Professional Documents

Culture Documents

Link Belt HC138A Specifications

Uploaded by

Jhony Espinoza Perez0 ratings0% found this document useful (0 votes)

3 views7 pagesLink Belt HC138A Specifications

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLink Belt HC138A Specifications

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views7 pagesLink Belt HC138A Specifications

Uploaded by

Jhony Espinoza PerezLink Belt HC138A Specifications

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

Eg

| 23 (cl) —_—_—_— Tel: (888) 337-BIGGE or (510) 638-8100

SN ee Ne Ee (el

Bid ia pt te Pe ATC)

MC

i

BT

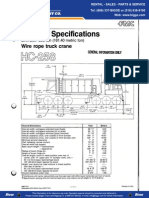

_ General Specifications

Link-Belt® 75-ton (68.03 metric ton)

Wire rope truck crane

AICS GENERAL INFORMATION ONLY

vere

1 Bh

cet

whe

Gay

gpa

sormos Se oa

CT AGRI ary Ls Cra Creek)

ear oar oo

@ ever fost mae | en intave postion ove rear =

ee 2 Sowenen .

me eal SSIES mane | ee

Sa TTT = 42 Sei

cones we |e Seaemeesceenoe—t——

‘Ground dearance under upper = Sane SEmmerhand boom ee

cement ae al Tagine a

eo = Siege

eee irae [ae Se ecto

aera es enemas,

ee ere SEES

Sooo, ee |e a a

“Radius of Boorfoat pin = ‘oar Bere rae geese tant we

a at Simmer fale

GENERAL INFORMATION ONLY

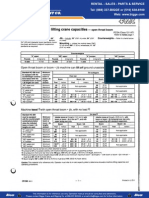

Axle loadings — approximate .

=

sie [ raion es

The um woe rope" (271m). (Bm)

Tir eat

Sena ume C22 ee mth

ee Pied

Wie oe el ate amr = 3am|> Teel © : ra

Rosse Ses Tel: ;

Pevawuee Foie B : :

Fis mmmon eae gy: HE) : 2

‘en carr tate ot) ml elt as

So aaa ele el: als dl: tag

@ See a: Hh: |: sf: rire

Sarige mee BE EE BE Bl i BE

a ou uage ran Coote set weight 9 OM E71 sng sae tau comer.

adheres to,

mae

2} CCE a LL

*MC

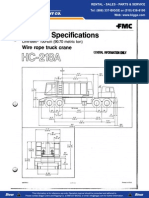

General Specifications

Carrier

| Bacxm| Type

FMC: 8 x 4 drive, 260° (6.60 m)

wheelbase, 1170" (8.35 m) wide,

Main members hest treated

chined surface for

‘mounting turntable bearing. Formed

channel front bumper.

‘Turntable bearing

Outer race, with integral swing (ring)

sear bolted to carrer

eed

Easily removed, mounts on front

bumper hooks. Refer to ling capacity

charts for counterweight requirements

‘Bumper counterweight

‘Bumper counterwaight “AY ~ 1,500 18s.

(650 3).

=

Shuler FTKC-34L; bogie beam mounted

tandem axles, single wheels. Track —

110%" (280 my).

Front axles:

-—

| Bogie

oe

Hendrickson; rubber ushed equalizer beams

fd forgue oss

_—

Clark Planetary 80-57000, bogie

‘mounted tandem axles, dual wheels.

Track — 100° (254 m).

Boole

ome

Hendrickson; bronge-bushed equalizer

beam ridbor bushed torque rods.

Tag axle — Optional; Transport Trailer,

‘equipped with air brakes, 10:00 x 20F

(F2eply rating) dual ties.

‘Wheels and rims — Front; cast spoke

type. Rear; integral with planetary hubs.

Tires

Single tres front; dual tres rear.

Standard ~ 14:00» 209 (1-9 rating)

{Goodyear Custom Hit.

‘Optional — 14:00 x 204 (18-y tating) A

Service Goodyear, 14:00» 20 (18-9) rating)

SAL Gooayear: 14:00 x 205 (lap rating)

HET Goneral, 100 x 200 (18-1y rating)

Goocrieh

=

Full width, double box, front and rear;

pin connected to carrier trame.

Hygraulcaly operated beam and jack

‘oylinders individually controlled trom

each side of cartier. Hydraulic power

Supplied by PTO-criven hydraulic pump.

‘Check valve at each jack cylinder.

Outriggers

Optional — Outrigger beam and ack cylinder

Controle in erane upper ab.

#

Front center

hydraulic jack

with float

loquired for handling 360° swing rated

‘capacities. Warning horn sounds if

‘ground surface allows front outriggers

{o settle

Floats — Low profile, alloy ste! ightweight:

‘500.76 square base.

‘Traller hitch — Optional; includes

and electric connections at rear of

tarrier for taller lights anc air brakes.

— 8-wheol air brakes.

‘Service — Single ig

Tour front wneels: Max bral

veal

chambers on

‘on four reat

Size and area — Rear whoo 16%" x7"

(0.42 0.18): total etectve Bring a

‘square inches (2.996 em’) per ae. Front

‘wheels: 17-3 4 (048 x 007m): total

stective ining aed, 248 square laches

(1 600 em por ax,

455

Parking — Brakes on tour rear wheels spring

‘applied: air contro valve on dash

Emargeney — hic brakes on four rear wheais

Spring apply automaticaly iar pressure

‘ops to 48 pss. (910.28 KPa) in sytem,

Emergency brake may be manualy applied

any time by hand control of dash-mourted air

conta valve

GENERAL INFORMATION ONLY

Steering

Power hydraulic assist. Ross HPS 70

steering gear; 18° (0.46 m) diameter

steering wh

u | Engines

Diesel; 120k starter, pressure

lubrication, hydraulic pump, dry toe al

cleaner, and 14.5 cen. (0.41 mimin) air

compressor.

Standard — GM 6V-92TR cess. 6 oyinaer. 2

ele. 884 (0.127) bore, 5 (019 m) svoke

She Cun. © 047 om) daplacement 318

brake horsepower (237 138 W) at 2.10 r.m,

‘governed load spoes, Peak torque Oe & Toe

(72301) at 1400 rpm. Pusnbutten electne

Shutaown 120! 83 amp alternator

‘Optional — Cummins NTC-290 dlese6

finder, & cycle, 5 (014) bore, §

(0.78 my) stoke, BSS cu. in. 14079 om)

{splacement, 390 brake horsepower

(aie 255 W) at 2200 rpm governed lose

Speed. Peak torque $90 fs (F281 sat

51500 cpm. Electric shutdown 12-08. 75

amp alternator

Clutch — Lipe-Roliway, 14° (0.96 =),

2olate, dy disc.

Transmissions

Main — Ful RTOO15; 15 speeds fornard. 2

Auriliary — Fuller AT202;2-sp008, msship

‘mounting for efeeping ony

Universals — Rockwell Standard or

Mechanics type drive tubes: neecle

bearings,

Gab — one-man, offset, fully enclose

Fubber suspension mounted bucket

seat with eeat bell, Nowe absorbing

Ingulation with vinyl covering, sound

‘eduction headliner, carpet floor mat;

isolated from engine compartment

‘rubber mounted for sound level

‘eduction. Instrument panel and cash

Includes speedometer, odometer,

voltmeter. and gauges for fuel, engine

temperature, air and oil pressures. Low

air pressure warning buzzer, key locking

‘Switch, pushbutton starter, throte

‘control, tachometer, heater and

Selroster, 2-peed electile windshield

‘wiper, windshield washer, and dry type

fire extinguisher.

ane

eae

2} CCE a LL

. oo GENERAL INFORMATION ONLY

aS aRe oes REE

eee aeons ce Ses oe

feces arvana corona Sa

ieee aay cme Ta

i ST a = =

we pe oe a ge peat | ae ore | as Taras

sro Feber won | im | 1B] Be | Be | we | ae

guitcnes provide ciruit control for ah | iss | 205 ) 3208 | tor | 1625

cee ice em | zoe | es | dae | "er | tare

Seger | as marr] ee] bos

moet ga cet Se ee | | ae

serra pele ee | ae eee esas

Sr Oa Oak a | tm] ae | fase | ae | Ser

= me te |e ee | a | eee

=e pee | eee | tt Sie | ae |e

‘Siaapspe0d hop redocon low it baved on GM OV-RTA peak torque pm. — (TAG) LT mE

(137 lm) bones on Gurmine NTC-200poak torque tan (1.300) ~1.0™mpM (7.67 Km). Note: eer

‘Two 45-gallon (170.31 fter) capacity fuel sl ato ~ 887 to 1.0

tanks mounted under carrier with filer

spout on each side of carrier.

(wren | weary [evan | “wscsn |

ane

2) 7 CCLRC

IGGE or

eal)

Revolving upperstructure

a

Frame

All welded, stress relioved, precision

‘machined: machinery side housings

welded integral with frame.

co

Diesel; full pressure lubrication cil fer,

air cleaner, hour meter, foot and

Optional hand throttles. Manual controt

Shutdown for GM engine, electrical

shutdown for Cummins engine.

Engines

Inner race of bearing bolted to machined

surface on under side of frame.

Fuel tank

‘75-galion (286 liter) capacity ust tank

‘equipped with fue

‘ith lame arrest

jauge and fill pipe

Unit

GENERAL INFORMATION ONLY

‘Cummins

Triple roller chain enclosed in ll tight

cchain case with integral lubrication.

system

“Full Function" design, two-direct

ower available to all operating shafts

‘halts mounted on antriction bearings

in precision bored machinery side

housings. All load holst, swing, and

boomhoist functions independent of one

another. Components such a8 gears,

Pinions, chain whools, brake drums and

Clutch spiders involute splined to shafts.

Brum goaricluteh drum sssembii

bolted together and mounted on shafts,

fon anti-rction bearings. Machine-cut

teeth on drum gears, pions, spur

‘geers, and chain wheel. Chain whoo! and

‘and running in ol

om 71m om e-71N Nass-c220

Engine specifications with single stage with three stage, with three stage

torque canvertor® | torque converter® | _ torque converter®

Tuber oyinaere 3 3 3

Bore and s ie x5 (071 x0.19m) | Siex5' (0.11 x019m) | BY x6" (0.14 x08 m)

Piston displacement (cu. n) 2256 (6976 on’) 8256 8700m) | 855 14013 0m)

High idle speed «Pm 550 1940 1.960

Engine rpm. fl losd specs 800 ‘i300 1200

Tiel engine horsepower at ful foad speed | 165(123 047 W) 165723087 WT Tar (102167 WH

Peak torque (oot pounds) 4,400 7 €98 J) 23009 200) 1,808 2574 4)

Peak toraue rpm Output shat stati__| Output shat stan_| Output shat sta

Eoctical system Tzavolt TB Tesh

Batteries Ore/i2wot Onel2ott Twort ol

Disconnect between | Disconnect between | Disconnect belwoon

fen pester eerereas engine and converter__| engine and converter__| engine and converter

Transmission — = = =

‘Number chan whee! tooth it et e1

Number engine pinion toath a 23 2

“Gallison #TODO 475 torque converter.

‘Twin Disc #00-10088 T.. torave converte.

Power train

SB | Transmission {88 ) Machinery gear train

2} CCE a LL

GENERAL INFORMATION ONLY

Principal operating

functions

‘Speed-o-Matic* power hydraulic control

system; a variable pressure system

requiring no bieeding. Operating

pressure transmitted to all 2-shoe clutch

tylinders, and other hydraulic eylinders

as required. System includes constant

Gisplacement, engine driven, vane type

hydraulic pump to provide fiow of af,

‘accumulator to maintain system

‘operating pressure, unioader valve to

control pressure in accumulator. rel

valve to limit maximum pressure buildup

Jn system, fuletlow filter with 40 micron

disposable filter element, and variable

pressure control valves fo control drum

Clutches and other operating cylinders,

Load hoisting and

lowering

Wire rope drum gear tran (ront and rear

main, and optional thie, operating

‘drums) powsred by chain transmission

trom engine,

Font and rear main operating drums ~

Cne-poco, 14/036 m) root dameter smooth

‘rum ivcute splined to shale, Extended

length shafts permit instalation of power ond

lowering clutches, spec

requestor nd furis

Planetary driva units for ether or bath dens.

Load hoist drums

‘Third operating drums - Optional; mounts

{onward o ront main operating drums

One-piece, 10%" (027 m) roo! diameter

smooth drum: volute str

Towering elvtchigear unt on front main

‘operating drum shat

rum eutchos

@

Spoas-o-Matic® power hysrauic 2-2hoe

lutenes. tema expanding ned aluminum

ley shoes: clutch apices line to shat,

un grums bolted to drum spur gear and

‘Mounted on shafts on ant-ction bea

Front rar, ang optional third main ope

tum clutches, swing elutedea, and boom

hoist elute ae fully imerenangeabie,

Load holst elutohes ~ Front and rear ma

land optional nird. operating crums —

(146) chameter, 1 (0.54) Taco with

Load lowering clutches ~ Standard on rear

tain rum: options on font main, and

‘ptiona third, operating crams. Clatenes 18°

{0-48 m) eiamater, 812 (0.11 m) lace with

Drum planetary drive units — Optional

available for load hoist or fowering on

eithor or both front and reat main

operating drums. Planetary units mount

‘on extended drum shalts Between drum

Spur gears and 2-shoe cluten gums.

Availabe for elther increase or decrease

of standard load hoist or lowering line,

speeds — choice of increased or

‘decroased line speeds predetermined by

Customer at time of order, Two-shoe

Clutches control standard line speeds.

Planetary drive units controlled by

external contracting band brakes

through push button located on

appropriate control lever.

Q

Two-piece, external contracting band:

‘mechanically foot pedal operated. Foot

pedals equipped with latch to permit

Fecking brakes in applied postion,

Front and rear main drums = Brakes 92°

(0.81 m) diameter 4/707 60mm) face width

rum rakes

‘Optional third drum ~ Brake 260.86 m)

‘Slameter, (10169 mm) Tace wth

a

[oF

Standard for rant and

rum rotation indleatore

Srums. Two eteetrealy operted incicator

buttons, eevestad in drum cuteh contr!

lever handles: one button pulsates when rope

drums rotate in one craction the other

ta when drume rotate in

Betton putes

opposite.

Bolations

{rum or hook block speed based on Specie

number of pars of load host pe.

h |s

‘Spur gear driven: single bevel gears

(enclosed and running in oi) on

horizontal and vertical swing shafts

‘Swing pinion, involute splined to vertical

‘swing shaft, meshes with external tooth

(of swing gear integral with outer race of

turntable bearing,

1g system

©

(046m) damter.43°(0.11/m) 1

Tina, aluminum alloy shows,

Swing cturchos

2 with

‘Swing bvake ~ External contracting band

Spring applied, hySrauialy released by

‘operator contoiag lever. Brake drum

Inveluteepined to vers! swing shat: brake

18 (0.4 m) clameter. 5 (7820 mm) face

wath

Swing lock ~ Mechanically conolea paw!

fengages extemal teeth of tusntabe

ning (ng) gear

Maximum swing s980d - 84 «pa.

Boom hoist!

lowering system

Independent, spur gear driven, Precision

control — hoisting through power

hydraulic 2-shoe clutch; lowering

through low speed planetary drive unit,

wi

Boomhoist drum

10%" (0.27 m) root diameter. smooth

involute splined to shat.

GZ. | Beomhoist rum

D_| seeking pow!

Operator controlled spring applied

‘mechanical released.

6

18°(0 46 m)ciameter, 44 (0.11 m) face wich.

8

Optional in edition to pianatary baom

loweving. Two-shoe clutch perms higher

speed boom lowering mounted on shaft

fbtsige planstary un, cluzh ertm Bolted to

ute face af planetary housing Cluteh pow

hyarauilealy controled by deprecting

blenaid push button loctted on boom

holstiowerlag conto lever

‘Boom holst etch ~

‘oom lowering clutch

eae

ane

2} CCE a LL

GENERAL INFORMATION ONLY EWI

‘Boom holstiowering brake

mee

Exornal contacting band: sping apie,

hydraulically released as host clutch or

lowering planetary aro engaged. Brake drum

tnvoluta spina to shat braee 25/055 m)

Giameter, «(70180 mm) face width

Boom hoist limiting dovee ~ Provided to

restrict hoisting boom beyond recommonded

minimum radiue located on exterior

Fighthand side of operators ead,

AN

Battery, 12volt, 225 ampere hour, either

‘one of iwo Batteries depending on

fengine. Optional ~ battery lighting

system, including two sealed beam

automotive type adjustable headlights

located on cab Front root, one interior

Cab light and automotive type wiring

Optional ~ adcitional 50 watt sealed

‘beam automotive type headlight

‘mounted on boom. (Three maximum

quantity recommended.) Optional ~

‘Onan independent lignt plant with single

cylinder four cycle, air cooled diesel

engine with remote electric starting,

'3,000 wat, 120-volt, single-phase, 60

‘eles AC. including wiring in condut,

three interior cablights, trouble lamp

with cord and two 200 watt agjustabi

food lights.on cab front roof. Optional —

adational 300 watt floodlighis available

{for mounting on cab and Boom,

a

Environmental cab, modular type

isolated from upper machinery cab.

‘Tinted temperea glass panels in all

windows, Nand grab ral, adjustable,

Cushioned seat with head rest, arm rests

‘en control consoles, dry chemical fre

extinguisher. Cab Reateridetroster and

windshield wiper optional

Electrical system —

Operator's cab

cq | Machinery cab

Equipped with warning horn, hinged

doors on two sides, rear, and top.

Removable panels for machinery access,

roof-top access ladder, and skid

resistant finish on roof.

‘Bigge Crane and Rigging Co.

1070 Bigge verve

Sen Lando, CASS77

Phone: (88) 337 SIGGE or (50) 6368100,

Fax (10) 6304053,

Ena osbgge.con

Wo ss wagge.com

Gantry — Low type, mounted at top rear 200m top section ~ Hammerhead: 5(1.52.m)

‘of machinery side housings: supports long.

boom suspension system.

~Boompolnt machinery. Five 1818 (247 m)

‘oot diameter head sheaves, pis one or to

Gantry bai

By ‘rere ono hee sheen

Contains sb 12 (0.30 m) root siameter Rw

‘hoawos, mounted an antstcton bearings,

for tipan Boamnolat wire rape reving,

“Tubular; basic two-piece 20° (6.10 m)

long: 80° (0.76 m) wide, 24°(0.81 m) deep

‘at connections. Alloy stee!tubul

‘chords 1¥#" (38.10 mm) outside

iameter

sb

ccxmm | Counterwoight

A" counterweight — 18,000 tbs.

(8 165 49);""B" counterweight —

12,000 fos. (5 443 kg). (Refer to

counterweight requirement instructions

‘with iting eapactty chart)

‘Bese section ~ 10° 0 (8.05 m) tong,

«fb extensions ~ Avalabia in 10° (208 m)

Tengins with appropriate length pendants.

Maximum boom engine permed: open

threat boom = 190"(57 91m) boom plus £0

(1524 m) jb, hammarnead boom — 120

(64.86 m) boom plus 50 (18.247) jo.

Booms and jibs

ub connections - Insin, tapered pins.

Tip section ~ 10" 6" (305 m) tong: single peak

sheave 131%" (0.9 m) root diameter. moun

on anthtction bearings.

—

10° 0" (405 m) igh, mounted on jd base

{ection Two detecior sheaves mounted

wthin mast to guide whipine: mountes on

Sntreton bearings. Two oqualizr sheaves

‘lounted on top of mast — ane foro

Frontsay tne, one for ib ecksty tne

‘Tubular; two-piece basic boom 40"

(12.19 7m) long with open throst top

Section, 25° (7.62 m) long with

hammerhead top section. Boom 54°

(1.37 m) wide, 44° (1.12 m) deep at

‘centerline of connections. Alloy steel,

‘ound tubular chords 5" (76.20 mm)

‘utsige diameter,

sip mast

‘Base section ~ 20 (6.10 m) long. Boom

2s (60.99 mm) thisk on 88° (1 37 m) contre

Liting tugs on topside of base section to

faciltate attaching carrying links Tor earying

base section or for boom assembly,

dit stayiines ~ Front and reat stayin vary

in length depending on degree of jo oset

‘rom oom centerine; backstay tines

tached at Bottom enc of boom top section

{open threat boom, and at a point 20"

(610'm) below poak ot harmmerheas top

‘ection.

‘Boom extensions ~ Availabe in 8 (1.52 m)

10" (0 my), 18" (487 m) 20 (5107) and 80°

(2.14) tangs. Extended hub on feral

‘Connactons vee as anchor for link used 10

‘tach jb sayines, boom suspension

Pendants for boom assembly, apd Boom

midpoint suspencion pends,

You might also like

- Potain MR605Document4 pagesPotain MR605Jhony Espinoza PerezNo ratings yet

- Potain MR615Document16 pagesPotain MR615Jhony Espinoza Perez0% (1)

- Potain MR 415: FEM 1.001-A3Document4 pagesPotain MR 415: FEM 1.001-A3Jhony Espinoza PerezNo ratings yet

- Ahí Lo Puedes Hacer (En Ingles), Seleccionas en La Opción Que Dice "I Want To": Inquire About 3D ConcertsDocument1 pageAhí Lo Puedes Hacer (En Ingles), Seleccionas en La Opción Que Dice "I Want To": Inquire About 3D ConcertsJhony Espinoza PerezNo ratings yet

- Potain MR225ADocument4 pagesPotain MR225AJhony Espinoza Perez0% (1)

- SK575Document4 pagesSK575Néstor Villanueva GutiérrezNo ratings yet

- CTT721-40 HD23 Rev.001-5Document4 pagesCTT721-40 HD23 Rev.001-5Jhony Espinoza PerezNo ratings yet

- Potain MR 295: FEM 1.001-A3Document4 pagesPotain MR 295: FEM 1.001-A3Jhony Espinoza PerezNo ratings yet

- Terex Peiner SK315 PDFDocument6 pagesTerex Peiner SK315 PDFJhony Espinoza Perez0% (1)

- 7 Terex Comedil CBR40Document2 pages7 Terex Comedil CBR40Jhony Espinoza PerezNo ratings yet

- Normas de Control InternoDocument17 pagesNormas de Control InternoLuis ApazaNo ratings yet

- 250T Link Belt HC268Document8 pages250T Link Belt HC268Jhony Espinoza PerezNo ratings yet

- Link Belt HC278 Product GuideDocument6 pagesLink Belt HC278 Product GuideJhony Espinoza PerezNo ratings yet

- Terex Peiner SK415 PDFDocument6 pagesTerex Peiner SK415 PDFJhony Espinoza PerezNo ratings yet

- Link Belt HC258 SpecificationsDocument7 pagesLink Belt HC258 SpecificationsJhony Espinoza PerezNo ratings yet

- Link Belt HC248 Crane SpecificationsDocument8 pagesLink Belt HC248 Crane SpecificationsJhony Espinoza PerezNo ratings yet

- Link Belt HC218A SpecificationsDocument7 pagesLink Belt HC218A SpecificationsJhony Espinoza PerezNo ratings yet

- Trip Peru InsideDocument2 pagesTrip Peru InsideJhony Espinoza PerezNo ratings yet

- American 8460 Crane SpecificationsDocument9 pagesAmerican 8460 Crane SpecificationsJhony Espinoza PerezNo ratings yet

- Manual Del Arquitecto Descalzo PDFDocument275 pagesManual Del Arquitecto Descalzo PDFLaura Romero Salinas100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)