Professional Documents

Culture Documents

UG-45 Nozzle Sizing Rules Simplified

Uploaded by

shabbir626100%(1)100% found this document useful (1 vote)

1K views2 pagesASME Section VIII Division 1 UG-45 Requirements

Original Title

UG 45 Requirements

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentASME Section VIII Division 1 UG-45 Requirements

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views2 pagesUG-45 Nozzle Sizing Rules Simplified

Uploaded by

shabbir626ASME Section VIII Division 1 UG-45 Requirements

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

14.12.

2013

2010 Edition

Section VIIIVIII-1

ASME Section VIIIVIII-1

UG-45

Nozzle Sizing Rules

UG--45 Nozzle Neck Sizing

UG

UG-45 Simplification of Rules

Nozzle neck sizing rules of UG-45 are often misinterpreted

New rules modeled after those published in VIII-2

Simpler presentation however requires an understanding of

min/max rules.

Min. Thickness of standard wall pipe now acquired from Table,

instead of looking up in handbook

UG--45 Nozzle Neck Sizing

UG

The minimum wall thickness of nozzle necks shall be determined

as given below:

For access openings and openings used only for inspection:

tUG-45 = ta

ta

For other nozzles:

tb1, tb2

Determine tb.,

tb = min{tb3, max( tb1 , tb2)}

tUG-45 = max (ta , tb)

UG--45 Example

UG

P = 9766.243 kPa

T = 66 C

Material

Shell SA-516-70 ,S = 138 MPa

Shell I.D = 1219 in

Shell Nominal Thickness = 50 mm

Nozzle

SA-105

S = 138 MPa

Nozzle NPS 3 HB FVC Nozzle#600

Corrosion Allowance = 3.18 mm

ta = nozzle required thickness+C.A

tb1 = shell/head required thickness

for internal press

pressure

re

tb2 = shell/head required thickness

for external pressure

tb3 = min wall thickness of pipe

from Table UG-45

Table UG-45

UG--45 Calculations

UG

ta = 2.96+ 3.18 = 6.14 mm

tb1 = 45.28 mm

tb2 = 0.0

0 0 because no external pressure

tb3 = 4.80mm Min thickness of standard wall pipe

tb = min[tb3 , max(tb1 , tb2 )]

= min [4.8, max (45.28, 0.0)] = 4.8 mm

tUG-45= max ( ta, tb) = max (6.14, 4.8) = 6.14 mm

Nom. Thickness (6 .14 + 3.18) = 9.32 mm

Actual Thickness= 26.73 mm

14.12.2013

UG--45 for Pipe

UG

If using pipe, nom. Thickness (6 .14 + 3.18)/ 0.875

= 10.65 mm

Sch 160

11.13 mm

You might also like

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document8 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Liu YangtzeNo ratings yet

- E.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Document2 pagesE.1.1) Nozzle Neck Thickness For Cyl. Shell Nozzles As Per UG-45Rajesh KumarNo ratings yet

- ASME VIII-1 Calculations for Sample Pressure VesselDocument21 pagesASME VIII-1 Calculations for Sample Pressure VesselTrishul Nath Pallay100% (1)

- MAWP Burst Test Calculation ASME VIII-1Document1 pageMAWP Burst Test Calculation ASME VIII-1correenNo ratings yet

- Asme Section Viii, Division 1 InterpretationsDocument1,148 pagesAsme Section Viii, Division 1 InterpretationsajitNo ratings yet

- WRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)Document1 pageWRC-107 (WRC-537) and WRC-297. (WELDING RESEARCH COUNCIL)miteshpatel191No ratings yet

- UG-39 - Flat Head ReinforcementDocument3 pagesUG-39 - Flat Head ReinforcementAshish DhokNo ratings yet

- ASME B31.3 bend thickness calculationDocument7 pagesASME B31.3 bend thickness calculationvijayakumar2015100% (1)

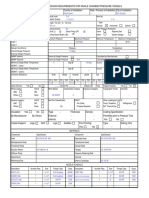

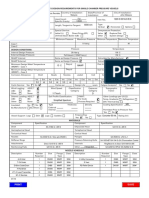

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument3 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsssNo ratings yet

- Form U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsDocument2 pagesForm U-Dr-1 User'S Design Requirements For Single Chamber Pressure VesselsAmit Sharma100% (1)

- Asme B31.8Document14 pagesAsme B31.8omar equihua100% (1)

- Table UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded JointsDocument1 pageTable UW-12 Maximum Allowable Joint Efficiencies For Arc and Gas Welded Jointsluis armandoNo ratings yet

- Asme b31 3 03 PDFDocument3 pagesAsme b31 3 03 PDFAtallah BoufatahNo ratings yet

- Tabla Uw-12Document1 pageTabla Uw-12Christian Lopez Mendez100% (1)

- ASME VIII Corroded Nozzle - Shell With Repad - UG-45 - UG-37 CalcDocument32 pagesASME VIII Corroded Nozzle - Shell With Repad - UG-45 - UG-37 CalcIonut FloricaNo ratings yet

- Impact Test Exemptions PEDDocument7 pagesImpact Test Exemptions PEDoberaiNo ratings yet

- Governing Thickness For Charpy Impact TestDocument1 pageGoverning Thickness For Charpy Impact TestAnonymous vnuWrIT7FWNo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- Lesson 09 UW16 UG37 New2Document38 pagesLesson 09 UW16 UG37 New2Kandregula Mohan BabuNo ratings yet

- MAWP CalculationDocument2 pagesMAWP CalculationMuhammad Zeeshan Wasi60% (5)

- AD 2000 Shell Under Intenal PressureDocument2 pagesAD 2000 Shell Under Intenal Pressuremechengg01No ratings yet

- Pipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Document9 pagesPipíng & Stress Analysis Ref - Sofware Caesar II. 06-09-2017 Autor - Ing R L Morard - U T N 1Oswaldo GuerraNo ratings yet

- Skirt To Dish Joint PDFDocument64 pagesSkirt To Dish Joint PDFPrajwal ShettyNo ratings yet

- PSV SIZING CALCULATIONSDocument3 pagesPSV SIZING CALCULATIONSAthiphap SrisupareerathNo ratings yet

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Document2 pagesPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayNo ratings yet

- Torque Values RTJ (B16.5)Document3 pagesTorque Values RTJ (B16.5)Dave Donohue100% (9)

- Exercise Questions For Section VIII Div.Document13 pagesExercise Questions For Section VIII Div.Karthikeyan Nadarajan100% (1)

- Asme Pcc-1 App O - 411-E-103 - Ch. Cover FLGDocument12 pagesAsme Pcc-1 App O - 411-E-103 - Ch. Cover FLGVilas AndhaleNo ratings yet

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- API 576 - Pressure GaugeDocument1 pageAPI 576 - Pressure GaugearianaseriNo ratings yet

- Pressure Vessel Inspection ReportDocument34 pagesPressure Vessel Inspection ReportJinlong SuNo ratings yet

- Mawp and MDMT Calculations PDFDocument5 pagesMawp and MDMT Calculations PDFobuse100% (7)

- Tube-to-Tubesheet Joints - BaherDocument51 pagesTube-to-Tubesheet Joints - BaherNAMO100% (3)

- Minimum Distance BW WeldsDocument2 pagesMinimum Distance BW Weldsroyalcom100% (1)

- ASME VS TRD CODE COMPARISON FOR BOILER DESIGNDocument1 pageASME VS TRD CODE COMPARISON FOR BOILER DESIGNsirang07100% (1)

- Compress CalculationDocument106 pagesCompress CalculationKrupal Patel100% (1)

- Figure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3Document5 pagesFigure 9.5-3 Spherical Shell With A Non Radial Nozzle en 13445-3 - Figure 9.5-3met-calcNo ratings yet

- Bolt Torque Calculations 1 PDFDocument1 pageBolt Torque Calculations 1 PDFshazanNo ratings yet

- AES Type Heat ExchangerDocument8 pagesAES Type Heat ExchangerSudhanshu67100% (1)

- Rstreng PDFDocument5 pagesRstreng PDFwellyNo ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Creep Calculations Carbon SteelDocument4 pagesCreep Calculations Carbon Steelshazan100% (1)

- API 510 Bolted Flat Head ThicknessDocument11 pagesAPI 510 Bolted Flat Head ThicknessAleiser Quevedo Acuña100% (1)

- Variable Design Point Method.Document56 pagesVariable Design Point Method.jwochNo ratings yet

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Document14 pagesASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (2)

- Ped Eam-0526-24-1-2006-03Document6 pagesPed Eam-0526-24-1-2006-03nathachaiNo ratings yet

- EJMA Calculation Report For Cryostat DNB 7HL9UC v1 3Document25 pagesEJMA Calculation Report For Cryostat DNB 7HL9UC v1 3zstNo ratings yet

- NozzlePRO PDFDocument185 pagesNozzlePRO PDFIan CarrNo ratings yet

- PV Elite - Nozzle Interference - The SolutionDocument4 pagesPV Elite - Nozzle Interference - The Solutionayounga100% (3)

- ASME PCC-1 Bolt Stress and Torque CalculationDocument11 pagesASME PCC-1 Bolt Stress and Torque Calculationndrarly100% (1)

- Ad2000 B13Document2 pagesAd2000 B13akisdassasNo ratings yet

- Tema Tubesheet Calculation SheetDocument1 pageTema Tubesheet Calculation SheetSanjeev KachharaNo ratings yet

- ASME Code Calculations: Minimum Wall ThicknessesDocument59 pagesASME Code Calculations: Minimum Wall ThicknessesKen Manning100% (1)

- N11 Nozzle CalDocument9 pagesN11 Nozzle Calגרבר פליקסNo ratings yet

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Ricardo Paz SoldanNo ratings yet

- Nozzle THKDocument6 pagesNozzle THKabhishek198327No ratings yet

- Code Calculation-ASME Section IDocument26 pagesCode Calculation-ASME Section IDevendra Bangar100% (10)

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)stalin_83No ratings yet

- UG 45 Sample CalculationDocument1 pageUG 45 Sample CalculationAris Purniawan100% (1)

- ASME Code CalculationsDocument24 pagesASME Code CalculationsTiu TonNo ratings yet

- AES-W-016 welding filler metalsDocument2 pagesAES-W-016 welding filler metalsmalika_00No ratings yet

- Pressure Points Newsletter - July 2016 - FINAL PDFDocument4 pagesPressure Points Newsletter - July 2016 - FINAL PDFshabbir626No ratings yet

- Welding Electrode Specification ChartDocument2 pagesWelding Electrode Specification ChartMahesh Kumar100% (2)

- Matrices and DeterminantsDocument36 pagesMatrices and Determinantsshabbir626No ratings yet

- Conformity Assessment PoliciesDocument10 pagesConformity Assessment Policiesshabbir626No ratings yet

- Set Theory Chapter 8 Concepts and ExamplesDocument40 pagesSet Theory Chapter 8 Concepts and Examplesshabbir626100% (1)

- Measuring National Output and Income: GDP, GNP, NNP ExplainedDocument24 pagesMeasuring National Output and Income: GDP, GNP, NNP Explainedshabbir626No ratings yet

- Electric Arc WeldingDocument23 pagesElectric Arc WeldingMubashar HassanNo ratings yet

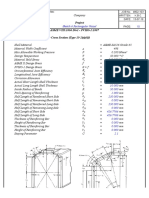

- Figure 1 Joggled Joint DetailDocument1 pageFigure 1 Joggled Joint Detailshabbir626No ratings yet

- Hardness Conversion ChartDocument1 pageHardness Conversion ChartIrwan NugrahaNo ratings yet

- Literature On Boiler Tube Fitup by ExpandingDocument17 pagesLiterature On Boiler Tube Fitup by Expandingakv030011No ratings yet

- 18 World Conference On Non Destructive Testing, 16-20 April 2012, Durban, South AfricaDocument9 pages18 World Conference On Non Destructive Testing, 16-20 April 2012, Durban, South AfricaArun KumarNo ratings yet

- Calibration MethodsDocument6 pagesCalibration Methodsshabbir626No ratings yet

- 02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical ApplicationsDocument12 pages02 Hilkes Gross Welding of CrMo Steels For Power Generation and Petrochemical Applicationsivanmatijevic100% (1)

- BPVC Viii-1 U-2Document3 pagesBPVC Viii-1 U-2shabbir626No ratings yet

- 37dl Plus - enDocument4 pages37dl Plus - enshabbir626No ratings yet

- PS-HT-11A Electric Resistance Heating PWHT ProcedureDocument4 pagesPS-HT-11A Electric Resistance Heating PWHT Procedureshabbir62650% (2)

- Design of Pressure VesselDocument137 pagesDesign of Pressure VesselCaptainToniesNo ratings yet

- Upvc Pressure Pipe StandardDocument4 pagesUpvc Pressure Pipe StandardTransgulf2013No ratings yet

- Chemistry Work Sheet 9th 1Document15 pagesChemistry Work Sheet 9th 1shabbir626No ratings yet

- Automatic Vs Manual Film ProcessingDocument26 pagesAutomatic Vs Manual Film Processingshabbir62650% (2)

- X-Ray Safety PresentationDocument87 pagesX-Ray Safety Presentationshabbir626100% (3)

- API 510 TestDocument3 pagesAPI 510 Testshabbir626No ratings yet

- Ultrasonic Testing of WeldsDocument2 pagesUltrasonic Testing of Weldsshabbir626No ratings yet

- ImmersionDocument11 pagesImmersionshabbir626No ratings yet

- Testing With Success SeriesDocument4 pagesTesting With Success Seriesshabbir626No ratings yet

- Vessel TestingDocument1 pageVessel Testingshabbir626No ratings yet

- Recommended Reading For Level IIIDocument1 pageRecommended Reading For Level IIIShankar Gurusamy50% (2)

- PT-MT Kurs NotuDocument300 pagesPT-MT Kurs NotuBahadir TekinNo ratings yet