- 400

written:

TDA-355

TNA-315

TEB-400

i low

i high

TNA

TNB

TL

TNA-355 - Casing made from high-quality grey

cast iron

Example 1:

(T) High-speed gearbox,

(L) low transmission ratio,

(E) single helical teeth with

(Q) quill shaft, centre distance

850 mm => designation:

TLEQ-850

Example 2:

(T) High-speed gearbox,

(S) high transmission ratio,

centre distance 710 mm

=> designation: TS-710

TB

TS

TB-900 - Steel casing - welded

Example 3:

(T) High-speed gearbox,

(D) thrust collar,

(B) mean transmission ratio,

(E) single helical teeth,

centre distance 800 mm

=> designation: TDBE-800

Gearbox Elements

4.1 Gear Set

Different gear sets characterize the gearbox series.

Following design options are

possible:

single helical teeth

single helical teeth with

thrust collar

double helical teeth

Double helical teeth

Single helical teeth

Single helical teeth with thrust

collar

The gear shaft is built in two different ways:

The quill shaft design

takes advantage of the

higher resilience of al long

shaft, whereby the power

flow is directed into the

output shaft that is located opposite to the driven

machine.

4.2 Bearings

Split journal bearings are

used for the standard design,

and one bearing of the gear

shaft is equipped with axial

stop collars. If higher speeds

are involved, radial tilting pad

bearings are mounted. The

use of separate axial thrust

bearings according to API

613 is also possible.

Journal bearing with offset profile

4.3 Seals

The gearboxes require pressure oil lubrication. The oil

may optionally be supplied

by a separate or a flangemounted oil pump. The gearbox can also be connected

to a central lubrication

system. The shaft ends of the

gearboxes are sealed by

means of a split, noncontact

labyrinth seal made from

aluminium. Upon request,

special seals are also

available.

5 Power loss and

efficiency

With view to power loss and

efficiency, RENK gearboxes

are designed to the optimum

possible. Decisive factors to

achieve a high efficiency are

the selection of the bearings

and their dimensioning as

well as the oil flow and type

of teeth.

6 Noise and

vibrations

Each gearbox is noise-optimised for nominal load. The

dimensioning of the teeth,

lubrication and casing is focused on low noise and quiet

operation.

7 Instrumentation

The gearboxes can be supplied with a number of monitoring instruments, such as

built-in resistance thermometers, thermocouples, vibration

detectors, speed sensors,

accelerometers, position

detectors and oil pressure

transmitters. These devices

are also available in exproof

or ATEX-design.

Quality Assurance

8 Accessories

The following accessories can

be supplied:

rotor turning devices

gear oil pump

screw-spindle pump

Rotor turning device

Gear oil pump

Screw spindle pump

9 Production and

Assembly

The gearboxes obtain highest

demands as the individual

components are manufactured on Hi-Tech-equipment,

and the gearbox assembly is

carried out by highly qualified

specialists. As far as quality

assurence is concerned, our

plant is certified according to

DIN / ISO 9001 / EN 29001.

Assembly of a TB-950

gearbox

10 Trial run

Every gearbox is subjected to

extensive inspections and

tests during which efficiency,

noise emission, vibration characteristics and proper function of the lubrication system

are thoroughly checked. The

results are recorded and

documented.

TB-630 Test run

Service around the Product

Our service team can and will

arrange and/or co-ordinate all

necessary measures and

ensures competent

assistance with remedies

without any loss of time.

Our highly qualified team of

experts will be supporting you

once the ordered gearbox or

coupling has left our factory.

The Service Team can be

contacted at any time to

assist you with any questions or problems you have.

In addition, our after-sales

service department is flanked

by a group of experienced

field engineers. We provide

constant support to these

team members to ensure that

complex queries are solved

fast and accurately.

RENK Aktiengesellschaft

Rheine Plant

Service

Rodder Damm 170

48432 Rheine

Germany

Phone: +49 59 71 / 790 260

Fax: +49 59 71 / 790 444

E-Mail: rheine@renk-ag.com

Internet: http://www.renk.de

We maintain the most

advanced test and inspection

facilities:

3D gear teeth measurement

3D coordinate measurement machine

crack testing, surface

testing and ultrasonic

testing

endoscope for inspecting

the inside

3 D measurement machine

Upon completion of the

analysis, you will receive an

examination report including

suggestions and recommendations as how to proceed.

Gearing measurement

Inspection of a high-speed gearbox

Further products of our range of couplings

3

1 Curved tooth coupling with hardened and

ground external and internal teeth and

tooth-by-tooth injection lubrication

2 High-speed diaphragm coupling

Type MCN

3 Raflex steel disk coupling

Type MTP according to API 610

Telephone: ++49 5971 790-0

Telefax: ++49 5971 790 208 und 790 256

E-mail: info.rheine@renk.biz

Internet: http://www.renk.eu

Neudruck RR 063/6.10-3,e 101148

RENK Aktiengesellschaft

Rheine works

Rodder Damm 170

D-48432 Rheine

You might also like

- 1051 and 1052 Style F and G Instruction ManualDocument36 pages1051 and 1052 Style F and G Instruction Manualtxlucky80No ratings yet

- JB Knowledge Park Mdu University, Faridabad: Project ReportDocument9 pagesJB Knowledge Park Mdu University, Faridabad: Project ReportShivam MishraNo ratings yet

- Din-981 KMDocument5 pagesDin-981 KMChris StefanouNo ratings yet

- The Teaching ProfessionDocument3 pagesThe Teaching ProfessionMichael V. MagallanoNo ratings yet

- Ansi ABMA7Document19 pagesAnsi ABMA7Andres Antonio Moreno CastroNo ratings yet

- Analyzing Taper Fits For ManufacturingDocument7 pagesAnalyzing Taper Fits For Manufacturingsalgado_24No ratings yet

- Shaft and Bearing Calculations in PumpsDocument21 pagesShaft and Bearing Calculations in Pumpsnarendradounde143No ratings yet

- Gear Guide 060817Document0 pagesGear Guide 060817Anonymous oAbjbl4HNo ratings yet

- Behold The Power of MindDocument2 pagesBehold The Power of MindBrandon CooperNo ratings yet

- 5.back StopDocument44 pages5.back Stopaiyubi20% (1)

- Review of Road Network Design: A Case Study of Kiri Kasama LGA - Jigawa StateDocument8 pagesReview of Road Network Design: A Case Study of Kiri Kasama LGA - Jigawa StateInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- PC Modular Helical 2015 02Document176 pagesPC Modular Helical 2015 02Carlos Catalán PinoNo ratings yet

- Gear PumpsDocument48 pagesGear PumpsAhmet gözükeleşNo ratings yet

- AGMADocument13 pagesAGMARizky MahendraNo ratings yet

- Calculation of Planetary Gear FrequenciesDocument6 pagesCalculation of Planetary Gear FrequenciesVojkan DamjanovićNo ratings yet

- Catalog KingcoleDocument33 pagesCatalog Kingcoleg_casalinuovo19812344No ratings yet

- Lista Normas EngranajesDocument5 pagesLista Normas EngranajesCarlosQuelartNo ratings yet

- Engr. Miriam B. VillanuevaDocument10 pagesEngr. Miriam B. VillanuevaJane Carnisel PasionNo ratings yet

- Viscometer Manual PDFDocument47 pagesViscometer Manual PDFBalqis yasinNo ratings yet

- DHB5A MS Range PDFDocument32 pagesDHB5A MS Range PDFAshutosh PandeyNo ratings yet

- Wartsila O P Transverse ThrusterDocument8 pagesWartsila O P Transverse ThrusterionesqNo ratings yet

- Renk Planetary Gears Type Pls PwsDocument8 pagesRenk Planetary Gears Type Pls Pwshumayun121No ratings yet

- Hydrodynamic Journal BearingDocument4 pagesHydrodynamic Journal BearingEbe Nezer GNo ratings yet

- Curved Tooth Couplings Disengageable at StandstillDocument8 pagesCurved Tooth Couplings Disengageable at Standstillmartensita24No ratings yet

- Renk High Speed Power GearsDocument12 pagesRenk High Speed Power Gearshumayun121No ratings yet

- Untitled PDFDocument48 pagesUntitled PDFakhil9182No ratings yet

- 2800 - UK - Renk EM PDFDocument6 pages2800 - UK - Renk EM PDFIvan DulicNo ratings yet

- High Speed Gear: Quality Driven High Speed Gears For The WorldDocument5 pagesHigh Speed Gear: Quality Driven High Speed Gears For The WorldNur YantoNo ratings yet

- ISO 8826 Rolling BearingsDocument17 pagesISO 8826 Rolling BearingsANIKET PATILNo ratings yet

- 02 RENK MAAG FieldService Maintenance enDocument18 pages02 RENK MAAG FieldService Maintenance enropmachadoNo ratings yet

- Renk High Torque Planetary Gears PBLZDocument12 pagesRenk High Torque Planetary Gears PBLZhumayun121No ratings yet

- Renold Couplings Cat 8thDocument96 pagesRenold Couplings Cat 8thjustsomeone1985100% (1)

- HYGUARD Safety CouplingsDocument32 pagesHYGUARD Safety CouplingsropmachadoNo ratings yet

- Renk Bearings Type HGDocument8 pagesRenk Bearings Type HGhumayun121No ratings yet

- RENK MAAG Turbo Gearboxes 0413-1Document24 pagesRENK MAAG Turbo Gearboxes 0413-1RCMNo ratings yet

- RENK Single Marine Gear Units enDocument7 pagesRENK Single Marine Gear Units enhumayun121No ratings yet

- Renk MaagDocument12 pagesRenk MaagDhananjay B KNo ratings yet

- Turbo Gears of G SeriesDocument4 pagesTurbo Gears of G SeriesrisegraNo ratings yet

- Intelligent Coupling Solutions For All Applications.: CouplingsDocument44 pagesIntelligent Coupling Solutions For All Applications.: Couplingsjvc hemitNo ratings yet

- SKF N10 Series CatalogDocument24 pagesSKF N10 Series CatalogJeff HawkinsNo ratings yet

- CatalogDocument24 pagesCatalogmuthuswamyNo ratings yet

- Renk PBLZ enDocument7 pagesRenk PBLZ enhumayun121No ratings yet

- Renk Etax TechonologyDocument6 pagesRenk Etax Techonologyhumayun121No ratings yet

- Bearing FitsDocument9 pagesBearing Fitsm2110No ratings yet

- BS 00046-1-1958 (2000)Document32 pagesBS 00046-1-1958 (2000)Mostafa Hussein AbdouNo ratings yet

- 22 PDFDocument25 pages22 PDFgavin kennedyNo ratings yet

- Design of Bearings & Miscellaneous ElementsDocument14 pagesDesign of Bearings & Miscellaneous ElementsjvanandhNo ratings yet

- Bombas Parker Pvp16Document10 pagesBombas Parker Pvp16Gustavo HuertasNo ratings yet

- Bearing CatalogueDocument12 pagesBearing CatalogueSandeep MatetiNo ratings yet

- Foam and Air ReleaseDocument5 pagesFoam and Air ReleaseToppy ToppyNo ratings yet

- JMD000645 PDFDocument7 pagesJMD000645 PDFTadveer Singh HoraNo ratings yet

- Thermal and Efficiency Characterization of A Low-Backlash Planetary GearboxDocument10 pagesThermal and Efficiency Characterization of A Low-Backlash Planetary Gearboxra maNo ratings yet

- ASSAG Cylkro (FACE) Gear Mounting InstructionsDocument6 pagesASSAG Cylkro (FACE) Gear Mounting InstructionscjdengateNo ratings yet

- Mathcad Tool For Design of Volute of Centrifugal Air CompressorDocument6 pagesMathcad Tool For Design of Volute of Centrifugal Air Compressorvishal.nithamNo ratings yet

- Housing Influences On Churning Losses in Geared TransmissionsDocument6 pagesHousing Influences On Churning Losses in Geared TransmissionsSaipriya BalakumarNo ratings yet

- Appendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Document17 pagesAppendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Dino Andrian100% (1)

- SKF Filament Wound BushingsDocument8 pagesSKF Filament Wound BushingsWes VendrigNo ratings yet

- Hydro 2020 Water Turbine.Document26 pagesHydro 2020 Water Turbine.Mạnh Ngô VănNo ratings yet

- Recommended Radial Clearance For Cast Bronze BearingDocument1 pageRecommended Radial Clearance For Cast Bronze BearingMachineryengNo ratings yet

- Limits and Fits KenDocument40 pagesLimits and Fits KennilamNo ratings yet

- Plain Bearings With: Maintenance-Free, Wear-ResistantDocument40 pagesPlain Bearings With: Maintenance-Free, Wear-ResistantJinto A JNo ratings yet

- Basic Series - Gear CouplingsDocument13 pagesBasic Series - Gear CouplingsfrarainsNo ratings yet

- Hda Operational ManualDocument48 pagesHda Operational ManualDouglas DuarteNo ratings yet

- Is 3688 1990Document19 pagesIs 3688 1990sarath6725No ratings yet

- TIMKEN - Zespoy Ozyskowe Typu E PDFDocument13 pagesTIMKEN - Zespoy Ozyskowe Typu E PDFPlamen KangalovNo ratings yet

- Catálogo Nord Redutores Aluminio SmoothmotorsDocument28 pagesCatálogo Nord Redutores Aluminio Smoothmotorsleonardo silveiraNo ratings yet

- Dealing With Sore Throats - The Little Things in My HeadDocument9 pagesDealing With Sore Throats - The Little Things in My Headkh_chu_1No ratings yet

- Search This Topic: Register Login Search Latest Topics Categories Binocular Questions & AnswersDocument5 pagesSearch This Topic: Register Login Search Latest Topics Categories Binocular Questions & Answerskh_chu_1No ratings yet

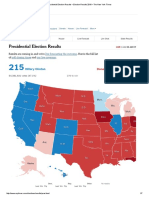

- Presidential Election Results - Election Results 2016 - The New York TimesDocument7 pagesPresidential Election Results - Election Results 2016 - The New York Timeskh_chu_1No ratings yet

- Your Inability To Form A Routine Is A Warning Sign That Something Deeper Is Wrong - QuartzDocument8 pagesYour Inability To Form A Routine Is A Warning Sign That Something Deeper Is Wrong - Quartzkh_chu_1No ratings yet

- Which Is The Worst Country in The World - QuoraDocument4 pagesWhich Is The Worst Country in The World - Quorakh_chu_1No ratings yet

- FulltextDocument6 pagesFulltextkh_chu_1No ratings yet

- Review of Bird Repellents: Digitalcommons@University of Nebraska - LincolnDocument9 pagesReview of Bird Repellents: Digitalcommons@University of Nebraska - Lincolnkh_chu_1No ratings yet

- BBC - Future - What Not To Do in A DisasterDocument20 pagesBBC - Future - What Not To Do in A Disasterkh_chu_1No ratings yet

- Dangerous Chemicals in Deodorant & Antiperspirant - A Detailed Review of The Chemicals, Research & Avoidance Tips - Natural Cosmetic NewsDocument10 pagesDangerous Chemicals in Deodorant & Antiperspirant - A Detailed Review of The Chemicals, Research & Avoidance Tips - Natural Cosmetic Newskh_chu_1No ratings yet

- BAM - The Slipperiest Material in The WorldDocument8 pagesBAM - The Slipperiest Material in The Worldkh_chu_1No ratings yet

- BBC - Soutik Biswas's India - How Churchill 'Starved' India PDFDocument2 pagesBBC - Soutik Biswas's India - How Churchill 'Starved' India PDFkh_chu_1No ratings yet

- Surprising Statistics About Hot People Versus Ugly People - Business InsiderDocument16 pagesSurprising Statistics About Hot People Versus Ugly People - Business Insiderkh_chu_1No ratings yet

- How To Beat A Mixed Martial Artist On The Street - Burton Richardson's JKD Unlimited - For Street Self DefenseDocument2 pagesHow To Beat A Mixed Martial Artist On The Street - Burton Richardson's JKD Unlimited - For Street Self Defensekh_chu_1No ratings yet

- Oktrends: Dating Research From Okcupid: Race and Attraction, 2009 - 2014Document5 pagesOktrends: Dating Research From Okcupid: Race and Attraction, 2009 - 2014kh_chu_1No ratings yet

- 901 - Ceragon - QinQ CFG - PDF v1.5Document21 pages901 - Ceragon - QinQ CFG - PDF v1.5mehdi_mehdiNo ratings yet

- KOMATSU Excavator Detail ExplainingDocument8 pagesKOMATSU Excavator Detail ExplainingPHÁT NGUYỄN THẾNo ratings yet

- RDA and The Semantic Web, Linked Data Environment: Barbara TillettDocument7 pagesRDA and The Semantic Web, Linked Data Environment: Barbara TillettPEDRO NESTARES BELLEZANo ratings yet

- Be220 Bes60d105 1 Parts CatalogueDocument159 pagesBe220 Bes60d105 1 Parts Cataloguejobin joyNo ratings yet

- MPI Exercises PDFDocument7 pagesMPI Exercises PDFSwapnil ShindeNo ratings yet

- Social Studies Domestic Violence Course WorkDocument27 pagesSocial Studies Domestic Violence Course Workkeeshan MohammedNo ratings yet

- Inter Sugar 1967 v69 n820Document34 pagesInter Sugar 1967 v69 n820Richard RondónNo ratings yet

- Tax SlabsDocument2 pagesTax SlabsFurqan HasanNo ratings yet

- Acquire To Retire Discussion DocumentDocument11 pagesAcquire To Retire Discussion DocumentShrasti VarshneyNo ratings yet

- SynMatrix Application Note 6 Synthesize MatrixDocument15 pagesSynMatrix Application Note 6 Synthesize MatrixHüseyin Nuri GülmezNo ratings yet

- Rajnandan Old ResumeDocument2 pagesRajnandan Old ResumeRaazz AryaNo ratings yet

- PhotographyDocument3 pagesPhotographyJohn Matthew ContignoNo ratings yet

- BS-BSP 210 Tutorial Sheet 3 PDFDocument2 pagesBS-BSP 210 Tutorial Sheet 3 PDFMwangoNo ratings yet

- Ccna2 Chap6 Lab 6.4.1Document3 pagesCcna2 Chap6 Lab 6.4.1jhe04No ratings yet

- Tormin Latest Brief CatalogDocument10 pagesTormin Latest Brief CatalogMantproca CANo ratings yet

- Barriers To The Adoption of Electronic Medical Records in Select Philippine Hospitals: A Case Study ApproachDocument7 pagesBarriers To The Adoption of Electronic Medical Records in Select Philippine Hospitals: A Case Study ApproachSMNo ratings yet

- Mg309 AssignmentDocument3 pagesMg309 AssignmentDarshika Singh - KumarNo ratings yet

- CHT1000 Rev BDocument3 pagesCHT1000 Rev BjalalNo ratings yet

- Systems Theory Practice PaperDocument7 pagesSystems Theory Practice PaperArumpac, Norjanah T.No ratings yet

- Lecture 7Document71 pagesLecture 7adrienleeNo ratings yet

- Human Modeling: CATIA V5 TrainingDocument78 pagesHuman Modeling: CATIA V5 TrainingLuis Angel GonzálezNo ratings yet

- ECG Noise Sources and Various Noise Removal Techniques: A SurveyDocument7 pagesECG Noise Sources and Various Noise Removal Techniques: A SurveyInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- VM-1000-1300 VMC-1100-1300 - V2012-01Document71 pagesVM-1000-1300 VMC-1100-1300 - V2012-01avalente112No ratings yet

- Answers To Saqs: Cambridge International A Level PhysicsDocument1 pageAnswers To Saqs: Cambridge International A Level PhysicsharshanauocNo ratings yet