Professional Documents

Culture Documents

ASME Code Calculations

Uploaded by

Tiu TonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASME Code Calculations

Uploaded by

Tiu TonCopyright:

Available Formats

Part A2

CHAPTER 2

Code Calculations ASME Section I

Here is what you w i l l be able to do when you complete each objective: 1. Given the tube material specification numbers, and other necessary parameters, use the formulae in PG-27.2.1 to calculate either the minimum required wall thickness or the maximum allowable working pressure for a boiler tube. 2. Given the material specification, construction method, and other necessary parameters, use the formulae in PG-27.2.2 to determine the required thickness and or maximum working pressure for boiler drums, headers, or piping. 3. Given the required specifications and operating conditions, use formula PG29.1 to calculate the required thickness of a seamless, unstayed dished head. 4. Given the design and the steam generation capacity of a boiler, read

the information in paragraphs PG-67 to PG-71 and understand the effect of these paragraphs on a specific boiler.

Note: All information and questions posed in this module utilize formulae and figures found in the 2004 ASME Academic Extract.

REVISED OCTOBER 2005

Chapter 2 Code Calculations ASME Section I

37

OBJECTIVE 1

Given the tube material specification numbers, and other necessary parameters, use the formulae in PG-27.2.1 to calculate either the minimum required wall thickness or the maximum allowable working pressure for a boiler tube.

SYMBOLS USED IN THE FORMULAE OF PG-27

The symbols in the formulae to be used in this module are found in Paragraph PG-27.3 and are defined as follows. It is extremely important that the correct units be applied when performing the calculations: t P D R E = = = = = minimum required thickness (millimetres, mm). (Also see PG-27.4, Note 7) maximum allowable working pressure (megapascals, MPa). (Note - this refers to gauge pressure) outside diameter of cylinder (millimetres, mm) inside radius of cylinder (millimetres, mm) efficiency of longitudinal welded joints or of ligaments between openings, whichever is lower. The values allowed for E are listed in PG-27.4, Note 1. This is a factor that has no units, (for example, the value of E for seamless cylinders is 1.00) maximum allowable stress value, at the operating temperature of the metal, as listed in the Section II, Part D, Table 1A, (megapascals, MPa). See PG-27.4, Note 2. The tables are located in an Section II, Part D at the back of the 2004 ASME Academic Code Extract. Each table spans four pages. Reference the line number on the first page to follow along each page until you find the correct temperature value required. minimum allowance for threading and structural stability, (millimetres, mm). See PG-27.4, Note 3 thickness factor for expanded tube ends (millimetres, mm). See PG-27.4, Note 4 a temperature coefficient: This factor has no units and has a value between 0.4 and 0.7. The values allowed for y are listed in PG-27.4, Note 6, (for example, for ferritic steel at 550C, the value of y is 0.7)

C e y

= = =

38

A2 Third Class SI Units

BOILER TUBE CALCULATIONS

To calculate the required minimum wall thickness or the maximum allowable working pressure of ferrous boiler tubing, up to and including 125 mm O.D., the following formulae, as given in PG-27.2.1, are used: Minimum thickness: t =

PD + 0.005 D + e 2S + P

2 t - 0.01 D - 2 e Maximum pressure: P = S D - ( t - 0.005 D - e )

Example 1 (to find tube wall thickness): Calculate the minimum required wall thickness of a superheater tube. The tube is 76 mm O.D. and is connected to a header by strength welding. The maximum allowable working pressure is 4150 kPa gauge and the average tube temperature is 400C. The tube material is alloy steel with specification SA-213-T11. Solution: From PG-27.2.1, the formula to use is:

t =

PD + 0.005 D + e 2S + P

First, find all the required factors for the formula: given that: P = 4150 kPa = 4.15 MPa D = 76.0 mm from Codes: e = 0 (from PG-27.4, Note 4, strength welded) S = 102 MPa = stress value at 400C for SA-213, T-11 *

*Note: This 102 MPa value for S is found in Section II, Part D, Table 1A, SA-

213, T-11. First locate the specification number, SA-213 T11, in the column under the headings Spec. No. and Type/Grade (page 267 of extract). Then scan across the table pages to page 269 the 400 column under Maximum Allowable Stress, MPa, for Metal Temperatures, C, Not Exceeding The corresponding value is 102 MPa.

Chapter 2 Code Calculations ASME Section I

39

Now, complete the calculation by substituting all factors into the formula:

t =

4.15 76 + 0.005 76 + 0 2 102 + 4.15 315.4 + 0.38 208.15

1.90 mm (Ans.)

= =

Information concerning the type of material used and the construction of the tube can be found in PG-9. The student should check PG-6 and PG-9 before starting calculations. The information in these sections will help direct the student to the correct section of Section II, Part D, Table 1A by indicating if the metal is carbon steel, low alloy steel, or high alloy steel. PG-6 deals with steel plate, PG-9.1 deals with boiler tubes or pressure containing parts, PG-9.2 deals with all superheater parts. These sections will also help to correctly select the values for E and e (as per PG-27, Note 1 and Note 6). Note: This value for the thickness of the tube is exclusive of manufacturers tolerances. (See PG-16.5) Example 2 (to find maximum allowable working pressure): Calculate the maximum allowable working pressure, in kPa, for a watertube boiler tube, which is 73.5 mm O.D. and has a minimum wall thickness of 4.71 mm. The tube is strength-welded into place in the boiler and is located in the furnace area of the boiler. Tube material is carbon steel, SA-192, with a mean wall temperature of 280C. Solution: From PG-27.2.1, the formula to use is:

2 t - 0.01 D - 2 e P = S D - ( t - 0.005 D - e )

First, find all the required factors for the formula: given that: t = 4.71 mm D = 73.5 mm

40

A2 Third Class SI Units

from Codes:

e = 0 (from PG-27.4, Note 4) S = 84.3 MPa = stress value at 375 C for SA-192, carbon steel *

*Note: This 84.3 MPa value for S is found in Section II, Part D, Table 1A.

Now, find SA-192 in the table and scan across to find the temperature. Youll notice that there is no column for 370C, so take the next higher temperature, which is 375C. Use the value of 84.3 MPa from this column. Note: In general, when a temperature given in a problem does not appear in Section II, Part D, Table 1A, select the next higher temperature from the table DO NOT INTERPOLATE BETWEEN VALUES.

Now, substitute the values of all factors into the formula:

( 2 4.71) - ( 0.01 73.5 ) - ( 2 0 ) P = 84.3 73.5 - ( 4.71- 0.005 73.5 - 0 ) 9.42 - 0.735 - 0 = 84.3 73.5 - ( 4.71- 0.3675 ) = 10.62 MPa (Ans.)

In both Example 1 and Example 2, the tubes were strength-welded into place. In this case the value of e is zero. In calculations involving tubes expanded into place, the appropriate value of e would be inserted into the formula. (See PG27.4, Note 4)

Chapter 2 Code Calculations ASME Section I

41

OBJECTIVE 2

Given the material specification, construction method, and other necessary parameters, use the formulae in PG-27.2.2 to determine the required thickness and or maximum working pressure for boiler drums, headers, or piping.

PIPING, DRUM AND HEADER CALCULATIONS

PG-27.2.2 (see page 7 of the 2004 ASME Codes Extract) gives the formulae that are used to calculate the required minimum thickness or the maximum allowable working pressure of ferrous piping, drums, and headers. The size of each component may be stated as the outside diameter or as the inside radius. The formulae that are applied differ in each case, and are as follows: To find the minimum thickness

If the outside diameter is given, use: t = PD +C 2 SE + 2 y P

If the inside radius is given, use: t = PR +C SE - (1 - y ) P

To find the maximum working pressure

If the outside diameter is given, use: P =

2 SE (t - C ) D - 2 y (t - C )

If the inside radius is given, use: P = SE (t - C ) R + (1- y )(t - C )

42

A2 Third Class SI Units

Example 3 (to find the required thickness of a boiler drum): Calculate the minimum required thickness, in mm, of a welded boiler drum having an inside diameter of 1.5 m. The drum welds are finished flush with the surface of the plate. The drum plate is carbon steel, SA-516-65, and the metal temperature will not exceed 250C. The maximum allowable working pressure is 4500 kPa gauge. The efficiency of the ligaments between the tube holes is 0.5. Solution: The inside diameter is given and therefore the formula from PG-27.2.2, for inside radius can be used can be used: t = PR + C SE - (1 - y ) P 4500 kPa gauge = 4.5 MPa D/2 = 0.75 m = 750 mm

given that: P = R =

E = 0.5 from Codes: C = 0 (from PG-27.4, Note 3: drum is larger than 100 mm) S = 128 MPa (Section II, Part D, Table 1A for SA-516-65 at 250C) y = 0.4 (PG-27.4, Note 6, ferritic at temperature below 480C) substituting these values into the equation: t = PR +C SE - (1 - y ) P

= = =

4.5 750 +0 128 0.5 - (1 - 0.4) 4.5 3375 64 - (0.6) 4.5 3375 61.3

= 55.06 mm (Ans.)

Chapter 2 Code Calculations ASME Section I

43

Example 4 (to find the maximum working pressure of a boiler drum): Calculate the maximum allowable working pressure for a welded drum if the plates are 25 mm thick and of material SA-299. The inside diameter of the drum is 988 mm and the joint efficiency is 100%. Assume the steam temperature will not exceed 400C. Solution: The inside diameter is given and therefore the formula from PG-27.2.2, for inside radius, can be used; P = given that: S E (t - C ) R + (1 - y ) (t - C )

t = 25 mm R = D/2 = 494.0 mm E = 1.0 (PG-27.4, Note 3)

from Codes: C = 0 (from PG-27.4, Note 3) S = 107 MPa (Section II, Part D, Table 1A for SA-299 at 400C) y = 0.4 (PG-27.4, Note 6, temperature less than 400C) substituting these values into the equation: P = SE (t - C ) R + (1- y )(t - C )

=

=

107 1(25 - 0) 494 + (1- 0.4)(25 - 0) 2675 509

= 5.26 MPa (Ans.)

44

A2 Third Class SI Units

Example 5 (to find the required thickness of a header): Calculate the required thickness, in mm, of a superheater outlet header, operating at 500C and having a maximum allowable working pressure of 17 MPa. The header material is SA-335-P5 and the outside diameter is 457.2 mm. Solution: The outside diameter is given and therefore the formula from PG-27.2.2, for outside diameter should be used: PD t = + C 2 SE + 2 yP given that: P = 17.0 MPa D = 457.2 mm from Codes: C = 0 (from PG-27.4, Note 3) S = 61.7 MPa (Section II, Part D, Table 1A for SA-335-P5 at 500C) y = 0.5 (PG-27.4, Note 6) E = 1.0 (PG-27.4 Note 1) substituting these values into the equation: t = PD +C 2SE + 2 yP 17 457.2 = +0 ( 2 61.7 1) + ( 2 0.5 17 )

7772.4 140.4

= 55.36 mm (Ans.)

Chapter 2 Code Calculations ASME Section I

45

Example 6 (to find the required thickness of a high-pressure boiler pipe): Calculate the minimum thickness required for a seamless steel feedwater pipe of material SA-209, grade T1. The outside diameter of the pipe is 323.85 mm and the operating pressure and temperature are 5200 kPa and 500C respectively. The pipe is plain-ended. Assume that the material is an austenitic steel. Note: Plain-end pipe is that which does not have its wall thickness reduced when joined to another pipe. For example, pipe lengths welded together rather than joined by threading are classed as plain-end pipes. Solution: The outside diameter is given and therefore the formula from PG-27.2.2, for outside diameter should be used: PD t = +C 2SE + 2 yP given that: P = 5.2 MPa D = 323.85 mm from Codes: C = 0 (from PG-27.4, Note 3; 4 inch nominal and larger) S = 72.1 MPa (Section II, Part D, Table 1A for SA-209-T1, at 500C) y = 0.4 (PG-27.4, Note 6; austenitic steel at 500C) E = 1.0 (PG-27.4 Note 1; seamless pipe as per PG-9.1) substituting these values into the equation: t =

=

PD +C 2SE + 2 yP

5.2 323.85 +0 ( 2 72.11) + ( 2 0.4 5.2 )

1684.02 148.36 = 11.35 mm (Ans.)

46

A2 Third Class SI Units

Note on Manufacturers Tolerance: The calculated thickness in Example 6 does not include the manufacturers tolerance. Since the manufacturing process does not produce absolutely uniform wall thickness, an allowance is added, which is called the manufacturing tolerance. This is usually done by increasing the minimum required thickness, as calculated in the formula, by 12.5%. Example 7 (for minimum thickness of steam piping): Calculate the required minimum thickness (in mm) of steam piping which will carry steam at a pressure of 4300 kPa gauge and a temperature of 370C. The piping is plain-end, 273.05 mm O.D.; the material is low alloy steel, SA-335 P11. A manufacturers tolerance of 12.5% must be added to the pipe. Solution: The outside diameter is given and therefore the formula from PG-27.2.2, for outside diameter should be used: t = PD +C 2SE + 2 yP

given that: P = 4.3 MPa D = 273.05 mm from Codes: C = 0 (from PG-27.4, Note 3) S = 104 MPa (Section II, Part D, Table 1A for SA-335-P11, at 370C) y = 0.4 (PG-27.4, Note 6; ferritic steel at 475C) E = 1.0 (PG-27.4 Note 1) substituting these values into the equation: t = PD +C 2SE + 2 yP 4.3 273.05 = +0 ( 2 104 1) + ( 2 0.4 4.3)

1174.12 = 5.55 mm 211.44

multiply by 1.125 to add the manufacturers tolerance of 12.5%:

t = 5.55 x 1.125 = 6.24 mm (Ans.)

Chapter 2 Code Calculations ASME Section I

47

OBJECTIVE 3

Given the required specifications and operating conditions, use formula PG-29.1 to calculate the required thickness of a seamless, unstayed dished head.

DISHED HEAD CALCULATIONS

The following Paragraphs from PG-29 must be considered when performing calculations on dished heads.

Paragraph PG-29.1 states that the thickness of a blank, unstayed dished head with the pressure on the concave side, when it is a segment of a sphere, shall be calculated by the following formula: t

5PL 4.8S

The symbols in this formula are defined as follows: t = minimum thickness of plates (mm)

P = maximum allowable working pressure (MPa) L = radius (mm) to which the head is dished, measured on the concave side mm S = maximum allowable working stress (MPa), using values Section II, Part D, Table 1A Paragraph PG-29.2 states: The radius to which the head is dished shall be not greater than the outside diameter of the flanged portion of the head. If two different portions of the head are dished to different radii, then the longer radius shall be used as the value of L in the formula. Paragraph PG-29.3 states that when a head, dished to a segment of a sphere, has a flanged-in manhole or access opening that exceeds 6 in. (150 mm) in any dimension, then its thickness must be 15%, or no

48

A2 Third Class SI Units

case less than 1/8 in. (3.0 mm), additional thickness over a blank head. As calculated by the formula in PG-29.1. Note: This would apply to a manhole such as is found on the end of a boiler drum.

Paragraph PG-29.5 states that in the case of a dished head with a flanged-in manhole, if the dish radius L is less than 80% of the diameter of the shell to which the head is attached, then, when calculating the thickness by: t

5PL 4.8S

the value of L must be made equal to 80% of the shell diameter. In addition, the thickness thus calculated must be increased by the greater of 15% or 3.0 mm (PG-29.3) to compensate for the flangedin manhole. This method of calculation will give the minimum thickness for any form of head having a flanged-in manhole.

Paragraph PG-29.6 states that no head, except a full-hemispherical head, shall be of lesser thickness than required for a seamless shell of the same diameter.

Example 8: Calculate the thickness of a seamless, unstayed dished head with pressure on the concave side, having a flanged-in manhole 280 mm by 380 mm. The head has a diameter of 1235 mm and is a segment of a sphere with a dish radius of 1016 mm. The maximum allowable working pressure is 1380 kPa, the material is SA285 C and the metal temperature does not exceed 204C. Solution: First thing to check: Is the radius of the dish at least 80% of the radius of the shell, per PG-29.5? 1016/1235 = 0.823 = 82.3 % This is greater than 80%, so the value of L in the formula will be 1016 mm. Use the formula from PG-29.1: t

5PL 4.8S

Chapter 2 Code Calculations ASME Section I

49

given that: P = 1.380 MPa L = 1016 mm (radius of the curvature of the sphere) from Codes: S = 108 MPa (Section II, Part D, Table 1A for SA-285-C, at 250 C) substituting these values into the equation: t

5PL 4.8S 5 1.380 1016 4.8 108

= 13.52 mm

This would be the thickness of a blank head, that is a head with no manhole. In this case there is a manhole and it exceeds the 152 mm allowed by PG-29.3. Therefore, the thickness must be increased by 15% or by 3.0 mm whichever is greater. 15% of 13.52 mm = 0.15 x 13.52 = 2.028 mm But this is less than 3.0 mm, so the thickness must be increased by 3.0 mm. Therefore, the required thickness is: 13.52 mm + 3.0 mm = 16.52 mm (Ans.) Example 9: Calculate the thickness of a seamless, blank unstayed dished head having pressure on the concave side. The head has a diameter of 1067 mm and is a segment of a sphere with a dish radius of 915 mm. The maximum allowable working pressure is 2068 kPa and the material is SA-285 A. The metal temperature does not exceed 250C.

50

A2 Third Class SI Units

Solution: First thing to check: Is the radius of the dish at least 80% of the radius of the shell, per PG-29.5? 915/1067 = .857 = 85.7% This is greater than 80%, so the value of L in the formula will be 915 mm. Use the formula from PG-29.1: t

5PL 4.8S

given that: P = 2.068 MPa L = 915 mm (radius of the curvature of the sphere) from Codes: S = 88.9 MPa (Section II, Part D, Table 1A for SA-285 A, at 250C) substituting these values into the equation: 5 2.068 915 t = 4.8 88.9 = 22.17 mm From PG-29.6, the head in this example must be as thick as, or thicker than, a seamless shell of the same diameter. Therefore, before we can confirm that the calculated thickness of 22.17 mm is adequate, we must determine the shell thickness. Calculate the shell thickness using the appropriate formula from PG-27.2.2 where: C = 0 y = 0.4 t =

t =

then:

PD +C 2S + 2 yP

2.068 1067 +0 ( 2 88.9 ) + ( 2 0.4 2.068)

= 12.30 mm

Since 25.27 is greater than 12.30 mm, the head thickness of 22.17 mm, as calculated before, is adequate.

Chapter 2 Code Calculations ASME Section I

51

Example 10: Calculate the thickness of the head in Example 9 if it has a flanged-in manhole. Solution: The thickness of the blank head in Example 2 is equal to 22.17 mm. According to PG-29.3, this thickness must be increased by the greater of 3.0 mm or 15%. 22.17 mm x 0.15 = 3.33 mm

Since this is greater than 3.0 mm, increase the thickness by 3.33 mm: Head thickness = 22.17 mm + 3.33 mm = 25.50 mm (Ans.)

52

A2 Third Class SI Units

OBJECTIVE 4

Given the required specifications and operating conditions, use formulae in paragraphs PG-29.11 and PG-29.12 to calculate the required thickness of an unstayed, full-hemispherical head.

HEMISPHERICAL HEAD CALCULATIONS

When a boiler head is in the form of a complete hemi-sphere, termed fullhemispherical, the requirements of Paragraph PG-29.11 apply. This paragraph states that the minimum required thickness for a blank, unstayed, fullhemispherical head with the pressure on the concave side shall be calculated by one the following two formulae: t

PL 2S - 0.2 P

The above formula should not be uses when the required thickness of the head given by the formula exceeds 35.6% of the inside radius and is used for shells or headers that are designed according to PG-27.2.2, and if the head is integrally formed on a seamless shell.

Paragraph PG-29.12 states if a flanged-in manhole, meeting code requirements, is placed in a full-hemispherical head, then the thickness of the head is calculated using the same formula as for a head dished to the segment of a sphere (per PG-29.1 and PG-29.5), with a dish radius equal to 80% of the shell diameter and with the added thickness for the manhole (per PG-29.3). That is, the following formula is used, where the value of L in the formula is 80% of the diameter of the shell. t

5PL 4.8S

Chapter 2 Code Calculations ASME Section I

53

Example 11: Calculate the minimum required thickness, in mm, for a blank, unstayed, fullhemispherical head, with the pressure on the concave side. The head is fabricated from seamless material and is double butt welded to the shell. All reinforcement is removed and fully radiographed. The radius to which the head is dished is 700 mm, maximum allowable working pressure is 4000 kPa, and the head material (SA-285 C) will not reach a temperature greater than 340C Solution: Use the formula from PG-29.11: t

PL 2S - 0.2 P

given that: P = 4.0 MPa L = 700 mm (radius of the curvature of the head) from Codes: S = 101 MPa (Section II, Part D, Table 1A for SA-285 C, at 350 C) substituting these values into the equation:

t =

4.0 700 ( 2 101) ( 0.2 4 )

= 13.92 mm (Ans)

Example 12: A seamless, welded, full-hemispherical head is welded to a boiler shell that has an inside diameter of 1100 mm. Maximum working pressure is 3500 kPa, the material is SA-226 1, and operating temperature is 300C. The head has a flanged in manhole that meets code requirements. Calculate the minimum required thickness for the head. Solution: With this question PG-29.12 applies. Therefore use the formula from PG-29.1: (per PG-29.12) t =

5 PL 4.8 S

given that: P = 3.5 MPa from codes: S = 107 MPa (Section II, Part D, Table 1A for SA-226, at 300C)

54

A2 Third Class SI Units

L = 880 mm (80% of 1100 mm per PG-29.1) substituting these values into the equation:

5 3.5 880 4.8 107

= 29.98 mm From PG-29.3, due to the manhole, this thickness calculation must be increased by the greater of 15% or 3.0 mm. 29.98 mm x 0.15 = 4.50 mm Since this is greater than 3.0 mm, the thickness must be increased by this amount: t = 29.98 mm + 4.50 mm = 34.48 mm (Ans.)

Chapter 2 Code Calculations ASME Section I

55

OBJECTIVE 5

Given the design and the steam generation capacity of a boiler, read the information in paragraphs PG-67 to PG-71 and understand the effect of these paragraphs on a specific boiler.

PG-67 PG-72: SAFETY VALVES (and Safety Relief Valves)

Paragraphs PG-67 to PG-72 of ASME Code, Section 1, deal with safety valves and safety relief valves. In particular, these sections cover the following topics:

PG-67 Boiler Safety Valve Requirements: the types and numbers of safety valves required on the various types of boiler (that is, the boiler proper) PG-68 Superheater and Reheater Safety Valve Requirements: locations and capacities of superheater and reheater safety valves PG-69 Certification of Capacity of Safety Valves: rules for the testing of safety valve capacities by manufacturers PG-70 Capacity of Safety Valves: methods and requirements for relieving capacity of safety valves PG-71 Mounting: required methods for attaching safety valves to boilers PG-72 Operation: guidelines for the operating ranges of safety valve popping and blowdown pressures

The code requirements for safety and safety relief valves contain some very specific technical data. The requirements differ significantly between different types of boilers, with special references being made to specific types of boilers, such as electric, waste heat, once-through, high-temperature water boilers, and organic fluid vaporizer generators. All rules cannot be covered here, and the student must review the sections mentioned above to understand where the special conditions exist. Each student is advised to read each entire section in the 2004 ASME Academic Extract.

56

A2 Third Class SI Units

Coefficient of Discharge

For each design of safety valve or safety relief valve the manufacturer shall submit for test at least three valves for each of three different sizes. Tests will be performed on each valve to determine its lift capacity, popping and blow-down pressures and actual relieving capacity. An individual coefficient KD (of discharge), shall be established for each valve using the formula below.

KD =

actual steam flow = individual coeficient of dischage theoretical steam flow

The average K from the tests will be taken as the coefficient of design and shall be used for determining the relieving capacity of all sizes and pressures of the design, in the following formula: For 45 deg seat valves: WT = 5.25 x DLP x 0.707 For flat seat valves: WT = 5.25 x DLP For nozzle-type safety valves: WT = 5.25 x AP where:

WT A D L P

= = = = =

theoretical flow, (kg/h) nozzle throat area (mm2) seat diameter (mm) lift at pressure P (mm) (1.03 x set pressure + 0.101 (MPa) or (set pressure + 0.014+ 0.101 (MPa) whichever is greater

Chapter 2 Code Calculations ASME Section I

57

PG-70: CAPACITY OF SAFETY VALVES

PG-70.1 states that Subject to the minimum number required by PG-67.1, the number of safety valve or safety relief valve required shall be determined on the basis of the maximum designed steaming capacity, as determined by the boiler Manufacturer. And the relieving capacity marked on the valves by the manufacturer. Each student should read the contents of Paragraph PG-67.1 in full: Each Boiler shall have at least one safety valve or safety relief valve and if it has more than 47m2 of bare tube water heating surface, or if an electric boiler has a power input of more than 1,100 kW, it shall have two or more safety valves or safety relief valves. For boilers with combined

58

A2 Third Class SI Units

CHAPTER QUESTIONS

1. Calculate the minimum required tube thickness, in mm, for a watertube boiler using tubes of 69.85 mm diameter tubes of material SA-210C, operating at a maximum allowable working pressure of 1400 kPa and a mean wall temperature of 355C. The tubes are strength-welded to the drums and headers. A steam header between the boiler and first stop valve is to be fabricated of 6 inch NPS pipe. The material specification is SA-335 P1 seamless pipe. The operating pressure will be 7000 kPa at 325C. What will be the minimum required thickness of the pipe wall, including the manufactures tolerance required by code. What is the maximum allowable working pressure for a welded drum, given that the material is SA-442-60, the plate thickness is 30 mm, the inside diameter is 1055 mm, and the temperature will not exceed 425C. A seamless, blank, unstayed dished head, with pressure on the concave side, has a diameter of 905 mm and is a segment of a sphere with a dish radius of 700 mm. The maximum allowable working pressure is 1760 kPa, the material is SA-299, and the metal temperature does not exceed 300C. What is the minimum required thickness of the head material? Calculate the minimum required thickness for a full-hemispherical head, with the pressure on the concave side, if the head is made from SA-285A steel, has a maximum working temperature of 335C, an operating pressure of 1800 kPa, and an I.D. of 915 mm. The head is seamless, buttwelded to the shell. Calculate the maximum allowable working pressure, in kPa, for a watertube boiler tube, which is 60.0 mm O.D. and has a minimum wall thickness of 3.9 mm. The tube is located in the furnace area of the boiler. Tube material is low alloy, SA-209-T1a, with a mean wall temperature of 300C.

2.

3.

4.

5.

6.

You might also like

- Load Sensing + PumpsDocument32 pagesLoad Sensing + PumpsHERNANDO A BECERRA100% (2)

- ASME CalculationDocument25 pagesASME Calculationalinor_tn100% (1)

- Design & Construction of Piping SystemsDocument115 pagesDesign & Construction of Piping SystemsSuresh Babu100% (13)

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDocument5 pagesASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNo ratings yet

- ASME Code CalculationsDocument45 pagesASME Code CalculationsPunith Rangegowda100% (12)

- Secondary Condensate B API650 Sloshing Impact RoofDocument22 pagesSecondary Condensate B API650 Sloshing Impact RoofFrancisco OrtuzarNo ratings yet

- Design by AnalysisDocument22 pagesDesign by AnalysisJEELE77No ratings yet

- Boiler Tube Failure Analysis - 1Document7 pagesBoiler Tube Failure Analysis - 1SrinivasaNo ratings yet

- WPCE Pump-In Sub by NOV ELMARDocument1 pageWPCE Pump-In Sub by NOV ELMARvipequi50No ratings yet

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand Outtry&tryNo ratings yet

- Pipping FormulaDocument8 pagesPipping Formularajeshsabitha80No ratings yet

- Calculation Trunion (By Maniacs)Document5 pagesCalculation Trunion (By Maniacs)SyahkullahNo ratings yet

- R1 WGFE20-0047 Training Text for M701JAC GT Disassembly Scope of Planned MaintenanceDocument37 pagesR1 WGFE20-0047 Training Text for M701JAC GT Disassembly Scope of Planned Maintenancebmw316100% (2)

- Flange For Not Subject To Pressure Vessel DIN 28034Document3 pagesFlange For Not Subject To Pressure Vessel DIN 28034Farzad Sadr0% (1)

- Lesson 09 UW16 UG37 New2Document38 pagesLesson 09 UW16 UG37 New2Kandregula Mohan BabuNo ratings yet

- Parts Manual Compressor Model Airsource Plus - Ir: SERIAL NUMBER RANGE 349459 To 349464Document53 pagesParts Manual Compressor Model Airsource Plus - Ir: SERIAL NUMBER RANGE 349459 To 349464heruNo ratings yet

- Code Calculation-ASME Section IDocument26 pagesCode Calculation-ASME Section IDevendra Bangar100% (10)

- Victaulic G 105Document116 pagesVictaulic G 105lolochoNo ratings yet

- Design of Piping SystemsDocument115 pagesDesign of Piping SystemsDushyant Varshney100% (2)

- AD 2000 Head Under Extenal PressureDocument2 pagesAD 2000 Head Under Extenal Pressuremechengg01100% (1)

- Design of Piping Systems by Tengku SyahdilanDocument115 pagesDesign of Piping Systems by Tengku SyahdilanRagerishcire KanaalaqNo ratings yet

- Pressure Part Design (See Also Stresses, Allowable or Permissible in Pressure Parts)Document3 pagesPressure Part Design (See Also Stresses, Allowable or Permissible in Pressure Parts)OmarHddadNo ratings yet

- Power Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Document43 pagesPower Plant Operation Turbine & Auxiliaries: 18 February 2013 PMI Revision 00 1Alok Ranjan Tripathi100% (1)

- Liting Lug Calculation VesselsDocument11 pagesLiting Lug Calculation VesselsSudar Mysha0% (1)

- ASME Pressure Vessels Basic CalculationsDocument23 pagesASME Pressure Vessels Basic CalculationsrichamNo ratings yet

- CO2 Flooding Systems for Ships: Key Components, Regulations and Operating PrinciplesDocument37 pagesCO2 Flooding Systems for Ships: Key Components, Regulations and Operating Principleskarthi4052100% (1)

- AES Type Heat ExchangerDocument8 pagesAES Type Heat ExchangerSudhanshu67100% (1)

- Reinforcement For Multi OpeningsDocument1 pageReinforcement For Multi OpeningsSajal KulshresthaNo ratings yet

- Compressed Air System For Chemical and Industrial PlantsDocument23 pagesCompressed Air System For Chemical and Industrial Plantsjkhan_724384No ratings yet

- Self Venting Drain PDFDocument4 pagesSelf Venting Drain PDFIBIKUNLENo ratings yet

- ASME B31.3 Tri-Clamp FEA Stress Analysis ReportDocument18 pagesASME B31.3 Tri-Clamp FEA Stress Analysis ReportBertrandMezatioNo ratings yet

- Supply Flange ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS To 1500LBS - Jinan Hyupshin Flanges Co., LTDDocument3 pagesSupply Flange ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS To 1500LBS - Jinan Hyupshin Flanges Co., LTDSandipNo ratings yet

- Calculations For: Calculations No. Asme Viii Div 1 Ed 2019Document21 pagesCalculations For: Calculations No. Asme Viii Div 1 Ed 2019David Vanegas100% (1)

- Heat Transfer: Understanding Steam Trap OperationDocument6 pagesHeat Transfer: Understanding Steam Trap Operationgustav agudeloNo ratings yet

- Advanced Heat Exchangers: Shell & Tube Marine CondensersDocument16 pagesAdvanced Heat Exchangers: Shell & Tube Marine CondensersMarco CambeiroaNo ratings yet

- Sample Design Calculation - Vessel Supported On LugsDocument11 pagesSample Design Calculation - Vessel Supported On Lugsandry4jc100% (1)

- API 650 Tank Nozzle Stand OutDocument5 pagesAPI 650 Tank Nozzle Stand OutJunaid MateenNo ratings yet

- Deaera DesignDocument13 pagesDeaera DesignBhanu K PrakashNo ratings yet

- Part A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves FurnacesDocument25 pagesPart A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves Furnacesfujiman35100% (1)

- API 620 Silo Cs Normal TempDocument189 pagesAPI 620 Silo Cs Normal TempMinh Vo BinhNo ratings yet

- Analysis of a rectangular pressure vesselDocument7 pagesAnalysis of a rectangular pressure vesselPressure VesselNo ratings yet

- ASME Code Calculations: Minimum Wall ThicknessesDocument59 pagesASME Code Calculations: Minimum Wall ThicknessesKen Manning100% (1)

- MotorDocument116 pagesMotorRutvi Vishal Vaghela100% (1)

- Section VIII CalDocument22 pagesSection VIII CalthodathersNo ratings yet

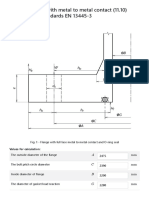

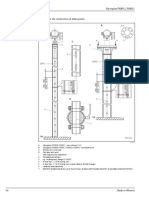

- Full Face Flange With Metal To Metal Contact (11.10) EN 13445-3Document5 pagesFull Face Flange With Metal To Metal Contact (11.10) EN 13445-3met-calcNo ratings yet

- CEPE02100A1 CAG Updated Jan23 14Document60 pagesCEPE02100A1 CAG Updated Jan23 14rudi setiawanNo ratings yet

- Toriconical Head 87 PsiDocument2 pagesToriconical Head 87 PsiFabio Augusto Hincapie HenaoNo ratings yet

- Flange calculation as per ASME Section VIIIDocument9 pagesFlange calculation as per ASME Section VIIIDarshan PanchalNo ratings yet

- Stillwell Pipe ArrangementDocument1 pageStillwell Pipe ArrangementVishalDhiman100% (1)

- Asme - HeaderDocument3 pagesAsme - HeaderReadersmoNo ratings yet

- QT 16Cr PDFDocument1 pageQT 16Cr PDFYaroslav RuizNo ratings yet

- E4.5.1 6 PTB 4 2015 PDFDocument50 pagesE4.5.1 6 PTB 4 2015 PDFKingston RivingtonNo ratings yet

- Asme VDocument1 pageAsme VMohd AnsariNo ratings yet

- 299 - Elliptical Head Design Tool Ver E4.01Document1 page299 - Elliptical Head Design Tool Ver E4.01Pankaj SinglaNo ratings yet

- Understanding ASME Section I Boiler Safety ValvesDocument19 pagesUnderstanding ASME Section I Boiler Safety ValvesMarcelo Kleber FelisbertoNo ratings yet

- Use of Type (3) Welds in ASME Pressure Vessel Design - PVEngDocument4 pagesUse of Type (3) Welds in ASME Pressure Vessel Design - PVEngnaveenbaskaran1989No ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- Asme Section I: Section - Iii Code ExtractionDocument3 pagesAsme Section I: Section - Iii Code ExtractionReadersmo100% (1)

- 2276 1Document2 pages2276 1hogoyoNo ratings yet

- Toriconical Head Ver 1.1Document4 pagesToriconical Head Ver 1.1Iqbal AhmadsNo ratings yet

- Clearance CalculationDocument12 pagesClearance CalculationshazanNo ratings yet

- LARGE DIAMETER FLANGES & FITTINGS GUIDEDocument38 pagesLARGE DIAMETER FLANGES & FITTINGS GUIDEAshfaq Anwer100% (1)

- Pressure Test Requirements for Unfired Pressure Vessels According to EN 13445Document14 pagesPressure Test Requirements for Unfired Pressure Vessels According to EN 13445Nanang PhNo ratings yet

- Pipe Flanges and FittingsDocument12 pagesPipe Flanges and FittingsBangun KartaNo ratings yet

- Eqn Reference ASME BPVC r1sDocument5 pagesEqn Reference ASME BPVC r1sagarcia654127No ratings yet

- Calculo Brida Ejemplo PV - EliteDocument8 pagesCalculo Brida Ejemplo PV - ElitePedro Montes MarinNo ratings yet

- 516 Vs 515Document2 pages516 Vs 515Madan YadavNo ratings yet

- Ejma7r2 Bellows Worksheet-1Document11 pagesEjma7r2 Bellows Worksheet-1odormicchiNo ratings yet

- Revised Second Class Course Section A1 SI Units Ligament EfficiencyDocument5 pagesRevised Second Class Course Section A1 SI Units Ligament EfficiencyOscar Franco MNo ratings yet

- Engineering Design: 600 900 Flange Rating, #Document4 pagesEngineering Design: 600 900 Flange Rating, #Mayur PatelNo ratings yet

- Pressure Part DesignDocument3 pagesPressure Part DesignOmarHddadNo ratings yet

- Visit To PenthouseDocument12 pagesVisit To PenthouseTiu TonNo ratings yet

- Swarovski Crystal Earring Catalog with 30 ProductsDocument25 pagesSwarovski Crystal Earring Catalog with 30 ProductsTiu TonNo ratings yet

- Environmental Concepts with Tolerance Design Optimization ModelDocument1 pageEnvironmental Concepts with Tolerance Design Optimization ModelTiu TonNo ratings yet

- Effect of Air Ingress in BoilersDocument6 pagesEffect of Air Ingress in BoilersAnvita Chebrolu100% (1)

- Modeling Software Quality With Classification Trees 265: The Figure Uses A Logarithmic Scale For ProfitDocument1 pageModeling Software Quality With Classification Trees 265: The Figure Uses A Logarithmic Scale For ProfitTiu TonNo ratings yet

- 00284Document1 page00284Tiu TonNo ratings yet

- Logo UndanganDocument1 pageLogo UndangansyerrooNo ratings yet

- Fempfocus Summer 2005 PDFDocument24 pagesFempfocus Summer 2005 PDFTiu TonNo ratings yet

- NAVSEA RCM Handbook DTD 18 April 2007 PDFDocument105 pagesNAVSEA RCM Handbook DTD 18 April 2007 PDFTiu TonNo ratings yet

- 248 T. M. Khoshgoftaar and E. B. Allen: Et Al. (1992) ), Artificial Neural Networks (Khoshgoftaar and Lanning (1995) ), andDocument1 page248 T. M. Khoshgoftaar and E. B. Allen: Et Al. (1992) ), Artificial Neural Networks (Khoshgoftaar and Lanning (1995) ), andTiu TonNo ratings yet

- Abacunas PDFDocument9 pagesAbacunas PDFTiu TonNo ratings yet

- Software, Mar. 14-32Document1 pageSoftware, Mar. 14-32Tiu TonNo ratings yet

- PDFDocument1 pagePDFTiu TonNo ratings yet

- Modeling Software Quality With Classification Trees 249Document1 pageModeling Software Quality With Classification Trees 249Tiu TonNo ratings yet

- Software, Mar. 14-32Document1 pageSoftware, Mar. 14-32Tiu TonNo ratings yet

- Logo BismillahDocument1 pageLogo BismillahTiu TonNo ratings yet

- Modeling Software Quality With Classification Trees 267: AcknowledgmentsDocument1 pageModeling Software Quality With Classification Trees 267: AcknowledgmentsTiu TonNo ratings yet

- A Methodology For The Measurement of Test Effectiveness 241Document1 pageA Methodology For The Measurement of Test Effectiveness 241Tiu TonNo ratings yet

- X - /ife - Is Smaller Than The Width, A . Then For Any Given Input, Only The SmallDocument1 pageX - /ife - Is Smaller Than The Width, A . Then For Any Given Input, Only The SmallTiu TonNo ratings yet

- 260 T. M. Khoshgoftaar and E. B. Allen: T I L LDocument1 page260 T. M. Khoshgoftaar and E. B. Allen: T I L LTiu TonNo ratings yet

- Reliability analysis of complex systemsDocument1 pageReliability analysis of complex systemsTiu TonNo ratings yet

- Sec 2 BappendixaDocument8 pagesSec 2 BappendixaTiu TonNo ratings yet

- Conclusions: How To Test The Skewness and The KurtosisDocument1 pageConclusions: How To Test The Skewness and The KurtosisTiu TonNo ratings yet

- 00 ContentsDocument7 pages00 ContentsTiu TonNo ratings yet

- G (T) (A-M (T) / (4) : 20 X. Zhang and H. PhamDocument1 pageG (T) (A-M (T) / (4) : 20 X. Zhang and H. PhamTiu TonNo ratings yet

- 00011Document1 page00011Tiu TonNo ratings yet

- Steam8 BoilerDocument2 pagesSteam8 BoilerTiu TonNo ratings yet

- Process Heating Source Book 2Document114 pagesProcess Heating Source Book 2kalpeshds100% (2)

- SWM RelatedDocument42 pagesSWM RelatedMrityunjay MallikNo ratings yet

- RLNG Pipeline Process ReportDocument9 pagesRLNG Pipeline Process ReportUmair A. KhanNo ratings yet

- RTDocument4 pagesRTargaNo ratings yet

- Eclipse Winnox Burners: Model WX0100Document4 pagesEclipse Winnox Burners: Model WX0100yulianoNo ratings yet

- TDI TURBOSTARTä Model 56B Industrial Gas Turbine StarterDocument4 pagesTDI TURBOSTARTä Model 56B Industrial Gas Turbine StartersxasxasxNo ratings yet

- YORK Taurus High Wall 50Hz R22 2015 Mechanical CommentsDocument2 pagesYORK Taurus High Wall 50Hz R22 2015 Mechanical CommentsBoulos NassarNo ratings yet

- Valco Power - Eng.Document16 pagesValco Power - Eng.dhmbasNo ratings yet

- ME 2351 Gas Dynamics and Jet Propulsion Unit 4Document14 pagesME 2351 Gas Dynamics and Jet Propulsion Unit 4Arivukkarasan SundaresanNo ratings yet

- Steam Turbine & Generator Lifting PlanDocument4 pagesSteam Turbine & Generator Lifting PlanThirukumaran ElangovanNo ratings yet

- Xưởng Sản Xuất Theo Tiêu Chuẩn GmpDocument1 pageXưởng Sản Xuất Theo Tiêu Chuẩn GmpnhacotungNo ratings yet

- MPX Status Information ( ) : Energía EnergíaDocument2 pagesMPX Status Information ( ) : Energía Energíatatiana araujoNo ratings yet

- Illustrate Your Answers With NEAT Sketches Wherever NecessaryDocument4 pagesIllustrate Your Answers With NEAT Sketches Wherever Necessarya c s KumarNo ratings yet

- Flow Meters and Orifice PlatesDocument4 pagesFlow Meters and Orifice PlatesayberkNo ratings yet

- M15 - (Compressed Air) RevGBDocument25 pagesM15 - (Compressed Air) RevGBVAN VIET NGONo ratings yet

- Thrust Reverser Hydraulics - Maintenance Practices 1. GeneralDocument8 pagesThrust Reverser Hydraulics - Maintenance Practices 1. GeneralMaria Elisabeth RamirezNo ratings yet

- Compressor troubleshooting guideDocument40 pagesCompressor troubleshooting guideBenito Antonio Formoso LouroNo ratings yet

- UEE Unit 5 - GKDocument55 pagesUEE Unit 5 - GKRajvir Kaur SidhuNo ratings yet

- Oilgear Specificl Controls TrainingDocument26 pagesOilgear Specificl Controls TrainingYuriPasenkoNo ratings yet

- Front and Rear SphereDocument4 pagesFront and Rear SphereRamalingam PrabhakaranNo ratings yet

- Laminar and Turbulent in Pipe-2 PDFDocument20 pagesLaminar and Turbulent in Pipe-2 PDFBoos yousufNo ratings yet